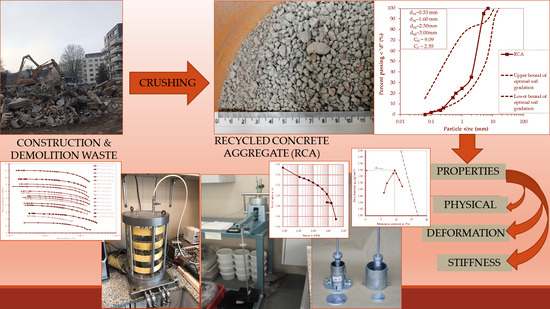

Physical, Deformation, and Stiffness Properties of Recycled Concrete Aggregate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Sample Preparation

2.2. Physical Properties Analysis

- water content;

- grain size distribution analysis;

- bulk density, specific density;

- optimum moisture content and maximum bulk density of the soil skeleton;

- compressibility parameters;

- water permeability;

- California Bearing Ratio (CBR) CBR load index. The CBR is a measure of resistance of a material to penetration of a standard plunger under controlled density and moisture conditions.

2.3. Deformation Properties Analysis

2.4. Resonant Column Test Procedure

- the details of the resonant column tests program

- a/

- mean effective stress (p’), corresponding to

- b/

- the output amplitude of the applied voltage,

- the details of the test material

- a/

- height (h) and mass (m) of the specimen,

- b/

- overconsolidation ratio (OCR), which can be computed from the preconsolidation stress (σ’p), and the overburden vertical effective stress (σ’z), as

- c/

- bulk density (ρ) is defined as the dry weight of soil per unit volume of soil, as

3. Results and Discussion

3.1. Physical Properties Results

3.2. Oedometer Tests Results

3.3. Dynamic Tests Results

4. Conclusions

- The examined anthropogenic material is compacted in a similar way to natural aggregates, where a characteristic value of the optimum moisture content is observed. The tested RCA achieved maximum dry density ρd, max = 1.94 g/cm3 at the optimum moisture content of 9.5%.

- Oedometric modulus of primary loading (M0) had lower values than for natural aggregates. However, the oedometric modulus of secondary loading (M) had an extremely high value. Such results are connected with the susceptibility of RCA on static compaction. Other deformation parameters obtained from the oedometer test behaved in the same manner.

- Shear modulus degradation curves of RCA had the same shape as the same curves but for natural aggregates.

- Due to the loading/unloading/reloading cycle, some improvement in GMAX values was observed. Stress history had a more significant impact on stiffness properties in RCA than in natural gravel soil, which results again from the susceptibility of RCA on static compaction.

- Due to the loading/unloading/reloading cycle, a significant reduction of the range of linear response of RCA for dynamic loading is observed. This can be related to high consolidation stress values and micro-damage of RCA grains.

- Extensive studies should still be conducted on the crushing properties of RCA, as well as on the impact of this process on various geotechnical parameters, like hydraulic conductivity, effective stress, consolidation, and shear strength parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skotnicki, Ł.; Kuźniewski, J. Zastosowanie kruszywa betonowego z recyklingu w mieszankach mineralno-cementowo-emulsyjnych. Przegląd Komun. 2018, 11, 30–36. [Google Scholar]

- Sas, W.; Głuchowski, A.; Szymański, A. Behavior of recycled concrete aggregate improved with lime addition during cyclic loading. Int. J. Geomate 2016, 10, 1662–1669. [Google Scholar] [CrossRef]

- Pisarczyk, S.; Falaciński, P.; Żuraw, L. Wykorzystanie odpadów budowlanych w inżynierskich konstrukcjach ziemnych. Pr. Nauk. Politech. Warszawskiej. Inżynieria Sr. 2003, 45, 5–25. [Google Scholar]

- Zabielska-Adamska, K. Wybrane zastosowania materiałów odpadowych w Geoinżynierii. Inżynieria Morska Geotech. 2012, 4, 286–293. [Google Scholar]

- Kijowski, G. Kruszywo z betonu. Bud. Technol. Archit. 2006, 2, 46–47. [Google Scholar]

- Rafalski, L. Podbudowy Drogowe; IBDiM, Ed.; IBDiM: Warszawa, Poland, 2007. [Google Scholar] [CrossRef]

- Sas, W.; Szymański, A.; Malinowska, E.; Gabryś, K. Geotechniczne uwarunkowania zastosowania materiałów antropogenicznych w budownictwie. Inżynieria Morska Geotech. 2012, 4, 376–389. [Google Scholar]

- He, H.; Senetakis, K.; Coop, M.R. Stiffness of recycled composite aggregate. Soil Dyn. Earthq. Eng. 2018, 110, 185–194. [Google Scholar] [CrossRef]

- Tatsuoka, F.; Tomita, Y.I.; Iguchi, Y.; Hirakawa, D. Strength, and stiffness of compacted crushed concrete aggregate. Soils Found 2013, 53, 835–852. [Google Scholar] [CrossRef] [Green Version]

- Głuchowski, A.; Gabryś, K.; Soból, E.; Šadzevičius, R.; Sas, W. Geotechnical properties of anthropogenic soils in road engineering. Sustainability 2020, 12, 4843. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- UEPG. A Sustainable Industry for a Sustainable Europe; Annual Review, UEPG: Brussels, Belgium, 2017. [Google Scholar]

- Curović, N. Recycled concrete—ecology and economic criterias. J. Appl. Eng. Sci. 2016, 14, 271–274. [Google Scholar] [CrossRef] [Green Version]

- Głuchowski, A.; Sas, W.; Dzięcioł, J.; Soból, E.; Szymański, A. Permeability and Leaching Properties of Recycled Concrete Aggregate as an Emerging Material in Civil Engineering. Appl. Sci. 2019, 9, 81. [Google Scholar] [CrossRef] [Green Version]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behavior of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- PN-EN 1992-1-1-2008. Eurokod 2. Projektowanie konstrukcji z beton. Część 1-1: Reguły ogólne i reguły dla budynków. Available online: https://sklep.pkn.pl/pn-en-1992-1-1-2008p.html (accessed on 14 March 2008).

- PN-B-06250-1988. Beton zwykły. Available online: https://docer.pl/doc/s8v5n15 (accessed on 14 March 2008).

- Galvín, A.P.; Ayuso, J.; García, I.; Jiménez, J.R.; Gutiérrez, F. The effect of compaction on the leaching and pollutant emission time of recycled aggregates from construction and demolition waste. J. Clean. Prod. 2014, 83, 294–304. [Google Scholar] [CrossRef]

- WT-4:2010. Załącznik Nr 3 do Zarządzenia nr 102 Generalnego Dyrektora Dróg Krajowych i Autostrad z dnia 19 Listopada 2010 r.: Mieszanki Niezwiązane do dróg Krajowych WT-4 2010 Wymagania Techniczne, Warsaw, Poland. Available online: https://www.gddkia.gov.pl/userfiles/articles/d/Dokumenty_techniczne/WT4.pdf (accessed on 18 April 2010).

- PN-EN 13286-2:2010. Mieszanki Niezwiązane i Związane Spoiwem Hydraulicznym. Część 2: Metody Określania Gęstości i Zawartości Wody. Zagęszczanie metodą Proctora. Available online: https://sklep.pkn.pl/pn-en-13286-2-2010e.html (accessed on 31 July 2009).

- Sas, W.; Głuchowski, A.; Gabryś, K.; Soból, E.; Szymański, A. Deformation Behavior of Recycled Concrete Aggregate during Cyclic and Dynamic Loading Laboratory Tests. Materials 2016, 9, 780. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gabryś, K.; Sas, W.; Soból, E.; Głuchowski, A. Torsional shear device for testing the dynamic properties of recycled material. Studia Geotech. Mech. 2016, 38, 15–24. [Google Scholar] [CrossRef] [Green Version]

- Gabryś, K.; Soból, E.; Sas, W.; Šadzevičius, R.; Skominas, R. Warsaw Glacial Quartz Sand with different grain-size characteristics and its shear wave velocity from various interpretation methods of BET. Materials 2021, 14, 544. [Google Scholar] [CrossRef]

- Bowles, J.E. Engineering Properties of Soils and Their Measurement, 4th ed.; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Mayne, P.W. Stress-Strain-Strength-Flow Parameters from Enhanced in-Situ Tests. In Proceedings of the International Conference on In-Situ Measurement of Soil Properties & Case Histories In-Situ, Bali, Indonesia, 21–24 May 2001; pp. 27–48. [Google Scholar]

- Clayton, C.R.I. Stiffness at small strain: Research and practice. Géotechnique 2011, 61, 5–37. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Zhou, A.; Wang, W.; Jiang, P. Characterization of the dynamic properties of clay-gravel mixtures at low strain level. Sustainability 2020, 12, 1616. [Google Scholar] [CrossRef] [Green Version]

- Sas, W.; Gabryś, K.; Szymański, A. Experimental studies of dynamic properties of Quaternary clayey soils. Soil Dyn. Earthq. Eng. 2017, 95, 29–39. [Google Scholar] [CrossRef]

- Gabryś, K.; Soból, E.; Markowska-Lech, K.; Szymański, A. Shear Modulus of Compacted Sandy Clay from Various Laboratory Methods; (IOP Conference Series Materials Science and Engineering 471 4); IOP Publishing: Bristol, UK, 2019; p. 042022. [Google Scholar]

- GDS Instruments Ltd. 2010 Product Helpsheets; GDS Instruments Ltd.: Hook, UK, 2010. [Google Scholar]

- PN-EN ISO 17892-4:2017-01 Rozpoznanie i badania geotechniczne—Badania laboratoryjne gruntów—Cześć 4: Badanie uziarnienia gruntów. Available online: https://sklep.pkn.pl/pn-en-iso-17892-4-2017-01e.html (accessed on 22 February 2018).

- PN-EN ISO 14688-1: 2018-05 Rozpoznanie i badania geotechniczne—Oznaczanie i klasyfikowanie gruntów—Część 1: Oznaczanie i opis. Available online: https://sklep.pkn.pl/pn-en-iso-14688-1-2018-05e.html (accessed on 22 February 2018).

- Soból, E.; Sas, W.; Szymański, A. Scale effect in direct shear tests on recycled concrete aggregate. Studia Geotech. Mech. 2016, 37, 45–49. [Google Scholar] [CrossRef] [Green Version]

- Wolski, W.; Król, P.; Sas, W. Les Problems D’utilisation des Gravies Argileus Humides. De Bonne Granulometries, pour les Recharges des Barrages en Terre; XVII congress ICOLD: Paris, France, 1991; Volume 67. [Google Scholar]

- Bayat, M.; Ghalandarzadeh, A. Stiffness degradation and damping ratio of sand-gravel mixtures under saturated state. Int. J. Civ. Eng. 2018, 16, 1261–1277. [Google Scholar] [CrossRef]

- He, H.; Payan, M.; Senetakis, K. The behavior of a recycled road base aggregate and quartz sand with bender/extender element tests under variable stress state. Eur. J. Environ. Civ. Eng. 2018, 1–18. [Google Scholar] [CrossRef]

- Vucetic, M. Cyclic threshold shear strains in soils. J. Geotech. Eng. 1994, 120, 2208–2228. [Google Scholar] [CrossRef]

| Type of Loading | Mean Effective Stress | Output Amplitude | Height | Mass | Overconsolidation Ratio | Bulk Density |

|---|---|---|---|---|---|---|

| p’ (kPa) | Range (V) | h (mm) | m (g) | OCR (-) | ρ (g/cm3) | |

| First loading | 45 | 0.001–0.06 | 140.10 | 1056.33 | 1.0 | 1.96 |

| 90 | 0.006–0.1 | 140.09 | 1029.38 | 1.0 | 1.91 | |

| 135 | 0.0005–0.07 | 139.95 | 1026.94 | 1.0 | 1.91 | |

| 180 | 0.0008–0.08 | 139.86 | 1009.94 | 1.0 | 1.88 | |

| 225 | 0.0004–0.08 | 139.81 | 986.46 | 1.0 | 1.83 | |

| Unloading | 180 | 0.0005–0.08 | 139.82 | 982.20 | 1.25 | 1.83 |

| 135 | 0.0005–0.06 | 139.84 | 985.65 | 1.67 | 1.83 | |

| 90 | 0.0005–0.06 | 139.87 | 996.87 | 2.5 | 1.85 | |

| 45 | 0.0005–0.02 | 139.82 | 1014.77 | 5.0 | 1.89 | |

| Reloading | 90 | 0.0005–0.04 | 139.86 | 999.96 | 2.5 | 1.86 |

| 135 | 0.0005–0.05 | 139.85 | 987.86 | 1.67 | 1.84 | |

| 180 | 0.0005–0.07 | 139.82 | 967.78 | 1.25 | 1.80 | |

| 225 | 0.0005–0.07 | 139.80 | 954.42 | 1.0 | 1.77 | |

| First loading | 270 | 0.0005–0.07 | 139.76 | 937.07 | 1.0 | 1.74 |

| 315 | 0.0005–0.1 | 139.73 | 889.42 | 1.0 | 1.65 |

| Parameter | Stress Range (kPa) | ||||

|---|---|---|---|---|---|

| First Loading 12.5–1600 | Reloading 800–1600 | First Loading 1600–3200 | |||

| Coefficient of volume compressibility mv (1/MPa) | 0.0275 | 0.0017 | 0.0128 | ||

| Oedometric modulus of primary loading M0 (MPa) | 36.33 | - | 78.02 | ||

| Oedometric modulus of secondary loading M (MPa) | - | 588.92 | - | ||

| Compression index CC (-) | 0.024 | - | 0.101 | ||

| Re—compression index Cr (-) | - | 0.0067 | - | ||

| Consolidation stress (kPa) | |||||

| 200 | 400 | 800 a | 1600 a | 3200 | |

| Coefficient of consolidation cv (m2/s) | 0.003 | 0.005 | 0.004 | 0.003 | 0.0007 |

| Average coefficient of consolidation cv avg (m2/s) | 0.003 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabryś, K.; Soból, E.; Sas, W. Physical, Deformation, and Stiffness Properties of Recycled Concrete Aggregate. Sustainability 2021, 13, 4245. https://doi.org/10.3390/su13084245

Gabryś K, Soból E, Sas W. Physical, Deformation, and Stiffness Properties of Recycled Concrete Aggregate. Sustainability. 2021; 13(8):4245. https://doi.org/10.3390/su13084245

Chicago/Turabian StyleGabryś, Katarzyna, Emil Soból, and Wojciech Sas. 2021. "Physical, Deformation, and Stiffness Properties of Recycled Concrete Aggregate" Sustainability 13, no. 8: 4245. https://doi.org/10.3390/su13084245