Digital Twin—Cyber Replica of Physical Things: Architecture, Applications and Future Research Directions

Abstract

:1. Introduction

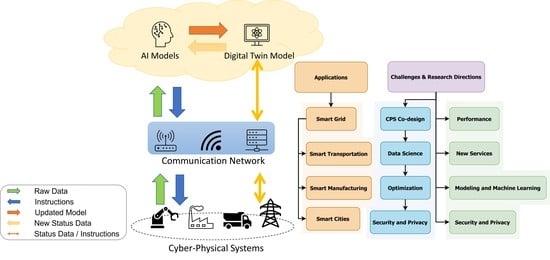

- We begin with the architecture design of existing DTs, which includes DT variants, DT sub-types, and IoT-based DT. We then review the data representation and communication protocols for DT. In addition, we present the use cases for applying DT into a variety of smart-world systems, which include smart grid, smart transportation, smart city, and smart manufacturing, as typical CPS.

- Based on the architecture and its applications to smart-world systems, we discuss challenges that arise from four perspectives: CPS, data science, optimization, and security and privacy. We also present several research directions for DT that we strongly feel need further research, including performance, new DT-driven services, modeling and machine learning, and security and privacy.

2. Digital Twin

2.1. Basic Concepts

2.2. Architecture

2.2.1. DT Variants

2.2.2. Types of DT

2.2.3. Architecture for IoT Systems

2.3. Data Representation

2.4. Communication Protocols

3. Integrating DT in CPS

3.1. Framework

3.2. Smart Grid

3.3. Smart Transportation

3.4. Smart Manufacturing

3.5. Smart Cities

4. Challenges

4.1. CPS Challenges

4.2. Data Science Challenges

4.3. Optimization Challenges

4.4. Security and Privacy Challenges

5. Research Directions

5.1. Performance

5.2. New DT-Driven Services

5.3. Modeling and Machine Learning

5.4. Security and Privacy

6. Final Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, L.D.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Stankovic, J. Research Directions for the Internet of Things. Internet Things J. IEEE 2014, 1, 3–9. [Google Scholar] [CrossRef]

- Liu, X.; Qian, C.; Hatcher, W.G.; Xu, H.; Liao, W.; Yu, W. Secure Internet of Things (IoT)-Based Smart-World Critical Infrastructures: Survey, Case Study and Research Opportunities. IEEE Access 2019, 7, 79523–79544. [Google Scholar] [CrossRef]

- Komninos, N.; Philippou, E.; Pitsillides, A. Survey in Smart Grid and Smart Home Security: Issues, Challenges and Countermeasures. IEEE Commun. Surv. Tutor. 2014, 16, 1933–1954. [Google Scholar] [CrossRef]

- Xu, G.; Yu, W.; Griffith, D.; Golmie, N.; Moulema, P. Toward Integrating Distributed Energy Resources and Storage Devices in Smart Grid. IEEE Internet Things J. 2017, 4, 192–204. [Google Scholar] [CrossRef]

- Liu, Y.; Weng, X.; Wan, J.; Yue, X.; Song, H.; Vasilakos, A.V. Exploring Data Validity in Transportation Systems for Smart Cities. IEEE Commun. Mag. 2017, 55, 26–33. [Google Scholar] [CrossRef]

- Xu, H.; Yu, W.; Griffith, D.; Golmie, N. A Survey on Industrial Internet of Things: A Cyber-Physical Systems Perspective. IEEE Access 2018, 6, 78238–78259. [Google Scholar] [CrossRef]

- Mahmud, M.S.; Wang, H.; Esfar-E-Alam, A.M.; Fang, H. A Wireless Health Monitoring System Using Mobile Phone Accessories. IEEE Internet Things J. 2017, 4, 2009–2018. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, N.; Wu, S.; Yang, Q. Deep Learning Driven Wireless Real-time Human Activity Recognition. In Proceedings of the ICC 2020—2020 IEEE International Conference on Communications (ICC), Online, 7–11 June 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Sun, Y.; Song, H.; Jara, A.J.; Bie, R. Internet of Things and Big Data Analytics for Smart and Connected Communities. IEEE Access 2016, 4, 766–773. [Google Scholar] [CrossRef]

- Du, R.; Santi, P.; Xiao, M.; Vasilakos, A.V.; Fischione, C. The Sensable City: A Survey on the Deployment and Management for Smart City Monitoring. IEEE Commun. Surv. Tutor. 2019, 21, 1533–1560. [Google Scholar] [CrossRef]

- Bartolini, A.; Corti, F.; Reatti, A.; Ciani, L.; Grasso, F.; Kazimierczuk, M.K. Analysis and Design of Stand-Alone Photovoltaic System for precision agriculture network of sensors. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Al Rasyid, M.U.H.; Nadhori, I.U.; Sudarsono, A.; Luberski, R. Analysis of slotted and unslotted CSMA/CA Wireless Sensor Network for E-healthcare system. In Proceedings of the 2014 International Conference on Computer, Control, Informatics and Its Applications (IC3INA), Bandung, Indonesia, 21–23 October 2014; pp. 53–57. [Google Scholar] [CrossRef]

- Pievanelli, E.; Plesca, A.; Stefanelli, R.; Trinchero, D. Dynamic wireless sensor networks for real time safeguard of workers exposed to physical agents in constructions sites. In Proceedings of the 2013 IEEE Topical Conference on Wireless Sensors and Sensor Networks (WiSNet), Austin, TX, USA, 20–23 January 2013; pp. 55–57. [Google Scholar] [CrossRef]

- Hatcher, W.G.; Yu, W. A Survey of Deep Learning: Platforms, Applications and Emerging Research Trends. IEEE Access 2018, 6, 24411–24432. [Google Scholar] [CrossRef]

- Liang, F.; Hatcher, W.G.; Liao, W.; Gao, W.; Yu, W. Machine Learning for Security and the Internet of Things: The Good, the Bad, and the Ugly. IEEE Access 2019, 7, 158126–158147. [Google Scholar] [CrossRef]

- Wu, D.; Shi, H.; Wang, H.; Wang, R.; Fang, H. A Feature-Based Learning System for Internet of Things Applications. IEEE Internet Things J. 2019, 6, 1928–1937. [Google Scholar] [CrossRef]

- Mohammadi, M.; Al-Fuqaha, A.; Sorour, S.; Guizani, M. Deep Learning for IoT Big Data and Streaming Analytics: A Survey. IEEE Commun. Surv. Tutor. 2018, 20, 2923–2960. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.; Cai, Z.; Yu, J.; Han, Q.; Li, Y. Deep Learning Based Inference of Private Information Using Embedded Sensors in Smart Devices. IEEE Netw. 2018, 32, 8–14. [Google Scholar] [CrossRef]

- Shi, W.; Cao, J.; Zhang, Q.; Li, Y.; Xu, L. Edge Computing: Vision and Challenges. IEEE Internet Things J. 2016, 3, 637–646. [Google Scholar] [CrossRef]

- Zhu, S.; Xu, J.; Guo, H.; Liu, Q.; Wu, S.; Wang, H. Indoor Human Activity Recognition Based on Ambient Radar with Signal Processing and Machine Learning. In Proceedings of the 2018 IEEE International Conference on Communications (ICC), Kansas City, MO, USA, 20–24 May 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Cai, Z.; Zheng, X.; Wang, J. Efficient Data Trading for Stable and Privacy Preserving Histograms in Internet of Things. In Proceedings of the 2021 IEEE International Performance, Computing, and Communications Conference (IPCCC), Austin, TX, USA, 11–13 November 2021; pp. 1–10. [Google Scholar] [CrossRef]

- Chen, S.Y.; Song, S.F.; Li, L.X.; Shen, J. Survey on smart grid technology. Power Syst. Technol. 2009, 33, 1–7. [Google Scholar] [CrossRef]

- Guan, Z.; Sun, N.; Xu, Y.; Yang, T. A Comprehensive Survey of False Data Injection in Smart Grid. Int. J. Wire. Mob. Comput. 2015, 8, 27–33. [Google Scholar] [CrossRef]

- Liu, Y.; Ning, P.; Reiter, M. False data injection attacks against state estimation in electric power grids. ACM Trans. Inf. Syst. Secur. 2011, 14, 13. [Google Scholar] [CrossRef]

- Xu, H.; Yu, W.; Liu, X.; Griffith, D.; Golmie, N. On Data Integrity Attacks against Industrial Internet of Things. In Proceedings of the 2020 IEEE International Conference on Dependable, Autonomic and Secure Computing, International Conference on Pervasive Intelligence and Computing, International Conference on Cloud and Big Data Computing, International Conference on Cyber Science and Technology Congress (DASC/PiCom/CBDCom/CyberSciTech), Calgary, AB, Canada, 17–22 August 2020; pp. 21–28. [Google Scholar] [CrossRef]

- Ponnusamy, V.K.; Kasinathan, P.; Madurai Elavarasan, R.; Ramanathan, V.; Anandan, R.K.; Subramaniam, U.; Ghosh, A.; Hossain, E. A Comprehensive Review on Sustainable Aspects of Big Data Analytics for the Smart Grid. Sustainability 2021, 13, 3322. [Google Scholar] [CrossRef]

- Walter, A.; Finger, R.; Huber, R.; Buchmann, N. Opinion: Smart farming is key to developing sustainable agriculture. Proc. Natl. Acad. Sci. USA 2017, 114, 6148–6150. [Google Scholar] [CrossRef] [Green Version]

- Jayaraman, P.P.; Yavari, A.; Georgakopoulos, D.; Morshed, A.; Zaslavsky, A. Internet of things platform for smart farming: Experiences and lessons learnt. Sensors 2016, 16, 1884. [Google Scholar] [CrossRef] [PubMed]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Aceto, G.; Persico, V.; Pescapé, A. A Survey on Information and Communication Technologies for Industry 4.0: State-of-the-Art, Taxonomies, Perspectives, and Challenges. Commun. Surv. Tutor. 2019, 21, 3467–3501. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital twin—the simulation aspect. In Mechatronic Futures; Springer: Berlin/Heidelberg, Germany, 2016; pp. 59–74. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.Y.; Nee, A.Y. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef] [Green Version]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Brosinsky, C.; Westermann, D.; Krebs, R. Recent and prospective developments in power system control centers: Adapting the digital twin technology for application in power system control centers. In Proceedings of the 2018 IEEE International Energy Conference (ENERGYCON), Limassol, Cyprus, 3–7 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Tzanis, N.; Andriopoulos, N.; Magklaras, A.; Mylonas, E.; Birbas, M.; Birbas, A. A hybrid cyber physical digital twin approach for smart grid fault prediction. In Proceedings of the 2020 IEEE Conference on Industrial Cyberphysical Systems (ICPS), Tampere, Finland, 9–12 June 2020; IEEE: Piscataway, NJ, USA, 2020; Volume 1, pp. 393–397. [Google Scholar] [CrossRef]

- Saad, A.; Faddel, S.; Youssef, T.; Mohammed, O.A. On the implementation of IoT-based digital twin for networked microgrids resiliency against cyber attacks. IEEE Trans. Smart Grid 2020, 11, 5138–5150. [Google Scholar] [CrossRef]

- Danilczyk, W.; Sun, Y.; He, H. Angel: An intelligent digital twin framework for microgrid security. In Proceedings of the 2019 North American Power Symposium (NAPS), Wichita, KS, USA, 13–15 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Bird, P. An updated digital model of plate boundaries. Geochem. Geophys. Geosystems 2003, 4, 1–46. [Google Scholar] [CrossRef]

- Remeikiene, R.; Gaspareniene, L.; Schneider, F.G. The definition of digital shadow economy. Technol. Econ. Dev. Econ. 2018, 24, 696–717. [Google Scholar] [CrossRef] [Green Version]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Haag, S.; Anderl, R. Digital twin–Proof of concept. Manuf. Lett. 2018, 15, 64–66. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Liu, Z. Reading behavior in the digital environment: Changes in reading behavior over the past ten years. J. Doc. 2005, 61, 700–712. [Google Scholar] [CrossRef] [Green Version]

- Čolaković, A.; Hadžialić, M. Internet of Things (IoT): A review of enabling technologies, challenges, and open research issues. Comput. Netw. 2018, 144, 17–39. [Google Scholar] [CrossRef]

- Hatcher, W.G.; Qian, C.; Gao, W.; Liang, F.; Hua, K.; Yu, W. Towards Efficient and Intelligent Internet of Things Search Engine. IEEE Access 2021, 9, 15778–15795. [Google Scholar] [CrossRef]

- Jaloudi, S. Communication Protocols of an Industrial Internet of Things Environment: A Comparative Study. Future Internet 2019, 11, 66. [Google Scholar] [CrossRef] [Green Version]

- Al-Sarawi, S.; Anbar, M.; Alieyan, K.; Alzubaidi, M. Internet of Things (IoT) communication protocols: Review. In Proceedings of the 2017 8th International Conference on Information Technology (ICIT), Amman, Jordan, 17–18 May 2017; pp. 685–690. [Google Scholar] [CrossRef]

- Stusek, M.; Zeman, K.; Masek, P.; Sedova, J.; Hosek, J. IoT Protocols for Low-power Massive IoT: A Communication Perspective. In Proceedings of the 2019 11th International Congress on Ultra Modern Telecommunications and Control Systems and Workshops (ICUMT), Dublin, Ireland, 28–30 October 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Azure. Digital Twin Definition Language. Available online: https://github.com/Azure/opendigitaltwins-dtdl (accessed on 26 January 2022).

- Conde, J.; Munoz-Arcentales, A.; Alonso, A.; Lopez-Pernas, S.; Salvachua, J. Modeling Digital Twin Data and Architecture: A Building Guide with FIWARE as Enabling Technology. IEEE Internet Comput. 2021, 1. [Google Scholar] [CrossRef]

- Foundation, O. Unified Architecture. Available online: https://opcfoundation.org/about/opc-technologies/opc-ua/ (accessed on 26 January 2022).

- Ala-Laurinaho, R.; Autiosalo, J.; Nikander, A.; Mattila, J.; Tammi, K. Data Link for the Creation of Digital Twins. IEEE Access 2020, 8, 228675–228684. [Google Scholar] [CrossRef]

- Autiosalo, J.; Vepsäläinen, J.; Viitala, R.; Tammi, K. A Feature-Based Framework for Structuring Industrial Digital Twins. IEEE Access 2020, 8, 1193–1208. [Google Scholar] [CrossRef]

- Kome, M.L.; Cuppens, F.; Cuppens-Boulahia, N.; Frey, V. CoAP Enhancement for a Better IoT Centric Protocol: CoAP 2.0. In Proceedings of the 2018 Fifth International Conference on Internet of Things: Systems, Management and Security, Valencia, Spain, 15–18 October 2018; pp. 139–146. [Google Scholar] [CrossRef]

- Silva, D.; Carvalho, L.I.; Soares, J.; Sofia, R.C. A Performance Analysis of Internet of Things Networking Protocols: Evaluating MQTT, CoAP, OPC UA. Appl. Sci. 2021, 11, 4879. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, B.; Zhang, J.; Zhu, J. Design of Remote Control Inverter Based on MQTT Communication Protocol. In Proceedings of the 2021 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 8–11 August 2021; pp. 1374–1378. [Google Scholar] [CrossRef]

- Cagnano, A.; De Tuglie, E.; Mancarella, P. Microgrids: Overview and guidelines for practical implementations and operation. Appl. Energy 2020, 258, 114039. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Portalo, J.M. Innovative multi-layered architecture for heterogeneous automation and monitoring systems: Application case of a photovoltaic smart microgrid. Sustainability 2021, 13, 2234. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y. Modbus/TCP based Network Control System for Water Process in the Firepower Plant. In Proceedings of the 2006 6th World Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006; Volume 1, pp. 432–435. [Google Scholar] [CrossRef]

- Sharma, A.; Airan, S.; Shah, D. Designing C Library for MODBUS-RTU to CANBUS and MODBUS-TCP IOT Converters. In Proceedings of the 2021 Second International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 4–6 August 2021; pp. 731–737. [Google Scholar] [CrossRef]

- Galketiya, T.; Kahahena, J.; Chandran, J.; Kavalchuk, I. Novel Communication System for SCADA Tied Smart Inverter for Vietnam. In Proceedings of the 2019 25th Asia-Pacific Conference on Communications (APCC), Ho Chi Minh City, Vietnam, 6–8 November 2019; pp. 331–335. [Google Scholar] [CrossRef]

- Tan, J.; Sha, X.; Dai, B.; Lu, T. Wireless Technology and Protocol for IIoT and Digital Twins. In Proceedings of the 2020 ITU Kaleidoscope: Industry-Driven Digital Transformation (ITU K), ONLINE, 7–11 December 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Zhou, M.; Yan, J.; Feng, D. Digital twin framework and its application to power grid online analysis. CSEE J. Power Energy Syst. 2019, 5, 391–398. [Google Scholar] [CrossRef]

- Dileep, G. A survey on grid technologies and applications. Renew. Energy 2020, 146, 2589–2625. [Google Scholar] [CrossRef]

- Lund, A.M.; Mochel, K.; Lin, J.W.; Onetto, R.; Srinivasan, J.; Gregg, P.; Chotai, S. Digital Wind Farm System. U.S. Patent US20160333855A1, 17 November 2016. [Google Scholar]

- Lund, A.M.; Mochel, K.; Lin, J.W.; Onetto, R.; Srinivasan, J.; Gregg, P.; Chotai, S. Digital Twin Interface for Operating Wind Farms. U.S. Patent US9995278B2, 12 June 2018. [Google Scholar]

- Danilczyk, W.; Sun, Y.L.; He, H. Smart Grid Anomaly Detection using a Deep Learning Digital Twin. In Proceedings of the 2020 52nd North American Power Symposium (NAPS), Tempe, AZ, USA, 11–13 October 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Baboli, P.T.; Babazadeh, D.; Kumara Bowatte, D.R. Measurement-based Modeling of Smart Grid Dynamics: A Digital Twin Approach. In Proceedings of the 2020 10th Smart Grid Conference (SGC), Kashan, Iran, 16–17 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, C.; Liu, L.; Qiu, T.; Jiang, J.; Pei, Q.; Song, H. Routing With Traffic Awareness and Link Preference in Internet of Vehicles. IEEE Trans. Intell. Transp. Syst. 2022, 23, 200–214. [Google Scholar] [CrossRef]

- Jiang, D.; Huo, L.; Lv, Z.; Song, H.; Qin, W. A Joint Multi-Criteria Utility-Based Network Selection Approach for Vehicle-to-Infrastructure Networking. IEEE Trans. Intell. Transp. Syst. 2018, 19, 3305–3319. [Google Scholar] [CrossRef]

- Rudskoy, A.; Ilin, I.; Prokhorov, A. Digital Twins in the Intelligent Transport Systems. Transp. Res. Procedia 2021, 54, 927–935. [Google Scholar] [CrossRef]

- Dasgupta, S.; Rahman, M.; Lidbe, A.D.; Lu, W.; Jones, S. A Transportation Digital-Twin Approach for Adaptive Traffic Control Systems. arXiv 2021, arXiv:2109.10863. [Google Scholar]

- Wang, X.; Song, H.; Zha, W.; Li, J.; Dong, H. Digital twin based validation platform for smart metro scenarios. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 386–389. [Google Scholar] [CrossRef]

- Sahal, R.; Alsamhi, S.H.; Brown, K.N.; O’Shea, D.; McCarthy, C.; Guizani, M. Blockchain-Empowered Digital Twins Collaboration: Smart Transportation Use Case. Machines 2021, 9, 193. [Google Scholar] [CrossRef]

- Guo, Y.; Zou, K.; Chen, S.; Yuan, F.; Yu, F. 3D Digital Twin of Intelligent Transportation System based on Road-Side Sensing. In Proceedings of the Journal of Physics: Conference Series, London, UK, 5 March 2021; IOP Publishing: Bristol, UK, 2021; Volume 2083, p. 032022. [Google Scholar]

- Wallace, F.R.E. Panel on Enabling Smart Manufacturing; APMS: State College, PA, USA, 2013. [Google Scholar]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Kunath, M.; Winkler, H. Integrating the Digital Twin of the manufacturing system into a decision support system for improving the order management process. Procedia Cirp 2018, 72, 225–231. [Google Scholar] [CrossRef]

- Redelinghuys, A.; Kruger, K.; Basson, A. A Six-Layer Architecture for Digital Twins with Aggregation; Springer: Berlin/Heidelberg, Germany, 2020; pp. 171–182. [Google Scholar] [CrossRef]

- Huo, Z.; Mukherjee, M.; Shu, L.; Chen, Y.; Zhou, Z. Cloud-based Data-intensive Framework towards fault diagnosis in large-scale petrochemical plants. In Proceedings of the 2016 International Wireless Communications and Mobile Computing Conference (IWCMC), Cyprus, Paphos, 5–9 September 2016; pp. 1080–1085. [Google Scholar] [CrossRef] [Green Version]

- Pfohl, H.C.; Yahsi, B.; Kurnaz, T. Concept and Diffusion-Factors of Industry 4.0 in the Supply Chain; Springer: Berlin/Heidelberg, Germany, 2017; pp. 381–390. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Brenner, B.; Hummel, V. A Seamless Convergence of the Digital and Physical Factory Aiming in Personalized Product Emergence Process (PPEP) for Smart Products within ESB Logistics Learning Factory at Reutlingen University. Procedia CIRP 2016, 54, 227–232. [Google Scholar] [CrossRef] [Green Version]

- Salah, B. Real-Time Implementation of a Fully Automated Industrial System Based on IR 4.0 Concept. Actuators 2021, 10, 318. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Židek, K.; Piteľ, J.; Adámek, M.; Lazorík, P.; Hošovský, A. Digital Twin of Experimental Smart Manufacturing Assembly System for Industry 4.0 Concept. Sustainability 2020, 12, 3658. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Low-cost, open source IoT-based SCADA system design using thinger. IO and ESP32 thing. Electronics 2019, 8, 822. [Google Scholar] [CrossRef] [Green Version]

- Kaur, M.J.; Mishra, V.P.; Maheshwari, P. The convergence of digital twin, IoT, and machine learning: Transforming data into action. In Digital Twin Technologies and Smart Cities; Springer: Berlin/Heidelberg, Germany, 2020; pp. 3–17. [Google Scholar] [CrossRef]

- Mishra, K.N.; Chakraborty, C. A novel approach toward enhancing the quality of life in smart cities using clouds and IoT-based technologies. In Digital Twin Technologies and Smart Cities; Springer: Berlin/Heidelberg, Germany, 2020; pp. 19–35. [Google Scholar] [CrossRef]

- Seuwou, P.; Banissi, E.; Ubakanma, G. The future of mobility with connected and autonomous vehicles in smart cities. In Digital Twin Technologies and Smart Cities; Springer: Berlin/Heidelberg, Germany, 2020; pp. 37–52. [Google Scholar] [CrossRef]

- Jraisat, L. Information sharing in sustainable value chain network (SVCN)—The perspective of transportation in cities. In Digital Twin Technologies and Smart Cities; Springer: Berlin/Heidelberg, Germany, 2020; pp. 67–77. [Google Scholar] [CrossRef]

- Anthopoulos, L.G.; Janssen, M.; Weerakkody, V. Comparing Smart Cities with different modeling approaches. In Proceedings of the 24th International Conference on World Wide Web, Florence, Italy, 18–22 May 2015; pp. 525–528. [Google Scholar] [CrossRef]

- Gharaibeh, A.; Salahuddin, M.A.; Hussini, S.J.; Khreishah, A.; Khalil, I.; Guizani, M.; Al-Fuqaha, A. Smart Cities: A Survey on Data Management, Security, and Enabling Technologies. IEEE Commun. Surv. Tutor. 2017, 19, 2456–2501. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, K.; Shen, Z.J.M. A Systematic Review of a Digital Twin City: A New Pattern of Urban Governance toward Smart Cities. J. Manag. Sci. Eng. 2021, 6, 125–134. [Google Scholar] [CrossRef]

- Shahat, E.; Hyun, C.T.; Yeom, C. City digital twin potentials: A review and research agenda. Sustainability 2021, 13, 3386. [Google Scholar] [CrossRef]

- Shirowzhan, S.; Tan, W.; Sepasgozar, S.M. Digital twin and CyberGIS for improving connectivity and measuring the impact of infrastructure construction planning in smart cities. ISPRS Int. J.-Geo-Inf. 2020, 9, 240. [Google Scholar] [CrossRef]

- Castro, D. Planning in Virtual Reality. Available online: https://www.govtech.com (accessed on 26 January 2022).

- Gassmann, O.; Böhm, J.; Palmié, M. Smart Cities: Introducing Digital Innovation to Cities; Emerald Group Publishing: Bentley, UK, 2019. [Google Scholar] [CrossRef]

- Schrotter, G.; Hürzeler, C. The digital twin of the city of Zurich for urban planning. PFG-Photogramm. Remote Sens. Geoinf. Sci. 2020, 88, 99–112. [Google Scholar] [CrossRef] [Green Version]

- Research, A. The Use of Digital Twins for Urban Planning to Yield US$280 Billion in Cost Savings by 2030. Available online: https://www.abiresearch.com/press/use-digital-twins-urban-planning-yield-us280-billion-cost-savings-2030/ (accessed on 26 January 2022).

- Xu, H.; Liu, X.; Yu, W.; Griffith, D.; Golmie, N. Reinforcement Learning-Based Control and Networking Co-Design for Industrial Internet of Things. IEEE J. Sel. Areas Commun. 2020, 38, 885–898. [Google Scholar] [CrossRef]

- Liang, F.; Qian, C.; Hatcher, W.G.; Yu, W. Search Engine for the Internet of Things: Lessons From Web Search, Vision, and Opportunities. IEEE Access 2019, 7, 104673–104691. [Google Scholar] [CrossRef]

- Pan, S.J.; Yang, Q. A Survey on Transfer Learning. IEEE Trans. Knowl. Data Eng. 2010, 22, 1345–1359. [Google Scholar] [CrossRef]

| Protocol Name | Protocol Type | Protocol Characteristics |

|---|---|---|

| DTDL | Data Representation | As an open-standard platform, it defines six characteristics of IoT components and enables seamless data transmission between different DTs. |

| FIWARE | Data Representation | It supports DT data transmission and the processing of contextual information received from various IoT components. |

| OPC UA | Data Representation | As a modeling framework, it can retrieve information from raw data, support data manipulation, and provide monitoring capabilities. |

| FDTF | Data Representation | As a DT structure, it enables the DT system to share information based on the data link between DT components. |

| CoAP | Communication | As a specialized web communication protocol based on the User Datagram Protocol (UDP), it is tailored for resource-restricted devices, supports the transmission of data via Hypertext Transfer Protocol (HTTP), and provides a publish and subscribe mechanism to simplify the process of obtaining continuous data from the sensor. |

| MQTT | Communication | As a communication protocol based on Transmission Control Protocol (TCP), it enables lightweight way for IoT devices to communicate, provides reliable data transfer, and can establish a long-existing outgoing TCP protocol to enable transmission. |

| Modbus TCP/IP | Communication | As a communication protocol based on Transmission Control Protocol (TCP), it realizes the connection between industrial devices, provides reliable data transfer, and contains built-in checksum protection. |

| URLLC | Communication | As a communication protocol, it tends to achieve low latency and reliability in the transmission process between IoT devices. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, C.; Liu, X.; Ripley, C.; Qian, M.; Liang, F.; Yu, W. Digital Twin—Cyber Replica of Physical Things: Architecture, Applications and Future Research Directions. Future Internet 2022, 14, 64. https://doi.org/10.3390/fi14020064

Qian C, Liu X, Ripley C, Qian M, Liang F, Yu W. Digital Twin—Cyber Replica of Physical Things: Architecture, Applications and Future Research Directions. Future Internet. 2022; 14(2):64. https://doi.org/10.3390/fi14020064

Chicago/Turabian StyleQian, Cheng, Xing Liu, Colin Ripley, Mian Qian, Fan Liang, and Wei Yu. 2022. "Digital Twin—Cyber Replica of Physical Things: Architecture, Applications and Future Research Directions" Future Internet 14, no. 2: 64. https://doi.org/10.3390/fi14020064