1. Introduction

Ethanol is being promoted as an alternative energy source due to its economic, environmental, societal, and strategic benefits [

1,

2,

3,

4,

5,

6,

7]. Ethanol can be produced from plant materials such as lignocellulose, starch, and sugar. Ethanol production from starch and sugar, however, has issues related to environment, food security, and grain price increase [

8,

9]. Lignocellulosic ethanol, on the other hand, can displace more non-renewable energy and reduce environmental risks more efficiently than can starch- or sugar-based ethanol [

10,

11]. Also, lignocellulosic feedstocks are abundant, relatively cheap, and widely available [

7,

12,

13,

14]. The United States has an annual potential of producing about 189 million m

3 of biofuels from lignocellulosic feedstocks [

12]. Lignocellulosic ethanol production technology is still evolving, and once streamlined, lignocellulosic biomass has the potential to make substantial contribution toward biofuel production [

15]. One of the most suitable and abundantly available lignocellulosic feedstocks is maize (

Zea mays L.) stover, the above-ground portion of the maize plant minus the grains [

16,

17]. In the USA, maize is a principal feedstock for ethanol production [

18] and is expected to contribute approximately 42% of the target annual use of biofuels in the country by 2022 [

19].

Maize biomass yield is influenced by a number of environmental and management factors. Variation in cultivar, irrigation amount, planting date, or soil type can cause a considerable variation in maize stover yield. Accordingly, alterations in these variables might also affect non-renewable energy displacement and carbon emissions associated with maize stover-based ethanol production [

20,

21]. Previous studies that examined these issues did not specifically address the effects of cultivar, irrigation, planting date, and soil type on maize stover yield and stover-based ethanol production systems [

20,

21,

22].

Biofuel production is associated with the issue of non-renewable energy displacement or energy sustainability [

2,

3,

5,

6]. The sustainability of biofuel production can be quantified using net energy value (NEV), a measure defined as the difference between renewable energy produced and non-renewable energy used to produce the renewable energy [

23]. While a positive NEV value is an indication of a sustainable system, a larger NEV value indicates that the system is more sustainable.

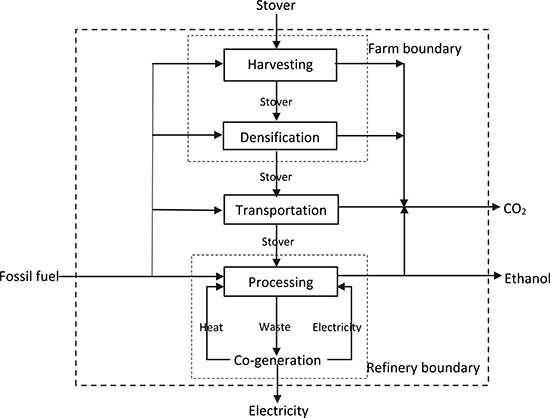

Another important issue regarding biofuel production is CO

2 emissions during feedstock delivery and ethanol processing [

24,

25]. The increasing level of CO

2 in the atmosphere has been identified as a cause of global warming [

2,

26], a driver of several environmental problems. With the rise in concern about global climate change, therefore, studying CO

2 emissions becomes more and more important. For determining the effect of biofuel production on the environment, many previous studies have used CO

2 emissions as a basis. With a rise in stover yield, CO

2 emissions increase due to more material to harvest, transport, and process. During these activities, about 95.72 kg CO

2 is emitted for each Mg of stover [

24,

25]. The yield increase is beneficial; the associated emissions increase, however, is not. To reflect the positive aspect of yield increase as well as the negative aspect of a rise in emissions, a system of measurement called the carbon credits balance (CCB; [

20]) can be used. One carbon credit can be regarded as a reward for extracting one Mg of CO

2 gas from the atmosphere. The CCB is defined as the amount of CO

2 (Mg) taken up by a maize plant from the atmosphere through fixation and stored in the stover minus the amount of CO

2 (Mg) emitted to the atmosphere through burning of fossil fuel for supplying a given quantity of stover to a biorefinery and processing it. Supply includes all activities in the feedstock supply chain, namely harvesting, collection, storage, and transportation. While a positive CCB value is indicative of an environmentally friendly ethanol production system (in terms of carbon emissions reduction), a larger value is an indication of a more environmentally friendly system.

Among the various regions of the USA, the southeastern region is more suitable for biomass production due to long crop growing seasons and high rainfall [

27]. Due to an increase in the demand for ethanol, an interest in cultivating maize for ethanol production is growing in this country. In Mississippi, a southeastern state, favorable environmental conditions make biomass production a potential source of income for farmers. The large historical in addition to recently increasing maize area, as well as increasing maize yields, increasing switch of farmers from cotton to maize, and favorable climate and soil conditions for maize production in Mississippi all suggest that a large area is potentially available for maize stover-based ethanol production in this state [

28,

29]. The climate, soils, and other crop-growing conditions in Mississippi are also representative for other states in the southeastern USA. Although the southeastern region has good potential for lignocellulosic ethanol production, the production is still limited to the experimental scale [

30]. The response of ethanol production systems to various environmental and crop management factors are largely unknown for this region [

22,

31,

32]. Detailed knowledge about the impacts of variability in management and environment on the sustainability and eco-friendliness of maize stover-based ethanol production systems might be helpful in evaluating maize stover as a potential energy feedstock. Thus, additional information is needed to characterize the sustainability and eco-friendliness of maize stover-based ethanol production systems as influenced by management and environmental factors such as cultivar, irrigation, planting date, and soil.

The objective of this study was to identify the crop management options—the combinations of various management variables, namely cultivar, irrigation, planting date, and soil—that would maximize the energy sustainability and eco-friendliness of maize stover-based ethanol production systems in the Mississippi Delta. Specifically, this study examined how variations in these management variables would affect the NEV and CCB of maize stover-based ethanol production systems using crop modeling approach.

3. Results

3.1. Cultivar Coefficients

Values of the cultivar coefficients estimated for the four cultivars are presented in

Table 4. For all cultivars, values of both P1 and P5 were the same because they belonged to the same maturity group, short season, and were estimated using the same values of both P2 and PHINT. The only coefficients that were different across cultivars were G2 and G3, both of which decreased in the order of AvTop5, DynaGro-High, DynaGro-Mid, and DynaGro-Low because AvTop5 and DynaGro-High belonged to top yielders, DynaGro-Mid to mid yielders, and DynaGro-Low to low yielders. Among the cultivars, AvTop5 and DynaGro-High were not different among themselves as they were from the same group, high-yielders. However, they were different from DynaGro-Mid and DynaGro-Low, the mid- and low-yielders, respectively. Cultivars DynaGro-Mid and DynaGro-Low were also different from each other as they were from different groups.

Table 4.

Cultivar coefficients estimated for various maize cultivars in the Mississippi Delta.

Table 4.

Cultivar coefficients estimated for various maize cultivars in the Mississippi Delta.

| Cultivar | Cultivar coefficient a |

|---|

| P1 | P2 | P5 | G2 | G3 | PHINT |

|---|

| AvTop5 | 201 | 0.2 | 950 | 930 | 9.5 | 45 |

| DynaGro-High | 201 | 0.2 | 950 | 900 | 9.2 | 45 |

| DynaGro-Mid | 201 | 0.2 | 950 | 820 | 8.4 | 45 |

| DynaGro-Low | 201 | 0.2 | 950 | 770 | 7.9 | 45 |

The statistics associated with the performance of the model while estimating the cultivar coefficients for each of the four cultivars is presented in

Figure 3. The figure as well as the values of the goodness-of-fit measures used—RMSE, % error,

R2, and d-index—indicated that the performance of the CERES-Maize model was satisfactory. The model-simulated yields agreed with the observed yields (MSUES;

http://msucares.com/pubs/crops3.html#grain) reasonably well.

Figure 3.

The CERES-Maize-simulated vs. observed grain yields of maize (Mg·ha−1) in the Mississippi Delta for cultivar: (a) AvTop5; (b) DynaGro-High; (c) DynaGro-Mid; and (d) DynaGro-Low.

Figure 3.

The CERES-Maize-simulated vs. observed grain yields of maize (Mg·ha−1) in the Mississippi Delta for cultivar: (a) AvTop5; (b) DynaGro-High; (c) DynaGro-Mid; and (d) DynaGro-Low.

3.2. Cultivar Effect

For all locations, the NEV values of cultivars AvTop5 and DynaGro-High did not vary from each other as they belonged to the same class, high-yielders, but varied from those of DynaGro-Mid and DynaGro-Low which were different from each other as they belonged to two different groups, mid-yielders and low-yielders, respectively (

Table 5 and

Figure 4). For all locations, the NEV values of DynaGro-High were highest and those of DynaGro-Low lowest as they were from high-yielders and low-yielders, respectively. The CCB had the same patterns as the NEV (

Figure 4) because the latter was linearly associated with the former as:

CCB = 0.2218

NEV + 0.0477, where CCB is in credits·ha

−1 and NEV in GJ·ha

−1.

Table 5.

Mean net energy values (NEV: GJ·ha

−1) associated with various factors and treatments at three locations in the Mississippi Delta. This table is summarized in

Figure 4 for easier interpretation.

Table 5.

Mean net energy values (NEV: GJ·ha−1) associated with various factors and treatments at three locations in the Mississippi Delta. This table is summarized in Figure 4 for easier interpretation.

| Factor | Treatment | Location |

|---|

| Tunica | Moorhead | Vicksburg |

|---|

| Soil | Sandy loam | †B24.80c § | C24.22c | A30.27a |

| Silty loam | A26.79a | A26.58a | A26.77c |

| Silty clay loam | B25.04b | B25.51b | A28.24b |

| Cultivar | AvTop5 | B26.94a | B27.06a | A30.97a |

| DynaGro-High | B27.16a | B27.27a | A30.90a |

| DynaGro-Mid | B25.11b | B24.87b | A27.28b |

| DynaGro-Low | B22.97c | B22.64c | A24.60c |

| Irrigation (dry year) | No | B24.46c | B23.43b | A30.85b |

| Light | B29.22a | C25.34a | A33.60a |

| Moderate | B29.49a | C25.39a | A33.75a |

| Heavy | B29.40a | C24.66a | A33.42a |

| Extreme | B27.12b | C22.77b | A30.16b |

| Irrigation (wet year) | No | A20.36b | B15.09a | A22.37a |

| Light | A23.23a | B15.09a | A22.37a |

| Moderate | A22.69a | B15.10a | A21.87a |

| Heavy | A22.70a | C14.69a | B20.96a |

| Extreme | A20.80b | C10.38b | B17.40b |

| Irrigation (average year) | No | B25.34c | B25.27c | A28.80b |

| Light | B26.60a | B26.47a | A29.63a |

| Moderate | B26.53a | B26.36a | A29.55a |

| Heavy | B25.99b | B25.78b | A28.99b |

| Extreme | B23.26d | B23.29d | A25.22c |

The NEV and CCB values of each cultivar in Vicksburg were greater than those in the other locations due to its larger root zone depth (RZD) and higher water holding capacity (WHC) (

Table 1). The soil profile of larger RZD with higher WHC held more plant-available water in the soil for a longer period of time, thus leading to higher stover yields and ultimately greater NEV and CCB values. Although the average root zone in Tunica was deeper (169 cm) than that in Moorhead (152 cm), the average WHC of the former was lower (0.16) than that of the latter (0.18). Thus, no difference in NEV as well as CCB was found between these two locations for all cultivars.

Figure 4.

Mean net energy values (NEV: GJ·ha−1) for various factors, treatments, and locations. Values represented by the bars of the same color pattern across the treatments of a factor within a location are not significantly different, whereas those represented by the bars of different patterns are different from each other. For instance, the cultivars AT and DH for Moorhead (green bars) are not different from each other but are so from DM and DL which are different from each other. Abbreviations: SA = sandy loam, SL = silt loam, SC = silty clay loam, AT = average top 5, DH = DyanGro-High, DM = DynaGro-Mid, DL = Dynagro-Low, NO = no, LT = light, MO = moderate, HV = heavy, EX = extreme, M = Meadville, T = Tunica, V = Vicksburg, DY = dry year, WY = wet year, and AY = average year.

Figure 4.

Mean net energy values (NEV: GJ·ha−1) for various factors, treatments, and locations. Values represented by the bars of the same color pattern across the treatments of a factor within a location are not significantly different, whereas those represented by the bars of different patterns are different from each other. For instance, the cultivars AT and DH for Moorhead (green bars) are not different from each other but are so from DM and DL which are different from each other. Abbreviations: SA = sandy loam, SL = silt loam, SC = silty clay loam, AT = average top 5, DH = DyanGro-High, DM = DynaGro-Mid, DL = Dynagro-Low, NO = no, LT = light, MO = moderate, HV = heavy, EX = extreme, M = Meadville, T = Tunica, V = Vicksburg, DY = dry year, WY = wet year, and AY = average year.

3.3. Irrigation Effect

In general, NEV and CCB each showed a sigmoid relationship with the amount of irrigation applied. The NEV and CCB responses varied with weather conditions (

Table 5 and

Figure 4). Under dry conditions, the NEV and CCB values associated with light, moderate, and heavy irrigations were larger than those with no and extreme irrigations, but were not different among themselves for all locations. The difference in NEV as well as CCB with no irrigation was because soil never remained dry with light, moderate, and heavy irrigations as at least 25% of the field capacity was always maintained. Because soil water content even with light irrigation was nearly enough to sustain basic plant physiological processes, it did not vary across light, moderate, and heavy irrigations. Larger irrigation amounts did add additional water to the soil, but the marginal utilities of the added waters were not larger. The NEV and CCB values associated with no and extreme irrigations were smaller than those with light, moderate, and heavy irrigations because of drought and flooding, respectively. No and extreme irrigations had about the same values of NEV as well as CCB for Moorhead and Vicksburg, but different values for Tunica due to variation in minimum precipitation (out of 720 scenarios) during growing seasons. The minimum precipitation in Moorhead and Vicksburg was about the same, 170 and 155 mm, respectively, whereas that in Tunica, 231 mm, was significantly larger. Under dry conditions, larger precipitation led to more plant-available water, higher yields, and thus larger values of both NEV and CCB. For each irrigation treatment, values of NEV as well as CCB were different across locations due to variations in the RZD and WHC of their soils. In general, the NEV and CCB values increased in the order of Moorhead, Tunica, and Vicksburg for all irrigation treatments due to differences in RZD and WHC. The average values of RZD and WHC, respectively, were 152 cm and 0.16 for Moorhead, 170 cm and 0.18 for Tunica, and 187 cm and 0.21 for Vicksburg.

Under wet conditions, the values of both NEV and CCB associated with light, moderate, and heavy irrigations were not different from each other in all locations because irrigation did not significantly contribute to plant-available water as a large amount of water was already present in the soil. The NEV and CCB values associated with light, moderate, and heavy irrigations were larger than those with no and extreme irrigations in Tunica, but only with extreme irrigation in Moorhead and Vicksburg. The difference with no irrigation in Tunica was due to smaller precipitation. Because of high water content already in the soil due to large precipitation, the no irrigation could raise further the yields and thus the NEV as well as CCB values in Moorhead and Vicksburg. Instead, the increased irrigation amounts reduced yields and thus NEV and CCB values due to flooding. The NEV and CCB values associated with no and extreme irrigations were about the same in Tunica, but different in Moorhead and Vicksburg each due to precipitation differences (Tunica: 573 mm, Moorhead: 858 mm, Vicksburg: 853 mm). Because of large precipitation, the NEV and CCB values in Moorhead and Vicksburg fell down even below rainfed level due to excessive flooding. In Tunica, however, they did plunge significantly below rainfed level because of relatively less precipitation and flooding. At low irrigation levels (no, light, and moderate), the NEV and CCB values in Moorhead were smaller than those in Tunica and Vicksburg, which were about the same, but at high irrigation levels (heavy and extreme), the NEV and CCB values were different across locations. The smaller values of NEV and CCB in Moorhead were due to larger precipitation and shallower root zone (152 cm) and thus more water logging. Vicksburg had about the same precipitation, but its root zone was deeper (203 cm) so its root zone did not saturate as quickly as that of Moorhead and the NEV and CCB values did not plunge much. The difference across locations with heavy and extreme irrigations was because at these irrigation treatments even the deepest layer of Vicksburg got nearly saturated, causing yields and thus NEV and CCB values to decline further.

Under average conditions, values of both NEV and CCB associated with light and moderate irrigations were the largest of all irrigation treatments for all locations due to optimum soil moisture conditions. For the same reason, the NEV and CCB values associated with light and moderate irrigations were about the same. Values of NEV as well as CCB associated with extreme irrigation were lowest for all locations because of excessive irrigation and frequent flooding. The NEV and CCB values associated with heavy irrigation were larger than those with no irrigation due to less water deficit, but smaller than those with light and moderate irrigations due to more waterlogging. For all irrigation treatments, the NEV and CCB values in Vicksburg were larger than those in Tunica and Moorhead whereby values were about the same. The larger values of both NEV and CCB in Vicksburg were mainly due to its larger RZD and higher WHC.

3.4. Planting Date Effect

Both NEV and CCB increased with a delay in planting date until the middle part of the planting window, peaked at 18 April for Vicksburg, 25 April for Moorhead, and 4 May for Tunica, and declined thereafter (

Figure 5). Such responses were due to temperature and solar radiation, both of which increased quickly in the beginning but slowly later in the season (

Figure 1). While the rate of temperature increase affected the rates of plant physiological activities and development, the rate of solar radiation affected the rates of photosynthesis and plant growth. When day temperatures reached above favorable temperature range, crop growth and development rates decreased considerably, causing the NEV and CCB values to fall.

Figure 5.

Planting date effect on: (a) net energy value (NEV) and (b) carbon credit balance (CCB) at three locations in the Mississippi Delta. The largest marker for each location in each panel indicates the largest value of the response variable and the associated optimum planting date. Values connected by dashed lines were not significantly different (p < 0.05) from the largest value for the given location. Planting dates: D1 = 4 March, D2 = 11 March, D3 = 18 March, D4 = 25 March, D5 = 4 April, D6 = 11 April, D7 = 18 April, D8 = 25 April, D9 = 4 May, D10 = 11 May, D11 = 18 May, and D12 = 25 May.

Figure 5.

Planting date effect on: (a) net energy value (NEV) and (b) carbon credit balance (CCB) at three locations in the Mississippi Delta. The largest marker for each location in each panel indicates the largest value of the response variable and the associated optimum planting date. Values connected by dashed lines were not significantly different (p < 0.05) from the largest value for the given location. Planting dates: D1 = 4 March, D2 = 11 March, D3 = 18 March, D4 = 25 March, D5 = 4 April, D6 = 11 April, D7 = 18 April, D8 = 25 April, D9 = 4 May, D10 = 11 May, D11 = 18 May, and D12 = 25 May.

Although the overall response of NEV and CCB each to planting date was the same across locations, values of both NEV and CCB and the optimum planting dates/windows were different. For Moorhead and Tunica, the NEV/CCB values associated with initial planting dates (in March) were about the same because the amount of solar radiation in these locations during this period was also the same (

Figure 1b). During the mid and terminal parts of the planting window, however, the values for Tunica were larger than those for Moorhead due to the difference in solar radiation. Values of NEV/CCB in Vicksburg were the largest of all locations for all planting dates. However, due to decreasing differences in both temperature and solar radiation, the NEV/CCB gaps between Vicksburg and Tunica decreased almost linearly until the planting date reached peak values. Values of temperature and solar radiation in Vicksburg were always larger than those in Tunica throughout the first half of the crop growing season, but with a linear decrease in the gap. During the second half of the season, however, values of solar radiation in Tunica were always larger than those in Vicksburg. The larger values of NEV/CCB in Vicksburg than in Tunica even at the terminal part of the planting window were due to more radiation during initial vegetative phase. The decline in NEV/CCB values thereafter was due to high temperatures.

Due to daily rise in solar radiation and temperature in the northern hemisphere during spring and summer seasons, values of NEV and CCB increased for every delay in planting until an optimum planting date (associated with the highest yield) was reached. The NEV and CCB values associated with planting dates after the optimum date declined due to temperatures too high to optimal plant growth. Because in a particular day or period locations at lower latitudes get warmer earlier, Vicksburg (32.36° N) attained the optimum planting date earlier (18 April) than the other locations. The NEV and CCB values associated with planting dates after 18 April kept declining as daily maximum temperature entered suboptimal zone, thus hampering germination and early crop development. Moorhead (33.45° N) and Tunica (34.68° N) approached the peak values with the planting dates of 25 April and 4 May, respectively, after which they entered the suboptimal temperature zone.

For Vicksburg, the NEV and CCB values associated with planting dates 11 April, 18 April, and 25 April were not significantly different from those associated with 18 April, the optimum planting date, indicating 11–25 April as the optimum planting window for this location (

Figure 5). Similarly, the optimum planting windows for Moorhead and Tunica were found to be the periods of 18 April through 7 May and 25 April through 11 May. With a northward shift in location from Vicksburg to Moorhead to Tunica, the optimum planting window shifted forward by a week.

3.5. Soil Effect

The values of NEV as well as CCB associated with the three soils were different from each other for all locations (

Table 5 and

Figure 4) due to variation in soil properties (

Table 1). The order of difference among the soils, however, was different across locations. While silt loam was the largest producer of stover yields and thus was associated with the largest values of both NEV and CCB for Tunica and Moorhead, sandy loam produced the most and provided the largest values for Vicksburg. Among the three soils, the smallest values of NEV and CCB for Tunica and Moorhead were associated with sandy loam and those for Vicksburg with silt loam. The largest and smallest NEV/CCB values associated with silt loam and sandy loam for Tunica were due to its highest and lowest WHCs, respectively. The largest, intermediate, and smallest NEV/CCB values associated with silt loam, silty clay loam, and sandy loam for Moorhead were due to, respectively, the largest, intermediate, and smallest values of WHC, soil organic carbon content (SOC), and cation exchange capacity (CEC) each. For Vicksburg, sandy loam was associated with the largest NEV/CCB values due to its highest WHC and deepest root zone and silt loam with the smallest values due to its shallowest root zone and relatively lower WHC. Silty clay loam had smaller NEV/CCB values than sandy loam due to its smaller WHC, SOC, and CEC values, but larger NEV/CCB values than silt loam due to its deeper root zone and larger values of SOC and SEC.

The NEV and CCB values associated with sandy loam were different across locations. The sandy loam-related values were largest for Vicksburg due to its highest WHC and deeper root zone and smallest for Moorhead due to its shallowest root zone and smallest CEC and SOC values. The NEV and CCB values in Tunica were intermediate due to its intermediate RZD, WHC, CEC, and SOC values. For silt loam-associated values, no location was different from the others because of similar soil properties. For silty clay loam-related values, only Vicksburg was different due to its highest WHC and deepest root zone. Moorhead and Tunica did not vary from each other because of similar soil properties.

3.6. Interaction Effect

To examine the interaction effects of the four factors, the factor combinations associated with the largest and smallest values of NEV and CCB were chosen out of the total 720 scenarios and analyzed for each location and each of the three weather conditions. Under dry condition, values of both NEV and CCB increased by 121%, 126%, and 257% for Tunica, Vicksburg, and Moorhead, respectively, when moved from the lowest to the highest value scenario (

Table 6). Under wet condition, the increase was 279%, 297%, and 552% for Tunica, Vicksburg, and Moorhead, respectively. Under average weather condition, values of both NEV and CCB increased by 416%, 665%, and 690% for Vicksburg, Moorhead, and Tunica, respectively. For shifts from dry to wet, dry to average, and wet to average conditions, the gaps widened by 2.1 to 2.4, 2.6 to 5.7, and 1.2 to 2.5 folds, respectively, depending on location.

Table 6.

Values of net energy (NEV: GJ·ha−1) and carbon credit balance (CCB: credits·ha−1) under highest and lowest production situations for dry, average, and wet years at three locations.

Table 6.

Values of net energy (NEV: GJ·ha−1) and carbon credit balance (CCB: credits·ha−1) under highest and lowest production situations for dry, average, and wet years at three locations.

| Scenario | Tunica | Moorhead | Vicksburg |

|---|

| Combination | NEV | CCB | Combination | NEV | CCB | Combination | NEV | CCB |

|---|

| Dry year | Lowest | C4-I1-D8-S1 a | 38 | 8 | C4-I5-D1-S1 | 24 | 5 | C4-I5-D12-S3 | 44 | 9 |

| Highest | C2-I5-D5-S1 | 85 | 18 | C2-I5-D10-S2 | 85 | 18 | C1-I3-D2-S3 | 99 | 21 |

| PI b | - | 121 | 121 | - | 257 | 257 | - | 126 | 126 |

| Wet year | Lowest | C4-I3-D3-S1 | 22 | 5 | C4-I5-D5-S1 | 13 | 3 | C4-I5-D3-S2 | 21 | 5 |

| Highest | C2-I5-D13-S1 | 83 | 18 | C2-I4-D12-S2 | 82 | 18 | C1-I1-D8-S3 | 84 | 18 |

| PI | - | 279 | 279 | - | 552 | 552 | - | 297 | 297 |

| Av. year | Lowest | C4-I1-D12-S1 | 12 | 3 | C4-I5-D5-S1 | 13 | 3 | C4-I5-D2-S2 | 21 | 5 |

| Highest | C2-I4-D1-S1 | 97 | 21 | C2-I1-D12-S3 | 96 | 21 | C1-I5-D6-S1 | 108 | 23 |

| PI | - | 690 | 690 | - | 665 | 665 | - | 416 | 416 |

The factor combinations associated with the lowest and highest scenarios under the three weather conditions did not show any specific pattern due to interactions among the factors (

Table 6). For each location, the interaction effects were significant for most of the 2-, 3-, and 4-factor interactions. The insignificant interactions were very few and varied by location due to differences in root zone depth and water holding capacity.

3.7. Travel Distance Effect

The values of NEV and CCB estimated in terms of per Mg stover used for ethanol production and per m

3 ethanol produced for three locations in the Mississippi Delta are presented in

Table 7. The figures in the table show that travel distance has negative influence on NEV

s, NEV

e, CCB

s, and CCB

e. The values of these variables decreased in the order of Vicksburg, Moorhead, and Tunica because the travel distance increased in the same order. Although the NEV/CCB variables decreased with an increase in travel distance, they did not vary significantly across locations due to little contribution of transportation relative to those of the other activities in the biomass supply chain combined (Equations (2) and (4)). The insignificant difference was also because the travel distance difference across locations was not significantly large. Even though the differences were not very significant, the results at least gave an impression that the energy and emission costs of stover-based ethanol production would increase with an increase in travel distance.

Table 7.

Net energy value (NEV) and carbon credit balance (CCB) as influenced by travel distance for three locations in the Mississippi Delta.

Table 7.

Net energy value (NEV) and carbon credit balance (CCB) as influenced by travel distance for three locations in the Mississippi Delta.

| Variable a | Unit | Location |

|---|

| Vicksburg | Moorhead | Tunica |

|---|

| Travel distance (D) | km | 90 | 145 | 160 |

| NEV | NEVs | GJ·Mg−1 | 6.29 | 6.19 | 6.17 |

| NEVe | GJ·m−3 | 20.96 | 20.65 | 20.56 |

| CCB | CCBs | credits·Mg−1 | 1.397 | 1.390 | 1.388 |

| CCBe | credits·m−3 | 4.656 | 4.632 | 4.625 |

4. Discussion

This study demonstrated that different soils in combination with different cultivars, planting dates, and irrigation amounts change the NEV and CCB of maize stover-based ethanol production. This study is different from the previous ones that examined biofuel production systems, such as Shapouri

et al. [

23], Kim and Dale [

59], Hill

et al. [

70], and Pradhan

et al. [

71], in that not only did it analyze ethanol production from NEV and CCB perspectives but also explicitly accounted for the effects of variability in cultivar, irrigation level, planting date, and soil type using a modeling approach.

This study showed that cultivar can significantly affect the NEV and CCB of stover-based ethanol production for the Mississippi Delta, which is in agreement with the results of Persson

et al. [

30] and Woli

et al. [

20]. Persson

et al. [

30] compared three maize hybrids in Georgia and found NEV to be significantly different across cultivars. Woli

et al. [

20] demonstrated that the CCB and NEV of switchgrass-based ethanol production systems in Mississippi could be increased with alternative soil and cultivar options.

As this study showed, variation in irrigation levels could significantly change the values of NEV and CCB. Persson

et al. [

22,

32] also found similar results for the NEV associated with maize grain-based ethanol production for Georgia. The positive effects of irrigation on NEV and CCB were due to increased stover yields. Woli and Paz [

21] found that the sustainability and eco-friendliness of ethanol production associated with maize-stover and switchgrass would increase with an increase in yield level and utilization rate. Under all the three weather conditions, extreme irrigation produced the lowest yields and thus the smallest values of NEV and CCB, and light and moderate irrigations produced the largest values. Under dry conditions, light, moderate, and heavy irrigations produced the largest values of NEV and CCB. Under wet conditions, however, no effect of irrigation on these variables was found, except for extreme irrigation. The differences in NEV and CCB among irrigation treatments, however, are valid under the assumption that the energy and emissions costs of irrigation are applied to grain, not stover, a by-product of grain production.

This study also demonstrated that planting date has significant effects on NEV and CCB, and that these variables can be maximized by planting the crop during the optimum planting window of 11–25 April for Vicksburg, 18 April through 7 May for Moorhead, and 25 April through 11 May for Tunica. Persson

et al. [

22] also found that delayed planting increased maize yields, but the differences among the three planting dates they compared (3, 17, and 31 March) were not large. The optimum planting windows estimated in our study did not match with those suggested by the Mississippi State University Extension Service: 5 March through 10 April for Vicksburg, 15 March through 20 April for Moorhead, and 20 March through 25 April for Tunica [

36]. The suggested windows are based on maintaining soil temperature at 10–13 °C at the beginning of planting season, avoiding the outbreak of insects and diseases later in the season through early crop development, and avoiding water and temperature stresses during peak growing period, which generally occurs in July and August if planted late. These suggestions are for all years and all cultivars in general. Our estimates, on the other hand, are based on weather-specific simulations. Moreover, the MSUES-suggested dates are for typical cultivars, whereas our estimated dates are based on new hybrids. In southeastern USA, maize can be planted from late February through early July, and summer rainfall is often more favorable for the crop planted from mid-May to mid-June [

37]. Maize hybrids that are being developed from tropical germplasm are adapted to the summer rainfall pattern in this region [

72]. However, planting is generally terminated by early May due to severe insect pressure later in the season [

37]. Because our study represented only standard production conditions (no occurrence of pest and disease assumed), the estimated optimum planting windows were defined mainly by genotype and weather variables. Thus, these estimates are mainly applicable to standard production conditions. Because planting date is a function of cultivar (genotype) and new cultivars evolve every year, determining the optimum planting date for every new cultivar through research is necessary. Our estimates may be taken as a starting point for new hybrids.

The results of this study indicated that soils with deeper root zones and larger values of WHC, CEC, and SOC can produce larger values of NEV and CCB. Persson

et al. [

32] also observed that larger values of NEV were associated with soils with higher WHC.

The NEV and CCB values were found to increase with an increase in stover yield, but to decrease with an increase in travel distance. However, the influence of stover yield on NEV and CCB was found to have been far more than that of travel distance because the latter affected only transportation costs, whereas the former affected the costs of all activities in the feedstock supply chain [

24]. The ratio of CO

2 emitted to CO

2 fixed was 0.071 for Vicksburg, 0.076 for Moorhead, and 0.077 for Tunica. That is, the overall ratio of CO

2 emitted to stover yield in the Mississippi Delta was about 0.0001. These results indicated that increasing feedstock yields should get more emphasis [

73] relative to decreasing travel distance or decreasing the emissions from feedstock transportation although both are important. Macedo

et al. [

74] also found similar results for sugarcane-based ethanol production systems in Brazil.

This study showed, in terms of NEV and CCB, respectively, that the sustainability and eco-friendliness of maize stover-based ethanol production in the Mississippi Delta could be increased with alternative cultivar, irrigation, and planting date options. The location-specific information on the responses of NEV and CCB to these options might be helpful to maize stover producers and biorefineries in this region in promoting the sustainability (in terms of non-renewable energy displacement) and eco-friendliness (in terms of carbon emissions reduction) of ethanol production. Farming practices increasing NEV and CCB might be promoted through various measures, policies, and programs such as consumer awareness [

75], government support [

76,

77,

78], and personal carbon trading [

79,

80].

The factors and variables considered in this study represented only simplified conditions. For simplicity, other crop management variables such as fertilization, plant protection, and tillage were assumed to be fixed and in standard conditions. For instance, soils were assumed to be fertile, and crops were assumed to be well protected from pests and diseases. In reality, however, these conditions might vary over time and space. Removing stover from the production field might promote soil erosion, deplete soil carbon, and reduce the return of nutrients to the soil. For the ethanol production system considered in this study, the removal rate that would keep soil erosion within tolerable soil-loss limit and would also not let soil carbon level deplete was assumed to be 40% [

60]. This removal rate, however, applies only to a region having nearly level ground and continuous maize production with mulch-till system. For the other regions that are different from the one considered in this study, this removal rate might promote soil erosion and carbon depletion. For the other systems, therefore, this removal rate may not be applicable. The stover removal rate even with tolerable soil-loss limit removes some nutrients from the soil. In this study, however, the nutrient replacement cost was not considered for stover, a by-product of maize grain production. If stover production also is an objective of growing maize, the nutrient replacement cost must be considered for stover. Assuming stover as a free material (by-product), the energy use and CO

2 emissions associated with stover production for producing or applying various inputs were not included in analyses [

66]. In the systems that do not consider stover a free material, however, the energy used and CO

2 emitted during input production and application must also be accounted for. The optimum planting dates or windows determined for the three locations were based on average yields of 30 years, that is, 30 replications. For other replication numbers, the results could be different because of annual climate variability. The optimum planting dates might fluctuate more with fewer replications, but could be more robust with more replications. In our study, the weather data of the 1971–2000 normal period was used, considering the three-decade interval as long enough to filter out many of the short-term inter-annual fluctuations and anomalies and short enough to reflect long-term climatic trends [

81]. Our study computed CCB only for the production side of ethanol, that is, for supplying a given quantity of stover to a biorefinery and processing it. The CO

2 emissions associated with distribution and combustion of ethanol were beyond the scope of this study.

This work may be regarded as an example of studying the effects of soil, cultivar, and management on the NEV and CCB of ethanol from crop residues and other lignocellulosic resources. The effects of these variables on other feedstocks may be studied applying the methodology used in this study. To provide a broader perspective of soil, cultivar, and management effects on greenhouse gas (GHG) emissions, additional GHGs such as methane and nitrous oxide may be considered [

60]. The approach of our study might be expanded to other maize production areas of Mississippi or other maize growing states such as the Corn Belt. This study considered travel distance as fixed assuming the production area as small. As travel distance is influenced by several factors such as crop yield, production area, and refinery capacity [

82], computing NEV and CCB as a function of varying travel distance may be a consideration for a future study. The objective of this study was to identify the agronomic conditions—the combinations of cultivar, irrigation, planting date, and soil—that would maximize the NEV and CCB of the ethanol production systems under the contemporary set of farm and refinery technologies, so a fixed set of energy and emission values were used in this study. If the objective were also to identify the engineering conditions—the combinations of various harvesting, baling, transportation, and processing technologies—the energy and emission constants would be parameters and thus have ranges of values. This study did not include the engineering aspects considering agricultural community using the contemporary set of technologies as the principal target audience; identifying engineering conditions that would maximize the NEV and CCB values, however, can be a potential subject matter for a separate future study targeted for a broader audience.