Effects of Solution Treatment on Damping Capacities of Binary Mg-X (X = Ga and Er) Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructures of Binary Mg-X (X = Ga and Er) Alloys

3.2. Effects of Solution Treatment on Damping Capacity

3.3. Effects of Solute Atoms on Damping Capacity

3.4. Damping Mechanism of Binary Solid Solution Mg-X (X = Ga and Er) Alloys

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trang, T.T.T.; Zhang, J.H.; Kim, J.H.; Zargaran, A.; Hwang, J.H.; Suh, B.C.; Kim, N.J. Designing a magnesium alloy with high strength and high formability. Nat. Commun. 2018, 9, 2522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cai, Q.; Zhu, S. The nexus between vibration-based energy harvesting and structural vibration control: A comprehensive review. Renew. Sust. Energ. Rev. 2022, 155, 111920. [Google Scholar] [CrossRef]

- Chen, W.; Yu, W.; Ma, C.; Ma, G.; Zhang, L.; Wang, H. A review of novel ternary nano-layered MAX phases reinforced AZ91D magnesium composite. J. Magnes. Alloy. 2022, 10, 1457–1475. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Cheng, H.; Nazeer, F.; Khan, M.A. Microstructure evolution of Mg-Zn-Zr magnesium alloy against soft steel core projectile. J. Mater. Sci. Technol. 2021, 79, 46–61. [Google Scholar] [CrossRef]

- Wei, K.; Hu, R.; Yin, D.; Xiao, L.; Pang, S.; Cao, Y.; Zhou, H.; Zhao, Y.; Zhu, Y. Grain size effect on tensile properties and slip systems of pure magnesium. Acta Mater. 2021, 206, 116604. [Google Scholar] [CrossRef]

- Ren, R.; Fan, J.; Wang, B.; Zhang, Q.; Li, W.; Dong, H. Hall-Petch relationship and deformation mechanism of pure Mg at room temperature. J. Alloy. Compd. 2022, 920, 165924. [Google Scholar] [CrossRef]

- Nazeer, F.; Long, J.; Yang, Z.; Li, C. Superplastic deformation behavior of Mg alloys: A-review. J. Magnes. Alloy. 2022, 10, 97–109. [Google Scholar] [CrossRef]

- Hu, J.; Wan, D.; Hu, Y.; Wang, H.; Jiang, Y.; Xue, Y.; Li, L. A hysteretic loop phenomenon at strain amplitude dependent damping curves of pre-strained pure Mg during cyclic vibration. J. Alloy. Compd. 2021, 886, 161303. [Google Scholar] [CrossRef]

- Yan, Z.; Zhu, J.; Zhang, Z.; Wang, Q.; Xue, Y. The microstructural, textural, and mechanical effects of high-pressure torsion processing on Mg alloys: A review. Front. Mater. 2022, 9, 964992. [Google Scholar] [CrossRef]

- Somekawa, H.; Tsuru, T. Effect of alloying elements on grain boundary sliding in magnesium binary alloys: Experimental and numerical studies. Mat. Sci. Eng. A-Struct. 2017, 708, 267–273. [Google Scholar] [CrossRef]

- Somekawa, H.; Watanabe, H.; Basha, D.A.; Singh, A.; Inoue, T. Effect of twin boundary segregation on damping properties in magnesium alloy. Scr. Mater. 2017, 129, 35–38. [Google Scholar] [CrossRef]

- Hazeli, K.; Sadeghi, A.; Pekguleryuz, M.O.; Kontsos, A. Damping and dynamic recovery in magnesium alloys containing strontium. Mat. Sci. Eng. A-Struct. 2014, 589, 275–279. [Google Scholar] [CrossRef]

- Niu, R.-L.; Yan, F.-J.; Wang, Y.-S.; Duan, D.-P.; Yang, X.-M. Effect of Zr content on damping property of Mg-Zr binary alloys. Mat. Sci. Eng. A-Struct. 2018, 718, 418–426. [Google Scholar] [CrossRef]

- Wen, L.H.; Ji, Z.S.; Hu, M.L.; Ning, H.Y. Microstructure and mechanical properties of Mg-3.0Nd-0.4Zn-0.4Zr magnesium alloy. J. Magnes. Alloy. 2014, 2, 85–91. [Google Scholar] [CrossRef] [Green Version]

- Jun, J.-H. Damping behaviors of as-cast and solution-treated AZ91-Ca magnesium alloys. J. Alloy. Compd. 2014, 610, 169–172. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, J.; Wang, H.; Ma, S.; Huang, S.; Li, S.; Pan, F. Enhanced Damping Capacities of Mg-Ce Alloy by the Special Microstructure with Parallel Second Phase. J. Mater. Sci. Technol. 2017, 33, 941–946. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Z.; Gao, S.; Lu, R.; Qin, D.; Yang, W.; Pan, F. Optimization of mechanical and damping properties of Mg-0.6Zr alloy by different extrusion processing. J. Magnes. Alloy. 2015, 3, 79–85. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.-S.; Chen, J.-H.; Yan, H.-G.; Li, Q.; Xia, W.-J.; Su, B.; Zhu, W.-J. Solid solution strengthening and damping capacity of Mg-Ga binary alloys. Trans. Nonferrous Metal. Soc. 2022, 32, 2852–2865. [Google Scholar] [CrossRef]

- Granato, A.; Lücke, K. Theory of Mechanical Damping Due to Dislocations. J. Appl. Phys. 1956, 27, 583–593. [Google Scholar] [CrossRef]

- Granato, A.; Lücke, K. Application of Dislocation Theory to Internal Friction Phenomena at High Frequencies. J. Appl. Phys. 1956, 27, 789–805. [Google Scholar] [CrossRef]

- Sugimoto, K.; Niiya, K.; Okamoto, T.; Kishitake, K. Study of damping capacity in magnesium alloys. Trans. Jpn. Inst. Met. 1977, 18, 277–288. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Yan, H.; Chen, J.; Xia, W.; Su, B.; Song, M. Effects of solid solution elements on damping capacities of binary magnesium alloys. Mat. Sci. Eng. A-Struct. 2020, 772, 138707. [Google Scholar] [CrossRef]

- Somekawa, H.; Schuh, C.A. Effect of solid solution elements on nanoindentation hardness, rate dependence, and incipient plasticity in fine grained magnesium alloys. Acta Mater. 2011, 59, 7554–7563. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Z.; Liu, T.; Qiu, Z.; Su, Y.; Zhang, J.; Lin, C.; Wang, L. Recent Progress in Functionalized Coatings for Corrosion Protection of Magnesium Alloys-A Review. Materials 2022, 15, 3912. [Google Scholar] [CrossRef] [PubMed]

- Lu, R.; Jiao, K.; Zhao, Y.; Li, K.; Yao, K.; Hou, H. Influence of Long-Period-Stacking Ordered Structure on the Damping Capacities and Mechanical Properties of Mg-Zn-Y-Mn As-Cast Alloys. Materials 2020, 13, 4654. [Google Scholar] [CrossRef]

- Zhang, Z.; Zeng, X.; Ding, W. The influence of heat treatment on damping response of AZ91D magnesium alloy. Mat. Sci. Eng. A-Struct. 2005, 392, 150–155. [Google Scholar] [CrossRef]

- Ren, L.B.; Quan, G.F.; Xu, Y.G.; Yin, D.D.; Lu, J.W.; Dang, J.T. Effect of heat treatment and pre-deformation on damping capacity of cast Mg-Y binary alloys. J. Alloy. Compd. 2017, 699, 976–982. [Google Scholar] [CrossRef]

- Mohedano, M.; Blawert, C.; Yasakau, K.A.; Arrabal, R.; Matykina, E.; Mingo, B.; Scharnagl, N.; Ferreira, M.G.S.; Zheludkevich, M.L. Characterization and corrosion behavior of binary Mg-Ga alloys. Mater. Charact. 2017, 128, 85–99. [Google Scholar] [CrossRef]

- Huang, W.; Chen, J.; Yan, H.; Xia, W.; Su, B. High plasticity mechanism of high strain rate rolled Mg-Ga alloy sheets. J. Mater. Sci. Technol. 2022, 101, 187–198. [Google Scholar] [CrossRef]

- Kubasek, J.; Vojtech, D.; Lipov, J.; Ruml, T. Structure, mechanical properties, corrosion behavior and cytotoxicity of biodegradable Mg-X (X=Sn, Ga, In) alloys. Mat. Sci. Eng. C-Mater. 2013, 33, 2421–2432. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, Y.; Yang, L.; Chen, T.; Li, D.; Wu, L.; Jiang, B.; Steinbrück, M.; Pan, F. The oxidation behavior of Mg-Er binary alloys at 500 °C. Corros. Sci. 2022, 195, 109961. [Google Scholar] [CrossRef]

- Chaudry, U.M.; Kim, T.H.; Park, S.D.; Kim, Y.S.; Hamad, K.; Kim, J.-G. Effects of calcium on the activity of slip systems in AZ31 magnesium alloy. Mat. Sci. Eng. A-Struct. 2019, 739, 289–294. [Google Scholar] [CrossRef]

- Wu, B.L.; Wan, G.; Du, X.H.; Zhang, Y.D.; Wagner, F.; Esling, C. The quasi-static mechanical properties of extruded binary Mg-Er alloys. Mat. Sci. Eng. A-Struct. 2013, 573, 205–214. [Google Scholar] [CrossRef]

| Elements | Atomic Radius (Å) |

|---|---|

| Ga | 1.40 |

| Er | 1.76 |

| Mg | 1.60 |

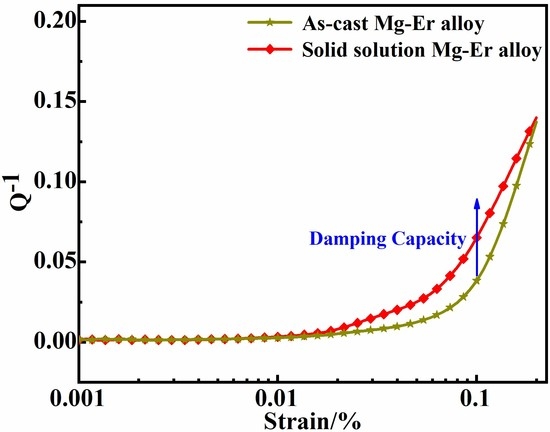

| Alloys | Strain (ε) | Damping Capacity |

|---|---|---|

| as-cast Mg-Ga | 10−3 | 0.024 |

| as-cast Mg-Er | 10−3 | 0.038 |

| solid solution Mg-Ga | 10−3 | 0.042 |

| solid solution Mg-Er | 10−3 | 0.065 |

| pure Mg | 10−3 | 0.180 |

| Element Atom | Ga | Er |

|---|---|---|

| atomic radius (r) | 1.40 | 1.76 |

| atomic radius difference (Δr) | −0.20 | 0.16 |

| at.% | 3.10 | 6.90 |

| damping capacity | 0.042 | 0.065 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Wang, J.; Wang, Z.; Wang, X.; Dang, C.; Wan, Z.; Zou, Y.; Wang, J.; Pan, F. Effects of Solution Treatment on Damping Capacities of Binary Mg-X (X = Ga and Er) Alloys. Materials 2022, 15, 8172. https://doi.org/10.3390/ma15228172

Dong X, Wang J, Wang Z, Wang X, Dang C, Wan Z, Zou Y, Wang J, Pan F. Effects of Solution Treatment on Damping Capacities of Binary Mg-X (X = Ga and Er) Alloys. Materials. 2022; 15(22):8172. https://doi.org/10.3390/ma15228172

Chicago/Turabian StyleDong, Xiaoyang, Jinxing Wang, Zichuan Wang, Xiyu Wang, Cong Dang, Zhicheng Wan, Yi Zou, Jingfeng Wang, and Fusheng Pan. 2022. "Effects of Solution Treatment on Damping Capacities of Binary Mg-X (X = Ga and Er) Alloys" Materials 15, no. 22: 8172. https://doi.org/10.3390/ma15228172