Case Studies for Dangerous Dust Explosions in South Korea during Recent Years

Abstract

:1. Introduction

2. Dust Explosions in South Korea from 1984 to 2018

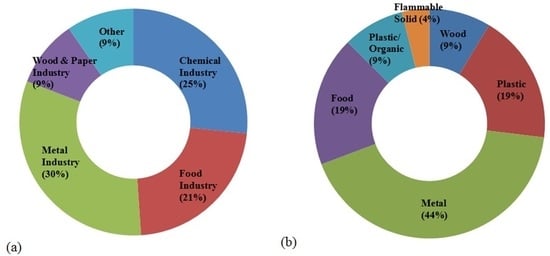

2.1. Dust Explosions for South Korea

2.2. Recent Dust Explosions

3. Case Studies

3.1. HDPE (High Density Polyethylene) Explosions

3.2. PP (Polypropylene) Silo Explosions

3.3. Dust Explosion by Ammonium Perchlorate

4. Discussion

4.1. Dust Explosion for Other Countries

4.2. Characteristics of Dust Explosions between South Korean and Other Countries

4.3. Effective Protective/Mitigatory Measures of Dust Explosions

5. Conclusions

- (i)

- Good housekeeping is necessary to prevent accumulation and scattering of dust on the floor of the building;

- (ii)

- Dust generating facilities should be improved by means of installment of the lid or a sealed structure so that dust is not scattered to the outside;

- (iii)

- A metal separator must be installed at the crusher inlet to prevent sparks;

- (iv)

- All dust generation facilities should be connected to the damping system, and if there is a risk of heat accumulation due to internal fixation, a thermometer should be installed;

- (v)

- If the gas used to calibrate the sensor differs from the actual measurement of the gas concentration, the manufacturer provides the correction value, and the user must apply the correction value to set the sensor sensitivity and alarm;

- (vi)

- Silos used in the production and storage of various resin products must be evaluated and monitored for the occurrence of gas concentrations at a normal time, due to process characteristics;

- (vii)

- Oxygen concentrations must be lower than the explosion minimum concentration through the inclusion of an inert gas, such as nitrogen. If a change in oxygen concentration is observed, it is considered to be a dangerous situation, and the operation should be immediately stopped until the problem is resolved;

- (viii)

- High-speed operation valves, explosion pressure vents, and explosion suppression devices should be installed to protect against dust explosions.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amyotte, P.R.; Eckhoff, R.K. Dust explosion causation, prevention and mitigation: An overview. J. Chem. Health Saf. 2010, 17, 15–28. [Google Scholar] [CrossRef]

- Mclouth, M.E.; Paulus, H.J. Air pollution from the grain industry. J. Air Pollut. Control Assoc. 1961, 11, 313–317. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Current status and expected future trends in dust explosion research. J. Loss Prev. Process Ind. 2005, 18, 225–237. [Google Scholar] [CrossRef]

- Cashdollar, K.L. Overview of dust explosibility characteristics. J. Loss Prev. Process Ind. 2000, 13, 183–199. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S.A. Dust explosions—Cases, causes, consequences, and control. J. Hazard. Mater. 2007, 140, 7–44. [Google Scholar] [CrossRef]

- Steen, H. Handbuch Des Explosionsschutzes, 1st ed.; Wiley-VCH: Weinheim, Germany, 2000; pp. 7–35. [Google Scholar]

- Vijayaraghavan, G. Impact Assessment, Modeling, and Control of Dust Explosions in Chemical Process Industries. Master’s Thesis, Coimbatore Institute of Technology, Coimbatore, India, 2004. [Google Scholar]

- NFPA 68. Standard on Explosion Protection by Deflagration Venting; National Fire Protection Association: Batterymarch Park, MA, USA, 2013. [Google Scholar]

- Eckhoff, R.K. Explosion Hazards in the Process Industries, 2nd ed.; Gulf Professional Publishing: Houston, TX, USA, 2016; pp. 253–383. [Google Scholar]

- Eckhoff, R.K. Dust Explosions in the Process Industries, 3rd ed.; Gulf Professional Publishing: Houston, TX, USA, 2003; pp. 1–156. [Google Scholar]

- CSB. Sugar Dust Explosion and Fire; Report No. 2008-05-1-GA; U.S. Chemical Safety and Hazard Investigation Board: Washington, DC, USA, 2009.

- State Administration of Work Safety. Investigation Report on the Major Dust Explosion Accident in Kunshan, Jiangshu. 2014. Available online: http://www.chinasafety.gov.cn/newpage/Contents/Channel_21356/2014/1230/244871/content_244871.htm (accessed on 6 November 2016).

- Li, G.; Yang, H.-X.; Yuan, C.-M.; Eckhoff, R.K. A catastrophic aluminium-alloy dust explosion in China. J. Loss Prev. Process Ind. 2016, 39, 121–130. [Google Scholar] [CrossRef]

- Štroch, P. Do not underestimate danger of explosion; Even dust can destroy equipment and kill. Perspect. Sci. 2016, 7, 312–316. [Google Scholar] [CrossRef] [Green Version]

- Nifuka, M.; Katoh, H. Incendiary characteristics of electrostatic discharge for dust and gas explosion. J. Loss Prev. Process Ind. 2001, 14, 547–551. [Google Scholar] [CrossRef]

- Marmo, L.; Cavallero, D.; Debernardi, M.L. Aluminum dust explosion risk analysis in metal workings. J. Loss Prev. Process Ind. 2004, 17, 449–465. [Google Scholar] [CrossRef]

- CSB. Aluminum Dust Explosion; U.S. Chemical Safety and Hazard Investigation Board: Washington, DC, USA, 2003.

- Taveau, J. Application of dust explosion protection systems. Procedia Eng. 2014, 84, 297–305. [Google Scholar] [CrossRef]

- Zheng, Y.; Feng, C.; Jing, G.; Qian, X.; Li, X.; Liu, Z.; Huang, P. A statistical analysis of coal mine accidents caused by coal dust explosions in China. J. Loss Prev. Process Ind. 2009, 22, 528–532. [Google Scholar] [CrossRef]

- Fabiano, B.; Curró, F.; Reverberi, A.P.; Palazzi, E. Coal dust emissions: From environmental control to risk minimization by underground transport. An applicative case-study. Process Saf. Environ. Prot. 2014, 92, 150–159. [Google Scholar] [CrossRef]

- Amyotte, P.R. Some myths and realities about dust explosions. Process Saf. Environ. Prot. 2014, 92, 292–299. [Google Scholar] [CrossRef]

- Amyotte, P.R. An. Introduction to Dust Explosions: Understanding the Myths and Realities of Dust Explosions for a Safer Workplace, 1st ed.; Elsevier: Waltham, MA, USA, 2013; pp. 117–120. [Google Scholar]

- Taveau, J. Secondary dust explosions: How to prevent them or mitigate their effects? Process Saf. Prog. 2012, 31, 36–50. [Google Scholar] [CrossRef]

- Farrell, T.M.; Vingerhoets, J.; Snoeys, J.; Going, J.E. Dust flame propagation in industrial scale piping- part 1: Empirical study in a conveying vessel-pipeline system. In Proceedings of the 9th Global Congress on Process Safety, San Antonio, TX, USA, 1 May 2013. [Google Scholar]

- Vogl, A.; Radandt, S. Explosionsübertragung durch dünne Rohrleitungen; FSA Report F-05-9903; Research Centre for Applied System Safety and Industrial Medicine: Manheim, Germany, 2005. [Google Scholar]

- Valiulis, J.V.; Zalosh, R.G.; Tamanini, F. Experiments on the propagation of vented dust explosions to connected equipment. Process Saf. Prog. 1999, 18, 99–106. [Google Scholar] [CrossRef]

- Skjold, T. Dust explosion modeling: Status and prospects. Part. Sci. Technol. Int. J. 2018, 36, 489–500. [Google Scholar] [CrossRef]

- U.S. Chemical Safety and Hazard Investigation Board. Investigation Report Combustible Dust Hazard Study; CSB Report 2006-H-1; U.S. Chemical Safety and Hazard Investigation Board: Washington, DC, USA, 2006.

- Cloney, C.; Snoeys, J. Chapter three- dust explosions: A serious concern. Methods Chem. Process Saf. 2019, 3, 33–69. [Google Scholar]

- 2017 Combustible Dust Incident Report. Available online: https://mailchi.mp/mydustexplosionresearch/weekly-dust-explosion-newsletter-563071 (accessed on 1 January 2017).

- Dust Explosion Statistics. Available online: http://www.dustexplosion.info/statistics.htm (accessed on 1 January 2019).

- The ARIA Database. Available online: https://www.aria.developpement-durable.gouv.fr/the-barpi/the-aria-database/?lang=en (accessed on 1 January 2019).

- Lunn, G.A.; Holbrow, P.; Andrews, S.; Gummer, J. Dust explosions in totally enclosed interconnected vessel systems. J. Loss Prev. Process. Ind. 1996, 9, 45–58. [Google Scholar] [CrossRef]

- Holbrow, P.; Andrew, S.; Lunn, G.A. Dust explosion preotection in linked vessels: Guidance for containment and venting. J. Loss Prev. Process. Ind. 1999, 12, 227–234. [Google Scholar] [CrossRef]

- Taveau, J. Dust explosion propagation and isolation. J. Loss Prev. Process. Ind. 2017, 48, 320–330. [Google Scholar] [CrossRef]

- Chaudhari, P.; Ravi, B.; Bagaria, P.; Mashuga, C. Improved partial inerting MIE test method for combustible dusts and its CFD validation. Process Saf. Environ. Prot. 2019, 122, 192–199. [Google Scholar] [CrossRef]

- Ackroyd, G.; Bailey, M.; Mullins, R. The effect of reduced oxygen levels on the electrostatic ignition sensitivity of dusts. J. Phys. Conf. Ser. 2011, 301, 012034. [Google Scholar] [CrossRef]

- Choi, K.; Choi, K.; Nishimura, K. Experimental study on the influence of the nitrogen concentration in the air on the minimum ignition energies of combustible powders due to electrostatic discharges. J. Loss Prev. Process Ind. 2015, 34, 163–166. [Google Scholar] [CrossRef]

- Tascon, A.; Ramirez-Gomez, A.; Aguado, P.J. Dust explosion in an experimental test silo: Influence of length/diameter ratio on vent area sizes. Biosyst. Eng. 2016, 148, 18–33. [Google Scholar] [CrossRef]

- Tascon, A. Dust of silos for dust explosions: Determination of vent area sizes and explosion pressures. Eng. Struct. 2017, 134, 1–10. [Google Scholar] [CrossRef]

- Moore, P.E. Automatic explosion protection systems. In Proceedings of the Shenyang International Symposium on Dust Explosions, Shenyang, China, 14–16 September 1987; pp. 316–348. [Google Scholar]

- Klemens, R. Dynamicss of dust explosions suppression by means of extinguishing powder in various industrial conditions. J. Loss Prev. Process Ind. 2007, 20, 667–674. [Google Scholar] [CrossRef]

- Neikov, O.D.; Naboychenko, S.; Yefimov, N.V. Handbook of Non-Ferrous Metal Powders, 2nd ed.; Elsevier: Burlington, MA, USA, 2019; pp. 865–928. [Google Scholar]

- Morgan, A.J. The Arresting of Explosions to Minimize Environmental Damage. Ph.D. Thesis, Brunel University, Middlesex, UK, 2000. [Google Scholar]

- Cybulski, K.; Dyduch, Z.; Lebecki, K.; Sliz, J. Efficiency of triggered barriers in dust explosion. In Proceedings of the 5th Internat. Coll. Dust Explosions, Warsaw, Poland, 19–22 April 1993; pp. 437–447. [Google Scholar]

| Year/Month | Equipment | Hazard Material | Accident Process |

|---|---|---|---|

| 2018/5 | Rocket propulsion plant | Ammonium perchlorate | Grinding |

| 2018/5 | Dust collector | Zirconium oxide | Grinding |

| 2018/4 | Dissolution | Tungsten oxide alloy | Injection of metal powder |

| 2018/4 | Alloy Manufacturing | Co–Cr alloy | Manufacture of alloy powder |

| 2017/7 | Silo | Polypropylene | PP pellet transfer |

| 2016/1 | Mixer | Propanoic acid | Mixing process |

| 2015/10 | Silo | Terephthalic acid | Welding and cutting of manhole |

| 2015/9 | Chemical Manufacturing | Aluminum oxide mixture | Mixing process |

| 2015/3 | Reactor | Terephthalic acid | Injection of Terephthalic acid into reactor |

| 2015/5 | Melting furnace | Waste Aluminum | Injection of waste aluminum into furnace |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pak, S.; Jung, S.; Roh, C.; Kang, C. Case Studies for Dangerous Dust Explosions in South Korea during Recent Years. Sustainability 2019, 11, 4888. https://doi.org/10.3390/su11184888

Pak S, Jung S, Roh C, Kang C. Case Studies for Dangerous Dust Explosions in South Korea during Recent Years. Sustainability. 2019; 11(18):4888. https://doi.org/10.3390/su11184888

Chicago/Turabian StylePak, Seonggyu, Seongho Jung, Changhyun Roh, and Chankyu Kang. 2019. "Case Studies for Dangerous Dust Explosions in South Korea during Recent Years" Sustainability 11, no. 18: 4888. https://doi.org/10.3390/su11184888