Study on Heat and Mass Transfer Performance during Heating, Pressurization and Expansion Stage in Explosion Puffing at Low Temperature and High-Pressure

Abstract

:1. Introduction

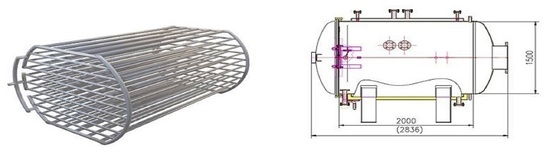

2. Brief Introduction to the Explosion-Puffing Technology at Low Temperature and High Pressure for Semi-Dried Apple Products

3. Construction of Theoretical Model of Technology on Heating Explosion Puffing at High Pressure

3.1. Theoretical Model of Heating and Pressure-Drying Stage

3.1.1. Heat Transfer Model from Heat Source to Air in Tank

3.1.2. Model of Heat Transfer from Air to Dried in Pot

3.1.3. Dried Fruit Temperature

3.1.4. Mass Transfer Model of Dried Fruit Drying

3.2. Theoretical Model of Expansion Stage

3.2.1. Instantaneous Expansion Drying Model

3.2.2. Model of Puffing Drying

3.3. Mass Transfer Equation

4. Analysis of Heat and Mass Transfer Performance

4.1. Analysis of Heat and Mass Transfer Performance at High-Pressure Heating Stage

4.1.1. Effect of Temperature in Tank on Heat and Mass Transfer Performance

4.1.2. Effect of Tank Pressure on Heat and Mass Transfer Performance

4.1.3. Effect of Running Time on Heat and Mass Transfer Performance

4.2. Analysis of Heat and Mass Transfer Performance in Expansion

5. Conclusions

- Increasing the temperature in the tank can develop the heat transfer performance and water evaporation rate of dried fruit and reduce the water content of dried fruit; however, the heat transfer performance of the heat source decreases and the heating time of the heat source increases.

- The pressure change in the tank has little effect on the mass transfer performance. When the pressure is reduced, the drying performance of dried fruit will be slightly increased. When the pressure decreases by 0.04 MPa, the water content of dried fruit decreases by only 0.06%.

- The moisture content of dried fruit decreases by 0.475% when the operation time is prolonged for 1 min.

- The precipitation water in expansion mainly comes from the instant expansion stage; the increase in temperature in the tank during the heating and pressurization stage has the greatest impact on the moisture content of the expanded dried fruit, followed by the operation time. The change in pressure in the tank has little impact on the moisture content of the expanded dried fruit.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol Table | |||||

| Symbol | Significance | Company | Symbol | Significance | Company |

| Subscript | Saturated steam enthalpy | kJ/kg | |||

| 0 | Before heating and pressurization | Heat transfer coefficient of expansion tank jacket | W/(m2·K) | ||

| 1 | After heating and pressurization/before instant expansion | Characteristic length | m | ||

| 2 | After instant expansion/before evacuation expansion | Mass | kg | ||

| 3 | After evacuation and expansion | Mass flux density | kg/(m2·s) | ||

| Air in tank | Pressure | MPa | |||

| Air moisture in tank | Heat transfer efficiency | W | |||

| Dried fruit | Latent heat of steam condensation | kJ/kg | |||

| Lower surface of dried fruit | Temperature | °C | |||

| Upper surface of dried fruit | System temperature | K | |||

| Dried fruit moisture | System thermodynamic energy | kJ | |||

| Dried fruit solid | Time | s | |||

| Heat source | Thermal conductivity | W/(m·K) | |||

| Expansion tank and jacket | Thickness | m | |||

| Expansion tank jacket | Density | kg/m3 | |||

| Condensate | Dynamic viscosity | Pa·s | |||

| Water content | Kinematic viscosity of air | m2/s | |||

| Text symbols | Nusselt number | ||||

| Moisture content | % | Prandtl number | |||

| Mass transfer distance | m | Grashof number | |||

| Heat transfer area | m2 | ||||

| Specific heat capacity | J/(kg·K) | ||||

| concentration | mol/m3 | ||||

| Jacket diameter | m | ||||

| Mass diffusion concentration | m2/s | ||||

| Convective heat transfer coefficient | W/(m2·K) | ||||

| Saturated water enthalpy | kJ/kg | ||||

References

- Li, H.; Fan, X. On the development of domestic fruit and vegetable industry. Priv. Sci. Technol. 2011, 10, 195. [Google Scholar]

- Yang, S. Current situation and development strategy of China’s fruit and vegetable processing industry. J. Chin. Inst. Food Sci. Tecnol. 2010, 10, 1–9. [Google Scholar]

- Xu, Y.; Xu, X.; Yuan, Y.; Wang, D.; Yuan, Y. Pore network study of heat and mass transter process for drying of fruit and vegetable porous media. J. Shaanxi Univ. Sci. Technol. 2017, 35, 135–139. [Google Scholar]

- Guo, X. Study on Dehydration and Expansion Key Technology of Fruites and Vegetables and Plant Design; Nanjing Agricultural University: Nanjing, China, 2015. [Google Scholar]

- Sun, F.; Jiang, S. Present situation and development of fruit and vegetable drying processing technologies in China. Cereal Food Ind. 2016, 23, 11–15. [Google Scholar]

- Liu, J.; Zhao, Y.; Shi, Q. Research Progress and Future Prospects of NovelPretreatment Technologies for the Drying of Fruits and Vegetables and Aquatic Products. Sci. Technol. Food Ind. 2022, 43, 32–42. [Google Scholar]

- Cheng, L. Study on the Expansion Drying and Storage Characteristics of Fruit Slices with Variable Temperature and Pressure Difference; Anhui Agricultural University: Hefei, China, 2012. [Google Scholar]

- Nadi, F.; Rahimi, G.H.; Younsi, R. Numerical Simulation of Vacuum Drying by Luikov’s Equations. Dry. Technol. Int. J. 2012, 30, 197–206. [Google Scholar] [CrossRef]

- Aprajeeta, J.; Gopirajah, R.; Anandharamakrishnan, C. Shrinkage and porosity effects on heat and mass transfer during potato drying. J. Food Eng. 2015, 144, 119–128. [Google Scholar] [CrossRef]

- Ma, L.; Bi, J.; Wei, Y. Study on influencing factors of apple puffing under low temperature and high pressure. Sci. Technol. Food Ind. 2005, 26, 88–90. [Google Scholar]

- Song, Y.; Chen, H.; Yuan, Y. Optimization of CO2-Low Temperature High Pressure Permeation Drying Process of Kiwifruit. Food Sci. 2020, 41, 229–234. [Google Scholar]

- Zhu, K.; Chen, H.; Dou, D.; Li, J. Energy analysis and improved conservation on the low-temperature and high-pressure explosion puffing equipment. China Acad. J. Electron. Publ. House 2011, 27, 137–141. [Google Scholar]

- Zhu, K.; Chen, H.; Dou, D.; Li, J. Mechanism analysis on the water transfer during the process of differential pressure explosion puffing for fruits and vegetables. Sci. Technol. Food Ind. 2012, 33, 83–85. [Google Scholar]

- Hu, Y. On Design of a New Type of Puffing and Drying Equipment for Fruits and Vegetables; Shaanxi University of Science & Technology: Xi’an, China, 2014. [Google Scholar]

- Hou, L.; Zhou, X.; Wang, S. Numerical analysis of heat and mass transfer in kiwifruit slices during combined radio frequency and vacuum drying. Int. J. Heat Mass Transf. 2020, 154, 119704. [Google Scholar] [CrossRef]

- Xu, F.; Li, C.; Chen, Z. Computer Simulation of Temperature Characteristics in the Process of Vacuum and Selective FIR Drying for Litchi. In Proceedings of the 2009 Second International Symposia on Intelligent Information Technology and Security Informatics, Moscow, Russia, 23–25 January 2009; pp. 34–38. [Google Scholar]

- Popiel, C.O.; Boguslawski, L. Heat transfer by laminar condensation on sphere surfaces. Int. J. Heat Mass Transf. 1979, 18, 1486–1488. [Google Scholar] [CrossRef]

- Yang, L. Experimental Study on Condensation Heat Transfer of Shell and Tube Heat Exchange; Nanjing Tech University: Nanjing, China, 2015. [Google Scholar]

- Yang, S.M. Improvement of the basic correlating equations and transition criteria of natural convection heat transfer. Heat Transf. —Asian Res. 2001, 30, 293–299. [Google Scholar] [CrossRef]

- Bejan, A.; Lage, J.L. The Prandtl number effect on the transition criteria of natural convection along a vertical surface. J. Heat Transfer. 1990, 112, 787–790. [Google Scholar] [CrossRef]

- Chamber, B.; Lee, T.Y.T. A numerical study of local and average natural convection Nusselt numbers for simultaneously convection above and below a uniformly heated horizontal thin plates. J. Heat Transfer. 1997, 119, 102–108. [Google Scholar] [CrossRef]

- Hines, A.L.; Maddox, R.N. Mass Transfer: Fundamentals and Applications; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1985; pp. 178–192. [Google Scholar]

| High- pressure heating phase | Influential factor | Reference value of process parameters | Change value of process parameters |

| Temperature in tank, °C | 100 | 90, 95, 100, 105, 110 | |

| Pressure in tank, MPa | 0.4 | 0.35, 0.375, 0.4, 0.425, 0.45 | |

| Running time, min | 10 | 9, 9.5, 10, 10.5, 11 | |

| Expansion stage | Instantaneous expansion pressure, Mpa | −0.078 | / |

| Evacuation and expansion pressure, Mpa | −0.098 | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruan, S.; Su, L.; Ou, H.; Lin, W.; Jiang, S.; Sun, F. Study on Heat and Mass Transfer Performance during Heating, Pressurization and Expansion Stage in Explosion Puffing at Low Temperature and High-Pressure. Energies 2022, 15, 7896. https://doi.org/10.3390/en15217896

Ruan S, Su L, Ou H, Lin W, Jiang S, Sun F. Study on Heat and Mass Transfer Performance during Heating, Pressurization and Expansion Stage in Explosion Puffing at Low Temperature and High-Pressure. Energies. 2022; 15(21):7896. https://doi.org/10.3390/en15217896

Chicago/Turabian StyleRuan, Shijie, Lei Su, Haoyu Ou, Wei Lin, Shuiquan Jiang, and Fang Sun. 2022. "Study on Heat and Mass Transfer Performance during Heating, Pressurization and Expansion Stage in Explosion Puffing at Low Temperature and High-Pressure" Energies 15, no. 21: 7896. https://doi.org/10.3390/en15217896