Green Nanomaterials for Smart Textiles Dedicated to Environmental and Biomedical Applications

Abstract

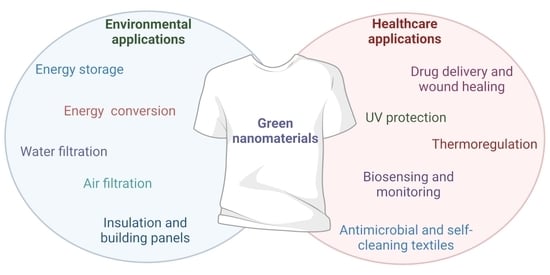

:1. Introduction

2. The Development of Sustainable and Environmentally Friendly Smart Textiles—An Overview

3. Green Synthesis Methods for Nanomaterials Used for Smart Textiles

4. Green Nanomaterials with Potential Applicability for Smart Textiles

5. Environmental and Medical Applications of Smart Textiles with Green Nanomaterials

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Au | Gold |

| Ag | Silver |

| WHO | World Health Organization |

| QD | quantum dots |

| ASTM | American Society for Testing and Materials |

| NP | nanoparticle |

| mm | millimetre |

| nm | nanometre |

| NM | nanomaterial |

| HPLC-MS | High-performance liquid chromatography-mass spectrometry |

| PCR | Polymerase chain reaction |

| ELISA | Enzyme-linked immunosorbent assay |

| Pt | Platinum |

| Pd | Palladium |

| Zn | Zinc |

| Cd | Cadmium |

| Cu | Copper |

| Fe | Iron |

| Ni | Nickel |

| Co | Cobalt |

| HAuCl4 | Tetrachloroauric Acid |

| H2PtCl6 | Hexachloroplatinic acid |

| RhCl3 | Rhodium (III) chloride |

| PdCl2 | Palladium (II) chloride |

| cm | centimetre |

| TiO2 | Titanium dioxide |

| RF | radio frequency |

| K | Kelvin |

| kHz | kilohertz |

| MHz | megahertz |

| kW | kilowatt |

| MW | megawatt |

| atm | atmosphere |

| sec | seconds |

| N | Nitrogen |

| DMF | dimethylformamide |

| PEG | polyethylene glycol |

| UV | ultraviolet |

| AuNPs | gold nanoparticles |

| °C | degrees Celsius |

| min | minutes |

| ZnO | Zinc oxide |

| SnO2 | Tin oxide |

| PbO | Lead (II) oxide |

| EC-SPR | Electrochemical—surface plasmon resonance sensor |

| DNA | Deoxyribonucleic Acid |

| LSPR | Localised surface plasmon resonance |

| SERS | Surface-enhanced Raman scattering |

| E. coli | Escherichia coli |

| PMNCs | polymeric nanocomposites |

| antibodies | ABs |

| GOX | glucose oxidase |

| PDA | polydopamine |

| DA | dopamine |

| CFU | colony-forming unit |

| mL | millilitre |

| PtNPs | platinum nanoparticles |

| PBNCs | polymeric bionanocomposites |

| L. monocytogenes | Listeria monocytogenes |

| μm | micrometre |

| LOD | Limit of detection |

| g | gram |

| β-Gal | β-galactosidase |

| S. typhimurium | Salmonella typhimurium |

| h | hours |

| PBS | phosphate buffered saline |

| EC | Commission Regulation |

| No | Number |

| S. boydii | Shigella boydii |

| ICS | immunochromatographic strip |

| S. aureus | Staphylococcus aureus |

| ATCC | American Type Culture Collection |

| MNPs | metal nanoparticles |

| MOs | metal oxides |

| CuO | copper oxide |

| Ag2O | silver oxide |

| CuNPs | Copper nanoparticles |

| pg | picograms |

| Fe3O4 | Iron oxide |

| SeNP | Selenium nanoparticle |

| FeNP | Iron nanoparticle |

| kg | kilogram |

| K | Potassium |

| Mg | Magnesium |

| Ca | Calcium |

| Hg | Mercury |

| IC | inhibition concentration |

| LC | lethal concentration |

| CMT | maximum permissible concentration |

| FDA | Food and Drug Administration |

| LOx | lactate oxidase |

| BC | Bio-cellulose |

| Co | Collagen |

| CuONPs | Copper oxide nanoparticles |

| fmol | femtomole |

| COVID-19 | Coronavirus Disease 2019 |

| SARS-CoV-2 | Severe acute respiratory syndrome coronavirus 2 |

| USD | The United States dollar |

| LDPE | Low-density polyethylene |

| RFID | Frequencies radio |

| EFSA | The European Food Safety Authority |

| MNTS | Micro- and Nanotechnologies |

| LDPE | Low-density polyethylene |

| OR | oil of oregano |

| RO | rosemary oil |

| SWNT | single walled carbon nanotube based |

| PLL | Poly-L-lysine |

| ESI | electrospray ionisation |

| GCE | glassy carbon electrode |

| PCL | polycaprolactone |

| PHB | polyhydroxy butyrate |

| PHV | polyhydroxy valerate |

| PE | polymers polyethylene |

| PVC | polyvinyl chloride |

| EVOH | ethylene vinyl alcohol |

| IgG | Immunoglobulin G |

| IgM | Immunoglobulin M |

| PBAT | poly (butylene adipate-co-terephthalate |

| TPS | cellulose-based thermoplastic starch |

| PLA | poly lactide |

| PHA | poly-hydroxyalkanoate |

| PHB | poly-hydroxybutyrate |

| PGA | poly-glutamic acid |

| MCF-7 | Michigan Cancer Foundation-7 |

| MOF | metal-organic framework |

| ZIF MOF | zeolitic imidazolate metal-organic framework |

| MWCNTs-COOH | carboxylated multi-walled carbon nanotube |

| WSP-CNT-PPy | weft-knitted spacer fabric-carbon nanotubes-polypyrrole |

| SNO2 | tin oxide |

| PEDOT | poly(3,4-ethylenedioxythiophene) |

| PEDOT:PSS | poly (3,4ethyeledioxythiopene) doped with poly(styrenesulfonate) |

| PVA | poly(vinyl alcohol) |

| TEMPO | treated viscose fabrics with 2,2,6,6-tetramethylpiperidine-1-oxy radical |

| TOCN | TEMPO-oxidized cellulose nanofibrils |

| CMCh | carboxymethyl chitosan |

| PANI | polyaniline |

References

- Islam, M.R.; Afroj, S.; Novoselov, K.S.; Karim, N. Smart Electronic Textile-Based Wearable Supercapacitors. Adv. Sci. 2022, 9, 2203856. [Google Scholar] [CrossRef] [PubMed]

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.F.; Bunko, K. The Use of ‘Smart’ Textiles for Wound Care. In Advanced Textiles for Wound Care: A Volume in Woodhead Publishing Series in Textiles; Elsevier Inc.: Amsterdam, The Netherlands, 2009; pp. 254–274. ISBN 9781845692711. [Google Scholar]

- Shi, J.; Liu, S.; Zhang, L.; Yang, B.; Shu, L.; Yang, Y.; Ren, M.; Wang, Y.; Chen, J.; Chen, W.; et al. Smart Textile-Integrated Microelectronic Systems for Wearable Applications. Adv. Mater. 2020, 32, e1901958. [Google Scholar] [CrossRef] [PubMed]

- Tosi, D.; Poeggel, S.; Iordachita, I.; Schena, E. Fibre Optic Sensors for Biomedical Applications. In Opto-Mechanical Fiber Optic Sensors: Research, Technology, and Applications in Mechanical Sensing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 301–333. [Google Scholar] [CrossRef]

- Persson, N.K.; Martinez, J.G.; Zhong, Y.; Maziz, A.; Jager, E.W.H. Actuating Textiles: Next Generation of Smart Textiles. Adv. Mater. Technol. 2018, 3, 1700397. [Google Scholar] [CrossRef]

- Bayramol, D.V.; Soin, N.; Shah, T.; Siores, E.; Matsouka, D.; Vassiliadis, S. Energy Harvesting Smart Textiles, 1st ed.; Springer: Cham, Switzerland, 2017; pp. 199–231. [Google Scholar] [CrossRef]

- Koncar, V. Introduction to Smart Textiles and Their Applications. In Smart Textiles and Their Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 1–8. ISBN 9780081005835. [Google Scholar]

- Ojuroye, O.; Torah, R.; Beeby, S.; Wilde, A. Smart Textiles for Smart Home Control and Enriching Future Wireless Sensor Network Data. Smart Sens. Meas. Instrum. 2017, 22, 159–183. [Google Scholar]

- Priniotakis, G.; Stachewicz, U.; van Hoof, J. Smart Textiles and the Indoor Environment of Buildings. Indoor Built Environ. 2022, 31, 1443–1446. [Google Scholar] [CrossRef]

- Libanori, A.; Chen, G.; Zhao, X.; Zhou, Y.; Chen, J. Smart Textiles for Personalized Healthcare. Nat. Electron. 2022, 5, 142–156. [Google Scholar] [CrossRef]

- Cochrane, C.; Hertleer, C.; Schwarz-Pfeiffer, A. Smart Textiles in Health: An Overview. In Smart Textils Applications; Elsevier: Amsterdam, The Netherlands, 2016; pp. 9–32. [Google Scholar] [CrossRef]

- Romagnoli, M.J.; Gonzalez, J.S.; Martinez, M.A.; Alvarez, V.A. Micro- and Nanotechnology Applied on Eco-Friendly Smart Textiles. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 1–19. [Google Scholar]

- Ossevoort, S.H.W. Improving the Sustainability of Smart Textiles. In Multidisciplinary Know-How for Smart-Textiles Developers; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; pp. 399–419. ISBN 9780857093424. [Google Scholar]

- The Impact of Textile Production and Waste on the Environment (Infographic)|News|European Parliament. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20201208STO93327/the-impact-of-textile-production-and-waste-on-the-environment-infographic (accessed on 7 April 2023).

- Fang, Y.; Zhao, X.; Chen, G.; Tat, T.; Chen, J. Smart Polyethylene Textiles for Radiative and Evaporative Cooling. Joule 2021, 5, 752–754. [Google Scholar] [CrossRef]

- Chen, X.; Memon, H.A.; Wang, Y.; Marriam, I.; Tebyetekerwa, M. Circular Economy and Sustainability of the Clothing and Textile Industry. Mater. Circ. Econ. 2021, 3, 1–19. [Google Scholar] [CrossRef]

- Shah, M.A.; Pirzada, B.M.; Price, G.; Shibiru, A.L.; Qurashi, A. Applications of Nanotechnology in Smart Textile Industry: A Critical Review. J. Adv. Res. 2022, 38, 55–75. [Google Scholar] [CrossRef]

- Zhao, J.; Lin, M.; Wang, Z.; Cao, X.; Xing, B. Engineered Nanomaterials in the Environment: Are They Safe? Crit. Rev. Env. Sci. Technol. 2021, 51, 1443–1478. [Google Scholar] [CrossRef]

- Lu, Y.; Ozcan, S. Green Nanomaterials: On Track for a Sustainable Future. Nano Today 2015, 10, 417–420. [Google Scholar] [CrossRef]

- Ahmed, S.; Ali, W. Green Nanomaterials Processing, Properties, and Applications. In Advanced Structured Materials; Springer: Singapore, 2020. [Google Scholar]

- Rani, M.; Keshu; Shanker, U. Green Nanomaterials: An Overview. In Green Functionalized Nanomaterials for Environmental Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 43–80. [Google Scholar] [CrossRef]

- Asmatulu, E.; Andalib, M.N.; Subeshan, B.; Abedin, F. Impact of Nanomaterials on Human Health: A Review. Environ. Chem. Lett. 2022, 20, 2509–2529. [Google Scholar] [CrossRef]

- Shamsi; Siddiqui, Z.S. Social Sciences & Humanities Green Product and Consumer Behavior: An Analytical Study. Pertanika J. Soc. Sci. Hum. 2017, 25, 1545–1554. [Google Scholar]

- Sawhney, A.P.S.; Condon, B.; Singh, K.V.; Pang, S.S.; Li, G.; Hui, D. Modern Applications of Nanotechnology in Textiles. Text. Res. J. 2008, 78, 731–739. [Google Scholar] [CrossRef]

- Perianes-Rodriguez, A.; Waltman, L.; van Eck, N.J. Constructing Bibliometric Networks: A Comparison between Full and Fractional Counting. J. Inf. 2016, 10, 1178–1195. [Google Scholar] [CrossRef]

- Verma, C.; Chhajed, M.; Singh, S.; Maji, P.K. Cellulose Nanocrystals for Environment-Friendly Self-Assembled Stimuli Doped Multisensing Photonics. ACS Appl. Polym. Mater. 2022, 4, 4047–4068. [Google Scholar] [CrossRef]

- Ruiz-Caldas, M.X.; Carlsson, J.; Sadiktsis, I.; Jaworski, A.; Nilsson, U.; Mathew, A.P. Cellulose Nanocrystals from Postconsumer Cotton and Blended Fabrics: A Study on Their Properties, Chemical Composition, and Process Efficiency. ACS Sustain. Chem. Eng. 2022, 10, 3787–3798. [Google Scholar] [CrossRef]

- Rybka, M.; Mazurek, Ł.; Konop, M. Beneficial Effect of Wound Dressings Containing Silver and Silver Nanoparticles in Wound Healing—From Experimental Studies to Clinical Practice. Life 2023, 13, 69. [Google Scholar] [CrossRef]

- Velusamy, P.; Kiruba, K.; Rajnish, K.N.; Madhavan, T.; Anbu, P. Recent Advances in the Development of Antimicrobial Nanotextiles for Prevention of Infectious Diseases Transmission in Healthcare Workers. In Green Chemistry for Sustainable Textiles. Modern Design and Approaches; Woodhead Publishing: Sawston, UK, 2021; pp. 17–26. [Google Scholar] [CrossRef]

- Qin, H.; Li, J.; He, B.; Sun, J.; Li, L.; Qian, L. Novel Wearable Electrodes Based on Conductive Chitosan Fabrics and Their Application in Smart Garments. Materials 2018, 11, 370. [Google Scholar] [CrossRef] [PubMed]

- Goda, E.S.; Abu Elella, M.H.; Hong, S.E.; Pandit, B.; Yoon, K.R.; Gamal, H. Smart Flame Retardant Coating Containing Carboxymethyl Chitosan Nanoparticles Decorated Graphene for Obtaining Multifunctional Textiles. Cellulose 2021, 28, 5087–5105. [Google Scholar] [CrossRef]

- Tien, N.D.; Lyngstadaas, S.P.; Mano, J.F.; Blaker, J.J.; Haugen, H.J. Recent Developments in Chitosan-Based Micro/Nanofibres for Sustainable Food Packaging, Smart Textiles, Cosmeceuticals, and Biomedical Applications. Molecules 2021, 26, 2683. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Danti, S.; de Clerk, K.; Lazzeri, A.; Morganti, P. Pullulan for Advanced Sustainable Body-and Skin-Contact Applications. J. Funct. Biomater. 2020, 11, 20. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, A.; Jarrais, B.; Rocha, I.M.; Pereira, C.; Pereira, M.F.R.; Freire, C. Efficient Immobilization of Montmorillonite onto Cotton Textiles through Their Functionalization with Organosilanes. Appl. Clay Sci. 2014, 101, 304–314. [Google Scholar] [CrossRef]

- Attia, N.F.; El Ebissy, A.A.; Hassan, M.A. Novel Synthesis and Characterization of Conductive and Flame Retardant Textile Fabrics. Polym. Adv. Technol. 2015, 26, 1551–1557. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J. Materials Sustainable Use of Nanomaterials in Textiles and Their Environmental Impact. Materials 2020, 13, 5134. [Google Scholar] [CrossRef]

- Abou Elmaaty, T.M.; Elsisi, H.; Elsayad, G.; Elhadad, H.; Plutino, M.R. Recent Advances in Functionalization of Cotton Fabrics with Nanotechnology. Polymers 2022, 14, 4273. [Google Scholar] [CrossRef]

- Ferreira, D.P.; Ferreira, A.; Fangueiro, R. Searching for Natural Conductive Fibrous Structures via a Green Sustainable Approach Based on Jute Fibres and Silver Nanoparticles. Polymers 2018, 10, 63. [Google Scholar] [CrossRef]

- Rohani, R.; Dzulkharnien, N.S.F.; Harun, N.H.; Ilias, I.A. Green Approaches, Potentials, and Applications of Zinc Oxide Nanoparticles in Surface Coatings and Films. Bioinorg. Chem. Appl. 2022, 2022, 3077747. [Google Scholar] [CrossRef]

- Turakhia, B.; Divakara, M.B.; Santosh, M.S.; Shah, S. Green Synthesis of Copper Oxide Nanoparticles: A Promising Approach in the Development of Antibacterial Textiles. J. Coat. Technol. Res. 2020, 17, 531–540. [Google Scholar] [CrossRef]

- Xu, J.; Huang, Y.; Zhu, S.; Abbes, N.; Jing, X.; Zhang, L. A Review of the Green Synthesis of ZnO Nanoparticles Using Plant Extracts and Their Prospects for Application in Antibacterial Textiles. J. Eng. Fibre Fabr. 2021, 16. [Google Scholar] [CrossRef]

- Mehravani, B.; Ribeiro, A.I.; Zille, A. Gold Nanoparticles Synthesis and Antimicrobial Effect on Fibrous Materials. Nanomaterials 2021, 11, 1067. [Google Scholar] [CrossRef]

- Gao, W.; Sun, L.; Zhang, Z.; Li, Z. Cellulose Nanocrystals Reinforced Gelatin/Bioactive Glass Nanocomposite Scaffolds for Potential Application in Bone Regeneration. J. Biomater. Sci. Polym. Ed. 2020, 31, 984–998. [Google Scholar] [CrossRef] [PubMed]

- Garavand, F.; Rouhi, M.; Jafarzadeh, S.; Khodaei, D.; Cacciotti, I.; Zargar, M.; Razavi, S.H. Tuning the Physicochemical, Structural, and Antimicrobial Attributes of Whey-Based Poly (L-Lactic Acid) (PLLA) Films by Chitosan Nanoparticles. Front. Nutr. 2022, 9, 793. [Google Scholar] [CrossRef]

- de Paiva Teixeira, M.H.; Lourenço, L.A.; Artifon, W.; de Castro Vieira, C.J.; Gómez González, S.Y.; Hotza, D. Eco-Friendly Manufacturing of Nano-TiO2 Coated Cotton Textile with Multifunctional Properties. Fibres Polym. 2020, 21, 90–102. [Google Scholar] [CrossRef]

- Bhardwaj, B.; Singh, P.; Kumar, A.; Kumar, S.; Budhwar, V. Eco-Friendly Greener Synthesis of Nanoparticles. Adv. Pharm. Bull. 2020, 10, 566. [Google Scholar] [CrossRef]

- Fariq, A.; Khan, T.; Yasmin, A. Microbial Synthesis of Nanoparticles and Their Potential Applications in Biomedicine. J. Appl. Biomed. 2017, 15, 241–248. [Google Scholar] [CrossRef]

- Sundrarajan, M.; Gowri, S. Green Synthesis of Titanium Dioxide Nanoparticles by Nyctanthes Arbor-Tristis Leaves Extract. Chalcogenide Lett. 2011, 8, 447–451. [Google Scholar]

- Nethravathi, P.C.; Shruthi, G.S.; Suresh, D.; Udayabhanu; Nagabhushana, H.; Sharma, S.C. Garcinia Xanthochymus Mediated Green Synthesis of ZnO Nanoparticles: Photoluminescence, Photocatalytic and Antioxidant Activity Studies. Ceram. Int. 2015, 41, 8680–8687. [Google Scholar] [CrossRef]

- Sangeetha, G.; Rajeshwari, S.; Venckatesh, R. Green Synthesis of Zinc Oxide Nanoparticles by Aloe Barbadensis Miller Leaf Extract: Structure and Optical Properties. Mater. Res. Bull. 2011, 46, 2560–2566. [Google Scholar] [CrossRef]

- Singh, J.; Dutta, T.; Kim, K.H.; Rawat, M.; Samddar, P.; Kumar, P. ‘Green’ Synthesis of Metals and Their Oxide Nanoparticles: Applications for Environmental Remediation. J. Nanobiotechnol. 2018, 16, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Hu, Z.; Zhang, J.; Wang, L.; Wu, C.; Xu, J. A Top-down Strategy to Synthesize Wurtzite Cu2ZnSnS4 Nanocrystals by Green Chemistry. Chem. Commun. 2016, 52, 9821–9824. [Google Scholar] [CrossRef]

- Adeyemi, J.O.; Oriola, A.O.; Onwudiwe, D.C.; Oyedeji, A.O. Plant Extracts Mediated Metal-Based Nanoparticles: Synthesis and Biological Applications. Biomolecules 2022, 12, 627. [Google Scholar] [CrossRef] [PubMed]

- Shafey, A.M. El Green Synthesis of Metal and Metal Oxide Nanoparticles from Plant Leaf Extracts and Their Applications: A Review. Green Process. Synth. 2020, 9, 304–339. [Google Scholar] [CrossRef]

- Khan, M.F.; Khan, M.A.; Faheem Khan, M.; Khan, M.A. Plant-Derived Metal Nanoparticles (PDMNPs): Synthesis, Characterization, and Oxidative Stress-Mediated Therapeutic Actions. Future Pharmacol. 2023, 3, 252–295. [Google Scholar] [CrossRef]

- Ying, S.; Guan, Z.; Ofoegbu, P.C.; Clubb, P.; Rico, C.; He, F.; Hong, J. Green Synthesis of Nanoparticles: Current Developments and Limitations. Env. Technol. Innov. 2022, 26, 102336. [Google Scholar] [CrossRef]

- Al-khattaf, F.S. Gold and Silver Nanoparticles: Green Synthesis, Microbes, Mechanism, Factors, Plant Disease Management and Environmental Risks. Saudi J. Biol. Sci. 2021, 28, 3624. [Google Scholar] [CrossRef]

- Hermosilla, E.; Díaz, M.; Vera, J.; Contreras, M.J.; Leal, K.; Salazar, R.; Barrientos, L.; Tortella, G.; Rubilar, O. Synthesis of Antimicrobial Chitosan-Silver Nanoparticles Mediated by Reusable Chitosan Fungal Beads. Int. J. Mol. Sci. 2023, 24, 2318. [Google Scholar] [CrossRef]

- Amina, S.J.; Guo, B. A Review on the Synthesis and Functionalization of Gold Nanoparticles as a Drug Delivery Vehicle. Int. J. Nanomed. 2020, 15, 9823. [Google Scholar] [CrossRef]

- Lee, K.X.; Shameli, K.; Yew, Y.P.; Teow, S.Y.; Jahangirian, H.; Rafiee-Moghaddam, R.; Webster, T.J. Recent Developments in the Facile Bio-Synthesis of Gold Nanoparticles (AuNPs) and Their Biomedical Applications. Int. J. Nanomed. 2020, 15, 275. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Yang, T.; Li, Z.; Yang, T. The Application of Biomolecules in the Preparation of Nanomaterials. In Biomedical Engineering—Frontiers and Challenges; InTech: London, UK, 2011. [Google Scholar] [CrossRef]

- Ungureanu, C.; Tihan, G.T.; Zgârian, R.G.; Fierascu, I.; Baroi, A.M.; Răileanu, S.; Fierăscu, R.C. Metallic and Metal Oxides Nanoparticles for Sensing Food Pathogens—An Overview of Recent Findings and Future Prospects. Materials 2022, 15, 5374. [Google Scholar] [CrossRef] [PubMed]

- Popescu, M.; Ungureanu, C. Biosensors in Food and Healthcare Industries: Bio-Coatings Based on Biogenic Nanoparticles and Biopolymers. Coatings 2023, 13, 486. [Google Scholar] [CrossRef]

- Hessel, V.; Tran, N.N.; Asrami, M.R.; Tran, Q.D.; Van Duc Long, N.; Escribà-Gelonch, M.; Tejada, J.O.; Linke, S.; Sundmacher, K. Sustainability of Green Solvents—Review and Perspective. Green Chem. 2022, 24, 410–437. [Google Scholar] [CrossRef]

- Ali, K.; Cherian, T.; Fatima, S.; Saquib, Q.; Faisal, M.; Alatar, A.A.; Musarrat, J.; Al-Khedhairy, A.A. Role of Solvent System in Green Synthesis of Nanoparticles. In Green Synthesis of Nanoparticles: Applications and Prospects; Springer: Singapore, 2020; pp. 53–74. [Google Scholar] [CrossRef]

- Hassanpour, M.; Shahavi, M.H.; Heidari, G.; Kumar, A.; Nodehi, M.; Moghaddam, F.D.; Mohammadi, M.; Nikfarjam, N.; Sharifi, E.; Makvandi, P.; et al. Ionic Liquid-Mediated Synthesis of Metal Nanostructures: Potential Application in Cancer Diagnosis and Therapy. J. Ion. Liq. 2022, 2, 100033. [Google Scholar] [CrossRef]

- Tsang, M.P.; Philippot, G.; Aymonier, C.; Sonnemann, G. Supercritical Fluid Flow Synthesis to Support Sustainable Production of Engineered Nanomaterials: Case Study of Titanium Dioxide. ACS Sustain. Chem. Eng. 2018, 6, 5142–5151. [Google Scholar] [CrossRef]

- Fernández-Merino, M.J.; Guardia, L.; Paredes, J.I.; Villar-Rodil, S.; Solís-Fernández, P.; Martínez-Alonso, A.; Tascón, J.M.D. Vitamin C Is an Ideal Substitute for Hydrazine in the Reduction of Graphene Oxide Suspensions. J. Phys. Chem. C 2010, 114, 6426–6432. [Google Scholar] [CrossRef]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-Based Composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef]

- De Freitas, L.F.; Varca, G.H.C.; Batista, J.G.D.S.; Lugão, A.B. An Overview of the Synthesis of Gold Nanoparticles Using Radiation Technologies. Nanomaterials 2018, 8, 939. [Google Scholar] [CrossRef]

- Khodashenas, B.; Ghorbani, H.R. Synthesis of Silver Nanoparticles with Different Shapes. Arab. J. Chem. 2019, 12, 1823–1838. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a Tiny Fibre with Huge Applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Yu, H.; Liu, Y.; Hai, Y.; Zhang, M.; Chen, P. Isolation and Characterization of Cellulose Nanofibres from Four Plant Cellulose Fibres Using a Chemical-Ultrasonic Process. Cellulose 2011, 18, 433–442. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A Fascinating Fibre Fabrication Technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef] [PubMed]

- Geng, X.; Kwon, O.H.; Jang, J. Electrospinning of Chitosan Dissolved in Concentrated Acetic Acid Solution. Biomaterials 2005, 26, 5427–5432. [Google Scholar] [CrossRef]

- Miras, N.; Alhalili, Z. Metal Oxides Nanoparticles: General Structural Description, Chemical, Physical, and Biological Synthesis Methods, Role in Pesticides and Heavy Metal Removal through Wastewater Treatment. Molecules 2023, 28, 3086. [Google Scholar] [CrossRef]

- Zhang, K.; Barhoum, A.; Xiaoqing, C.; Haoyi, L.; Samyn, P. Cellulose Nanofibres: Fabrication and Surface Functionalization Techniques. In Handbook of Nanofibres; Springer: Cham, Switzerland, 2019; pp. 1–41. [Google Scholar] [CrossRef]

- Owens, G.J.; Singh, R.K.; Foroutan, F.; Alqaysi, M.; Han, C.M.; Mahapatra, C.; Kim, H.W.; Knowles, J.C. Sol–Gel Based Materials for Biomedical Applications. Prog. Mater. Sci. 2016, 77, 1–79. [Google Scholar] [CrossRef]

- Conroy, J.F.; Power, M.E.; Norris, P.M. Applications for Sol-Gel-Derived Materials in Medicine and Biology. JALA—J. Assoc. Lab. Autom. 2000, 5, 52–57. [Google Scholar] [CrossRef]

- Bhawani, S.A.; Bhat, A.H.; Ahmad, F.B.; Ibrahim, M.N.M. Green Polymer Nanocomposites and Their Environmental Applications: Polymer-Based Nanocomposites for Energy and Environmental Applications. In Woodhead Publishing Series in Composites Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 617–633. [Google Scholar] [CrossRef]

- Dufresne, A. Cellulose Nanomaterials as Green Nanoreinforcements for Polymer Nanocomposites. Philos. Trans A Math Phys. Eng. Sci. 2018, 376, 20170040. [Google Scholar] [CrossRef]

- Abazari, M.; Badeleh, S.M.; Khaleghi, F.; Saeedi, M.; Haghi, F. Fabrication of Silver Nanoparticles-Deposited Fabrics as a Potential Candidate for the Development of Reusable Facemasks and Evaluation of Their Performance. Sci. Rep. 2023, 13, 1–16. [Google Scholar] [CrossRef]

- Abramov, O.V.; Gedanken, A.; Koltypin, Y.; Perkas, N.; Perelshtein, I.; Joyce, E.; Mason, T.J. Pilot Scale Sonochemical Coating of Nanoparticles onto Textiles to Produce Biocidal Fabrics. Surf Coat. Technol. 2009, 204, 718–722. [Google Scholar] [CrossRef]

- Rubeziene, V.; Baltusnikaite-Guzaitiene, J.; Abraitiene, A.; Sankauskaite, A.; Ragulis, P.; Santos, G.; Pimenta, J. Development and Investigation of PEDOT:PSS Composition Coated Fabrics Intended for Microwave Shielding and Absorption. Polymers 2021, 13, 1191. [Google Scholar] [CrossRef] [PubMed]

- Lund, A.; van der Velden, N.M.; Persson, N.K.; Hamedi, M.M.; Müller, C. Electrically Conducting Fibres for E-Textiles: An Open Playground for Conjugated Polymers and Carbon Nanomaterials. Mater. Sci. Eng. R Rep. 2018, 126, 1–29. [Google Scholar] [CrossRef]

- Jain, K.; Reid, M.S.; Larsson, P.A.; Wågberg, L. On the Interaction between PEDOT:PSS and Cellulose: Adsorption Mechanisms and Controlling Factors. Carbohydr. Polym. 2021, 260, 117818. [Google Scholar] [CrossRef] [PubMed]

- Pereira, C.; Pereira, A.M.; Freire, C.; Pinto, T.V.; Costa, R.S.; Teixeira, J.S. Nanoengineered Textiles: From Advanced Functional Nanomaterials to Groundbreaking High-Performance Clothing. In Handbook of Functionalized Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 611–714. [Google Scholar] [CrossRef]

- Korica, M.; Peršin, Z.; Zemljič, L.F.; Mihajlovski, K.; Dojčinović, B.; Trifunović, S.; Vesel, A.; Nikolić, T.; Kostić, M.M. Chitosan Nanoparticles Functionalized Viscose Fabrics as Potentially Durable Antibacterial Medical Textiles. Materials 2021, 14, 3762. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, P.; Zhang, Y.; Li, C. Durable Antibacterial and UV Protective Properties of Cotton Fabric Coated with Carboxymethyl Chitosan and Ag/TiO2 Composite Nanoparticles. Fibres Polym. 2022, 23, 386–395. [Google Scholar] [CrossRef]

- Park, S.Y.; Chung, J.W.; Priestley, R.D.; Kwak, S.Y. Covalent Assembly of Metal Nanoparticles on Cellulose Fabric and Its Antimicrobial Activity. Cellulose 2012, 19, 2141–2151. [Google Scholar] [CrossRef]

- Tripathi, R.; Narayan, A.; Bramhecha, I.; Sheikh, J. Development of Multifunctional Linen Fabric Using Chitosan Film as a Template for Immobilization of In-Situ Generated CeO2 Nanoparticles. Int. J. Biol. Macromol. 2019, 121, 1154–1159. [Google Scholar] [CrossRef]

- Andrade-Guel, M.; Ávila-Orta, C.A.; Cabello-Alvarado, C.; Cadenas-Pliego, G.; Esparza-González, S.C.; Pérez-Alvarez, M.; Quiñones-Jurado, Z.V. Non-Woven Fabrics Based on Nanocomposite Nylon 6/ZnO Obtained by Ultrasound-Assisted Extrusion for Improved Antimicrobial and Adsorption Methylene Blue Dye Properties. Polymers 2021, 13, 1888. [Google Scholar] [CrossRef]

- Vigneshwaran, N. Modification of Textile Surfaces Using Nanoparticles. In Surface Modification of Texttils; Elsevier: Amsterdam, The Netherlands, 2009; p. 164. [Google Scholar] [CrossRef]

- Xu, Y.; Wen, W.; Wu, J.M. Titania Nanowires Functionalized Polyester Fabrics with Enhanced Photocatalytic and Antibacterial Performances. J. Hazard. Mater. 2018, 343, 285–297. [Google Scholar] [CrossRef]

- Yu, J.; Pang, Z.; Zheng, C.; Zhou, T.; Zhang, J.; Zhou, H.; Wei, Q. Cotton Fabric Finished by PANI/TiO2 with Multifunctions of Conductivity, Anti-Ultraviolet and Photocatalysis Activity. Appl. Surf Sci. 2019, 470, 84–90. [Google Scholar] [CrossRef]

- Long, M.; Zheng, L.; Tan, B.; Shu, H. Photocatalytic Self-Cleaning Cotton Fabrics with Platinum (IV) Chloride Modified TiO2 and N-TiO2 Coatings. Appl. Surf. Sci. 2016, 386, 434–441. [Google Scholar] [CrossRef]

- Dhir, Y.J.; Dhir, Y.J. Natural Fibres: The Sustainable Alternatives for Textile and Non-Textile Applications. In Natural Fibre; InTech: London, UK, 2022. [Google Scholar] [CrossRef]

- Mattila, H. Yarn to Fabric: Intelligent Textiles. In Textiles and Fashion Materials, Design and Technology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 355–376. [Google Scholar] [CrossRef]

- Shojaeiarani, J.; Bajwa, D.S.; Chanda, S. Cellulose Nanocrystal Based Composites: A Review. Compos. Part C Open Access 2021, 5, 100164. [Google Scholar] [CrossRef]

- George, J.; Sabapathi, S.N. Cellulose Nanocrystals: Synthesis, Functional Properties, and Applications. Nanotechnol. Sci. Appl. 2015, 8, 45. [Google Scholar] [CrossRef]

- Schiavi, D.; Ronchetti, R.; Di Lorenzo, V.; Vivani, R.; Giovagnoli, S.; Camaioni, E.; Balestra, G.M. Sustainable Protocols for Cellulose Nanocrystals Synthesis from Tomato Waste and Their Antimicrobial Properties against Pseudomonas Syringae Pv. Tomato. Plants 2023, 12, 939. [Google Scholar] [CrossRef]

- Kamelnia, E.; Divsalar, A.; Darroudi, M.; Yaghmaei, P.; Sadri, K. Production of New Cellulose Nanocrystals from Ferula Gummosa and Their Use in Medical Applications via Investigation of Their Biodistribution. Ind. Crops Prod. 2019, 139, 111538. [Google Scholar] [CrossRef]

- Romruen, O.; Karbowiak, T.; Tongdeesoontorn, W.; Shiekh, K.A.; Rawdkuen, S. Extraction and Characterization of Cellulose from Agricultural By-Products of Chiang Rai Province, Thailand. Polymers 2022, 14, 1830. [Google Scholar] [CrossRef] [PubMed]

- Oun, A.A.; Rhim, J.W. Isolation of Cellulose Nanocrystals from Grain Straws and Their Use for the Preparation of Carboxymethyl Cellulose-Based Nanocomposite Films. Carbohydr. Polym. 2016, 150, 187–200. [Google Scholar] [CrossRef] [PubMed]

- Amr, A.; Ibrahim, H.; Amr, A.; Ibrahim, H. Bacterial Cellulose: Biosynthesis and Applications. In Next-Generation Textiles; InTech: London, UK, 2022. [Google Scholar] [CrossRef]

- Dufresne, A. 4. Bacterial Cellulose. In Nanocellulose; De Gruyter: Berlin, Germany; Boston, MA, USA, 2017; pp. 193–220. [Google Scholar]

- Butchosa, N.; Brown, C.; Larsson, P.T.; Berglund, L.A.; Bulone, V.; Zhou, Q. Nanocomposites of Bacterial Cellulose Nanofibres and Chitin Nanocrystals: Fabrication, Characterization and Bactericidal Activity. Green Chem. 2013, 15, 3404–3413. [Google Scholar] [CrossRef]

- El Miri, N.; Abdelouahdi, K.; Barakat, A.; Zahouily, M.; Fihri, A.; Solhy, A.; El Achaby, M. Bio-Nanocomposite Films Reinforced with Cellulose Nanocrystals: Rheology of Film-Forming Solutions, Transparency, Water Vapor Barrier and Tensile Properties of Films. Carbohydr. Polym. 2015, 129, 156–167. [Google Scholar] [CrossRef]

- Jose, C.; Anju, T.R.; Tharayil, A.; Sobolciak, P.; Krupa, I.; Al Maadeed, M.A.A.; Kargarzadeh, H.; Thomas, S. Date Palm Cellulose Nanocrystals (CNCs)/Polyamide Composites: Tailoring Morphological, Mechanical, and Thermal Properties. J. Compos. Sci. 2023, 7, 17. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, C.; Zhao, H.; Wang, J.; Yin, C.; Zhang, L.; Zhao, Y. Effects of Cellulose Nanocrystals and Cellulose Nanofibres on the Structure and Properties of Polyhydroxybutyrate Nanocomposites. Polymers 2019, 11, 63. [Google Scholar] [CrossRef]

- Qiu, X.; Hu, S. “Smart” Materials Based on Cellulose: A Review of the Preparations, Properties, and Applications. Materials 2013, 6, 738. [Google Scholar] [CrossRef] [PubMed]

- Eichhorn, S.J.; Etale, A.; Wang, J.; Berglund, L.A.; Li, Y.; Cai, Y.; Chen, C.; Cranston, E.D.; Johns, M.A.; Fang, Z.; et al. Current International Research into Cellulose as a Functional Nanomaterial for Advanced Applications. J. Mater. Sci. 2022, 57, 5697–5767. [Google Scholar] [CrossRef]

- Du, X.; Zhang, Z.; Liu, W.; Deng, Y. Nanocellulose-Based Conductive Materials and Their Emerging Applications in Energy Devices—A Review. Nano Energy 2017, 35, 299–320. [Google Scholar] [CrossRef]

- Liu, W.; Liu, K.; Du, H.; Zheng, T.; Zhang, N.; Xu, T.; Pang, B.; Zhang, X.; Si, C.; Zhang, K. Cellulose Nanopaper: Fabrication, Functionalization, and Applications. Nanomicro Lett. 2022, 14, 104. [Google Scholar] [CrossRef] [PubMed]

- Ismail, M.F.; Jasni, A.H.; Ooi, D.J. Fabrications of Cellulose Nanocomposite for Tailor-Made Applications. Polym. Polym. Compos. 2021, 29, 814–826. [Google Scholar] [CrossRef]

- Tavakolian, M.; Jafari, S.M.; van de Ven, T.G.M. A Review on Surface-Functionalized Cellulosic Nanostructures as Biocompatible Antibacterial Materials. Nano-Micro Lett. 2020, 12, 73. [Google Scholar] [CrossRef]

- Huo, Y.; Liu, Y.; Xia, M.; Du, H.; Lin, Z.; Li, B.; Liu, H. Nanocellulose-Based Composite Materials Used in Drug Delivery Systems. Polymers 2022, 14, 2648. [Google Scholar] [CrossRef] [PubMed]

- Seabra, A.B.; Bernardes, J.S.; Fávaro, W.J.; Paula, A.J.; Durán, N. Cellulose Nanocrystals as Carriers in Medicine and Their Toxicities: A Review. Carbohydr. Polym. 2018, 181, 514–527. [Google Scholar] [CrossRef] [PubMed]

- Căprărescu, S.; Zgârian, R.G.; Tihan, G.T.; Purcar, V.; Totu, E.E.; Modrogan, C.; Chiriac, A.L.; Nicolae, C.A. Biopolymeric Membrane Enriched with Chitosan and Silver for Metallic Ions Removal. Polymers 2020, 12, 1792. [Google Scholar] [CrossRef]

- Tihan, G.T.; Zgarian, R.G.; Berteanu, E.; Ionita, D.; Totea, G.; Iordachel, C.; Tatia, R.; Prodana, M.; Demetrescu, I. Alkaline Phosphatase Immobilization on New Chitosan Membranes with Mg2+ for Biomedical Applications. Mar. Drugs 2018, 16, 287. [Google Scholar] [CrossRef] [PubMed]

- Apetroaei, M.R.; Zgârian, R.G.; Manea, A.M.; Rau, I.; Tihan, G.T.; Schroder, V. New Source of Chitosan from Black Sea Marine Organisms Identification. Mol. Cryst. Liq. Cryst. 2016, 628, 102–109. [Google Scholar] [CrossRef]

- Apetroaei, M.; Manea, A.-M.; Tihan, G.; Zgârian, R.; Schroder, V.; Rău, I. Improved Method of Chitosan Extraction from Different Crustacean Species of Romanian Black Sea CoAST. Bull. Ser. B 2017, 79, 25–36. [Google Scholar]

- Hebeish, A.; Sharaf, S.; Farouk, A. Utilization of Chitosan Nanoparticles as a Green Finish in Multifunctionalization of Cotton Textile. Int. J. Biol. Macromol. 2013, 60, 10–17. [Google Scholar] [CrossRef]

- El-Naggar, N.E.A.; Shiha, A.M.; Mahrous, H.; Mohammed, A.B.A. Green Synthesis of Chitosan Nanoparticles, Optimization, Characterization and Antibacterial Efficacy against Multi Drug Resistant Biofilm-Forming Acinetobacter Baumannii. Sci. Rep. 2022, 12, 19869. [Google Scholar] [CrossRef] [PubMed]

- Yanat, M.; Schroën, K. Preparation Methods and Applications of Chitosan Nanoparticles; with an Outlook toward Reinforcement of Biodegradable Packaging. React. Funct. Polym. 2021, 161, 104849. [Google Scholar] [CrossRef]

- Zahedi, S.; Safaei Ghomi, J.; Shahbazi-Alavi, H. Preparation of Chitosan Nanoparticles from Shrimp Shells and Investigation of Its Catalytic Effect in Diastereoselective Synthesis of Dihydropyrroles. Ultrason. Sonochem. 2018, 40, 260–264. [Google Scholar] [CrossRef]

- Sathiyabama, M.; Parthasarathy, R. Biological Preparation of Chitosan Nanoparticles and Its in Vitro Antifungal Efficacy against Some Phytopathogenic Fungi. Carbohydr. Polym. 2016, 151, 321–325. [Google Scholar] [CrossRef]

- Attia, N.F.; Mohamed, A.; Hussein, A.; El-Demerdash, A.G.M.; Kandil, S.H. Greener Bio-Based Spherical Nanoparticles for Efficient Multilayer Textile Fabrics Nanocoating with Outstanding Fire Retardancy, Toxic Gases Suppression, Reinforcement and Antibacterial Properties. Surf. Interfaces 2023, 36, 102595. [Google Scholar] [CrossRef]

- Granados, A.; Pleixats, R.; Vallribera, A. Recent Advances on Antimicrobial and Anti-Inflammatory Cotton Fabrics Containing Nanostructures. Molecules 2021, 26, 8. [Google Scholar] [CrossRef] [PubMed]

- Navlani-García, M.; Arias, J.L.; Fernandes, M.; Padrão, J.; Ribeiro, A.I.; Fernandes, R.D.V.; Melro, L.; Nicolau, T.; Mehravani, B.; Alves, C.; et al. Polysaccharides and Metal Nanoparticles for Functional Textiles: A Review. Nanomaterials 2022, 12, 1006. [Google Scholar] [CrossRef]

- Ehtesabi, H.; Fayaz, M.; Hosseini-Doabi, F.; Rezaei, P. The Application of Green Synthesis Nanoparticles in Wound Healing: A Review. Mater. Today Sustain. 2023, 21, 100272. [Google Scholar] [CrossRef]

- Jafernik, K.; Ładniak, A.; Blicharska, E.; Czarnek, K.; Ekiert, H.; Wiącek, A.E.; Szopa, A. Chitosan-Based Nanoparticles as Effective Drug Delivery Systems—A Review. Molecules 2023, 28, 1963. [Google Scholar] [CrossRef] [PubMed]

- Rayhan, M.D.G.S.; Khan, M.K.H.; Shoily, M.T.; Rahman, H.; Rahman, M.d.R.; Akon, M.D.T.; Hoque, M.; Khan, M.D.R.; Rifat, T.R.; Tisha, F.A.; et al. Conductive Textiles for Signal Sensing and Technical Applications. Signals 2022, 4, 1–39. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, M.; Qiang, Z.; Song, J.; Wang, Y.; Fan, Y.; You, Z.; Liao, Y.; Zhu, M.; Ye, C. Multi-Functional and Highly Conductive Textiles with Ultra-High Durability through ‘Green’ Fabrication Process. Chem. Eng. J. 2021, 406, 127140. [Google Scholar] [CrossRef]

- Hebeish, A.; Shahin, A.A.; Rekaby, M.; Ragheb, A.A. New Environment-Friendly Approach for Textile Printing Using Natural Dye Loaded Chitosan Nanoparticles. Egypt. J. Chem. 2015, 58, 659–670. [Google Scholar]

- Ramlow, H.; Andrade, K.L.; Immich, A.P.S. Smart Textiles: An Overview of Recent Progress on Chromic Textiles. J. Text. Inst. 2020, 112, 152–171. [Google Scholar] [CrossRef]

- Valle, J.A.B.; de Valle, R.C.S.C.; Bierhalz, A.C.K.; Bezerra, F.M.; Hernandez, A.L.; Lis Arias, M.J. Chitosan Microcapsules: Methods of the Production and Use in the Textile Finishing. J. Appl. Polym. Sci. 2021, 138, 50482. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, Z.B.; Zhou, R.J.; Ma, S.S.; Li, Z.; Wang, M.X. Comparison of Compounded Fragrance and Chitosan Nanoparticles Loaded with Fragrance Applied in Cotton Fabrics. Text. Res. J. 2011, 81, 2056–2064. [Google Scholar] [CrossRef]

- Ilieș, A.; Hodor, N.; Pantea, E.; Ilieș, D.C.; Indrie, L.; Zdrîncă, M.; Iancu, S.; Caciora, T.; Chiriac, A.; Ghergheles, C.; et al. Antibacterial Effect of Eco-Friendly Silver Nanoparticles and Traditional Techniques on Aged Heritage Textile, Investigated by Dark-Field Microscopy. Coatings 2022, 12, 1688. [Google Scholar] [CrossRef]

- Logeswari, P.; Silambarasan, S.; Abraham, J. Ecofriendly Synthesis of Silver Nanoparticles from Commercially Available Plant Powders and Their Antibacterial Properties. Sci. Iran. 2013, 20, 1049–1054. [Google Scholar]

- Barbinta-Patrascu, M.E.; Gorshkova, Y.; Ungureanu, C.; Badea, N.; Bokuchava, G.; Lazea-Stoyanova, A.; Bacalum, M.; Zhigunov, A.; Petrovič, S. Characterization and Antitumoral Activity of Biohybrids Based on Turmeric and Silver/Silver Chloride Nanoparticles. Materials 2021, 14, 4726. [Google Scholar] [CrossRef] [PubMed]

- Fierascu, I.C.; Fierascu, I.; Baroi, A.M.; Ungureanu, C.; Ortan, A.; Avramescu, S.M.; Somoghi, R.; Fierascu, R.C.; Dinu-Parvu, C.E. Phytosynthesis of Biological Active Silver Nanoparticles Using Echinacea purpurea L. Extracts. Materials 2022, 15, 7327. [Google Scholar] [CrossRef]

- Ungureanu, C.; Fierascu, I.; Fierascu, R.C.; Costea, T.; Avramescu, S.M.; Călinescu, M.F.; Somoghi, R.; Pirvu, C. In Vitro and in Vivo Evaluation of Silver Nanoparticles Phytosynthesized Using Raphanus sativus L. Waste Extracts. Materials 2021, 14, 1845. [Google Scholar]

- Tippayawat, P.; Phromviyo, N.; Boueroy, P.; Chompoosor, A. Green Synthesis of Silver Nanoparticles in Aloe Vera Plant Extract Prepared by a Hydrothermal Method and Their Synergistic Antibacterial Activity. PeerJ 2016, 2016, e2589. [Google Scholar] [CrossRef]

- Roy, P.; Das, B.; Mohanty, A.; Mohapatra, S. Green Synthesis of Silver Nanoparticles Using Azadirachta Indica Leaf Extract and Its Antimicrobial Study. Appl. Nanosci. 2017, 7, 843–850. [Google Scholar] [CrossRef]

- Rolim, W.R.; Pelegrino, M.T.; de Araújo Lima, B.; Ferraz, L.S.; Costa, F.N.; Bernardes, J.S.; Rodigues, T.; Brocchi, M.; Seabra, A.B. Green Tea Extract Mediated Biogenic Synthesis of Silver Nanoparticles: Characterization, Cytotoxicity Evaluation and Antibacterial Activity. Appl. Surf. Sci. 2019, 463, 66–74. [Google Scholar] [CrossRef]

- Wilson, J.J.; Harimuralikrishnaa, T.; Ponmanickam, P.; Lakshmi, M.P.; Wilson, J.J.; Harimuralikrishnaa, T.; Ponmanickam, P.; Lakshmi, M.P. Bacterial Silver Nanoparticles: Method, Mechanism of Synthesis and Application in Mosquito Control. In Mosquito Research—Recent Advances in Pathogen Interactions, Immunity, and Vector Control Strategies; InTech: London, UK, 2023. [Google Scholar] [CrossRef]

- Iravani, S.; Korbekandi, H.; Mirmohammadi, S.V.; Zolfaghari, B. Synthesis of Silver Nanoparticles: Chemical, Physical and Biological Methods. Res. Pharm. Sci. 2014, 9, 385. [Google Scholar]

- Madani, M.; Hosny, S.; Alshangiti, D.M.; Nady, N.; Alkhursani, S.A.; Alkhaldi, H.; Al-Gahtany, S.A.; Ghobashy, M.M.; Gaber, G.A. Green Synthesis of Nanoparticles for Varied Applications: Green Renewable Resources and Energy-Efficient Synthetic Routes. Nanotechnol. Rev. 2022, 11, 731–759. [Google Scholar] [CrossRef]

- Suica-Bunghez, I.-R.; Elisabeta Barbinta-Patrascu, M.; Dumitrescu, O.; Ungureanu, C.; Fierascu, I.; Iordache, S.M.; Ion, R.-M. Environmental Engineering and Management. Environ. Eng. Manag. J. 2016, 15, 2085–2094. [Google Scholar]

- Barbinta-Patrascu, M.E.; Badea, N.; Ungureanu, C.; Iordache, S.M.; Constantin, M.; Purcar, V.; Rau, I.; Pirvu, C. Ecobiophysical Aspects on Nanosilver Biogenerated from Citrus Reticulata Peels, as Potential Biopesticide for Controlling Pathogens and Wetland Plants in Aquatic Media. J. Nanomater. 2017, 2017, 4214017. [Google Scholar] [CrossRef]

- Andra, S.; Balu, S.K.; Jeevanandam, J.; Muthalagu, M. Emerging Nanomaterials for Antibacterial Textile Fabrication. Naunyn-Schmiedeberg’s Arch. Pharmacol. 2021, 394, 1355–1382. [Google Scholar] [CrossRef] [PubMed]

- Barbinta-Patrascu, M.E.; Ungureanu, C.; Iordache, S.M.; Iordache, A.M.; Bunghez, I.R.; Ghiurea, M.; Badea, N.; Fierascu, R.C.; Stamatin, I. Eco-Designed Biohybrids Based on Liposomes, Mint-Nanosilver and Carbon Nanotubes for Antioxidant and Antimicrobial Coating. Mater Sci. Eng. C Mater. Biol. Appl. 2014, 39, 177–185. [Google Scholar] [CrossRef]

- Kumar, A.; Nath, K.; Parekh, Y.; Enayathullah, M.G.; Bokara, K.K.; Sinhamahapatra, A. Antimicrobial Silver Nanoparticle-Photodeposited Fabrics for SARS-CoV-2 Destruction. Colloid Interface Sci. Commun. 2021, 45, 100542. [Google Scholar] [CrossRef]

- Naysmith, A.; Mian, N.S.; Rana, S. Development of Conductive Textile Fabric Using Plackett–Burman Optimized Green Synthesized Silver Nanoparticles and in Situ Polymerized Polypyrrole. Green Chem. Lett. Rev. 2023, 16, 2158690. [Google Scholar] [CrossRef]

- Ahmad, S.; Subhani, K.; Rasheed, A.; Ashraf, M.; Afzal, A.; Ramzan, B.; Sarwar, Z. Development of Conductive Fabrics by Using Silver Nanoparticles for Electronic Applications. J. Electron. Mater. 2020, 49, 1330–1337. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.C.; Suryadevara, N.K.; Nag, A. Wearable Sensors for Healthcare: Fabrication to Application. Sensors 2022, 22, 5137. [Google Scholar] [CrossRef]

- Shaikh, T.N.; Chaudhari, S.B.; Patel, B.H.; Patel, M. Gauging Performance of Biosynthesized Silver Nanoparticles Loaded Polypropylene Nonwoven Based Textile Electrodes for 3-Lead Health Monitoring Electro Cardiogram on Analogous System. J. Ind. Text. 2021, 1 (Suppl. S3), 4350S–4371S. [Google Scholar] [CrossRef]

- Harifi, T.; Montazer, M. Application of Nanotechnology in Sports Clothing and Flooring for Enhanced Sport Activities, Performance, Efficiency and Comfort: A Review. J. Ind. Text. 2017, 46, 1147–1169. [Google Scholar] [CrossRef]

- Kaviarasu, C.; Prakash, D. Review on Phase Change Materials with Nanoparticle in Engineering Applications. J. Eng. Sci. Technol. Rev. 2016, 9, 26–386. [Google Scholar] [CrossRef]

- Barbinta-Patrascu, M.E.; Badea, N.; Ungureanu, C.; Constantin, M.; Pirvu, C.; Rau, I. Silver-Based Biohybrids “Green” Synthesized from Chelidonium majus L. Opt. Mater. 2016, 56, 94–99. [Google Scholar] [CrossRef]

- Montes-Hernandez, G.; Di Girolamo, M.; Sarret, G.; Bureau, S.; Fernandez-Martinez, A.; Lelong, C.; Eymard Vernain, E. In Situ Formation of Silver Nanoparticles (Ag-NPs) onto Textile Fibres. ACS Omega 2021, 6, 1316–1327. [Google Scholar] [CrossRef]

- Velgosova, O.; Mačák, L.; Lisnichuk, M.; Vojtko, M. Synthesis and Analysis of Polymorphic Silver Nanoparticles and Their Incorporation into the Polymer Matrix. Polymers 2022, 14, 2666. [Google Scholar] [CrossRef]

- Ray, A.; Singha, K.; Pandit, P.; Maity, S. Advanced Ultraviolet Protective Agents for Textiles and Clothing. In Advances in Functional and Protective Textiles; Elsevier: Amsterdam, The Netherlands, 2020; pp. 243–260. [Google Scholar] [CrossRef]

- Qasim, M.; Clarkson, A.N.; Hinkley, S.F.R. Green Synthesis of Carbon Nanoparticles (CNPs) from Biomass for Biomedical Applications. Int. J. Mol. Sci. 2023, 24, 1023. [Google Scholar] [CrossRef]

- Vasimalai, N.; Vilas-Boas, V.; Gallo, J.; De Fátima Cerqueira, M.; Menéndez-Miranda, M.; Manuel Costa-Fernández, J.; Diéguez, L.; Espiña, B.; Teresa Fernández-Argüelles, M. Green Synthesis of Fluorescent Carbon Dots from Spices for in Vitro Imaging and Tumour Cell Growth Inhibition. Beilstein J. Nanotechnol. 2018, 9, 530–544. [Google Scholar] [CrossRef]

- Magnabosco, G.; Pantano, M.F.; Rapino, S.; Di Giosia, M.; Valle, F.; Taxis, L.; Sparla, F.; Falini, G.; Pugno, N.M.; Calvaresi, M. A Plant Bioreactor for the Synthesis of Carbon Nanotube Bionic Nanocomposites. Front. Bioeng. Biotechnol. 2020, 8, 1287. [Google Scholar] [CrossRef]

- Ndlwana, L.; Raleie, N.; Dimpe, K.M.; Ogutu, H.F.; Oseghe, E.O.; Motsa, M.M.; Msagati, T.A.M.; Mamba, B.B. Sustainable Hydrothermal and Solvothermal Synthesis of Advanced Carbon Materials in Multidimensional Applications: A Review. Materials 2021, 14, 94. [Google Scholar] [CrossRef] [PubMed]

- Ilanchezhiyan, P.; Zakirov, A.S.; Kumar, G.M.; Yuldashev, S.U.; Cho, H.D.; Kang, T.W.; Mamadalimov, A.T. Highly Efficient CNT Functionalized Cotton Fabrics for Flexible/Wearable Heating Applications. RSC Adv. 2015, 5, 10697–10702. [Google Scholar] [CrossRef]

- Alimohammadi, F.; Parvinzadeh, M.; Shamei, A. Carbon Nanotube Embedded Textiles. US20110171413A1, 19 March 2011. Available online: https://patents.google.com/patent/US20110171413A1/en (accessed on 27 April 2023).

- Su, Y.; Zhou, H.; Guo, X.; Zheng, Y.; Yang, X.; Huang, H.; Zhou, L.-M.; Su, Z. Ultrafast-Responsive Carbon Nanotube-Grafted Fibre Textiles. Compos. Commun. 2023, 38, 101496. [Google Scholar] [CrossRef]

- Shariati, A.; Hosseini, S.M.; Chegini, Z.; Seifalian, A.; Arabestani, M.R. Graphene-Based Materials for Inhibition of Wound Infection and Accelerating Wound Healing. Biomed. Pharmacother. 2023, 158, 114184. [Google Scholar] [CrossRef]

- Ali, I.H.; Ouf, A.; Elshishiny, F.; Taskin, M.B.; Song, J.; Dong, M.; Chen, M.; Siam, R.; Mamdouh, W. Antimicrobial and Wound-Healing Activities of Graphene-Reinforced Chitosan/Gelatin Nanofibrous Nanocomposite Scaffolds. ACS Omega 2022, 7, 1838. [Google Scholar] [CrossRef] [PubMed]

- Ghulam, A.N.; Dos Santos, O.A.L.; Hazeem, L.; Backx, B.P.; Bououdina, M.; Bellucci, S. Graphene Oxide (GO) Materials—Applications and Toxicity on Living Organisms and Environment. J. Funct. Biomater. 2022, 13, 77. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Chen, S.; Liu, Y.; Zhao, B. Progress in Preparation, Characterization, Surface Functional Modification of Graphene Oxide: A Review. J. Saudi Chem. Soc. 2022, 26, 101560. [Google Scholar] [CrossRef]

- Jang, H.S.; Moon, M.S.; Kim, B.H. Electronic Textiles Fabricated with Graphene Oxide-Coated Commercial Textiles. Coatings 2021, 11, 489. [Google Scholar] [CrossRef]

- Antimicrobial, B.; Pino, P.; Bosco, F.; Mollea, C.; Onida, B. Antimicrobial Nano-Zinc Oxide Biocomposites for Wound Healing Applications: A Review. Pharmaceutics 2023, 15, 970. [Google Scholar] [CrossRef]

- Nandhini, S.N.; Sisubalan, N.; Vijayan, A.; Karthikeyan, C.; Gnanaraj, M.; Gideon, D.A.M.; Jebastin, T.; Varaprasad, K.; Sadiku, R. Recent Advances in Green Synthesized Nanoparticles for Bactericidal and Wound Healing Applications. Heliyon 2023, 9, e13128. [Google Scholar] [CrossRef] [PubMed]

- Peralta-Videa, J.R.; Huang, Y.; Parsons, J.G.; Zhao, L.; Lopez-Moreno, L.; Hernandez-Viezcas, J.A.; Gardea-Torresdey, J.L. Plant-Based Green Synthesis of Metallic Nanoparticles: Scientific Curiosity or a Realistic Alternative to Chemical Synthesis? Nanotechnol. Environ. Eng. 2016, 1, 1–29. [Google Scholar] [CrossRef]

- Popescu, S.; Zarif, M.E.; Dumitriu, C.; Ungureanu, C.; Pirvu, C. Silk Fibroin-Based Hybrid Nanostructured Coatings for Titanium Implantable Surfaces Modification. Coatings 2020, 10, 518. [Google Scholar] [CrossRef]

- Howard, F.H.N.; Gao, Z.; Bin Mansor, H.; Yang, Z.; Muthana, M.; Howard, F.H.N.; Gao, Z.; Mansor, H.B.; Yang, Z.; Muthana, M. Silk Fibroin Nanoparticles: A Biocompatible Multi-Functional Polymer for Drug Delivery; InTech: London, UK, 2023. [Google Scholar] [CrossRef]

- Pham, D.T.; Tiyaboonchai, W. Fibroin Nanoparticles: A Promising Drug Delivery System. Drug Deliv. 2020, 27, 431. [Google Scholar] [CrossRef] [PubMed]

- Harsanto, B.; Primiana, I.; Sarasi, V.; Satyakti, Y. Sustainability Innovation in the Textile Industry: A Systematic Review. Sustainability 2023, 15, 1549. [Google Scholar] [CrossRef]

- Bungau, C.C.; Bungau, T.; Prada, I.F.; Prada, M.F. Green Buildings as a Necessity for Sustainable Environment Development: Dilemmas and Challenges. Sustainability 2022, 14, 13121. [Google Scholar] [CrossRef]

- Kapoor, R.T.; Rafatullah, M.; Qamar, M.; Qutob, M.; Alosaimi, A.M.; Alorfi, H.S.; Hussein, M.A. Review on Recent Developments in Bioinspired-Materials for Sustainable Energy and Environmental Applications. Sustainability 2022, 14, 16931. [Google Scholar] [CrossRef]

- Hassan, M.; Abou-Zeid, R.; Hassan, E.; Berglund, L.; Aitomäki, Y.; Oksman, K. Membranes Based on Cellulose Nanofibres and Activated Carbon for Removal of Escherichia coli Bacteria from Water. Polymers 2017, 9, 335. [Google Scholar] [CrossRef] [PubMed]

- Żywicka, A.; Ciecholewska-Juśko, D.; Szymańska, M.; Drozd, R.; Sobolewski, P.; Junka, A.; Gorgieva, S.; El Fray, M.; Fijałkowski, K. Argon Plasma-Modified Bacterial Cellulose Filters for Protection against Respiratory Pathogens. Carbohydr. Polym. 2023, 302, 120322. [Google Scholar] [CrossRef] [PubMed]

- Lippi, M.; Riva, L.; Caruso, M.; Punta, C. Cellulose for the Production of Air-Filtering Systems: A Critical Review. Materials 2022, 15, 976. [Google Scholar] [CrossRef]

- Stanislas, T.T.; Bilba, K.; de Oliveira Santos, R.P.; Onésippe-Potiron, C.; Savastano Junior, H.; Arsène, M.A. Nanocellulose-Based Membrane as a Potential Material for High Performance Biodegradable Aerosol Respirators for SARS-CoV-2 Prevention: A Review. Cellulose 2022, 29, 8001–8024. [Google Scholar] [CrossRef]

- Jhinjer, H.S.; Singh, A.; Bhattacharya, S.; Jassal, M.; Agrawal, A.K. Metal-Organic Frameworks Functionalized Smart Textiles for Adsorptive Removal of Hazardous Aromatic Pollutants from Ambient Air. J. Hazard. Mater. 2021, 411, 125056. [Google Scholar] [CrossRef]

- Marino, P.; Donnarumma, P.R.; Bicalho, H.A.; Quezada-Novoa, V.; Titi, H.M.; Howarth, A.J. A Step toward Change: A Green Alternative for the Synthesis of Metal-Organic Frameworks. ACS Sustain. Chem. Eng. 2021, 9, 16356–16362. [Google Scholar] [CrossRef]

- Jaffar, S.S.; Saallah, S.; Misson, M.; Siddiquee, S.; Roslan, J.; Saalah, S.; Lenggoro, W. Recent Development and Environmental Applications of Nanocellulose-Based Membranes. Membranes 2022, 12, 287. [Google Scholar] [CrossRef]

- Kotia, A.; Yadav, A.; Raj, T.R.; Keischgens, M.G.; Rathore, H.; Sarris, I.E. Carbon Nanoparticles as Sources for a Cost-Effective Water Purification Method: A Comprehensive Review. Fluids 2020, 5, 230. [Google Scholar] [CrossRef]

- Memisoglu, G.; Murugesan, R.C.; Zubia, J.; Rozhin, A.G. Graphene Nanocomposite Membranes: Fabrication and Water Treatment Applications. Membranes 2023, 13, 145. [Google Scholar] [CrossRef]

- Arora, B.; Attri, P. Carbon Nanotubes (CNTs): A Potential Nanomaterial for Water Purification. J. Compos. Sci. 2020, 4, 135. [Google Scholar] [CrossRef]

- Xie, A.; Cui, J.; Yang, J.; Chen, Y.; Lang, J.; Li, C.; Yan, Y.; Dai, J. Graphene Oxide/Fe(III)-Based Metal-Organic Framework Membrane for Enhanced Water Purification Based on Synergistic Separation and Photo-Fenton Processes. Appl. Catal. B 2020, 264, 118548. [Google Scholar] [CrossRef]

- Qi, Q.; Wang, Y.; Wang, W.; Ding, X.; Yu, D. High-Efficiency Solar Evaporator Prepared by One-Step Carbon Nanotubes Loading on Cotton Fabric toward Water Purification. Sci. Total Environ. 2020, 698, 134136. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Qi, Q.; Fan, J.; Wang, W.; Yu, D. Simple and Robust MXene/Carbon Nanotubes/Cotton Fabrics for Textile Wastewater Purification via Solar-Driven Interfacial Water Evaporation. Sep. Purif. Technol. 2021, 254, 117615. [Google Scholar] [CrossRef]

- Dolez, P.I. Energy Harvesting Materials and Structures for Smart Textile Applications: Recent Progress and Path Forward. Sensors 2021, 21, 6297. [Google Scholar] [CrossRef]

- Artero, V. Bioinspired Catalytic Materials for Energy-Relevant Conversions. Nat. Energy 2017, 2, 1–6. [Google Scholar] [CrossRef]

- Ma, W.; Lv, M.; Cao, F.; Fang, Z.; Feng, Y.; Zhang, G.; Yang, Y.; Liu, H. Synthesis and Characterization of ZnO-GO Composites with Their Piezoelectric Catalytic and Antibacterial Properties. J. Environ. Chem. Eng. 2022, 10, 107840. [Google Scholar] [CrossRef]

- Jha, A.K.; Prasad, K. Synthesis of BaTiO3 Nanoparticles: A New Sustainable Green Approach. Integr. Ferroelectr. 2010, 117, 49–54. [Google Scholar] [CrossRef]

- Sharma, M.; Sondhi, H.; Krishna, R.; Srivastava, S.K.; Rajput, P.; Nigam, S.; Joshi, M. Assessment of GO/ZnO Nanocomposite for Solar-Assisted Photocatalytic Degradation of Industrial Dye and Textile Effluent. Environ. Sci. Pollut. Res. 2020, 27, 32076–32087. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Chang, C.; Anbalagan, A.K.; Lee, C.H.; Tai, N.H. Reduced Graphene Oxide/Zinc Oxide Coated Wearable Electrically Conductive Cotton Textile for High Microwave Absorption. Compos. Sci. Technol. 2020, 188, 107994. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, X.; Wang, J.; Zhao, Y. Recent Progress of Energy-Storage-Device-Integrated Sensing Systems. Nanomaterials 2023, 13, 645. [Google Scholar] [CrossRef]

- Dou, L.; Zeng, Z.; Cheng, D.; Li, S.; Ke, W.; Cai, G. Weft-Knitted Spacer Fabric for Highly Stretchable–Compressible Strain Sensor, Supercapacitor, and Joule Heater. Nanomaterials 2022, 12, 3684. [Google Scholar] [CrossRef]

- Li, Z.; Ma, Y.; Wang, L.; Du, X.; Zhu, S.; Zhang, X.; Qu, L.; Tian, M. Multidimensional Hierarchical Fabric-Based Supercapacitor with Bionic Fibre Microarrays for Smart Wearable Electronic Textiles. ACS Appl. Mater. Interfaces 2019, 11, 46278–46285. [Google Scholar] [CrossRef]

- Dang, X.; Yi, H.; Ham, M.H.; Qi, J.; Yun, D.S.; Ladewski, R.; Strano, M.S.; Hammond, P.T.; Belcher, A.M. Virus-Templated Self-Assembled Single-Walled Carbon Nanotubes for Highly Efficient Electron Collection in Photovoltaic Devices. Nat. Nanotechnol. 2011, 6, 377–384. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Kurmus, H.; Milas, J.; Arulrajah, A.; Horpibulsuk, S.; Kadir, A.A. Nanoparticles in Construction Materials and Other Applications, and Implications of Nanoparticle Use. Materials 2019, 12, 3052. [Google Scholar] [CrossRef]

- Aguda, O.N.; Lateef, A. Novel Biosynthesis of Silver Nanoparticles through Valorization of Parkia Biglobosa Fermented-Seed Wastewater: Antimicrobial Properties and Nanotextile Application. Environ. Technol. Innov. 2021, 24, 102077. [Google Scholar] [CrossRef]

- Tuwalska, A.; Grabska-Zielińska, S.; Sionkowska, A. Chitosan/Silk Fibroin Materials for Biomedical Applications—A Review. Polymers 2022, 14, 1343. [Google Scholar] [CrossRef]

- Bagheri, M.; Validi, M.; Gholipour, A.; Makvandi, P.; Sharifi, E. Chitosan Nanofibre Biocomposites for Potential Wound Healing Applications: Antioxidant Activity with Synergic Antibacterial Effect. Bioeng. Transl. Med. 2022, 7, e10254. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.X.; Mo, X.M.; Zhang, K.H.; Fan, L.P.; Yin, A.L.; He, C.L.; Wang, H.S. Fabrication of Chitosan/Silk Fibroin Composite Nanofibres for Wound-Dressing Applications. Int. J. Mol. Sci. 2010, 11, 3529–3539. [Google Scholar] [CrossRef] [PubMed]

- Ruckdashel, R.R.; Venkataraman, D.; Park, J.H. Smart Textiles: A Toolkit to Fashion the Future. J. Appl. Phys. 2021, 129, 130903. [Google Scholar] [CrossRef]

- Sánchez-Machado, D.I.; López-Cervantes, J.; Martínez-Ibarra, D.M.; Escárcega-Galaz, A.A.; Vega-Cázarez, C.A. The Use of Chitosan as a Skin-Regeneration Agent in Burns Injuries: A Review. E-Polym. 2022, 22, 75–86. [Google Scholar] [CrossRef]

- Alharbi, N.D.; Amer, H.H.; El-Zaher, N.A.; Guirguis, O.W. Development and Characterization of Cotton Fabrics by Dipping in Solutions of Chitosan and ZnO-Nanoparticles as Promising Environmentally Friendly Reinforcements for Polymer Composites. Polym. Polym. Compos. 2022, 30, 09673911221148826. [Google Scholar] [CrossRef]

- Patil, P.P.; Reagan, M.R.; Bohara, R.A. Silk Fibroin and Silk-Based Biomaterial Derivatives for Ideal Wound Dressings. Int. J. Biol. Macromol. 2020, 164, 4613–4627. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Ouyang, Q.; Li, Y.; Zhang, P.; Jin, W.; Qu, S.; Yang, F.; He, Z.; Qin, M. Nanomaterials for Delivering Antibiotics in the Therapy of Pneumonia. Int. J. Mol. Sci. 2022, 23, 15738. [Google Scholar] [CrossRef] [PubMed]

- Loo, Y.Y.; Rukayadi, Y.; Nor-Khaizura, M.A.R.; Kuan, C.H.; Chieng, B.W.; Nishibuchi, M.; Radu, S. In Vitro Antimicrobial Activity of Green Synthesized Silver Nanoparticles against Selected Gram-Negative Foodborne Pathogens. Front. Microbiol. 2018, 9, 1555. [Google Scholar] [CrossRef] [PubMed]

- Chota, A.; George, B.P.; Abrahamse, H. Recent Advances in Green Metallic Nanoparticles for Enhanced Drug Delivery in Photodynamic Therapy: A Therapeutic Approach. Int. J. Mol. Sci. 2023, 24, 4808. [Google Scholar] [CrossRef]

- Jain, A.; Kongkham, B.; Puttaswamy, H.; Butola, B.S.; Malik, H.K.; Malik, A. Development of Wash-Durable Antimicrobial Cotton Fabrics by In Situ Green Synthesis of Silver Nanoparticles and Investigation of Their Antimicrobial Efficacy against Drug-Resistant Bacteria. Antibiotics 2022, 11, 864. [Google Scholar] [CrossRef]

- Asmat-Campos, D.; Delfín-Narciso, D.; Juárez-Cortijo, L. Textiles Functionalized with ZnO Nanoparticles Obtained by Chemical and Green Synthesis Protocols: Evaluation of the Type of Textile and Resistance to UV Radiation. Fibres 2021, 9, 10. [Google Scholar] [CrossRef]

- Karthik, S.; Siva, P.; Balu, K.S.; Suriyaprabha, R.; Rajendran, V.; Maaza, M. Acalypha Indica–Mediated Green Synthesis of ZnO Nanostructures under Differential Thermal Treatment: Effect on Textile Coating, Hydrophobicity, UV Resistance, and Antibacterial Activity. Adv. Powder Technol. 2017, 28, 3184–3194. [Google Scholar] [CrossRef]

- Hassan, S.S.M.; Azab, W.I.M.E.; Ali, H.R.; Mansour, M. Green Synthesis and Characterization of ZnO Nanoparticles for Photocatalytic Degradation of Anthracene. Adv. Nat. Sci. Nanosci. Nanotechnol. 2015, 6, 045012. [Google Scholar] [CrossRef]

- Crisan, M.C.; Teodora, M.; Lucian, M. Copper Nanoparticles: Synthesis and Characterization, Physiology, Toxicity and Antimicrobial Applications. Appl. Sci. 2021, 12, 141. [Google Scholar] [CrossRef]

- Shamena Selas, S.B.; Vijay, J.; Arun Karthick, S.; Saraswathi, S. Preparation and Analysis of Nano Materials for Smart Textile in Continuous Monitoring of Physiological Parameters. In Proceedings of the 2020 5th International Conference on Devices, Circuits and Systems (ICDCS), Coimbatore, India, 5–6 March 2020; pp. 307–310. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. Environmentally Friendly Synthesis of Poly(3,4-Ethylenedioxythiophene): Poly(Styrene Sulfonate)/SnO2 Nanocomposites. Polymers 2021, 13, 2445. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, S.; Bhowal, A.C.; Kandimalla, R.; Kundu, S. Structural and Electrical Behaviours of PEDOT:PSS Thin Films in Presence of Negatively Charged Gold and Silver Nanoparticles: A Green Synthesis Approach. Synth. Met. 2021, 279, 116848. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, X.; Fu, J.; Liu, R.; He, H.; Ma, J.; Yu, M.; Ramakrishna, S.; Long, Y. Electrospinning of Ultrafine Conducting Polymer Composite Nanofibres with Diameter Less than 70 Nm as High Sensitive Gas Sensor. Materials 2018, 11, 1744. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Li, J.; Reddy, V.S.; Ji, D.; Ramakrishna, S.; Xu, L. Flexible Textile-Based Sweat Sensors for Wearable Applications. Biosensors 2023, 13, 127. [Google Scholar] [CrossRef]

- Abdelhamid, H.N.; Mathew, A.P. Cellulose–metal organic frameworks (CelloMOFs) hybrid materials and their multifaceted Applications: A review. Coord. Chem. Rev. 2022, 451, 214263. [Google Scholar] [CrossRef]

- De Fazio, R.; Proto, R.; Del-Valle-Soto, C.; Velázquez, R.; Visconti, P. New Wearable Technologies and Devices to Efficiently Scavenge Energy from the Human Body: State of the Art and Future Trends. Energies 2022, 15, 6639. [Google Scholar] [CrossRef]

- Deng, Z.; Guo, L.; Chen, X.; Wu, W. Smart Wearable Systems for Health Monitoring. Sensors 2023, 23, 2479. [Google Scholar] [CrossRef]

- Ivanoska-Dacikj, A.; Stachewicz, U. Smart textiles and wearable technologies-opportunities offered in the fight against pandemics in relation to current COVID-19 state. Rev. Adv. Mater. Sci. 2020, 59, 487–505. [Google Scholar] [CrossRef]

- Gao, J.; Karp, J.M.; Langer, R.; Joshi, N. The Future of Drug Delivery. Chem. Mater. 2023, 35, 359–363. [Google Scholar] [CrossRef]

- Yu, R.; Zhang, H.; Guo, B. Conductive Biomaterials as Bioactive Wound Dressing for Wound Healing and Skin Tissue Engineering. Nano-Micro Lett. 2021, 14, 1–46. [Google Scholar] [CrossRef] [PubMed]

| Textile | Nanomaterials | Synthesis Method | Integration Method | Application | Ref. |

|---|---|---|---|---|---|

| cotton | silver nanoparticles | green synthesis using seaweed extract (Padina gymnospora) | coating | Antibacterial and water-repellent textiles for healthcare and outdoor use | [38] |

| jute | silver nanoparticles | green synthesis using plant extract | ultraviolet (UV) photoreduction and by using polyethylene glycol as a reducing agent and stabilizer | Antibacterial and durable textiles for agricultural and industrial use | [39] |

| cotton | zinc oxide nanoparticles | green synthesis using plant extracts such as Anisochilus carnosus and Plectranthus amboinicus | sol–gel method with a green solvent | UV-resistant and antibacterial textiles for outdoor and healthcare use | [40] |

| cotton | copper oxide nanoparticles | green synthesis using green plant Carica papaya leaves | dispersion | A medical textile to avoid cross-infection within a clinical environment | [41] |

| antibacterial fabric | zinc oxide nanoparticles | green synthesis using Moringa oleifera extract | melt spinning, dry-jet wet spinning | Antibacterial and UV-protective textiles for healthcare and outdoor use | [42] |

| synthetic fibres | gold nanoparticles | green synthesis using Lantana camara linn leaf extract | dip coating, electroless, screen printing, dropwise, immersion, sonication, and electrospinning | Antimicrobial and conductive textiles for healthcare and wearable electronics | [43] |

| gelatine-bioactive glass | cellulose nanocrystals | green synthesis using Komagataeibacter xylinus bacterium | freeze-drying technique | Fabrication of synthetic bone tissue scaffolds with high compressive strength and wettability | [44] |

| poly(l-lactic acid) | chitosan nanoparticles | green synthesis using a natural biopolymer such as chitosan | casting | Antibacterial and durable textiles | [45] |

| cotton | TiO2 nanoparticles | green synthesis using Azadirachta indica leaf extract | immobilisation | Decontamination, self-cleaning of intense stains, and bacterial inhibition without TiO2 UV-activation | [46] |

| Textile Substrates | Nanomaterials | Interaction | Integration Method | Ref. |

|---|---|---|---|---|

| cotton | (CMCh) and Ag/TiO2 composites | Covalent, esterification between the hydroxyl group of cotton and carboxyl group of CMCh | pad-dry-cure | [91] |

| viscose | 2,2,6,6-tetramethylpiperidine-1-oxy radical (TEMPO)-oxidized cellulose nanofibrils (TOCN) | Covalent, functional groups (COOH and CHO) suitable for irreversible binding of chitosan nanoparticles | TEMPO-mediated oxidation of native cellulose | [90] |

| cotton | AgNPs and PdNPs | Semi-covalent | impregnation with thiol-modified cellulose fabric | [92] |

| cotton | CeO2 nanoparticles | Non-covalent | immobilisation of CeO2 nanoparticles on a chitosan-treated linen fabric using in situ synthesis | [93] |

| non-Woven Fabrics | Nanocomposite Nylon 6/ZnO | Non-covalent | ultrasound-assisted Extrusion | [94] |

| wool-polyamide/polyester textiles | TiO2 nanoparticles | Non-covalent | wet chemical technique | [95] |

| polyester fabrics | Titania nanowires | Non-covalent | Sol–gel | [96] |

| cotton fabric | PANI/TiO2 | Non-covalent | polymerization | [97] |

| cotton fabrics | Platinum (IV) chloride modified TiO2 and N-TiO2 nanosols | Non-covalent | dip-coating process | [98] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popescu, M.; Ungureanu, C. Green Nanomaterials for Smart Textiles Dedicated to Environmental and Biomedical Applications. Materials 2023, 16, 4075. https://doi.org/10.3390/ma16114075

Popescu M, Ungureanu C. Green Nanomaterials for Smart Textiles Dedicated to Environmental and Biomedical Applications. Materials. 2023; 16(11):4075. https://doi.org/10.3390/ma16114075

Chicago/Turabian StylePopescu, Melania, and Camelia Ungureanu. 2023. "Green Nanomaterials for Smart Textiles Dedicated to Environmental and Biomedical Applications" Materials 16, no. 11: 4075. https://doi.org/10.3390/ma16114075