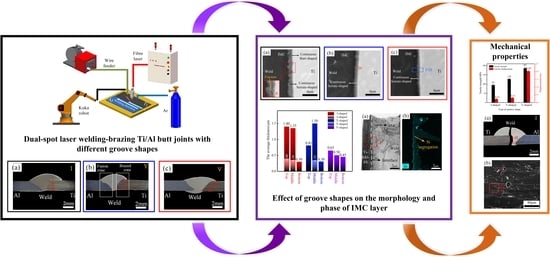

The Microstructure and Mechanical Properties of Dual-Spot Laser Welded-Brazed Ti/Al Butt Joints with Different Groove Shapes

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Surface and Cross-Sections Characteristics in Ti/Al Welds

3.2. Effect of Groove Shape on the Interfacial Structure

3.3. Thermal History

3.4. Mechanical Performance

4. Conclusions

- (1)

- When the groove shape was I-shaped and Y-shaped, the weld face appearance was discontinuous, and the rear surface of the Ti alloy was not successfully wetted. With the groove shape changed to V-shape, the Ti/Al joint was sound with a satisfactory weld face appearance.

- (2)

- The characteristics of the IMC layer were affected by the groove shapes for the Ti side. An inhomogeneous IMC layer was generated at the brazing interface in joints with I-shaped and Y-shaped grooves. For joints with V-shaped grooves, the IMC layer was the most homogeneous, and the thickness difference was only 0.20 μm. The phases of the IMC were Ti(Al,Si)3 phase and nanosized Ti7Al5Si12 and Ti5Si3 phases.

- (3)

- The groove shape for the Ti side affected the temperature field at the brazing interface, and then affected the formation process of the IMC layer. The smallest temperature gradient was obtained in joints with V-shaped grooves, which was 43 °C, resulting in the most homogeneous IMC layer. The uneven temperature field in joints with I-shaped and Y-shaped grooves resulted in an inhomogeneous IMC layer.

- (4)

- The tensile strength of the Ti/Al joint was dominated by the morphology and distribution of the IMC layer. An inhomogeneous IMC layer decreased the tensile property of joints with I-shaped and Y-shaped grooves. The continuous serrated-shaped IMC layer enhanced the interfacial bonding strength of joints with V-shaped grooves. The highest tensile strength reached 187 MPa.

Author Contributions

Funding

Conflicts of Interest

References

- Tan, C.; Song, X.; Chen, B.; Li, L.; Feng, J. Enhanced interfacial reaction and mechanical properties of laser welded-brazed Mg/Ti joints with Al element from filler. Mater. Lett. 2016, 167, 38–42. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Guo, G.; Wang, G.; Wei, H. Effects of different powders on the micro-gap laser welding-brazing of an aluminium-steel butt joint using a coaxial feeding method. Mater. Des. 2016, 109, 10–18. [Google Scholar] [CrossRef]

- Zhou, L.; Min, J.; He, W.; Huang, Y.; Song, X. Effect of welding time on microstructure and mechanical properties of Al-Ti ultrasonic spot welds. J. Manuf. Process. 2018, 33, 64–73. [Google Scholar] [CrossRef]

- Plaine, A.; Suhuddin, U.; Alcântara, N.; Dos Santos, J. Microstructure and mechanical behavior of friction spot welded AA6181-T4/Ti6Al4V dissimilar joints. Int. J. Adv. Manuf. Technol. 2017, 92, 3703–3714. [Google Scholar] [CrossRef]

- Zhao, H.; Yu, M.; Jiang, Z.; Zhou, L.; Song, X. Interfacial microstructure and mechanical properties of Al/Ti dissimilar joints fabricated via friction stir welding. J. Alloys Compd. 2019, 789, 139–149. [Google Scholar] [CrossRef]

- Oliveira, A.; Mello, C.; Riva, R. Influence of Si Coating on Interfacial Microstructure of Laser Joining of Titanium and Aluminium Alloys. Mater. Res. 2018, 21, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Peng, Y.; Cui, C.; Gao, Q.; Zhou, Q.; Zhu, J. Microstructure and mechanical characterization of re-melted Ti-6Al-4V and Al-Mg-Si alloys butt weld. Vacuum 2018, 154, 58–67. [Google Scholar] [CrossRef]

- Kreimeyer, M.; Wagner, F.; Vollertsen, F. Laser processing of aluminum–titanium-tailored blanks. Opt. Lasers Eng. 2005, 43, 1021–1035. [Google Scholar] [CrossRef]

- Chen, X.; Xie, R.; Lai, Z.; Liu, L.; Zou, G.; Yan, J. Ultrasonic-assisted brazing of Al–Ti dissimilar alloy by a filler metal with a large semi-solid temperature range. Mater. Des. 2016, 95, 296–305. [Google Scholar] [CrossRef]

- Nandagopal, K.; Kailasanathan, C. Analysis of mechanical properties and optimization of gas tungsten Arc welding (GTAW) parameters on dissimilar metal titanium (6Al 4V) and aluminium 7075 by Taguchi and ANOVA techniques. J. Alloys Compd. 2016, 682, 503–516. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M. Modeling and experimental analysis of fiber laser offset welding of Al-Ti butt joints. Int. J. Adv. Manuf. Technol. 2016, 83, 89–98. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Méasson, A.; Cicala, E.; Duband, M.; Peyre, P. Aluminum to titanium laser welding-brazing in V-shaped groove. J. Mater. Process. Technol. 2017, 245, 24–36. [Google Scholar] [CrossRef]

- Gao, M.; Chen, C.; Gu, Y.; Zeng, X. Microstructure and Tensile Behavior of Laser Arc Hybrid Welded Dissimilar Al and Ti Alloys. Materials 2014, 7, 1590–1602. [Google Scholar] [CrossRef]

- Kim, Y.-C.; Fuji, A. Factors dominating joint characteristics in Ti-Al friction welds. Sci. Technol. Weld. Join. 2002, 7, 149–154. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, J.; Ye, Z.; Cheng, Z.; Yang, J.; Chen, S. Influence of welding parameters on the IMCs and the mechanical properties of Ti/Al butt joints welded by MIG/TIG double-sided arc welding-brazing. J. Alloys Compd. 2018, 747, 764–771. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y.; Dai, J.; Huang, J. Improving interfacial reaction nonhomogeneity during laser welding–brazing aluminum to titanium. Mater. Des. 2011, 32, 4408–4416. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Peyre, P. Yb–YAG laser offset welding of AA5754 and T40 butt joint. J. Mater. Process. Technol. 2015, 223, 139–149. [Google Scholar] [CrossRef]

- Vaidya, W.; Horstmann, M.; Ventzke, V.; Petrovski, B.; Koçak, M.; Kocik, R.; Tempus, G. Improving interfacial properties of a laser beam welded dissimilar joint of aluminium AA6056 and titanium Ti6Al4V for aeronautical applications. J. Mater. Sci. 2010, 45, 6242–6254. [Google Scholar] [CrossRef] [Green Version]

- Song, Z.; Nakata, K.; Wu, A.; Liao, J. Interfacial microstructure and mechanical property of Ti6Al4V/A6061 dissimilar joint by direct laser brazing without filler metal and groove. Mater. Sci. Eng. A 2013, 560, 111–120. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Cicala, E.; Peyre, P.; Grevey, D. Direct keyhole laser welding of aluminum alloy AA5754 to titanium alloy Ti6Al4V. J. Mater. Process. Technol. 2015, 217, 96–104. [Google Scholar] [CrossRef] [Green Version]

- Baqer, Y.; Ramesh, S.; Yusof, F.; Manladan, S. Challenges and advances in laser welding of dissimilar light alloys: Al/Mg, Al/Ti, and Mg/Ti alloys. Int. J. Adv. Manuf. Technol. 2018, 95, 4353–4369. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, S.; Li, L. Influence of interfacial reaction layer morphologies on crack initiation and propagation in Ti/Al joint by laser welding-brazing. Mater. Des. 2010, 31, 227–233. [Google Scholar] [CrossRef]

- Sahul, M.; Sahul, M.; Vyskoč, M.; Čaplovič, Ľ.; Pašák, M. Disk Laser Weld Brazing of AW5083 Aluminum Alloy with Titanium Grade 2. J. Mater. Eng. Perform. 2017, 26, 1346–1357. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, W.; Li, Y.; Chen, H. Effect of laser-arc offset and laser-deviation angle on the control of a Ti-Al interlayer. J. Mater. Process. Technol. 2019, 271, 336–345. [Google Scholar] [CrossRef]

- Yang, G.; Ma, J.; Carlson, B.; Wang, H.-P.; Kovacevic, R. Effect of laser beam configuration on microstructure evolution and joint performance in laser joining AA 6111 panels. Mater. Des. 2017, 123, 197–210. [Google Scholar] [CrossRef]

- Harooni, M.; Carlson, B.; Kovacevic, R. Dual-beam laser welding of AZ31B magnesium alloy in zero-gap lap joint configuration. Opt. Laser Technol. 2014, 56, 247–255. [Google Scholar] [CrossRef]

- Pang, S.; Chen, W.; Zhou, J.; Liao, D. Self-consistent modeling of keyhole and weld pool dynamics in tandem dual beam laser welding of aluminum alloy. J. Mater. Process. Technol. 2015, 217, 131–143. [Google Scholar] [CrossRef]

- Saida, K.; Ohnishi, H.; Nishimoto, K. Fluxless laser brazing of aluminium alloy to galvanized steel using a tandem beam–dissimilar laser brazing of aluminium alloy and steels. Weld. Int. 2010, 24, 161–168. [Google Scholar] [CrossRef]

- Laukant, H.; Wallmann, C.; Korte, M.; Glatzel, U. Flux-less joining technique of aluminium with zinc-coated steel sheets by a dual-spot-laser beam. Adv. Mater. Res. 2005, 6–8, 163–170. [Google Scholar] [CrossRef]

- Yan, S.; Hong, Z.; Watanabe, T.; Jingguo, T. CW/PW dual-beam YAG laser welding of steel/aluminum alloy sheets. Opt. Lasers Eng. 2010, 48, 732–736. [Google Scholar] [CrossRef]

- Mohammadpour, M.; Yazdian, N.; Yang, G.; Wang, H.; Carlson, B.; Kovacevic, R. Effect of dual laser beam on dissimilar welding-brazing of aluminum to galvanized steel. Opt. Laser Technol. 2018, 98, 214–228. [Google Scholar] [CrossRef]

- Xia, H.; Tao, W.; Li, L.; Tan, C.; Zhang, K.; Ma, N. Effect of laser beam models on laser welding-brazing Al to steel. Opt. Laser Technol. 2020, 122, 105845. [Google Scholar] [CrossRef]

- Sun, J.; Yan, Q.; Li, Z.; Huang, J. Effect of bevel angle on microstructure and mechanical property of Al/steel butt joint using laser welding-brazing method. Mater. Des. 2016, 90, 468–477. [Google Scholar] [CrossRef]

- Shouzheng, W.; Yajiang, L.; Juan, W.; Kun, L. Research on cracking initiation and propagation near Ti/Al interface during TIG welding of titanium to aluminium Research on cracking initiation and propagation near Ti/Al interface during TIG welding of titanium to aluminium. Kov. Mater. 2014, 52. [Google Scholar]

- Li, L.; Xia, H.; Tan, C.; Ma, N. Effect of groove shape on laser welding-brazing Al to steel. J. Mater. Process. Technol. 2018, 252, 573–581. [Google Scholar] [CrossRef]

- Qin, G.; Ji, Y.; Ma, H.; Ao, Z. Effect of modified flux on MIG arc brazing-fusion welding of aluminum alloy to steel butt joint. J. Mater. Process. Technol. 2017, 245, 115–121. [Google Scholar] [CrossRef]

- Wang, H.; Yuan, X.; Li, T.; Wu, K.; Sun, Y.; Xu, C. TIG welding-brazing of Ti6Al4V and Al5052 in overlap configuration with assistance of zinc foil. J. Mater. Process. Technol. 2018, 251, 26–36. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y. Interfacial reaction mode and its influence on tensile strength in laser joining Al alloy to Ti alloy. Mater. Sci. Technol. 2010, 26, 230–235. [Google Scholar] [CrossRef]

- Chen, S.; Li, L.; Chen, Y.; Huang, J. Joining mechanism of Ti/Al dissimilar alloys during laser welding-brazing process. J. Alloys Compd. 2011, 509, 891–898. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, S.; Chang, Y.; Kattner, U. A thermodynamic description of the Ti/Al system. Intermetallics 1997, 5, 471–482. [Google Scholar] [CrossRef]

| Material | Al | Si | Fe | Cu | Zn | Mn | Mg | Ti | V |

|---|---|---|---|---|---|---|---|---|---|

| 6061-T6 Al | Bal. | 0.63 | 0.29 | 0.27 | 0.01 | 0.07 | 1.00 | 0.02 | - |

| Ti6Al4V | 6.21 | - | 0.135 | - | - | - | - | Bal. | 3.93 |

| Al-12Si | Bal. | 12.0 | 0.80 | 0.30 | 0.20 | 0.05 | 0.10 | - | - |

| Welding Parameters | Value |

|---|---|

| Laser power/W | 2200 |

| Welding speed/(m × min−1) | 0.36 |

| Wire feed speed/(cm × min−1) | 288 |

| Defocus/mm | +20 |

| Laser offset from weld centerline/mm | 0.3 |

| Flowrate of shielding gas (Argon)/(L × min−1) | 15 |

| Test Zone | Element | ||

|---|---|---|---|

| Ti | Al | Si | |

| I | 23.4 | 68.0 | 8.6 |

| II | 21.8 | 61.6 | 15.6 |

| III | 24.2 | 68.8 | 7.0 |

| IV | 25.6 | 66.3 | 8.1 |

| V | 25.6 | 64.6 | 9.8 |

| VI | 20.4 | 64.3 | 15.3 |

| VII | 24.6 | 65.3 | 10.1 |

| Test Zone | Element | ||

|---|---|---|---|

| Ti | Al | Si | |

| A | 21.7 | 67.0 | 11.4 |

| B | 1.6 | 91.8 | 6.6 |

| C | 23.1 | 68.5 | 8.4 |

| D | 23.4 | 64.2 | 12.4 |

| E | 25.7 | 66.8 | 7.5 |

| F | 0.0 | 92.0 | 8.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Lei, Z.; Zhang, X.; Cai, E.; Chen, Y. The Microstructure and Mechanical Properties of Dual-Spot Laser Welded-Brazed Ti/Al Butt Joints with Different Groove Shapes. Materials 2020, 13, 5105. https://doi.org/10.3390/ma13225105

Li P, Lei Z, Zhang X, Cai E, Chen Y. The Microstructure and Mechanical Properties of Dual-Spot Laser Welded-Brazed Ti/Al Butt Joints with Different Groove Shapes. Materials. 2020; 13(22):5105. https://doi.org/10.3390/ma13225105

Chicago/Turabian StyleLi, Peng, Zhenglong Lei, Xinrui Zhang, Enze Cai, and Yanbin Chen. 2020. "The Microstructure and Mechanical Properties of Dual-Spot Laser Welded-Brazed Ti/Al Butt Joints with Different Groove Shapes" Materials 13, no. 22: 5105. https://doi.org/10.3390/ma13225105