Bioengineering Composite Aerogel-Based Scaffolds That Influence Porous Microstructure, Mechanical Properties and In Vivo Regeneration for Bone Tissue Application

Abstract

:1. Introduction

1.1. Biomimetic Graft Biomaterials for Bone Regeneration

1.2. Aerogel-Based Biomaterials

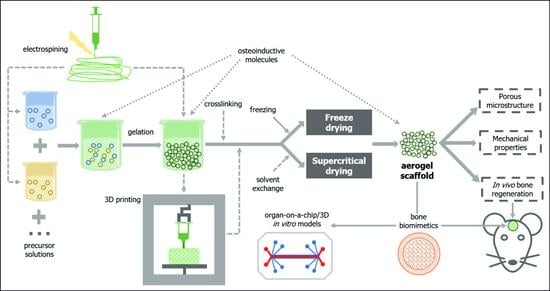

2. Preparation Methods of Composite Aerogels for Bone Regeneration

2.1. Supercritical Drying

| References | Material | Preparation Methodology | Porous Properties | In Vitro Mechanical Properties | Bone Regeneration In Vivo (microCT Analysis) |

|---|---|---|---|---|---|

| Perez-Moreno et al. (2020) [7] | Silica (SiO2)/chitosan (CS 0, 4, 8, 16, 20 wt.%) (SCS) composite aerogels | Ultrasonic preparation of precursors, ultrasonic sol–gel, aging and solvent exchange, scCO2 drying (40 °C, 10 MPa) | Pore size (nm): 11.211 (SCS8)–14.108 (SCS16) (BJH method) | Young’s modulus (MPa): 0.66 (SCS16)–11.57 (SiO2) | _ |

| Perez-Moreno et al. (2023) [53] | Chitosan (CS 8 wt.%)–silica (SiO2) hybrid aerogel (SCS8A) | Ultrasonic preparation of precursors, ultrasonic sol–gel, aging and solvent exchange, scCO2 drying (40 °C, 10 MPa) | Pore size (nm): 16.9 (SiO2A), 17.3 (SCS8A) (BJH method) | _ | _ |

| Reyes-Peces et al. (2023) [54] | Hybrid silica–3-glycidoxypropyl trimethoxysilane (GPTMS)–gelatin (SG) (15, 25, 30 wt.% of gelatin content)-based aerogel | One-step sol–gel (with crosslinking), scCO2 drying (90 bar, 40 °C) | Mean pore diameter (nm): 8.6 (SG30)–10.8 (SG15) (BJH method) | Young’s modulus (MPa): 30.81 (SG15)–78.55 (SG30) (dry); 1.65 (SG30)–3.71 (SG15) (wet). Compressive strength (MPa): 3.69 (SG15)–9.90 (SG30) (dry); 0.10 (SG30)–0.33 (SG15) (wet). Maximum compressive strain (%): 14.06 (SG30)–27.67 (SG25) (dry); 4.08 (SG30)–4.55 (SG15) (wet). | _ |

| Iglesias-Mejuto et al. (2021) [41] | 3D-printed alginate (Alg 6%)–hydroxyapatite (HA 0, 8, 16, 24 wt.%) aerogel scaffolds | Sol–gel to obtain bioinks, 3D printing of hydrogels, gelation, conversion into alcogels, scCO2 drying (40 °C, CO2 flow rate 5–7 g/min, 120 bar, 4 h) | Mean pore diameter (nm): 19 (Alg 6%, HA 0%, CaCl2 1 M)–31 (Alg 6%, HA 24%, CaCl2 1 M) (BJH method). Macropores (SEM imaging). Total porosity (%): 80.33 (Alg 6%, HA 24%, CaCl2 1 M)–88.56 (Alg 6%, HA 0%, CaCl2 1 M) (helium pycnometer) | _ | _ |

| Maleki et al. (2019) [26] | Silica–silk fibroin (SF) aerogel hybrids | One step aqueous-based sol–gel, unidirectional freeze casting (slow (33 cm/h) or rapid (66 cm/h) cooling rate until −10 °C or −196 °C), scCO2 drying | Porosity (%): 91 (silica–SF-10-33)–94 (silica–SF-196-33 and silica–SF-196-66) (helium pycnometer). Pore diameter (nm): 16 (silica–SF-10-66 and silica–SF-196-66)–18 (silica–SF-10-33) (BJH method). Macropore diameter (µm): 0.52 (silica–SF-10-66)–17.84 (silica–SF-196-33) (SEM imaging) | Maximum compression strength (MPa): 0.36 (silica–SF-10-66)–1.6 (silica–SF-196-33). Young’ s modulus (MPa): 4.03 (silica–SF-10-33)–7.3 (silica–SF-196-33). | Femur defect in rats—25 days New bone density of scaffold (silica–SF-196-33) implanted defect was similar to native bone |

2.2. Freeze Drying

| References | Material | Preparation Methodology | Porous Properties | In Vitro Mechanical Properties | Bone Regeneration In Vivo (microCT Analysis) |

|---|---|---|---|---|---|

| Karamat-Ullah et al. (2021) [23] | Silica (0.6 or 3 ratio)–silk fibroin gel-based ink for hybrid aerogel-based scaffold conjugated with CM (cecropin melittin)–RGD peptide (60 or 120 μg) | Sol–gel-based hybrid ink, 3D printing, unidirectional freeze casting, freeze drying (−60 °C for 24 h) | Mesopore diameter (nm): 15.6 (Silica-3-SF-CM-RGD-60)–17.2 (Silica–3-SF) (BJH method). Micropore size (μm): 18−20 (nanoCT and SEM imaging). Macropore size (μm): 500–1000 (microCT analysis and SEM imaging). | Young’s modulus (kPa): 31.98 (Silica-0.6-SF-CM-RGD-60)–283.5 (Silica-3-SF-CM-RGD-60) along the pore (freezing) direction | _ |

| Ng et al. (2022) [11] | Methacrylated silk fibroin (SF-MA) and ciprofloxacin-loaded methacrylated hollow mesoporous silica microcapsules (HMSC-MA) aerogel-based composite scaffolds (SF-MA-HMSC) | Self-assembled SF methacrylation, synthesis of HMSC, HMSC methacrylation, sol–gel of HMSC–MA and SF–MA-15 and 30 (4 and 2 w/v%), 3D printing of the hydrogel ink, ciprofloxacin-loading, UV photopolymerization/crosslinking, freeze casting (liquid N2), freeze drying (−60 °C, 24 h) | Pore size (µm): ~1000 (macropores); ~100–120 (interconnected micropores) (micro and nanoCT analysis); mesoporosities | _ | _ |

| Al-Jawuschi et al. (2023) [21] | Silk fibroin methacrylate (SF-MA) incorporated with methacrylate polyvinyl pyrrolidine (PVP)-bismuth sulfide (Bi2S3) nanobelts 3D aerogel-based composite scaffold loaded with sorafenib (SFN) (SF-MA-20-PVP-Bi2S3-MA-x) (x = 5, 10 and 15 mass of loaded nanobelts) | Self-assembled SF methacrylation, PVP-Bi2S3 nanobelts prepared by hydrothermal method, PVP-Bi2S3 nanobelts methacrylation, sol–gel of SF-MA-20-PVP-Bi2S3-MA-x, 3D printing of the hydrogel ink, UV photopolymerization/crosslinking, freeze casting (liquid N2), freeze drying (−40 °C, 24 h), SFN loading | Pore size (µm): ~1000 (macropores) (SEM imaging); 7–23 (interconnected micropores) (SEM imaging); no meso- or nanopores | _ | _ |

| Chen et al. (2021) [9] | Dual network silk fibroin (SF)/cellulose/nHA (S–C–H) composite aerogel | Sol–gel, crosslinking, freeze drying (24 h) | _ | Tensile strength (MPa): 7.73 (S–C–H (1:8:1 ratio)). Bending strength (MPa): 25.91 (S–C–H (1:8:1 ratio)). | _ |

| Chen et al. (2022) [25] | Mineralized (hydroxyapatite) silk fibroin (SF)/cellulose (M–S–C) interpenetrating network composite aerogel | Sol–gel, mineralization in situ (24 h), freeze drying (−56 °C, 48 h) | Interconnected (SEM imaging) porosity increased from 98.4% (S–C) to 99.2% (M–S–C) after in situ mineralization (ethanol liquid immersion method) | Compressive strength (MPa): 22.4 (M–S–C), 11.1 (M–C). Elastic modulus (MPa): ~600 (M–S–C)–~375 (M–C and S–C). | _ |

| Liu et al. (2022a) [10] | Poly(lactic acid)/gelatin (PLA/Gel)/silica (SiO2 0, 20, 40, 60%) nanofiber composite aerogel | Electrospinning of PLA/Gel nanofibers and SiO2 nanofibers, sol–gel, freezing (−80 °C 12 h), freeze drying (72 h), muffle furnace for crosslinking | PLA/Gel exhibited compact nanofiber sheets along with mesopores; PLA/Gel/SiO2 aerogels showed loose fibers morphology and uniform pores with increasing SiO2 (SEM imaging) | Ultimate compressive strength (kPa): 516.7 (PLA/Gel/SiO2-60)–866.6 (PLA/Gel/SiO2-40) (dry state). Compressive modulus (kPa): ~60 (PLA/Gel/SiO2-40)–~30 (PLA/Gel/SiO2-60) (dry state). Shape recovery rate (wet state) of PLA/Gel/SiO2-40 was 94% and 91% after 50 and 100 cycles. | Calvaria defect (diameter 5 mm) in rats—12 weeks. New bone coverage (%): 93 (PLA/Gel/SiO2-40), ~60 (PLA/Gel), ~35 (control). BV/TV (%): ~65 (PLA/Gel/SiO2-40), ~35 (PLA/Gel), ~30 (control). BMD (g·cm–3): 0.213 (PLA/Gel/SiO2-40), 0.131 (PLA/Gel), 0.097 (control). |

| Liu et al. (2022b) [22] | Polyvinyl alcohol (PVA)/modified carbon nanotubes (MCNTs 0.05, 0.10 or 0.15 wt.%)/hydroxyapatite (HAp) aerogel scaffolds | PVA/MCNTs suspension, freezing (liquid N2 for 10 min), freeze drying (48 h); suspension of PVA/MCNTs (0.05 wt.%) aerogels in SBF for 3 days for mineralization | Main pore size distribution 1000–1700 nm. Porosity (%): 70.10 (PVA/MCNTs (0.05 wt.%)/HAp)–76.03 (PVA) (mercury porosimetry). | Stiffness (at 70% deformation, MPa): ~1.5 (PVA/MCNTs (0.10 and 0.15 wt.%))–4.2 (PVA/MCNTs (0.05 wt.%)/HAp) | Calvaria defect (diameter 5 mm) in rats—8 weeks. BV/TV and BS/TS (%): ~100% (PVA/MCNTs (0.05 wt.%)/HAp), ~80% (PVA/MCNTs (0.05 wt.%)). BMD (g·cm–3): ~0.5 (PVA/MCNTs (0.05 wt.%)/HAp), ~0.4 (PVA/MCNTs (0.05 wt.%)). |

| Weng et al. (2018) [44] | 3D hybrid nanofiber aerogels of PLGA–collagen–gelatin (PCG) and Sr–Cu codoped bioactive glass (BG) nanofibers (60:40) loaded with E7–BMP (bone morphogenetic protein)–2 peptide | Sol–gel, electrospinning, crosslinking; fragmentation of nanofibers, sol–gel of nanofibers, rapid freeze casting (–30 °C, −50 °C or −80 °C in ethanol for 1 min or –196 °C in liquid N2), freeze drying (−55 °C for 72 h), thermal crosslinking, solvent exchange, freeze drying | Size of pores was around 30 µm (for freezing temperatures −30 °C to −80 °C). Much smaller pores for −196 °C freezing temperatures (SEM imaging). | Compression modulus (MPa): ~0.25 (PCG–BG (25:75))–~2.25 (PCG–BG (100:0)) | Calvaria defect (diameter 8 mm) in rats—8 weeks. BV/TV (%): 65 (PCG–BG (60:40) E7–BMP). Bone formation area (%): 68 (PCG–BG (60:40) E7–BMP). |

| Li et al. (2021) [43] | 3D hybrid nanofiber aerogels of PLGA–collagen–gelatin (PCG) and bioactive glass (BG) nanofibers (60:40) loaded with polycation miR-26a nanoparticles (NPs) | Sol–gel, electrospinning of PCG and BG nanofibers, crosslinking; fragmentation of nanofibers, sol–gel of nanofibers, freezing (−20 °C for 3 h and −80 °C for 15 min), freeze drying, thermal crosslinking, freeze drying | Interconnected pores, diameter 100 μm (SEM imaging) | _ | Calvaria defect (diameter 8 mm) in rats—4 weeks. Bone volume (mm3): 2.1 (Blank), 7.5 (aerogel/miR–NC NPs), 21.8 (aerogel/miR-26a NPs). BV/TV (%): 6.0 (Blank), 21.4 (aerogel/miR–NC NPs), 62.2 (aerogel/miR-26a NPs). Bone formation area (%): 7.3 (Blank), 19.7 (aerogel/miR–NC NPs), 56.4 (aerogel/miR-26a NPs). |

| Ruphuy et al. (2018) [56] | Nano-hydroxyapatite/chitosan (nHApCS, 70/30) hybrid scaffold (different neutralization methods: untreated, NaOHEtOH, scCO2-75/75) | nHAp and CS dispersion, freezing (–20 °C overnight), freeze drying (24 h) and: –immersion in NaOH/ethanol, washing, freeze drying or –scCO2 (2 cycles at 75 °C, 8.0 MPa) residual solvent removal and sterilization | Total porosity (%): 81 (n–HApCS–scCO2-75/75),83 (nHApCS–untreated), 93 (nHApCS–NaOHEtOH) (gas pycnometer). Mean pore size (µm): 86 (nHApCS–untreated), 72 (nHApCS–scCO2–75/75), 63 (nHApCS–NaOHEtOH) (SEM imaging). | Storage modulus (at 1 Hz after 1 h in PBS, kPa): 6.8 (nHApCS–untreated), 20.5 (nHApCS–scCO2–75/75), 13.3 (nHApCS–NaOHEtOH). | _ |

| Souto-Lopes et al. (2023) [57] | 3D nanohydroxyapatite/chitosan (nHAp/CS, 70/30) or CS scaffold | nHAp and CS dispersion, freezing (–20 °C overnight), freeze drying (24 h), scCO2 (continuous batch cycles at 75 °C, 8.0 MPa for 2 h) residual solvent removal and sterilization | Total porosity (%): 77 (CS), 78 (nHAp/CS). Full interconnectivity. Pore diameter (µm): 152 (CS), 201 (nHAp/CS) (microCT analysis). | Storage modulus (at 1 Hz, kPa): 37.0 (nHAp/CS 1 h in PBS)–38.8 (nHAp/CS 28 days in PBS); 11.9 (CS 1 h in PBS)–7.8 (CS 28 days in PBS). Storage modulus (at 10 Hz, kPa): 47.1 (nHAp/CS 1 h in PBS)–42.3 (nHAp/CS 28 days in PBS); 16.3 (CS 1 h in PBS)–8.7 (CS 28 days in PBS). | _ |

| Liu et al. (2019) [58] | Graphene oxide (0, 0.05, 0.1, 0.2% GO)–collagen (COL) aerogels | Sol–gel, freezing, freeze drying (−50 °C for 8 h), crosslinking, freeze drying | Porosity (%): 78.1 (0.2% GO–COL)–83.6 (0.1% GO–COL) (liquid displacement method). Pore size (μm): 100–160 (SEM imaging). | Elastic modulus (compression, MPa): 0.20 (COL)–0.51 (0.2% GO–COL) | 2 craniofacial bone defects (diameter 5 mm) in rats—12 weeks. BV (mm3): ~3 (0.05% GO–COL)–~6 (0.2% GO–COL). BV/TV (%): ~8 (0.05% GO–COL)–~16 (0.2% GO–COL). |

| Li et al. (2018) [55] | Sugarcane aerogel-derived borate bioglass scaffolds (SBBS) | Sol–gel preparation of borate glass, curing; freezing (−80 °C for 48 h) of sugarcane carbon hydrogels, freeze drying; borate loading on sugarcane aerogels, oven drying | _ | Compressive strength (MPa): ~0.55 (less concentrated curing solution)–~0.75 (more concentrated curing solution) for 30-5B SBBS | Bilateral ulnar bone defect (7 mm radial length and 3 × 3 mm2 cross-sectional area) in rabbits—8 weeks. The defect with vertically oriented SBBS was completely healed. |

| Ye et al. (2019) [16] | Nano-hydroxyapatite/PLLA/gelatin (nHA/PLA/Gel)–peptide (PEP, BMP–2 derived peptides) 3D nanofibrous scaffolds | PLA and Gel solution homogenization, nHA dispersion, electrospinning, cut and dispersion of nanofibers, freeze drying (24 h), thermo-crosslinking, crosslinking, freeze drying (48 h), polydopamine (pDA) coating, immersion in BMP–2 peptide solution, freeze drying | Interconnected pores from tens of microns to 300 µm (SEM imaging) | Young’s modulus (kPa): ~45 (PLA/Gel)–~65 (nHA/PLA/Gel) (wet) | Calvaria defect (diameter 6 mm) in rats—8 weeks. BV/TV (%): ~15 (PLA/Gel)–~45 (nHA/PLA/Gel–PEP). |

| Zhang et al. (2021) [46] | Three-layered scaffold of poly(L–lactide)/gelatin/hyaluronic acid/chondroitin sulfate (PLA/Gel/HA/CS) fibers and PLA/Gel gradient biomineralized fiber composite aerogels grafted with E7-peptide (A–E7G) | Electrospinning of PLA/Gel/HA/CS and PLA/Gel fibers, porogen incorporation, freezing (liquid N2), freeze drying (24 h), crosslinking heat treatment, porogen removal, soaking of PLA/Gel in 5SBF (24 or 48 h), aerogel layer adhesion with photocurable methacrylated gelatin (GelMA), photocrosslinking, E7-peptide grafting, freeze drying | Compressive stress (at 80% strain, MPa): 0.23 (PLA/Gel/HA/CS aerogel layer), 0.62 (PLA/Gel 5SBF 24 h aerogel layer), ~0.6 (A–G trilayered scaffold), 1.4 (PLA/Gel 5SBF 48 h aerogel layer) | Bilateral double knee osteochondral full thickness defects (4 mm · 4 mm) in rabbits—12 weeks. BV/TV (%): ~20 (Blank), ~30 (PLA/Gel), ~35 (A–G) ~50 (A–E7G). Tb.Th (mm): ~0.2 (Blank)–~0.35 (A–E7G). Tb.N (1/mm): ~1.25 (Blank)–~2.0 (A–E7G). |

2.3. Ambient Pressure Drying

| References | Material | Preparation Methodology | Porous Properties | In Vitro Mechanical Properties | Bone Regeneration In Vivo (microCT Analysis) |

|---|---|---|---|---|---|

| Perez-Moreno et al. (2021) [60] | Silica (SiO2)–chitosan (CS 8 wt.%)–tricalcium phosphate (TCP 10 or 20 wt.%) (SCS8T) xerogels | Ultrasonic preparation of precursors, ultrasonic sol–gel, washing (unwashed (U), in ethanol for 1 (E1) or 7 days (E7) or in water for 30 d (W30)), ambient pressure drying (80 °C, 48 h) | Pore size (nm): 3.0 (SCS8T20_U)–3.3 (SCS8_U, SCS8T10_U); 4.7 (SCS8T20_E1)–6.7 (SCS8_E1); 6.0 (SCS8T20_E7)–7.1 (SCS8_E7); 2.5 (SCS8_W30)–2.7 (SCS8T10_W30, SCS8T20_W30) (BJH method) | _ | _ |

| Perez-Moreno et al. (2023) [53] | Chitosan (CS 8 wt.%)—silica (SiO2) hybrid/tricalcium phosphate (TCP 10 wt.%) xerogel (SCS8T10X) | Ultrasonic preparation of precursors, ultrasonic sol–gel, aging and solvent exchange, ambient pressure drying (50 °C) | Pore size (nm): 4.7 (SiO2X), 5.0 (SCS8X), 7.5 (SCS8T10X) (BJH method) | _ | _ |

3. Properties of Composite Aerogels for Bone Regeneration

3.1. Aerogels’ Porous Structure

3.2. Aerogels’ In Vitro Mechanical Properties

3.3. Aerogels and In Vivo Bone Regeneration Potential

4. Future Research Approaches for Aerogels and Bone Regeneration

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuste, I.; Luciano, F.C.; González-Burgos, E.; Lalatsa, A.; Serrano, D. Mimicking bone microenvironment: 2D and 3D in vitro models of human osteoblasts. Pharmacol. Res. 2021, 169, 105626. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Zhang, S.; Ying, Z.; Liu, J.; Zhou, Y.; Chen, F. Engineering of aerogel-based biomaterials for biomedical applications. Int. J. Nanomed. 2020, 15, 2363–2378. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gartner, L.P. Textbook of Histology, 4th ed.; Elsevier: Philadelphia, PA, USA, 2017. [Google Scholar]

- Burr, D.B.; Allen, M.R. Basic and Applied Bone Biology, 2nd ed.; Elsevier: London, UK, 2019. [Google Scholar]

- Robles-Linares, J.A.; Ramírez-Cedillo, E.; Siller, H.R.; Rodríguez, C.A.; Martínez-López, J.I. Parametric modeling of biomimetic cortical bone microstructure for additive manufacturing. Materials 2019, 12, 913. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nasello, G.; Alamán-Díez, P.; Schiavi, J.; Pérez, M.Á.; McNamara, L.; García-Aznar, J.M. Primary Human Osteoblasts Cultured in a 3D Microenvironment Create a Unique Representative Model of Their Differentiation Into Osteocytes. Front. Bioeng. Biotechnol. 2020, 8, 336. [Google Scholar] [CrossRef] [PubMed]

- Perez-Moreno, A.; Reyes-Peces, M.d.l.V.; de Los Santos, D.M.; Pinaglia-Tobaruela, G.; de la Orden, E.; Vilches-Pérez, J.I.; Salido, M.; Piñero, M.; de la Rosa-Fox, N. Hydroxyl groups induce bioactivity in silica/chitosan aerogels designed for bone tissue engineering. In vitro model for the assessment of osteoblasts behavior. Polymers 2020, 12, 2802. [Google Scholar] [CrossRef]

- Asha, S.; Ananth, A.N.; Jose, S.P.; Rajan, M.J. Reduced graphene oxide aerogel networks with soft interfacial template for applications in bone tissue regeneration. Appl. Nanosci. 2018, 8, 395–405. [Google Scholar] [CrossRef]

- Chen, Z.-J.; Shi, H.-H.; Zheng, L.; Zhang, H.; Cha, Y.-Y.; Ruan, H.-X.; Zhang, Y.; Zhang, X.-C. A new cancellous bone material of silk fibroin/cellulose dual network composite aerogel reinforced by nano-hydroxyapatite filler. Int. J. Biol. Macromol. 2021, 182, 286–297. [Google Scholar] [CrossRef]

- Liu, M.; Shafiq, M.; Sun, B.; Wu, J.; Wang, W.; EL-Newehy, M.; EL-Hamshary, H.; Morsi, Y.; Ali, O.; Khan, A.U.R. Composite superelastic aerogel scaffolds containing flexible SiO2 nanofibers promote bone regeneration. Adv. Healthc. Mater. 2022, 11, 2200499. [Google Scholar] [CrossRef]

- Ng, P.; Pinho, A.R.; Gomes, M.C.; Demidov, Y.; Krakor, E.; Grume, D.; Herb, M.; Lê, K.; Mano, J.; Mathur, S. Fabrication of Antibacterial, Osteo-Inductor 3D Printed Aerogel-Based Scaffolds by Incorporation of Drug Laden Hollow Mesoporous Silica Microparticles into the Self-Assembled Silk Fibroin Biopolymer. Macromol. Biosci. 2022, 22, 2100442. [Google Scholar] [CrossRef]

- Anastasio, A.T.; Paniagua, A.; Diamond, C.; Ferlauto, H.R.; Fernandez-Moure, J.S. Nanomaterial nitric oxide delivery in traumatic orthopedic regenerative medicine. Front. Bioeng. Biotechnol. 2021, 8, 592008. [Google Scholar] [CrossRef]

- Berrio, M.; Oñate, A.; Salas, A.; Fernández, K.; Meléndrez, M. Synthesis and applications of graphene oxide aerogels in bone tissue regeneration: A review. Mater. Today Chem. 2021, 20, 100422. [Google Scholar] [CrossRef]

- Guo, J.; Yang, X.; Chen, J.; Wang, C.; Kang, Y.; Jiang, T.; Chen, M.; Li, W.; Zhou, C.; Chen, Z. Accelerated Bone Regeneration by an Astaxanthin-Modified Antioxidant Aerogel through Relieving Oxidative Stress via the NRF2 Signaling Pathway. ACS Biomater. Sci. Eng. 2022, 8, 4524–4534. [Google Scholar] [CrossRef] [PubMed]

- Rong, R.; Li, H.; Dong, X.; Hu, L.; Shi, X.; Du, Y.; Deng, H.; Sa, Y. Silk fibroin-chitosan aerogel reinforced by nanofibers for enhanced osteogenic differentiation in MC3T3-E1 cells. Int. J. Biol. Macromol. 2023, 233, 123501. [Google Scholar] [CrossRef] [PubMed]

- Ye, K.; Liu, D.; Kuang, H.; Cai, J.; Chen, W.; Sun, B.; Xia, L.; Fang, B.; Morsi, Y.; Mo, X. Three-dimensional electrospun nanofibrous scaffolds displaying bone morphogenetic protein-2-derived peptides for the promotion of osteogenic differentiation of stem cells and bone regeneration. J. Colloid Interface Sci. 2019, 534, 625–636. [Google Scholar] [CrossRef]

- Goimil, L.; Braga, M.E.; Dias, A.M.; Gomez-Amoza, J.L.; Concheiro, A.; Alvarez-Lorenzo, C.; de Sousa, H.C.; Garcia-Gonzalez, C.A. Supercritical processing of starch aerogels and aerogel-loaded poly (ε-caprolactone) scaffolds for sustained release of ketoprofen for bone regeneration. J. CO2 Util. 2017, 18, 237–249. [Google Scholar] [CrossRef]

- Osorio, D.A.; Lee, B.E.; Kwiecien, J.M.; Wang, X.; Shahid, I.; Hurley, A.L.; Cranston, E.D.; Grandfield, K. Cross-linked cellulose nanocrystal aerogels as viable bone tissue scaffolds. Acta Biomater. 2019, 87, 152–165. [Google Scholar] [CrossRef]

- Santos-Rosales, V.; Iglesias-Mejuto, A.; García-González, C.A. Solvent-free approaches for the processing of scaffolds in regenerative medicine. Polymers 2020, 12, 533. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.-J.; Yu, H.-P.; Wang, X.-L.; Ning, B.-B.; Gao, J.; Shi, Y.-Q.; Zhu, Y.-J.; Duan, J.-L. Correction: Highly porous and elastic aerogel based on ultralong hydroxyapatite nanowires for high-performance bone regeneration and neovascularization. J. Mater. Chem. B 2021, 9, 7566. [Google Scholar] [CrossRef]

- Al-Jawuschi, N.; Chen, S.; Abie, N.; Fischer, T.; Fare, S.; Maleki, H.H. Self-Assembly-Driven Bi2S3 Nanobelts Integrated a Silk-Fibroin-Based 3D-Printed Aerogel-Based Scaffold with a Dual-Network Structure for Photothermal Bone Cancer Therapy. Langmuir 2023, 39, 4326–4337. [Google Scholar] [CrossRef]

- Liu, S.; Li, D.; Chen, X.; Jiang, L. Biomimetic cuttlebone polyvinyl alcohol/carbon nanotubes/hydroxyapatite aerogel scaffolds enhanced bone regeneration. Colloids Surf B Biointerfaces 2022, 210, 112221. [Google Scholar] [CrossRef]

- Karamat-Ullah, N.; Demidov, Y.; Schramm, M.; Grumme, D.; Auer, J.; Bohr, C.; Brachvogel, B.; Maleki, H. 3D printing of antibacterial, biocompatible, and biomimetic hybrid aerogel-based scaffolds with hierarchical porosities via integrating antibacterial peptide-modified silk fibroin with silica nanostructure. ACS Biomater. Sci. Eng. 2021, 7, 4545–4556. [Google Scholar] [CrossRef] [PubMed]

- El-Wakil, N.; Kamel, R.; Mahmoud, A.A.; Dufresne, A.; Abouzeid, R.E.; Abo El-Fadl, M.T.; Maged, A. Risedronate-loaded aerogel scaffolds for bone regeneration. Drug Deliv. 2023, 30, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.-J.; Zhang, Y.; Zheng, L.; Zhang, H.; Shi, H.-H.; Zhang, X.-C.; Liu, B. Mineralized self-assembled silk fibroin/cellulose interpenetrating network aerogel for bone tissue engineering. Biomater. Adv. 2022, 134, 112549. [Google Scholar] [CrossRef] [PubMed]

- Maleki, H.; Shahbazi, M.-A.; Montes, S.; Hosseini, S.H.; Eskandari, M.R.; Zaunschirm, S.; Verwanger, T.; Mathur, S.; Milow, B.; Krammer, B. Mechanically strong silica-silk fibroin bioaerogel: A hybrid scaffold with ordered honeycomb micromorphology and multiscale porosity for bone regeneration. ACS Appl. Mater. Interfaces 2019, 11, 17256–17269. [Google Scholar] [CrossRef] [PubMed]

- Kistler, S.S. Coherent expanded aerogels and jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Vareda, J.P.; Lamy-Mendes, A.; Durães, L. A reconsideration on the definition of the term aerogel based on current drying trends. Microporous Mesoporous Mater. 2018, 258, 211–216. [Google Scholar] [CrossRef]

- García-González, C.A.; Budtova, T.; Durães, L.; Erkey, C.; Del Gaudio, P.; Gurikov, P.; Koebel, M.; Liebner, F.; Neagu, M.; Smirnova, I. An opinion paper on aerogels for biomedical and environmental applications. Molecules 2019, 24, 1815. [Google Scholar] [CrossRef] [Green Version]

- Stergar, J.; Maver, U. Review of aerogel-based materials in biomedical applications. J. Sol-Gel Sci. Technol. 2016, 77, 738–752. [Google Scholar] [CrossRef]

- Alemán, J.; Chadwick, A.V.; He, J.; Hess, M.; Horie, K.; Jones, R.G.; Kratochvíl, P.; Meisel, I.; Mita, I.; Moad, G. Definitions of terms relating to the structure and processing of sols, gels, networks, and inorganic-organic hybrid materials (IUPAC Recommendations 2007). Pure Appl. Chem. 2007, 79, 1801–1829. [Google Scholar] [CrossRef]

- Martins, M.; Barros, A.A.; Quraishi, S.; Gurikov, P.; Raman, S.; Smirnova, I.; Duarte, A.R.C.; Reis, R.L. Preparation of macroporous alginate-based aerogels for biomedical applications. J. Supercrit. Fluids. 2015, 106, 152–159. [Google Scholar] [CrossRef] [Green Version]

- El-Naggar, M.E.; Othman, S.I.; Allam, A.A.; Morsy, O.M. Synthesis, drying process and medical application of polysaccharide-based aerogels. Int. J. Biol. Macromol. 2020, 145, 1115–1128. [Google Scholar] [CrossRef]

- Ferreira-Gonçalves, T.; Constantin, C.; Neagu, M.; Reis, C.P.; Sabri, F.; Simón-Vázquez, R. Safety and efficacy assessment of aerogels for biomedical applications. Biomed. Pharmacother. 2021, 144, 112356. [Google Scholar] [CrossRef]

- Guastaferro, M.; Reverchon, E.; Baldino, L. Polysaccharide-based aerogel production for biomedical applications: A comparative review. Materials 2021, 14, 1631. [Google Scholar] [CrossRef]

- Hegedűs, C.; Czibulya, Z.; Tóth, F.; Dezső, B.; Hegedűs, V.; Boda, R.; Horváth, D.; Csík, A.; Fábián, I.; Tóth-Győri, E. The Effect of Heat Treatment of β-Tricalcium Phosphate-Containing Silica-Based Bioactive Aerogels on the Cellular Metabolism and Proliferation of MG63 Cells. Biomedicines 2022, 10, 662. [Google Scholar] [CrossRef] [PubMed]

- Yahya, E.B.; Amirul, A.; HPS, A.K.; Olaiya, N.G.; Iqbal, M.O.; Jummaat, F.; AK, A.S.; Adnan, A. Insights into the role of biopolymer aerogel scaffolds in tissue engineering and regenerative medicine. Polymers 2021, 13, 1612. [Google Scholar] [CrossRef] [PubMed]

- Goimil, L.; Santos-Rosales, V.; Delgado, A.; Evora, C.; Reyes, R.; Lozano-Perez, A.A.; Aznar-Cervantes, S.D.; Cenis, J.L.; Gómez-Amoza, J.L.; Concheiro, A. scCO2-foamed silk fibroin aerogel/poly (ε-caprolactone) scaffolds containing dexamethasone for bone regeneration. J. CO2 Util. 2019, 31, 51–64. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, Y.-n.; Wan, J.; Cui, R.; Yu, X.; Zhao, G.; Lin, K. A novel multifunctional carbon aerogel-coated platform for osteosarcoma therapy and enhanced bone regeneration. J. Mater. Chem. B 2020, 8, 368–379. [Google Scholar] [CrossRef]

- Li, D.; Chen, K.; Duan, L.; Fu, T.; Li, J.; Mu, Z.; Wang, S.; Zou, Q.; Chen, L.; Feng, Y. Strontium ranelate incorporated enzyme-cross-linked gelatin nanoparticle/silk fibroin aerogel for osteogenesis in OVX-induced osteoporosis. ACS Biomater. Sci. Eng. 2019, 5, 1440–1451. [Google Scholar] [CrossRef]

- Iglesias-Mejuto, A.; García-González, C.A. 3D-printed alginate-hydroxyapatite aerogel scaffolds for bone tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 131, 112525. [Google Scholar] [CrossRef]

- Tyshkunova, I.V.; Poshina, D.N.; Skorik, Y.A. Cellulose cryogels as promising materials for biomedical applications. Int. J. Mol. Sci. 2022, 23, 2037. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Qian, D.; Chen, L.; Mo, X.; Wang, L.; Wang, Y.; Cui, W. Electrospun fibrous sponge via short fiber for mimicking 3D ECM. J. Nanobiotechnol. 2021, 19, 131. [Google Scholar] [CrossRef]

- Weng, L.; Boda, S.K.; Wang, H.; Teusink, M.J.; Shuler, F.D.; Xie, J. Novel 3D hybrid nanofiber aerogels coupled with BMP-2 peptides for cranial bone regeneration. Adv. Healthc. Mater. 2018, 7, 1701415. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Ren, Y.; Shafiq, M.; Chen, Y.; Tang, H.; Li, B.; EL-Newehy, M.; EL-Hamshary, H.; Morsi, Y.; Zheng, H. Converging 3D printing and electrospinning: Effect of poly (L-lactide)/gelatin based short nanofibers aerogels on tracheal regeneration. Macromol. Biosci. 2022, 22, 2100342. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Fang, J.; Fu, L.; Chen, L.; Dai, W.; Huang, H.; Wang, J.; Zhang, X.; Cai, Q.; Yang, X. Gradient fibrous aerogel conjugated with chemokine peptide for regulating cell differentiation and facilitating osteochondral regeneration. Chem. Eng. J. 2021, 422, 130428. [Google Scholar] [CrossRef]

- Chen, Y.; Shafiq, M.; Liu, M.; Morsi, Y.; Mo, X. Advanced fabrication for electrospun three-dimensional nanofiber aerogels and scaffolds. Bioact. Mater. 2020, 5, 963–979. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; John, J.V.; McCarthy, A.; Xie, J. New forms of electrospun nanofiber materials for biomedical applications. J. Mater. Chem. B 2020, 8, 3733–3746. [Google Scholar] [CrossRef]

- García-González, C.A.; Concheiro, A.; Alvarez-Lorenzo, C. Processing of materials for regenerative medicine using supercritical fluid technology. Bioconjugate Chem. 2015, 26, 1159–1171. [Google Scholar] [CrossRef]

- Gupta, R.B.; Shim, J.-J. Solubility in Supercritical Carbon Dioxide, 1st ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Zhang, J.; Davis, T.A.; Matthews, M.A.; Drews, M.J.; LaBerge, M.; An, Y.H. Sterilization using high-pressure carbon dioxide. J. Supercrit. Fluids 2006, 38, 354–372. [Google Scholar]

- Gomes, P.B.; Mata, V.G.; Rodrigues, A.E. Production of rose geranium oil using supercritical fluid extraction. J. Supercrit. Fluids 2007, 41, 50–60. [Google Scholar] [CrossRef]

- Pérez-Moreno, A.; Piñero, M.; Fernández-Montesinos, R.; Pinaglia-Tobaruela, G.; Reyes-Peces, M.V.; Mesa-Díaz, M.d.M.; Vilches-Pérez, J.I.; Esquivias, L.; de la Rosa-Fox, N.; Salido, M. Chitosan-Silica Hybrid Biomaterials for Bone Tissue Engineering: A Comparative Study of Xerogels and Aerogels. Gels 2023, 9, 383. [Google Scholar] [CrossRef]

- Reyes-Peces, M.V.; Fernández-Montesinos, R.; Mesa-Díaz, M.d.M.; Vilches-Pérez, J.I.; Cárdenas-Leal, J.L.; de la Rosa-Fox, N.; Salido, M.; Piñero, M. Structure-Related Mechanical Properties and Bioactivity of Silica–Gelatin Hybrid Aerogels for Bone Regeneration. Gels 2023, 9, 67. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Ai, F.; Shen, W.; Yang, Y.; Zhou, Y.; Deng, J.; Li, C.; Ding, X.; Xin, H.; Wang, X. Microstructural orientation and precise regeneration: A proof-of-concept study on the sugar-cane-derived implants with bone-mimetic hierarchical structure. ACS Biomater. Sci. Eng. 2018, 4, 4331–4337. [Google Scholar] [CrossRef] [PubMed]

- Ruphuy, G.; Souto-Lopes, M.; Paiva, D.; Costa, P.; Rodrigues, A.; Monteiro, F.; Salgado, C.; Fernandes, M.; Lopes, J.; Dias, M. Supercritical CO2 assisted process for the production of high-purity and sterile nano-hydroxyapatite/chitosan hybrid scaffolds. J. Biomed. Mater. Res. B Appl. Biomater. 2018, 106, 965–975. [Google Scholar] [CrossRef] [PubMed]

- Souto-Lopes, M.; Grenho, L.; Manrique, Y.; Dias, M.M.; Fernandes, M.H.; Monteiro, F.J.; Salgado, C.L. Full physicochemical and biocompatibility characterization of a supercritical CO2 sterilized nano-hydroxyapatite/chitosan biodegradable scaffold for periodontal bone regeneration. Biomater. Adv. 2023, 146, 213280. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, C.; Mou, S.; Li, J.; Zhou, M.; Zeng, Y.; Luo, C.; Sun, J.; Wang, Z.; Xu, W. Biocompatible graphene oxide–collagen composite aerogel for enhanced stiffness and in situ bone regeneration. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 105, 110137. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.; Yahya, E.B.; Tajarudin, H.A.; Balakrishnan, V.; Nasution, H. Insights into the role of biopolymer-based xerogels in biomedical applications. Gels 2022, 8, 334. [Google Scholar] [CrossRef]

- Pérez-Moreno, A.; Reyes-Peces, M.V.; Vilches-Pérez, J.I.; Fernández-Montesinos, R.; Pinaglia-Tobaruela, G.; Salido, M.; De la Rosa-Fox, N.; Piñero, M. Effect of washing treatment on the textural properties and bioactivity of silica/chitosan/TCP xerogels for bone regeneration. Int. J. Mol. Sci. 2021, 22, 8321. [Google Scholar] [CrossRef]

- Li, L.; Wang, P.; Liang, H.; Jin, J.; Zhang, Y.; Shi, J.; Zhang, Y.; He, S.; Mao, H.; Xue, B. Design of a Haversian system-like gradient porous scaffold based on triply periodic minimal surfaces for promoting bone regeneration. J. Adv. Res. 2023, in press. [Google Scholar] [CrossRef]

- Santos-Rosales, V.; Gallo, M.; Jaeger, P.; Alvarez-Lorenzo, C.; Gómez-Amoza, J.L.; García-González, C.A. New insights in the morphological characterization and modelling of poly(-caprolactone) bone scaffolds obtained by supercritical CO2 foaming. J. Supercrit. Fluids 2020, 166, 105012. [Google Scholar] [CrossRef]

- John, J.V.; McCarthy, A.; Wang, H.; Luo, Z.; Li, H.; Wang, Z.; Cheng, F.; Zhang, Y.S.; Xie, J. Freeze-Casting with 3D-Printed Templates Creates Anisotropic Microchannels and Patterned Macrochannels within Biomimetic Nanofiber Aerogels for Rapid Cellular Infiltration. Adv. Healthc. Mater. 2021, 10, 2100238. [Google Scholar] [CrossRef]

- Galván-Chacón, V.P.; Zampouka, A.; Hesse, B.; Bohner, M.; Habibovic, P.; Barata, D. Bone-on-a-Chip: A Microscale 3D Biomimetic Model to Study Bone Regeneration. Adv. Eng. Mater. 2022, 24, 2101467. [Google Scholar] [CrossRef]

- Monteduro, A.G.; Rizzato, S.; Caragnano, G.; Trapani, A.; Giannelli, G.; Maruccio, G. Organs-on-chips technologies–A guide from disease models to opportunities for drug development. Biosens. Bioelectron. 2023, 231, 115271. [Google Scholar] [CrossRef] [PubMed]

- Almela, T.; Al-Sahaf, S.; Brook, I.M.; Khoshroo, K.; Rasoulianboroujeni, M.; Fahimipour, F.; Tahriri, M.; Dashtimoghadam, E.; Bolt, R.; Tayebi, L. 3D printed tissue engineered model for bone invasion of oral cancer. Tissue Cell. 2018, 52, 71–77. [Google Scholar] [CrossRef]

- Sharma, R.; Perez, M.R.; da Silva, V.A.; Thomsen, J.; Bhardwaj, L.; Andrade, T.A.; Alhussan, A.; Willerth, S.M. 3D bioprinting complex models of cancer. Biomater. Sci. 2023, 11, 3414–3430. [Google Scholar] [CrossRef]

- Blache, U.; Metzger, S.; Vallmajo-Martin, Q.; Martin, I.; Djonov, V.; Ehrbar, M. Dual role of mesenchymal stem cells allows for microvascularized bone tissue-like environments in PEG hydrogels. Adv. Healthc. Mater. 2016, 5, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Han, S.H.; Kook, Y.-M.; Lee, K.-M.; Jin, Y.-Z.; Koh, W.-G.; Lee, J.H.; Lee, K. A novel 3D indirect co-culture system based on a collagen hydrogel scaffold for enhancing the osteogenesis of stem cells. J. Mater. Chem. B 2020, 8, 9481–9491. [Google Scholar] [CrossRef] [PubMed]

- Cui, H.; Esworthy, T.; Zhou, X.; Hann, S.Y.; Glazer, R.I.; Li, R.; Zhang, L.G. Engineering a Novel 3D Printed Vascularized Tissue Model for Investigating Breast Cancer Metastasis to Bone. Adv. Healthc. Mater. 2020, 9, 1900924. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souto-Lopes, M.; Fernandes, M.H.; Monteiro, F.J.; Salgado, C.L. Bioengineering Composite Aerogel-Based Scaffolds That Influence Porous Microstructure, Mechanical Properties and In Vivo Regeneration for Bone Tissue Application. Materials 2023, 16, 4483. https://doi.org/10.3390/ma16124483

Souto-Lopes M, Fernandes MH, Monteiro FJ, Salgado CL. Bioengineering Composite Aerogel-Based Scaffolds That Influence Porous Microstructure, Mechanical Properties and In Vivo Regeneration for Bone Tissue Application. Materials. 2023; 16(12):4483. https://doi.org/10.3390/ma16124483

Chicago/Turabian StyleSouto-Lopes, Mariana, Maria Helena Fernandes, Fernando Jorge Monteiro, and Christiane Laranjo Salgado. 2023. "Bioengineering Composite Aerogel-Based Scaffolds That Influence Porous Microstructure, Mechanical Properties and In Vivo Regeneration for Bone Tissue Application" Materials 16, no. 12: 4483. https://doi.org/10.3390/ma16124483