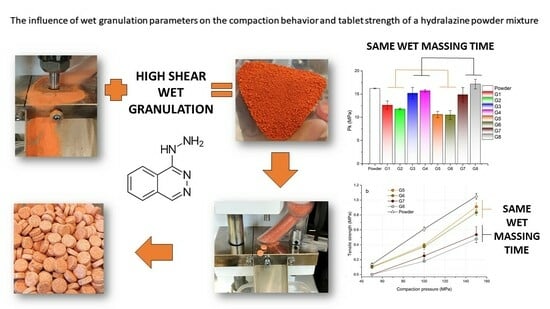

The Influence of Wet Granulation Parameters on the Compaction Behavior and Tablet Strength of a Hydralazine Powder Mixture

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Material

2.2. Particle Size Analysis

2.3. Bulk, Tapped and True Density

2.4. FT4 Compressibility

2.5. Wet Granulation of the Powder Mixture

2.6. Granule Size and Shape

2.7. Angle of Repose

2.8. Powder and Granule Compaction

2.9. Tensile Strength of Tablets

2.10. Heckel Analysis

2.11. Kawakita and Ludde Analysis

2.12. Adams Analysis

2.13. Tableting by Eccentric Press

2.14. Uniformity of Mass

3. Results and Discussion

3.1. Evaluation of Particle Size of Mixture

3.2. Evaluation of Granule Size and Shape

3.3. Evaluation of Densities and Compressibility Index

3.4. Evaluation of Angle of Repose

3.5. FT4 Compressibility

3.6. Tabletability of Powder Mixtures and Granules

3.7. Evaluation of Compaction Processes

3.8. Evaluation of Eccentric Tableting

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Genedy, S.; Khames, A.; Hussein, A.; Sarhan, H. Hydralazine HCl rapidly disintegrating sublingual tablets: Simple dosage form of higher bioavailability and enhanced clinical efficacy for potential rapid control on hypertensive preeclampsia. Drug Des. Devel. Ther. 2018, 12, 3753–3766. [Google Scholar] [CrossRef]

- Agarwal, D.S.P.; Ahuja, A. Preparation and evaluation of muco-adhesive buccal tablets of hydralazine hydrochloride. Indian J. Pharm. Sci. 1997, 59, 135–141. [Google Scholar]

- Tam, S.W.; Sabolinski, M.L.; Worcel, M.; Packer, M.; Cohn, J.N. Lack of bioequivalence between different formulations of isosorbide dinitrate and hydralazine and the fixed-dose combination of isosorbide dinitrate/hydralazine: The V-HeFT paradox. Clin. Pharmacokinet. 2007, 46, 885–895. [Google Scholar] [CrossRef]

- Matsui, F.; Robertson, D.L.; Lovering, E.G. Determination of hydrazine in pharmaceuticals III: Hydralazine and isoniazid using glc. J. Pharm. Sci. 1983, 72, 948–951. [Google Scholar] [CrossRef]

- Thong, B.Y.H.; Tan, T.C. Epidemiology and risk factors for drug allergy. Br. J. Clin. Pharmacol. 2011, 71, 684–700. [Google Scholar] [CrossRef]

- Persson, A.S.; Pazesh, S.; Alderborn, G. Tabletability and compactibility of α-lactose monohydrate powders of different particle size. I. Experimental comparison. Pharm. Dev. Technol. 2022, 27, 319–330. [Google Scholar] [CrossRef]

- Singh, B.; Pahuja, S.; Kapil, R.; Ahuja, N. Formulation development of oral controlled release tablets of hydralazine: Optimization of drug release and bioadhesive characteristics. Acta Pharm. 2009, 59, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Al-Suwayeh, A.A.; El-Shaboury, M.H.; Al-Baraki, S.M.; Elgorashy, A.S.; Taha, E.I. In vitro and in vivo evaluation of sustained release hydralazine hydrochloride tablets prepared by thermal granulation technique. Aust. J. Basic Appl. Sci. 2009, 3, 2866–2875. [Google Scholar]

- Mughal, M.A.; Saripella, K.K.; Kouba, C.; Iqbal, Z.; Neau, S.H. Coated hydralazine hydrochloride beads for sustained release after oral administration. Drug Dev. Ind. Pharm. 2013, 39, 1439–1446. [Google Scholar] [CrossRef]

- Vanitha, K.; Varma, M.; Ramesh, A. Floating tablets of hydralazine hydrochloride: Optimization and evaluation. Braz. J. Pharm. Sci. 2013, 49, 811–819. [Google Scholar] [CrossRef]

- Acharya, H.; Patel, R. Development and Optimization of Gastro-Retentive Formulation of Hydralazine HCl. Int. J. Pharm. Sci. Drug Res. 2016, 8, 249–253. [Google Scholar] [CrossRef]

- Hagelstein, V.; Gerhart, M.; Wagner, K.G. Tricalcium citrate–a new brittle tableting excipient for direct compression and dry granulation with enormous hardness yield. Drug Dev. Ind. Pharm. 2018, 44, 1631–1641. [Google Scholar] [CrossRef]

- Persson, A.S.; Alderborn, G. A hybrid approach to predict the relationship between tablet tensile strength and compaction pressure using analytical powder compression. Eur. J. Pharm. Biopharm. 2018, 125, 28–37. [Google Scholar] [CrossRef] [PubMed]

- Vreeman, G.; Sun, C.C. A powder tabletability equation. Powder Technol. 2022, 408, 117709. [Google Scholar] [CrossRef]

- Adolfsson, Å.; Nyström, C. Tablet strength, porosity, elasticity and solid state structure of tablets compressed at high loads. Int. J. Pharm. 1996, 132, 95–106. [Google Scholar] [CrossRef]

- Wünsch, I.; Friesen, I.; Puckhaber, D.; Schlegel, T.; Finke, J.H. Scaling tableting processes from compaction simulator to rotary presses—Mind the sub-processes. Pharmaceutics 2020, 12, 310. [Google Scholar] [CrossRef]

- Juban, A.; Briançon, S.; Puel, F.; Hoc, T.; Nouguier-Lehon, C. Experimental study of tensile strength of pharmaceutical tablets: Effect of the diluent nature and compression pressure. EPJ Web Conf. 2017, 140, 13002. [Google Scholar] [CrossRef]

- Berkenkemper, S.; Kleinebudde, P. Compressibility analysis as robust in-die compression analysis for describing tableting behaviour. RPS Pharm. Pharmacol. Rep. 2022, 1, rqac004. [Google Scholar] [CrossRef]

- Yu, D.; Seelam, R.R.; Zhang, F.; Byrn, S.R.; Hoag, S.W. Evaluation of tableting performance of Poly (ethylene oxide) in abuse-deterrent formulations using compaction simulation studies. J. Pharm. Sci. 2021, 110, 2789–2799. [Google Scholar] [CrossRef]

- Wünsch, I.; Finke, J.H.; John, E.; Juhnke, M.; Kwade, A. A mathematical approach to consider solid compressibility in the compression of pharmaceutical powders. Pharmaceutics 2019, 11, 121. [Google Scholar] [CrossRef]

- Vreeman, G.; Sun, C.C. Mean yield pressure from the in-die Heckel analysis is a reliable plasticity parameter. Int. J. Pharm. X 2021, 3, 100094. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Zhang, Q.; Wang, P. Hydrochlorothiazide/Losartan Potassium Tablet Prepared by Direct Compression. Pharmaceutics 2022, 14, 1741. [Google Scholar] [CrossRef] [PubMed]

- Hassanpour, A.; Ghadiri, M. Distinct element analysis and experimental evaluation of the Heckel analysis of bulk powder compression. Powder Technol. 2004, 141, 251–261. [Google Scholar] [CrossRef]

- Nordström, J.; Welch, K.; Frenning, G.; Alderborn, G. On the physical interpretation of the Kawakita and Adams parameters derived from confined compression of granular solids. Powder Technol. 2008, 182, 424–435. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, J.; Zhao, X.; Liang, Z.; Qiao, Y.; Luo, G.; Xu, B. Using a Material Library to Understand the Change of Tabletability by High Shear Wet Granulation. Pharmaceutics 2022, 14, 2631. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhao, L.; Hong, Y.; Shen, L.; Lin, X. Attribute transmission and effects of diluents and granulation liquids on granule properties and tablet quality for high shear wet granulation and tableting process. Int. J. Pharm. 2023, 642, 123177. [Google Scholar] [CrossRef]

- Council of Europe. EDQM—European Directorate for the Quality of Medicines. In European Pharmacopoeia, 10th ed.; Council of Europe: Strasbourg, France, 2020. [Google Scholar]

- Dudhat, S.M.; Kettler, C.N.; Dave, R.H. To Study Capping or Lamination Tendency of Tablets Through Evaluation of Powder Rheological Properties and Tablet Mechanical Properties of Directly Compressible Blends. AAPS PharmSciTech 2017, 18, 1177–1189. [Google Scholar] [CrossRef]

- Tran, D.T.; Komínová, P.; Kulaviak, L.; Zámostný, P. Evaluation of multifunctional magnesium aluminosilicate materials as novel family of glidants in solid dosage products. Int. J. Pharm. 2021, 592, 120054. [Google Scholar] [CrossRef]

- Macho, O.; Kabát, J.; Gabrišová, Ľ.; Peciar, P.; Juriga, M.; Fekete, R.; Galbavá, P.; Blaško, J.; Peciar, M. Dimensionless criteria as a tool for creation of a model for predicting the size of granules in high-shear granulation. Part. Sci. Technol. 2018, 38, 381–390. [Google Scholar] [CrossRef]

- Peciar, P.; Macho, O.; Peciar, M.; Fekete, R. Multifunctional Granulator. European Patent WO2017089976A1, 1 June 2017. [Google Scholar]

- You, Y.; Guo, J.; Li, G.; Lv, X.; Wu, S.; Li, Y.; Yang, R. Investigation the iron ore fine granulation effects and particle adhesion behavior in a horizontal high-shear granulator. Powder Technol. 2021, 394, 162–170. [Google Scholar] [CrossRef]

- You, Y.; Guo, J.; Li, G.; Zheng, Z.; Li, Y.; Yu, Y.; Lv, X. Investigation on the granulation behavior of iron ore fine in a horizontal high-shear granulator. Particuology 2022, 68, 57–64. [Google Scholar] [CrossRef]

- Monaco, D.; Reynolds, G.K.; Tajarobi, P.; Litster, J.D.; Salman, A.D. Modelling the effect of L/S ratio and granule moisture content on the compaction properties in continuous manufacturing. Int. J. Pharm. 2023, 633, 122624. [Google Scholar] [CrossRef] [PubMed]

- Oka, S.; Smrčka, D.; Kataria, A.; Emady, H.; Muzzio, F.; Štěpánek, F.; Ramachandran, R. Analysis of the origins of content non-uniformity in high-shear wet granulation. Int. J. Pharm. 2017, 528, 578–585. [Google Scholar] [CrossRef] [PubMed]

- ISO 13322-2; Particle Size Analysis—Imange Analysis Methods—Dynamic Image Analysis. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 9276-6; Representation of Results of Particle Size Analysis—Descriptive and Quantitative Representation of Particle Shape and Morphology. International Organization for Standardization: Geneva, Switzerland, 2008.

- Fell, J.T.; Newton, J.M. Determination of tablet strength by the diametral-compression test. J. Pharm. Sci. 1970, 59, 688–691. [Google Scholar] [CrossRef] [PubMed]

- Heckel, R.W. Density-Pressure Relationships in Powder Compaction. Trans. Metall. Soc. AIME 1961, 221, 671–675. [Google Scholar]

- Kawakita, K.; Ludde, K.H. Some considerations on powder compression equations. Powder Technol. 1971, 4, 61–68. [Google Scholar] [CrossRef]

- Adams, M.J.; McKeown, R. Micromechanical analyses of the pressure-volume relationships for powders under confined uniaxial compression. Powder Technol. 1996, 88, 155–163. [Google Scholar] [CrossRef]

- Maroof, M.A.; Mahboubi, A.; Noorzad, A.; Safi, Y. A new approach to particle shape classification of granular mate. Transp. Geotech. 2020, 22, 100296. [Google Scholar] [CrossRef]

- Patel, S.; Kaushal, A.M.; Bansal, A.K. Effect of particle size and compression force on compaction behavior and derived mathematical parameters of compressibility. Pharm. Res. 2007, 24, 111–124. [Google Scholar] [CrossRef]

- Van den Ban, S.; Goodwin, D.J. The Impact of Granule Density on Tabletting and Pharmaceutical Product Performance. Pharm. Res. 2017, 34, 1002–1011. [Google Scholar] [CrossRef]

| Experiment | Impeller Speed (rpm) | Wet Massing Time (s) | Granulation Liquid (-) |

|---|---|---|---|

| G1 | 500 | W/O | H2O |

| G2 | 700 | W/O | H2O |

| G3 | 500 | 120 | H2O |

| G4 | 700 | 120 | H2O |

| G5 | 500 | W/O | PVP |

| G6 | 700 | W/O | PVP |

| G7 | 500 | 120 | PVP |

| G8 | 700 | 120 | PVP |

| Experiment | dmean (mm) | Span (-) | Sphericity (-) | Bulk Density (g/mL) | CI (%) | AoR (°) | CPS (%) |

|---|---|---|---|---|---|---|---|

| G1 | 0.92 | 1.57 | 0.89 | 0.606 | 12.00 | 33.43 ± 0.40 | 2.84 ± 0.27 |

| G2 | 1.32 | 1.14 | 0.87 | 0.573 | 11.25 | 32.19 ± 0.66 | 2.95 ± 0.33 |

| G3 | 1.23 | 0.87 | 0.87 | 0.658 | 10.11 | 31.62 ± 0.61 | 2.94 ± 0.29 |

| G4 | 1.30 | 0.83 | 0.87 | 0.666 | 11.00 | 29.36 ± 0.73 | 2.97 ± 0.29 |

| G5 | 1.12 | 1.49 | 0.86 | 0.516 | 15.00 | 31.59 ± 0.33 | 3.06 ± 0.28 |

| G6 | 1.23 | 1.35 | 0.86 | 0.535 | 12.00 | 32.14 ± 0.62 | 3.01 ± 0.34 |

| G7 | 1.43 | 0.91 | 0.87 | 0.681 | 8.00 | 32.46 ± 0.80 | 2.57 ± 0.29 |

| G8 | 1.37 | 0.86 | 0.86 | 0.693 | 11.00 | 31.36 ± 0.71 | 2.76 ± 0.23 |

| Powder mixture | N/A | 2.98 | N/A | 0.654 | 16.30 | 35.64 ± 0.26 | 6.24 ± 0.24 |

| Experiment | Py (MPa) | Pk (MPa) | τ0 (MPa) | UoM (%) |

|---|---|---|---|---|

| G1 | 141.35 ± 10.65 | 12.62 ± 0.89 | 7.01 ± 0.99 | 1.81 |

| G2 | 144.33 ± 4.71 | 11.77 ± 0.18 | 6.18 ± 0.27 | 5.35 |

| G3 | 141.90 ± 5.23 | 15.19 ± 1.25 | 10.56 ± 1.70 | 1.94 |

| G4 | 145.03 ± 3.82 | 15.71 ± 0.27 | 11.65 ± 0.37 | 3.30 |

| G5 | 136.89 ± 3.86 | 10.59 ± 0.68 | 4.53 ± 0.69 | 3.58 |

| G6 | 144.56 ± 3.85 | 10.49 ± 0.99 | 4.51 ± 1.14 | 4.97 |

| G7 | 145.75 ± 4.61 | 14.86 ± 1.54 | 10.22 ± 2.39 | 4.04 |

| G8 | 153.96 ± 8.64 | 17.15 ± 1.02 | 13.45 ± 1.62 | 1.96 |

| Powder mixture | 108.67 ± 7.56 | 16.20 ± 0.09 | 11.94 ± 0.49 | 1.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macho, O.; Gabrišová, Ľ.; Guštafík, A.; Jezso, K.; Juriga, M.; Kabát, J.; Blaško, J. The Influence of Wet Granulation Parameters on the Compaction Behavior and Tablet Strength of a Hydralazine Powder Mixture. Pharmaceutics 2023, 15, 2148. https://doi.org/10.3390/pharmaceutics15082148

Macho O, Gabrišová Ľ, Guštafík A, Jezso K, Juriga M, Kabát J, Blaško J. The Influence of Wet Granulation Parameters on the Compaction Behavior and Tablet Strength of a Hydralazine Powder Mixture. Pharmaceutics. 2023; 15(8):2148. https://doi.org/10.3390/pharmaceutics15082148

Chicago/Turabian StyleMacho, Oliver, Ľudmila Gabrišová, Adam Guštafík, Kristian Jezso, Martin Juriga, Juraj Kabát, and Jaroslav Blaško. 2023. "The Influence of Wet Granulation Parameters on the Compaction Behavior and Tablet Strength of a Hydralazine Powder Mixture" Pharmaceutics 15, no. 8: 2148. https://doi.org/10.3390/pharmaceutics15082148