Influence of Roll Speed during Roll Compaction and Its Effect on the Prediction of Ribbon Solid Fraction

Abstract

:1. Introduction

1.1. Roll Compaction/Dry Granulation

- The granule hardening for mainly plastic deformable materials;

- The particle size enlargement and decrease in surface binding area for tableting [5].

1.2. Models for the Prediction of Roll Compaction Processes

- The powder behaves as a solid body being deformed between the counter rotating rolls;

- The deformation takes place only in one axial direction and can be expressed as uniaxial compression;

- The mass flow between the rolls in steady state is constant.

2. Materials and Methods

2.1. Materials

2.2. Characterization of Raw Materials

2.2.1. Particle Density

2.2.2. Particle Size Distribution

2.2.3. Compressibility Index

2.2.4. Yield Pressure

2.3. Roll Compaction

2.3.1. General Settings

2.3.2. Calculation of

2.3.3. Dwell Time in Roll Compaction

2.4. Characterization of Ribbons

2.4.1. At-gap Ribbon Solid Fraction Measurement (

2.4.2. Prediction Accuracy (PA) of the at-gap Ribbon Solid Fraction Using the Midoux Number

2.4.3. Powder Pycnometry: Ribbon Solid Fraction Measurement (

2.4.4. Ribbon Tensile Strength

2.5. Granulation

2.6. Blending

2.7. Tableting

2.8. Characterization of Tablets

3. Results and Discussion

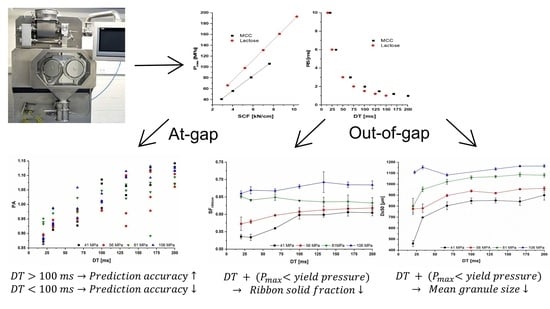

3.1. Influence of the Roll Speed on the Prediction Accuracy (PA) of the Midoux Number

3.2. Influence of the Roll Speed on the

3.3. Influence of the Roll Speed on the Granule Size

3.4. Impact of the Roll Speed on Tabletability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| I | Slipping zone |

| II | Compaction zone |

| III | Release zone |

| α | Nip angle |

| In-die tablet porosity | |

| θ | Roll angle |

| Particle density | |

| Particle density at nip angle | |

| Density at gap width | |

| In-die tablet density | |

| Predicted density at gap width | |

| Ribbon density | |

| CQA | Critical quality attribute |

| D | Roll diameter |

| d | Tablet diameter |

| D10 | 10 percent quantile of the granule size distribution |

| D50 | Median granule size |

| D90 | 90 percent quantile of the granule size distribution |

| DT | Dwell time |

| F | Force at tensile failure |

| h | height |

| K | Compressibility index |

| L | Length |

| m | Mass |

| MCC | Microcrystalline cellulose |

| Mi | Midoux number |

| Prediction accuracy of the Midoux number | |

| Pressure at nip angle | |

| Maximum roll pressure at gap width | |

| r | Radius |

| RCDG | Roll compaction/dry granulation |

| RS | Roll speed |

| S | Gap width: minimum distance between the rolls |

| SCF | Specific compaction force |

| SF | Solid fraction |

| Ratio between the solid fraction at lowest and at the highest dwell time | |

| Ribbon solid fraction at gap width | |

| Ribbon solid fraction at the highest dwell time | |

| Ribbon solid fraction at the lowest dwell time | |

| Predicted ribbon solid fraction using the Midoux number | |

| span | Span of loading |

| t | Time |

| Ribbon solid fraction | |

| Ribbon tensile strength | |

| Tablet tensile strength | |

| V | Ribbon volume |

| In-die tablet volume | |

| W | Roll width |

| w | Ribbon width |

References

- Miller, R.W. Roller compaction technology. In Handbook on Pharmaceutical Granulation, 2nd ed.; Parikh, D.M., Ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 159–188. [Google Scholar]

- Kleinebudde, P. Improving process understanding in roll compaction. J. Pharm. Sci. 2021, 111, 552–558. [Google Scholar] [CrossRef]

- Van der Voort Maarschalk, K.; Zuurman, K.; Vromans, H.; Bolhuis, G.; Lerk, C. Stress relaxation of compacts produced from viscoelastic materials. Int. J. Pharm. 1997, 151, 27–34. [Google Scholar] [CrossRef]

- Jaminet, F.; Hess, H. Studies on compacting and dry granulation. Pharm. Acta Helv. 1966, 41, 39–58. [Google Scholar] [PubMed]

- Sun, C.C.; Kleinebudde, P. Mini review: Mechanisms to the loss of tabletability by dry granulation. Eur. J. Pharm. Biopharm. 2016, 106, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Souihi, N.; Josefson, M.; Tajarobi, P.; Gururajan, B.; Trygg, J. Design space estimation of the roller compaction process. Ind. Eng. Chem. Res. 2013, 52, 12408–12419. [Google Scholar] [CrossRef]

- Nesarikar, V.V.; Vatsaraj, N.; Patel, C.; Early, W.; Pandey, P.; Sprockel, O.; Gao, Z.; Jerzewski, R.; Miller, R.; Levin, M. Instrumented roll technology for the design space development of roller compaction process. Int. J. Pharm. 2012, 426, 116–131. [Google Scholar] [CrossRef] [PubMed]

- Patel, B.A.; Adams, M.J.; Turnbull, N.; Bentham, A.C.; Wu, C.Y. Predicting the pressure distribution during roll compaction from uniaxial compaction measurements. Chem. Eng. J. 2010, 164, 410–417. [Google Scholar] [CrossRef]

- Al-Asady, R.B.; Dhenge, R.M.; Hounslow, M.J.; Salman, A.D. Roller compactor: Determining the nip angle and powder compaction progress by indentation of the pre-compacted body. Powder Technol. 2016, 300, 107–119. [Google Scholar] [CrossRef]

- Zhang, J.; Pei, C.; Schiano, S.; Heaps, D.; Wu, C.Y. The application of terahertz pulsed imaging in characterising density distribution of roll-compacted ribbons. Eur. J. Pharm. Biopharm. 2016, 106, 20–25. [Google Scholar] [CrossRef]

- Khorasani, M.; Amigo, J.M.; Sun, C.C.; Bertelsen, P.; Rantanen, J. Near-infrared chemical imaging (nir-ci) as a process monitoring solution for a production line of roll compaction and tableting. Eur. J. Pharm. Biopharm. 2015, 93, 293–302. [Google Scholar] [CrossRef]

- Mazor, A.; Perez-Gandarillas, L.; de Ryck, A.; Michrafy, A. Effect of roll compactor sealing system designs: A finite element analysis. Powder Technol. 2016, 289, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Peter, S.; Lammens, R.F.; Steffens, K.-J. Roller compaction/dry granulation: Use of the thin layer model for predicting densities and forces during roller compaction. Powder Technol. 2010, 199, 165–175. [Google Scholar] [CrossRef]

- Reimer, H.L.; Kleinebudde, P. Hybrid modeling of roll compaction processes with the Styl’One Evolution. Powder Technol. 2019, 341, 66–74. [Google Scholar] [CrossRef]

- Johanson, J.R. A rolling theory for granular solids. J. Appl. Mech. 1965, 32, 842–848. [Google Scholar] [CrossRef]

- Nesarikar, V.V.; Patel, C.; Early, W.; Vatsaraj, N.; Sprockel, O.; Jerzweski, R. Roller compaction process development and scale up using johanson model calibrated with instrumented roll data. Int. J. Pharm. 2012, 436, 486–507. [Google Scholar] [CrossRef]

- Reynolds, G.; Ingale, R.; Roberts, R.; Kothari, S.; Gururajan, B. Practical application of roller compaction process modeling. Comput. Chem. Eng. 2010, 34, 1049–1057. [Google Scholar] [CrossRef]

- So, C.; Leung, L.Y.; Muliadi, A.R.; Narang, A.S.; Mao, C. Simplifying johanson’s roller compaction model to build a “virtual roller compactor” as a predictive tool—Theory and practical application. Int. J. Pharm. 2021, 601, 120579. [Google Scholar] [CrossRef]

- Amini, H.; Akseli, I. A first principle model for simulating the ribbon solid fraction during pharmaceutical roller compaction process. Powder Technol. 2020, 368, 32–44. [Google Scholar] [CrossRef]

- Toson, P.; Lopes, D.G.; Paus, R.; Kumar, A.; Geens, J.; Stibale, S.; Quodbach, J.; Kleinebudde, P.; Hsiao, W.K.; Khinast, J. Model-based approach to the design of pharmaceutical roller-compaction processes. Int. J. Pharm. X 2019, 1, 100005. [Google Scholar] [CrossRef]

- Sousa, R.; Valente, P.C.; Nakach, M.; Bardet, L.; Wacquet, M.; Midoux, N.; Authelin, J.R. Roller compaction scale-up made simple: An approximate analytical solution to johanson’s rolling theory. J. Pharm. Sci. 2020, 109, 2536–2543. [Google Scholar] [CrossRef]

- Miguelez-Moran, A.M.; Wu, C.Y.; Dong, H.; Seville, J.P. Characterisation of density distributions in roller-compacted ribbons using micro-indentation and x-ray micro-computed tomography. Eur. J. Pharm. Biopharm. 2009, 72, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Iyer, R.M.; Hegde, S.; Singhal, D.; Malick, W. A novel approach to determine solid fraction using a laser-based direct volume measurement device. Pharm. Dev. Technol 2014, 19, 577–582. [Google Scholar] [CrossRef] [PubMed]

- Dumarey, M.; Wikstrom, H.; Fransson, M.; Sparen, A.; Tajarobi, P.; Josefson, M.; Trygg, J. Combining experimental design and orthogonal projections to latent structures to study the influence of microcrystalline cellulose properties on roll compaction. Int. J. Pharm. 2011, 416, 110–119. [Google Scholar] [CrossRef] [PubMed]

- Olaleye, B.; Wu, C.Y.; Liu, L.X. The effects of screw-to-roll speed ratio on ribbon porosity during roll compaction. Int. J. Pharm. 2020, 588, 119770. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Gururajan, B.; Reynolds, G.; Roberts, R.; Adams, M.J.; Wu, C.Y. A comparative study of roll compaction of free-flowing and cohesive pharmaceutical powders. Int. J. Pharm. 2012, 428, 39–47. [Google Scholar] [CrossRef]

- Ruangchayajatuporn, J.; Amornsakchai, T.; Sinchaipanid, N.; Mitrevej, A. Compaction behavior and optimization of spray-dried lactose with various amorphous content. J. Drug Deliv. Sci. Technol. 2011, 21, 175–181. [Google Scholar] [CrossRef]

- Mosig, J.; Kleinebudde, P. Critical evaluation of root causes of the reduced compactability after roll compaction/dry granulation. J. Pharm. Sci. 2015, 104, 1108–1118. [Google Scholar]

- Herting, M.G.; Kleinebudde, P. Roll compaction/dry granulation: Effect of raw material particle size on granule and tablet properties. Int. J. Pharm. 2007, 338, 110–118. [Google Scholar]

- Herting, M.G.; Kleinebudde, P. Studies on the reduction of tensile strength of tablets after roll compaction/dry granulation. Eur. J. Pharm. Biopharm. 2008, 70, 372–379. [Google Scholar]

- Malkowska, S.; Khan, K.A. Effect of re-conpression on the properties of tablets prepared by dry granulation. Drug Dev. Ind. Pharm. 2008, 9, 331–347. [Google Scholar]

- Wu, S.J.; Sun, C. Insensitivity of compaction properties of brittle granules to size enlargement by roller compaction. J. Pharm. Sci. 2007, 96, 1445–1450. [Google Scholar] [CrossRef]

| SCF [kN/cm] | Gap Width [mm] | RS [rpm] | Compressibility Index (K) | |

|---|---|---|---|---|

| 2.9 | 2.0 | 1.0–10.0 | 3.84 | 41 |

| 4.0 | 2.0 | 1.0–10.0 | 3.84 | 56 |

| 5.8 | 2.0 | 1.0–10.0 | 3.84 | 81 |

| 7.9 | 2.0 | 1.0–10.0 | 3.84 | 106 |

| RS [rpm] | MCC | Lactose |

|---|---|---|

| 1.0 | 200 | 150 |

| 1.2 | 167 | 125 |

| 1.5 | 133 | 100 |

| 2.0 | 100 | 75 |

| 3.0 | 67 | 50 |

| 6.0 | 33 | 25 |

| 10.0 | 20 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lück, M.; De Saeger, M.; Kleinebudde, P. Influence of Roll Speed during Roll Compaction and Its Effect on the Prediction of Ribbon Solid Fraction. Pharmaceutics 2022, 14, 2399. https://doi.org/10.3390/pharmaceutics14112399

Lück M, De Saeger M, Kleinebudde P. Influence of Roll Speed during Roll Compaction and Its Effect on the Prediction of Ribbon Solid Fraction. Pharmaceutics. 2022; 14(11):2399. https://doi.org/10.3390/pharmaceutics14112399

Chicago/Turabian StyleLück, Martin, Matthias De Saeger, and Peter Kleinebudde. 2022. "Influence of Roll Speed during Roll Compaction and Its Effect on the Prediction of Ribbon Solid Fraction" Pharmaceutics 14, no. 11: 2399. https://doi.org/10.3390/pharmaceutics14112399