Mechanical and Tribological Characterization of WC-Co and WC-AISI 304 Composites by a Newly Developed Equipment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimens

2.2. Tribological Testing

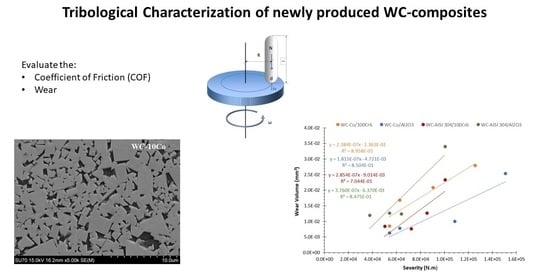

3. Results and Discussion

3.1. Friction Behavior

3.2. Wear Behaviour

4. Conclusions

- For all tests, a rapid increase in the coefficient of friction was observed in the first sliding meters, corresponding to the running-in regime. However, the friction curves corresponding to the WC-Co composite tend to have a more stable behavior compared to the curves corresponding to the WC-AISI 304 composite.

- The system composed of the WC-AISI 304/100Cr6 tribological pair, corresponds to the lowest mean coefficient of friction, while the system consisting of the tribological pair WC-Co/100Cr6, corresponds the highest mean coefficient of friction. However the values did not vary much for the different systems.

- The wear volume tends to increase with increasing severity. The lowest wear coefficient corresponds to the WC-CO/Al2O3 tribological pair for which it was observed the formation of a tribofilms/oxide layer while the highest wear coefficient occurs for the system corresponding to the WC-AISI 304/Al2O3 tribological pair.

- In the present research work, it is possible to verify that, the wear rate coefficient increases with a decrease in fracture toughness values, more than with an increase in hardness (since the hardness assumes very similar values).

- As a general conclusion and attending to the wear rates behaviour, even if the WC-AISI 304 composite behaves slightly worse, is undoubtedly an alternative since the wear rates are of the same order of the reference composite, WC-Co.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Ortner, H.M.; Ettmayer, P.; Kolaska, H. The history of the technological progress of hardmetals. Int. J. Refract. Met. Hard Mater. 2013, 44, 148–159. [Google Scholar] [CrossRef]

- Fernandes, C.M.S.; Rocha, A.F.; Cardoso, J.P.V.; Bastos, A.; Soares, E.; Sacramento, J.; Ferreira, M.; Senos, A. WC-stainless steel hardmetals. Int. J. Refract. Met. Hard Mater. 2018, 72, 21–26. [Google Scholar] [CrossRef]

- Schmidt&Magnusson/Larsherberts Offset. Understanding Cemented Carbides; Sandvik Hard Materials: Stockholm, Sweden, 2008; p. 20. [Google Scholar]

- Fernandes, C.; Vilhena, L.; Pinho, C.; Oliveira, F.; Soares, E.; Sacramento, J.; Senos, A. Mechanical characterization of WC–10 wt% AISI 304 cemented carbides. Mater. Sci. Eng. A 2014, 618, 629–636. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Materials science of cemented carbides—An overview. Mater. Des. 2001, 22, 483–489. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Fernandes, C.M.; Soares, E.; Sacramento, J.; Senos, A.M.R.; Ramalho, A. Abrasive wear resistance of WC–Co and WC–AISI 304 composites by ball-cratering method. Wear 2016, 346–347, 99–107. [Google Scholar] [CrossRef]

- Lassner, E.; Schubert, W.-D. Tungsten in Hardmetals. In Tungsten; Springer: Boston, MA, USA, 1999; pp. 321–363. [Google Scholar] [CrossRef]

- Prakash, L. Fundamentals and General Applications of Hardmetals. In Comprehensive Hard Materials; Elsevier: Oxford, UK, 2014; Volume 1, pp. 29–90. ISBN 9780080965284. [Google Scholar]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamental of Modern Manufacturing Material, Processes, and System, 5th ed.; John Wiley & Son, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- IARC. List of Classificaton—IARC Monographs on the Identification of Carcinogenic Hazards to Humans. Available online: https://monographs.iarc.fr/agents-classified-by-the-iarc/ (accessed on 16 September 2020).

- ECHA. Substance Information. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.028.325 (accessed on 16 September 2020).

- Global Energy Metals Corp. Cobalt. Available online: https://www.globalenergymetals.com/cobalt/cobalt-demand/ (accessed on 20 December 2021).

- Tracey, V. Nickel in hardmetals. Int. J. Refract. Met. Hard Mater. 1992, 11, 137–149. [Google Scholar] [CrossRef]

- Uhrenius, B. Phase Diagrams as a Tool for Production and Development of Cemented Carbides and Steels. Powder Met. 1992, 35, 203–210. [Google Scholar] [CrossRef]

- Shon, I.J.; Jeong, I.K.; Ko, I.Y.; Doh, J.M.; Woo, K.D. Sintering behavior and mechanical properties of WC-10Co, WC-10Ni and WC-10Fe hard materials produced by high-frequency induction heated sintering. Ceram. Int. 2009, 35, 339–344. [Google Scholar] [CrossRef]

- Hanyaloglu, C.; Aksakal, B.; Bolton, J. Production and indentation analysis of WC/Fe–Mn as an alternative to cobalt-bonded hardmetals. Mater. Charact. 2001, 47, 315–322. [Google Scholar] [CrossRef]

- Pereira, P.; Vilhena, L.; Sacramento, J.; Senos, A.; Malheiros, L.; Ramalho, A. Abrasive wear resistance of WC-based composites, produced with Co or Ni-rich binders. Wear 2021, 482–483, 203924. [Google Scholar] [CrossRef]

- Roulon, Z.; Lay, S.; Missiaen, J. Interface characteristics in cemented carbides with alternative binders. Int. J. Refract. Met. Hard Mater. 2020, 92, 105306. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Gong, F.; Ni, X.; Li, Z. Development and Application of WC-Based Alloys Bonded with Alternative Binder Phase. Crit. Rev. Solid State Mater. Sci. 2019, 44, 211–238. [Google Scholar] [CrossRef]

- Ojo-Kupoluyi, O.J.; Tahir, S.M.; Baharudin, B.T.H.T.; Hanim, M.A.A.; Anuar, M.S. Mechanical properties of WC-based hardmetals bonded with iron alloys—A review. Mater. Sci. Technol. 2017, 33, 507–517. [Google Scholar] [CrossRef]

- Pittari, J.J.; Murdoch, H.; Kilczewski, S.M.; Hornbuckle, B.C.; Swab, J.J.; Darling, K.A.; Wright, J.C. Sintering of tungsten carbide cermets with an iron-based ternary alloy binder: Processing and thermodynamic considerations. Int. J. Refract. Met. Hard Mater. 2018, 76, 1–11. [Google Scholar] [CrossRef]

- Tarraste, M.; Kübarsepp, J.; Juhani, K.; Mere, A.; Viljus, M. Effect of Carbon Stabilizing Elements on WC Cemented Carbides with Chromium Steel Binder. Mater. Sci. 2019, 25, 202–206. [Google Scholar] [CrossRef] [Green Version]

- Chychko, A.; García, J.; Ciprés, V.C.; Holmström, E.; Blomqvist, A. HV-KIC property charts of cemented carbides: A comprehensive data collection. Int. J. Refract. Met. Hard Mater. 2022, 103, 105763. [Google Scholar] [CrossRef]

- Wentzel, E.; Allen, C. The erosion-corrosion resistance of tungsten-carbide hard metals. Int. J. Refract. Met. Hard Mater. 1997, 15, 81–87. [Google Scholar] [CrossRef]

- Hochstrasser, S.; Latkoczy, C.; Virtanen, S.; Uggowitzer, P.; Schmutz, P. Analytical Characterization of the Corrosion Mechanisms of WC-Co by Electrochemical Methods and Inductively-Coupled Plasma Mass Spectroscopy. Corros. Sci. 2007, 49, 2002–2020. [Google Scholar] [CrossRef]

- Oliveira, A.; Bastos, A.; Fernandes, C.M.S.; Pinho, C.; Senos, A.; Soares, E.; Sacramento, J.; Zheludkevich, M.; Ferreira, M. Corrosion behaviour of WC-10% AISI 304 cemented carbides. Corros. Sci. 2015, 100, 322–331. [Google Scholar] [CrossRef]

- Chang, S.H.; Chen, S.L. Characterization and properties of sintered WC-Co and WC-Ni-Fe hard metal alloys. J. Alloys Compd. 2014, 585, 407–413. [Google Scholar] [CrossRef]

- Marques, B.; Fernandes, C.M.S.; Senos, A. Sintering, microstructure and properties of WC-AISI304 powder composites. J. Alloys Compd. 2013, 562, 164–170. [Google Scholar] [CrossRef]

- Rgp Balls. Sfere in Acciaio al Cromo AISI 52100 100Cr6. Available online: https://www.rgpballs.com/it/sfere-in-acciaio-al-cromo-aisi-52100-100cr6/ (accessed on 5 October 2020).

- CeramTec. Oxide Ceramics—Aluminum Oxide. Available online: https://www.ceramtec.com/ceramic-materials/aluminum-oxide/# (accessed on 5 October 2020).

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation fracture of WC-Co cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

- Salguero, J.; Vazquez-Martinez, J.M.; Del Sol, I.; Batista, M. Application of Pin-On-Disc Techniques for the Study of Tribological Interferences in the Dry Machining of A92024-T3 (Al–Cu) Alloys. Materials 2018, 11, 1236. [Google Scholar] [CrossRef] [Green Version]

- Okamoto, S.; Nakazono, Y.; Otsuka, K.; Shimoitani, Y.; Takada, J. Mechanical properties of WC/Co cemented carbide with larger WC grain size. Mater. Charact. 2005, 55, 281–287. [Google Scholar] [CrossRef]

- Djematene, F.; Djerdjare, B.; Boukantar, A.; Rezzoug, A.; Abdi, S.; Daoud, I. A comparative study of the dry sliding wear of WC-10wt.%(Co+Fe+Ni) cemented carbides pressureless sintered with different Fe/Co ratios. J. Asian Ceram. Soc. 2020, 8, 1043–1050. [Google Scholar] [CrossRef]

| WC (wt.%) | Co (wt.%) | AISI 304 (wt.%) | |

|---|---|---|---|

| WC-Co | 90 | 10 | - |

| WC-AISI 304 | 90 | - | 10 |

| Systems | Disc | Counterbody |

|---|---|---|

| WC-Co/100Cr6 | WC-Co | 100Cr6 |

| WC-Co/Al2O3 | WC-Co | Al2O3 |

| WC-AISI 304/100Cr6 | WC-AISI 304 | 100Cr6 |

| WC-AISI 304/Al2O3 | WC-AISI 304 | Al2O3 |

| Specimens | Hardness, HV30 (Kgf/mm2) | Fracture Toughness, KIC (MPa·m1/2) | Grain Size, G (μm) | |||

|---|---|---|---|---|---|---|

| Average | STDEV | Average | STDEV | Average | STDEV | |

| WC-Co | 1491 | 36 | 9.7 | 1.1 | 2.7 | 0.4 |

| WC-AISI 304 | 1542 | 18 | 7.8 | 0.3 | 2.1 | 0.2 |

| Test Number | N° Rotations | Time (s) | Sliding Distance (m) | Severity (N.m) |

|---|---|---|---|---|

| E1 | 36,000 | 10,800 | 2714 | 54,287 |

| E2 | 50,000 | 12,500 | 3142 | 62,832 |

| E3 | 72,000 | 18,000 | 4524 | 90,478 |

| E4 | 100,000 | 25,000 | 6283 | 125,664 |

| Test Number | µmed | Δµ |

|---|---|---|

| E1 | 0.344 | 0.012 |

| E2 | 0.414 | 0.021 |

| E3 | 0.371 | 0.013 |

| E4 | 0.341 | 0.027 |

| System | µmed | Δµ |

|---|---|---|

| WC-Co/100Cr6 | 0.368 | 0.029 |

| WC-Co/Al2O3 | 0.353 | 0.046 |

| WC-AISI 304/100Cr6 | 0.308 | 0.042 |

| WC-AISI 304/Al2O3 | 0.357 | 0.038 |

| System | Kcb (mm3/N·m) | Increase |

|---|---|---|

| WC-Co/100Cr6 | 1.174 × 10−8 | 1.2 X |

| WC-Co/Al2O3 | 9.531 × 10−9 | - |

| WC-AISI 304/100Cr6 | 9.380 × 10−7 | 98 X |

| WC-AISI 304/Al2O3 | 7.687 × 10−8 | 8 X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilhena, L.; Domingues, B.; Fernandes, C.; Senos, A.; Ramalho, A. Mechanical and Tribological Characterization of WC-Co and WC-AISI 304 Composites by a Newly Developed Equipment. Materials 2022, 15, 1187. https://doi.org/10.3390/ma15031187

Vilhena L, Domingues B, Fernandes C, Senos A, Ramalho A. Mechanical and Tribological Characterization of WC-Co and WC-AISI 304 Composites by a Newly Developed Equipment. Materials. 2022; 15(3):1187. https://doi.org/10.3390/ma15031187

Chicago/Turabian StyleVilhena, Luís, Bruno Domingues, Cristina Fernandes, Ana Senos, and Amílcar Ramalho. 2022. "Mechanical and Tribological Characterization of WC-Co and WC-AISI 304 Composites by a Newly Developed Equipment" Materials 15, no. 3: 1187. https://doi.org/10.3390/ma15031187