Experimental Investigation and RSM Modeling of the Effects of Injection Timing on the Performance and NOx Emissions of a Micro-Cogeneration Unit Fueled with Biodiesel Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Engine Test Bench and Measurement System

2.2. Fuels

2.3. Tests Methodology

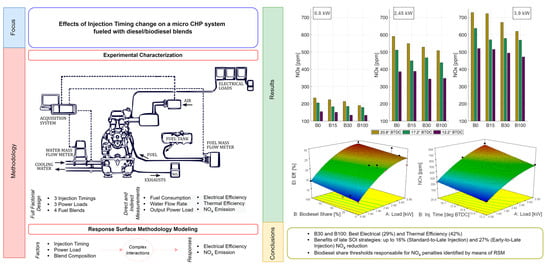

- The biodiesel percentage in the blends (four cases): 0, 15, 30, and 100% (i.e., the values are corresponding to the tested fuel types: B0, B15, B30, and B100).

- The power load (the three load conditions in terms of connected electric power): based on the generator output maximum power, the full load (3.90 kW), the partial load (2.45 kW), and the low load (0.90 kW) were set as reference test conditions by connecting different sets of resistors (used as power-dissipation units) to the electrical generator of the genset.

- Injection timing/SOI (three cases): based on the manufacturer’s technical indications, the standard injection timing has been defined as beginning at 17.2° before the top dead center (BTDC). Two other configurations were set by properly adjusting the number of shims in the injection pump: a late injection (timing), starting at 12.2° BTDC, and an early injection (timing), starting at 20.8° BTDC.

2.4. Response Surface Modeling

3. Results

3.1. Electrical Efficiency

3.2. NOx Emissions

4. Conclusions

- The electrical and thermal characterization of the micro-cogeneration system has demonstrated an overall improvement of the engine performance due to the biodiesel presence in the fuel blend. In particular, at full load, the peak value in electrical efficiency (29%) was observed with B30 and B100. Similar results have been obtained in terms of thermal efficiency, where B30 and B100 performed the best (42% of thermal efficiency). The combustion enhancements related to the use of an oxygenated fuel, such as biodiesel, mainly addressed this behavior and are confirmed by the recent scientific literature. A saturation threshold for the biodiesel share above 30% was identified. All this evidence were also confirmed by the RSM analysis, whose results show that the electrical efficiency is affected more by the variation of the electrical load (about +15%) than the biodiesel share (about +2.7%).

- The effect of the injection timing on NOx emissions was experimentally quantified in an overall emissions reduction of 27% on average when an early-to-late injection strategy was applied, and of 16% for a standard-to-late injection strategy. The beneficial effect of a late injection strategy on NOx emissions appears to have been homogeneously distributed among all output power conditions. Such findings can be explained according to the Thermal-NOx formation mechanism: by delaying the fuel injection, the in-cylinder combustion temperatures are reduced, and so the NOx emissions are lowered.

- As a result of the experimental campaign, it has emerged how the NOx-reduction capabilities of the late injection strategy decrease with higher biodiesel substitution rates, suggesting the further investigation of the biodiesel share saturation threshold. An extensive RSM analysis led to the formulation of two different regression models, both characterized by high predictive capabilities (R2 > 0.990). The main outcomes show (i) how the biodiesel share promotes an increase of NOx whenever it overcomes a set threshold that is proportional to the engine load (from about 66.5% to 85.7% of biodiesel share) and (ii) how reducing the values of the SOI leads to lower NOx emissions from about 10 ppm to 23 ppm per degree of the advance of the SOI, and this effect linearly increases with the engine load. The overall potential of the early-to-late injection strategy in terms of NOx emission reduction ranges from 3.2% (higher loads) to 7.5% (lower loads).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dabi, M.; Saha, U.K. Application Potential of Vegetable Oils as Alternative to Diesel Fuels in Compression Ignition Engines: A Review. J. Energy Inst. 2019, 92, 1710–1726. [Google Scholar] [CrossRef]

- Mwangi, J.K.; Lee, W.-J.; Chang, Y.-C.; Chen, C.-Y.; Wang, L.-C. An Overview: Energy Saving and Pollution Reduction by Using Green Fuel Blends in Diesel Engines. Appl. Energy 2015, 159, 214–236. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Jamil, M.A.; Gulzar, M. Potential of Tire Pyrolysis Oil as an Alternate Fuel for Diesel Engines: A Review. J. Energy Inst. 2021, 96, 205–221. [Google Scholar] [CrossRef]

- Vakalis, S.; Caligiuri, C.; Moustakas, K.; Malamis, D.; Renzi, M.; Baratieri, M. Modeling the Emissions of a Dual Fuel Engine Coupled with a Biomass Gasifier—Supplementing the Wiebe Function. Environ. Sci. Pollut. Res. 2018, 25, 35866–35873. [Google Scholar] [CrossRef]

- Mohamed Shameer, P.; Ramesh, K.; Sakthivel, R.; Purnachandran, R. Effects of Fuel Injection Parameters on Emission Characteristics of Diesel Engines Operating on Various Biodiesel: A Review. Sustain. Energy Rev. 2017, 67, 1267–1281. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Nallusamy, N.; Rajkumar, S. A Comprehensive Review on Performance, Combustion and Emission Characteristics of Biodiesel Fuelled Diesel Engines. Renew. Sustain. Energy Rev. 2017, 79, 1134–1159. [Google Scholar] [CrossRef]

- Dimitriou, P.; Tsujimura, T.; Suzuki, Y. Adopting Biodiesel as an Indirect Way to Reduce the NOx Emission of a Hydrogen Fumigated Dual-Fuel Engine. Fuel 2019, 244, 324–334. [Google Scholar] [CrossRef]

- Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Mohamed Shameer, P. A Review on the Properties, Performance and Emission Aspects of the Third Generation Biodiesels. Renew. Sustain. Energy Rev. 2018, 82, 2970–2992. [Google Scholar] [CrossRef]

- Mirhashemi, F.S.; Sadrnia, H. NOx Emissions of Compression Ignition Engines Fueled with Various Biodiesel Blends: A Review. J. Energy Inst. 2020, 93, 129–151. [Google Scholar] [CrossRef]

- Bär, F.; Hopf, H.; Knorr, M.; Schröder, O.; Krahl, J. Effect of Hydrazides as Fuel Additives for Biodiesel and Biodiesel Blends on NOx Formation. Fuel 2016, 180, 278–283. [Google Scholar] [CrossRef]

- Mehregan, M.; Moghiman, M. Experimental Investigation of the Distinct Effects of Nanoparticles Addition and Urea-SCR after-Treatment System on NOx Emissions in a Blended-Biodiesel Fueled Internal Combustion Engine. Fuel 2020, 262, 116609. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P.; Perrone, D.; Bova, S.; Castiglione, T. Analysis of Multi-Source Energy System for Small-Scale Domestic Applications. Integration of Biodiesel, Solar and Wind Energy. Energy Rep. 2020, 6, 652–659. [Google Scholar] [CrossRef]

- Perrone, D.; Algieri, A.; Morrone, P.; Castiglione, T. Energy and Economic Investigation of a Biodiesel-Fired Engine for Micro-Scale Cogeneration. Energies 2021, 14, 496. [Google Scholar] [CrossRef]

- Falbo, L.; Perrone, D.; Morrone, P.; Algieri, A. Integration of Biodiesel Internal Combustion Engines and Transcritical Organic Rankine Cycles for Waste-heat Recovery in Small-scale Applications. Int. J. Energy Res. 2022, 46, 5235–5249. [Google Scholar] [CrossRef]

- Thangaraja, J.; Anand, K.; Mehta, P.S. Biodiesel NOx Penalty and Control Measures—A Review. Renew. Sustain. Energy Rev. 2016, 61, 1–24. [Google Scholar] [CrossRef]

- Speight, J.G.; Loyalka, S.K. Handbook of Alternative Fuel; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Singh, Y.; Sharma, A.; Tiwari, S.; Singla, A. Optimization of Diesel Engine Performance and Emission Parameters Employing Cassia Tora Methyl Esters-Response Surface Methodology Approach. Energy 2019, 168, 909–918. [Google Scholar] [CrossRef]

- Alptekin, E. Emission, Injection and Combustion Characteristics of Biodiesel and Oxygenated Fuel Blends in a Common Rail Diesel Engine. Energy 2017, 119, 44–52. [Google Scholar] [CrossRef]

- Bietresato, M.; Caligiuri, C.; Renzi, M.; Mazzetto, F. Use of Diesel-Biodiesel-Bioethanol Blends in Farm Tractors: First Results Obtained with a Mixed Experimental-Numerical Approach. Energy Procedia 2019, 158, 965–971. [Google Scholar] [CrossRef]

- Chen, H.; Guo, Q.; Zhao, X.; Xu, M.; Ma, Y. Influence of Fuel Temperature on Combustion and Emission of Biodiesel. J. Energy Inst. 2016, 89, 231–239. [Google Scholar] [CrossRef]

- Bietresato, M.; Bolla, A.; Caligiuri, C.; Renzi, M.; Mazzetto, F. The Kinematic Viscosity of Conventional and Bio-Based Fuel Blends as a Key Parameter to Indirectly Estimate the Performance of Compression-Ignition Engines for Agricultural Purposes. Fuel 2021, 298, 120817. [Google Scholar] [CrossRef]

- Caresana, F. Impact of Biodiesel Bulk Modulus on Injection Pressure and Injection Timing. The Effect of Residual Pressure. Fuel 2011, 90, 477–485. [Google Scholar] [CrossRef]

- Caresana, F.; Bietresato, M.; Renzi, M. Injection and Combustion Analysis of Pure Rapeseed Oil Methyl Ester (RME) in a Pump-Line-Nozzle Fuel Injection System. Energies 2021, 14, 7535. [Google Scholar] [CrossRef]

- Adi, G.; Hall, C.; Snyder, D.; Bunce, M.; Satkoski, C.; Kumar, S.; Garimella, P.; Stanton, D.; Shaver, G. Soy-Biodiesel Impact on NO x Emissions and Fuel Economy for Diffusion-Dominated Combustion in a Turbo−Diesel Engine Incorporating Exhaust Gas Recirculation and Common Rail Fuel Injection. Energy Fuels 2009, 23, 5821–5829. [Google Scholar] [CrossRef]

- Liu, Z.-W.; Li, F.-S.; Wang, W.; Wang, B. Impact of Different Levels of Biodiesel Oxidation on Its Emission Characteristics. J. Energy Inst. 2019, 92, 861–870. [Google Scholar] [CrossRef]

- Graboski, M.S.; McCormick, R.L. Combustion of Fat and Vegetable Oil Derived Fuels in Diesel Engines. Prog. Energy Combust. Sci. 1998, 24, 125–164. [Google Scholar] [CrossRef]

- Özçelik, A.E.; Aydoğan, H.; Acaroğlu, M. Determining the Performance, Emission and Combustion Properties of Camelina Biodiesel Blends. Energy Convers. Manag. 2015, 96, 47–57. [Google Scholar] [CrossRef]

- Mikulski, M.; Duda, K.; Wierzbicki, S. Performance and Emissions of a CRDI Diesel Engine Fuelled with Swine Lard Methyl Esters-Diesel Mixture. Fuel 2016, 164, 206–219. [Google Scholar] [CrossRef]

- Huzayyin, A.S.; Bawady, A.H.; Rady, M.A.; Dawood, A. Experimental Evaluation of Diesel Engine Performance and Emission Using Blends of Jojoba Oil and Diesel Fuel. Energy Convers. Manag. 2004, 45, 2093–2112. [Google Scholar] [CrossRef]

- Caligiuri, C.; Renzi, M.; Bietresato, M.; Baratieri, M. Experimental Investigation on the Effects of Bioethanol Addition in Diesel-Biodiesel Blends on Emissions and Performances of a Micro-Cogeneration System. Energy Convers. Manag. 2019, 185, 55–65. [Google Scholar] [CrossRef]

- Alloune, R.; Balistrou, M.; Awad, S.; Loubar, K.; Tazerout, M. Performance, Combustion and Exhaust Emissions Characteristics Investigation Using Citrullus Colocynthis L. Biodiesel in DI Diesel Engine. J. Energy Inst. 2018, 91, 434–444. [Google Scholar] [CrossRef]

- Khalife, E.; Tabatabaei, M.; Demirbas, A.; Aghbashlo, M. Impacts of Additives on Performance and Emission Characteristics of Diesel Engines during Steady State Operation. Prog. Energy Combust. Sci. 2017, 59, 32–78. [Google Scholar] [CrossRef]

- Bietresato, M.; Caligiuri, C.; Bolla, A.; Renzi, M.; Mazzetto, F. Proposal of a Predictive Mixed Experimental-Numerical Approach for Assessing the Performance of Farm Tractor Engines Fuelled with Diesel-Biodiesel-Bioethanol Blends. Energies 2019, 12, 2287. [Google Scholar] [CrossRef] [Green Version]

- Shameer, P.M.; Ramesh, K. Assessment on the Consequences of Injection Timing and Injection Pressure on Combustion Characteristics of Sustainable Biodiesel Fuelled Engine. Renew. Sustain. Energy Rev. 2018, 81, 45–61. [Google Scholar] [CrossRef]

- Ganapathy, T.; Gakkhar, R.P.; Murugesan, K. Influence of Injection Timing on Performance, Combustion and Emission Characteristics of Jatropha Biodiesel Engine. Appl. Energy 2011, 88, 4376–4386. [Google Scholar] [CrossRef]

- Sharma, A.; Murugan, S. Combustion, Performance and Emission Characteristics of a Di Diesel Engine Fuelled with Non-Petroleum Fuel: A Study on the Role of Fuel Injection Timing. J. Energy Inst. 2015, 88, 364–375. [Google Scholar] [CrossRef]

- Dwivedi, G.; Sharma, M.P. Experimental Investigation on Thermal Stability of Pongamia Biodiesel by Thermogravimetric Analysis. Egypt. J. Pet. 2016, 25, 33–38. [Google Scholar] [CrossRef] [Green Version]

- Ecofox—Advanced Biofuels Producers & Traders (Vasto, CH—Italy). Available online: https://www.ecofox.eu/en/ (accessed on 1 March 2022).

- Maheshwari, N.; Balaji, C.; Ramesh, A. A Nonlinear Regression Based Multi-Objective Optimization of Parameters Based on Experimental Data from an IC Engine Fueled with Biodiesel Blends. Biomass Bioenergy 2011, 35, 2171–2183. [Google Scholar] [CrossRef]

- Bietresato, M.; Caligiuri, C.; Bolla, A.; Renzi, M.; Mazzetto, F. The Response Surface Methodology as a Tool to Evaluate the Effects of Using Diesel-Biodiesel-Bioethanol Blends as Farm Tractor Fuel. In International Mid-Term Conference of the Italian Association of Agricultural Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 539–549. [Google Scholar]

- Caligiuri, C.; Bietresato, M.; Renzi, M. The Effect of Using Diesel-Biodiesel-Bioethanol Blends on the Fuel Feed Pump of a Small-Scale Internal Combustion Engine. Energy Procedia 2019, 158, 953–958. [Google Scholar] [CrossRef]

- Nghia, N.T.; Khoa, N.X.; Cho, W.; Lim, O. A Study the Effect of Biodiesel Blends and the Injection Timing on Performance and Emissions of Common Rail Diesel Engines. Energies 2022, 15, 242. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; Volume 2, ISBN 9781118146927. [Google Scholar]

- Stat-Ease. StatEase—Statistics Made Easy, Guided Manual; Stat-Ease: Minneapolis, MN, USA, 2021. [Google Scholar]

- Arya, M.; Kumar Rout, A.; Samanta, S. A Review on the Effect of Engine Performance and Emission Characteristics of C.I. Engine Using Diesel-Biodiesel-Additives Fuel Blend. Mater. Today Proc. 2022, 51, 2224–2232. [Google Scholar] [CrossRef]

- Rai, V.R.; Shringi, D.; Mathur, Y.B. Performance Evaluation of Diesel-Jatropha Biodiesel-Methanol Blends in CI Engine. Mater. Today Proc. 2022, 51, 1561–1567. [Google Scholar] [CrossRef]

- Thaiyasuit, P.; Pianthong, K.; Milton, B. Combustion Efficiency and Performance of RSO Biodiesel as Alternative Fuel in a Single Cylinder CI Engine. Energy Explor. Exploit. 2012, 30, 153–166. [Google Scholar] [CrossRef] [Green Version]

- Lešnik, L.; Iljaž, J.; Hribernik, A.; Kegl, B. Numerical and Experimental Study of Combustion, Performance and Emission Characteristics of a Heavy-Duty Di Diesel Engine Running on Diesel, Biodiesel and Their Blends. Energy Convers. Manag. 2014, 81, 534–546. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H. Influence of Injection Timing and Split Injection Strategies on Performance, Emissions, and Combustion Characteristics of Diesel Engine Fueled with Biodiesel Blended Fuels. Fuel 2018, 213, 106–114. [Google Scholar] [CrossRef]

- Machacon, H. The Effect of Coconut Oil and Diesel Fuel Blends on Diesel Engine Performance and Exhaust Emissions. JSAE Rev. 2001, 22, 349–355. [Google Scholar] [CrossRef]

- Rajesh, S.; Kulkarni, B.M.; Banapurmath, N.R.; Kumarappa, S. Effect of Injection Parameters on Performance and Emission Characteristics of a CRDi Diesel Engine Fuelled with Acid Oil Biodiesel–Ethanol Blended Fuels. Biofuels 2018, 9, 353–367. [Google Scholar] [CrossRef]

- Hulwan, D.B.; Joshi, S.V. Performance, Emission and Combustion Characteristic of a Multicylinder DI Diesel Engine Running on Diesel–Ethanol–Biodiesel Blends of High Ethanol Content. Appl. Energy 2011, 88, 5042–5055. [Google Scholar] [CrossRef]

- Fang, Q.; Fang, J.; Zhuang, J.; Huang, Z. Effects of Ethanol–Diesel–Biodiesel Blends on Combustion and Emissions in Premixed Low Temperature Combustion. Appl. Therm. Eng. 2013, 54, 541–548. [Google Scholar] [CrossRef]

- Subramani, S.; Govindasamy, R.; Rao, G.L.N. Predictive Correlations for NOx and Smoke Emission of DI CI Engine Fuelled with Diesel-Biodiesel-Higher Alcohol Blends-Response Surface Methodology Approach. Fuel 2020, 269, 117304. [Google Scholar] [CrossRef]

| Technical Characteristic | Unit | Value |

|---|---|---|

| Engine type | - | Compression-ignition |

| Fuel injection system | - | Mechanical, governor-controlled |

| Nr. of cylinders | - | 1 |

| Valves per cylinder | - | 2 |

| Displacement | cm3 | 290 |

| Bore, stroke | mm, mm | 75, 55 |

| Connecting rod | mm | 102.96 |

| Compression ratio | - | 20:1 |

| Nominal injection pressure | bar | 200 |

| Nominal electric power (at 3000 rpm) | kW | 3.90 |

| Maximum rotational speed | rpm | 3600 |

| Specific fuel consumption (at 3000 rpm) | g·(kW·h)−1 | 305 |

| Measured Quantity | Manufacturer, Model | Measuring Principle/ Apparatus | Relative Accuracy | Measuring Range |

|---|---|---|---|---|

| Water mass flow | Siemens, MAG1100 | Electromagnetic flow sensor | ±0.4% | 0…10 m s−1 |

| Fuel mass flow | Siemens, Sitrans MASS2100 | Coriolis flow meter | ±0.1% | 0…30 kg h−1 |

| NOx concentration | MRU, Vario Plus | Electrochemical cells | ±5 ppm | 0…1000 ppm (NO); 0…200 ppm (NO2) |

| Cooling water temperature | TC Direct, TCK | K-type thermocouple | ±1 °C | −270…1260 °C |

| Electrical output power | HT, PQA820 | In-line voltage and current detection | ±(1% rdg + 6 dgt) | 0…9.99 kW |

| Property | Value | Reference Standard |

|---|---|---|

| Ester content (% m m−1) | 98.5 | EN 14103 |

| Density @15 °C (kg m−3) | 883.1 | EN ISO 3675 |

| Viscosity @40 °C (mm2 s−1) | 4.1–4.7 | EN ISO 3104 |

| Flash point (°C) | >160 | EN ISO 3679 |

| Cetane number (-) | >51 | EN ISO 5165 |

| Water content (mg kg−1) | 210 | EN ISO 12937 |

| Sulphur content (mg kg−1) | <10 | EN ISO 20846 |

| Iodine number (g(I2) (100 g)−1) | 105 | EN 14111 |

| Cloud point (°C) | −6 | EN 23015 |

| Blend Label | Biodiesel Share (%) | Measured Density @15 °C (kg/m3) | LHV (MJ/kg) |

|---|---|---|---|

| B0 | 0 | 832.5 | 42.60 |

| B15 | 15 | 840.9 | 41.84 |

| B30 | 30 | 847.7 | 41.08 |

| B100 | 100 | 883.1 | 37.53 |

| Calculated Quantity | Units | Percentage Uncertainty |

|---|---|---|

| m3/s | 0.54% | |

| m3/s | 0.43% | |

| - | 0.68% | |

| - | 0.69% | |

| ppm | 2.55% |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 463.08 | 5 | 92.62 | 28.01 | 0.0004 |

| A-Load (kW) | 379.43 | 1 | 379.43 | 114.74 | <0.0001 |

| B-Biodiesel Share (%) | 17.59 | 1 | 17.59 | 5.32 | 0.0606 |

| AB | 2.29 | 1 | 2.29 | 0.69 | 0.4374 |

| A2 | 30.59 | 1 | 30.59 | 9.25 | 0.0228 |

| B2 | 6.47 | 1 | 6.47 | 1.96 | 0.2115 |

| Residual | 19.84 | 6 | 3.31 | ||

| Cor Total | 482.92 | 11 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 454.32 | 3 | 151.44 | 42.37 | <0.0001 |

| A-Load (kW) | 406.12 | 1 | 406.12 | 113.62 | <0.0001 |

| B-Biodiesel Share (%) | 13.15 | 1 | 13.15 | 3.68 | 0.0913 |

| A2 | 30.59 | 1 | 30.59 | 8.56 | 0.0191 |

| Residual | 28.60 | 8 | 3.57 | ||

| Cor Total | 482.92 | 11 |

| Blend | Tex (°C) | (kg·s−1) | ΔTw (°C) | Pt (kW) | Pfuel (kW) | |

|---|---|---|---|---|---|---|

| B0 | 197.76 | 0.17 | 8.10 | 5.60 | 17.90 | 31.00 |

| B15 | 201.01 | 0.16 | 8.00 | 5.50 | 15.20 | 36.00 |

| B30 | 192.44 | 0.17 | 8.00 | 5.60 | 13.40 | 42.00 |

| B100 | 203.93 | 0.17 | 8.00 | 5.60 | 13.60 | 42.00 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 1.200333 × 106 | 9 | 1.333 × 105 | 422.09 | <0.0001 |

| A-Load (kW) | 8.473333 × 105 | 1 | 8.473333 × 105 | 2682.97 | <0.0001 |

| B-Inj. Time (deg BTDC) | 1.031333 × 105 | 1 | 1.031333 × 105 | 326.45 | <0.0001 |

| C-Biodiesel Share (%) | 14,290.03 | 1 | 14,290.03 | 45.25 | <0.0001 |

| AB | 12,583.78 | 1 | 12,583.78 | 39.85 | <0.0001 |

| AC | 1466.92 | 1 | 1466.92 | 4.65 | 0.0406 |

| BC | 1136.02 | 1 | 1136.02 | 3.60 | 0.0690 |

| A2 | 33,637.49 | 1 | 33,637.49 | 106.52 | <0.0001 |

| B2 | 308.80 | 1 | 308.80 | 0.98 | 0.3318 |

| C2 | 2955.39 | 1 | 2955.39 | 9.36 | 0.0051 |

| Residual | 8210.73 | 26 | 315.80 | ||

| Cor Total | 1.208 × 106 | 35 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 1.198333 × 106 | 7 | 1.712333 × 105 | 496.38 | <0.0001 |

| A-Load (kW) | 8.473333 × 105 | 1 | 8.473333 × 105 | 2457.00 | <0.0001 |

| B-Inj. Time (deg BTDC) | 1.245333 × 105 | 1 | 1.245333 × 105 | 361.18 | <0.0001 |

| C-Biodiesel Share (%) | 14,862.31 | 1 | 14,862.31 | 43.10 | <0.0001 |

| AB | 12,583.78 | 1 | 12,583.78 | 36.49 | <0.0001 |

| AC | 1466.92 | 1 | 1466.92 | 4.25 | 0.0485 |

| A2 | 33,637.49 | 1 | 33,637.49 | 97.54 | <0.0001 |

| C2 | 2955.39 | 1 | 2955.39 | 8.57 | 0.0067 |

| Residual | 9655.55 | 28 | 344.84 | ||

| Cor Total | 1.208 × 106 | 35 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 10.19 | 9 | 1.13 | 1057.48 | <0.0001 |

| A-Load (kW) | 7.47 | 1 | 7.47 | 6974.60 | <0.0001 |

| B-Inj. Time (deg BTDC) | 0.71 | 1 | 0.71 | 663.53 | <0.0001 |

| C-Biodiesel Share (%) | 0.092 | 1 | 0.092 | 86.19 | <0.0001 |

| AB | 9.581333 × 10−3 | 1 | 9.581333 × 10−3 | 8.95 | 0.0060 |

| AC | 8.461333 × 10−4 | 1 | 8.461333 × 10−4 | 0.79 | 0.3821 |

| BC | 1.800333 × 10−3 | 1 | 1.800333 × 10−3 | 1.68 | 0.2061 |

| A2a | 0.78 | 1 | 0.78 | 725.32 | <0.0001 |

| B2 | 8.323333 × 10−4 | 1 | 8.323333 × 10−4 | 0.78 | 0.3860 |

| C2 | 0.018 | 1 | 0.018 | 17.07 | 0.0003 |

| Residual | 0.028 | 26 | 1.071333 × 10−3 | ||

| Cor Total | 10.22 | 35 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F |

|---|---|---|---|---|---|

| Model | 10.19 | 6 | 1.70 | 1572.15 | <0.0001 |

| A-Load (kW) | 8.36 | 1 | 8.36 | 7746.07 | <0.0001 |

| B-Inj. Time (deg BTDC) | 0.84 | 1 | 0.84 | 778.61 | <0.0001 |

| C-Biodiesel Share (%) | 0.094 | 1 | 0.094 | 87.11 | <0.0001 |

| AB | 9.581333 × 10−3 | 1 | 9.581333 × 10−3 | 8.87 | 0.0058 |

| A2 | 0.78 | 1 | 0.78 | 719.13 | <0.0001 |

| C2 | 0.018 | 1 | 0.018 | 16.93 | 0.0003 |

| Residual | 0.031 | 29 | 1.080333 × 10−3 | ||

| Cor Total | 10.22 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caligiuri, C.; Bietresato, M.; Algieri, A.; Baratieri, M.; Renzi, M. Experimental Investigation and RSM Modeling of the Effects of Injection Timing on the Performance and NOx Emissions of a Micro-Cogeneration Unit Fueled with Biodiesel Blends. Energies 2022, 15, 3586. https://doi.org/10.3390/en15103586

Caligiuri C, Bietresato M, Algieri A, Baratieri M, Renzi M. Experimental Investigation and RSM Modeling of the Effects of Injection Timing on the Performance and NOx Emissions of a Micro-Cogeneration Unit Fueled with Biodiesel Blends. Energies. 2022; 15(10):3586. https://doi.org/10.3390/en15103586

Chicago/Turabian StyleCaligiuri, Carlo, Marco Bietresato, Angelo Algieri, Marco Baratieri, and Massimiliano Renzi. 2022. "Experimental Investigation and RSM Modeling of the Effects of Injection Timing on the Performance and NOx Emissions of a Micro-Cogeneration Unit Fueled with Biodiesel Blends" Energies 15, no. 10: 3586. https://doi.org/10.3390/en15103586