1. Introduction

The Energy Information Administration (EIA) reports that world energy consumption will grow by nearly 50% and the energy consumption in the residential and commercial buildings sector will increase by more than 65% between years 2018 and 2050 [

1].

Global development, constantly growing energy demand, and increasing environmental pollution require ecological changes in the energy sector (i.e., shift away from fossil fuels and use of ecological, alternative, and low-emission fuels). The increase in the use of renewable energy sources (RES) such as solar, wind, geothermal energy, and biomass is noticeable [

2].

One of the most exploited renewable energy sources is biomass. Its easy accessibility makes it one of the most popular renewable energy sources. As the structure of primary energy carriers changes, it is estimated that biomass share will increase to 35% of the total energy obtained [

3]. Over the years, a significant growth in the use of solid biofuels has been observed [

4]. This is dictated by the high energy potential of solid biomass worldwide. It is especially important in countries where coal still plays a major role in energy production (electricity and heat). Energy from biomass, compared to other unconventional sources, is characterized by high stability of acquisition and relatively simple processing and storage technologies, both on a small and large scale. Unfortunately, raw and unprocessed biomass is characterized by high moisture content, high water absorption capacity, and low bulk density, as well as low caloric value [

5]. Moreover, in pulverized firing systems, size reduction of biomass material is much more demanding than for coal due to its fibrous and more tenacious structure [

6,

7]. Thus, these biomass features negatively affect the transport, storage, and utilization processes. However, the energy sector expects a homogenous and good-quality biomass fuel. Therefore, due to its variable physical and chemical properties [

8], biomass requires valorization to improve the quality and energy density as a fuel.

For this purpose thermal processing of the raw biomass is used. In recent years, the torrefaction of biomass has gained popularity due to its ability to improve the fuel properties of the processed material [

9]. The process of torrefaction [

9,

10,

11] is heating the biomass to a temperature in the range 200 to 320 °C in the absence of or very limited access to oxygen [

12], and usually under atmospheric pressure [

7] and retention under these conditions for a defined period of time usually ca. 60 min [

13]. During torrefaction the biomass decomposes [

14], reducing moisture content, increasing lower heating value, and improving the hydrophobic properties [

13].

After the torrefaction process, the final product is characterized by 70% of the mass, and about 90% of the primary energy of fresh biomass. As a result of this process, the energy density increases, even by 30% [

15,

16]. It has been shown that during torrefaction at temperatures above 240 °C, hemicellulose decomposes, which is responsible for durability and flexibility [

16]. The higher the torrefaction temperature, the larger pores in the tested material. These changes reduce the mechanical durability of biomass [

17]. Owing to the pelletization of torrefied biomass, the bulk density increases to the range of 630–850 kg∙m

−3 [

18,

19] and the lower heating value (LHV) even more than 21 MJ∙kg

−1 [

20] (in case of typical biomass pellets LHV = 18–19 MJ∙kg

−1 [

19]). The pellets made of torrefied biomass are characterized by volumetric energy density at the level of 14–22 GJ∙m

−3 (for coal 18–24 GJ∙m

−3 [

12]), which enables its combustion in conventional PF (pulverized fuel) boilers without any changes in the feeding systems and the maintenance of nominal thermal power capacity [

21]. Therefore, it can be expected that in the near future the interest in torrefied pellets in electricity generation systems will increase [

17,

21].

One of the most effective processes of biofuels compaction is pelletization [

22]. The pelletization process is energy-consuming; the amount of energy used in the process is 1.5–2.5% of the total energy yield from biomass. The moisture content in pellets is low and usually does not exceed 10–12% [

23]. The agglomeration process increases the bulk density of biomass, which is crucial in terms of its storage and transport.

Due to the intensively developing pellet market in Europe, the EN ISO 17225-1:2014-07 standard was developed, specifying fuel quality classes and requirements for solid biofuels from natural resources processed from forestry, agriculture, horticulture, or cultivation of aquatic plants [

24]. Each class of pellets, in order to be certified, must meet the mechanical durability requirement (

DU index at least 97.5%), compliance, and safety [

25].

However, biomass pellets for energy purposes should have an optimal ratio of durability to grinding energy. The mechanical durability index

DU is a quality requirement and guarantees the resistance of granulates to impacts, shocks, and frictions during transport and storage (loading, unloading). In the case of thermal units fired by pellets, a high value of

DU index is recommended. On the other hand, for thermal units burning fuels in the pulverized form, in order to minimize costs and increase the capacity of the mill, the grinding energy is required to be as low as possible [

26]. As a result, the pellets with a lower value of

DU index are preferred (lower grinding costs).

To date, many of papers characterize pellets made from standard biomass such as wooden chips, straw, or energy crops in terms of energy applications. However, there are very limited data related to combined topic of its torrefaction, pelletization, mechanical durability, and grindability. As the use and management of agricultural biomass is very important for the local (agricultural regions) fuel market and farmers, knowledge about biomass processing and its impact on fuel properties is crucial.

In many reports, only one temperature of the thermal treatment of solid biomass is considered [

27], which provides limited data for analysis in terms of relations between temperature and the mechanical durability/grindability. Although Wang et al. [

28] applied different torrefaction temperatures (200 and 275 °C) after pelletization processing of woody biomass, only mechanical durability was investigated. The results indicated the decrease of the mechanical durability for higher torrefaction temperatures. In turn, Stelte et al. [

29] investigated effect of various torrefaction temperatures on mechanical durability of pellets; however, the torrefaction process was carried out before pelletization. However, in the literature there are no data focused on the simultaneous analysis of mechanical durability and grindability. Furthermore, in relation to the mechanical durability of pellets, most data correspond only to the ISO standard conditions (operation time of the working chamber 10 min) [

30]. Due to the extensive logistic operations with biomass (transportation, loading, unloading), the investigation of further changes in pellet properties is interesting from a scientific as well as practical point of view. The increase of the test operation time better reflects the actual conditions of pellet treatments. This approach is not widely investigated by other authors so far. Such investigations (but with frozen pellets) were performed by Dyjakon and Noszczyk [

31].

Taking into account the missing data in these issues, it is justified to perform research on the physical properties such as grindability (energy consumption) and mechanical durability (fuel quality) for pellets before and after the torrefaction process.

Therefore, this study aims to (i) investigate the effect of the torrefaction process of pellets on mechanical durability index DU, (ii) determine the impact of the torrefaction process of pellets on energy demand for grinding, (iii) evaluate the influence of torrefaction temperature on mechanical durability and the grindability process.

2. Materials and Methods

2.1. Materials

The research was carried out for five different pellets made of various waste biomass: sunflower husk (a), beetroot pomace (b), grass (c), pine tree (d), and wheat straw (e). Pellets are shown in

Figure 1. The length of the pellets was from 5 to 40 mm, and a diameter of 6 mm. The pellets investigated in this study were purchased from commercial fuel markets. These pellets were chosen due to their production from agricultural waste. They have an application potential for use as an alternative fuel and are not related to the deforestation process. Moreover, their wide usage may convince local farmers to produce the pellets, based on readily available agricultural residues, as well as support the development of the local fuel market and increased waste management.

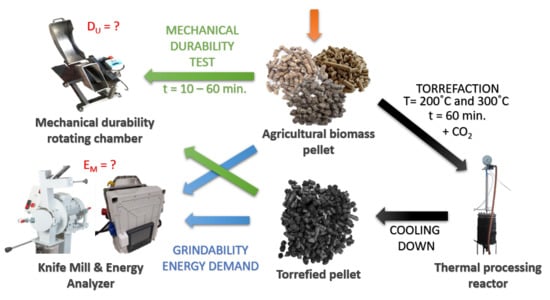

2.2. Torrefaction Process

The pellets were torrefied in an electrically heated reactor shown in

Figure 2. The torrefaction temperatures were 200 and 300 °C. The duration of the torrefaction process was 60 min. The chamber was loaded with a sample of pellets (ca. 7 kg). To maintain the nonoxidative atmosphere of the process, the reactor chamber was filled with inert gas (carbon dioxide CO

2 of 99.8% purity from a gas cylinder).

After the torrefaction process, the reactor was switched off. The torrefied pellets were kept in the reactor until they cooled to avoid self-ignition and combustion of the material. An example of the torrefied agricultural waste biomass pellets is shown in

Figure 2b.

2.3. Mechanical Durability Test

The mechanical durability test of investigated pellets was performed in the rotating chamber (Łukomet, Całowanie, Poland) constructed in accordance with PN-EN ISO 17831-1 standard, shown in

Figure 3.

Before testing, the pellets were passed through a 3.15 mm sieve to remove small particles. The mass of the pellet sample was 500 ± 10 g. The prepared pellet sample was placed in the working chamber of the device. The rotation speed of the working chamber was 50 rpm, and the duration of the test was 10 min.

After the test, the entire contents of the chamber were taken out and screened through a sieve of 3.15 mm. Then, the mass of the two fractions obtained was measured with an accuracy of 0.01 g using a laboratory scale, RADWAG PS 3500.R2 (RADWAG, Warsaw, Poland).

Afterward, both fractions were placed back into the rotating chamber and the testing procedure was repeated. The test was repeated five times until the total working time of the tested sample was 60 min. Each type of pellets was tested in three repetitions. The test procedure was applied to raw and torrefied pellets at two temperatures.

The mechanical durability index

DU was calculated using the formula:

where

DU is the mechanical durability index of pellets (%),

m1 is the mass of the sample placed in the working chamber of the device (g), and

m2 is the mass of the over-sieve fraction (g).

2.4. Pellets Grindability Test

The energy consumption for pellet grinding was tested with the use of an LMN 400 knife mill (TESTCHEM, Pszów, Poland), shown in

Figure 4a, with a sieve mesh size of 1 mm.

During the grinding process, the mill was connected to an energy consumption analyzer LUMEL ND40 (LUMEL, Zielona Góra, Poland) (

Figure 4b), recording the changes in power demand at 0.2 s intervals. It allowed for the calculation of energy consumption during the grinding process. After turning on the grinder and stabilizing it at idle, the sample was inserted into the working chamber of the knife mill. The electrical parameters of the mill during the grinding process were recorded in the energy consumption analyzer, accordingly. The mass of the pellet sample was 100 g. The measurements were performed in three repetitions.

The amount of energy used for grinding was calculated from the formula:

where

EM is the amount of energy used for pellets grinding (Wh∙kg

−1); P

1, P

2, and P

3 are the instantaneous powers of the knife mill during grinding for each electricity phase 1, 2, and 3 (W), respectively, t is the milling time (h), and m

p is a mass of the pellet sample (kg).

2.5. Technical and Chemical Analysis of the Pellets

In order to characterize the investigated pellet properties, proximate and ultimate analysis was performed. Sampling was performed by randomly taking the material (500 g) and grinding it to a fraction below 1 mm. The samples obtained in this way were used for further tests following the ISO standards.

The proximate analysis included parameters such as ash content (AC), lower heating value (LHV), higher heating value (HHV), moisture content (MC), volatile matter content (VMC), and fixed carbon content (FCC). The ultimate analysis included the determination of the content of carbon (C), hydrogen (H), nitrogen (N), oxygen (O), and sulfur (S).

Ash content was determined using an SNOL 8.2/1100 muffle furnace (SNOL, Utena, Lithuania) following the PN ISO 1171:2010 standard.

Following the PN-EN ISO 18134-2:2017-03E standard, the moisture content was determined using a moisture analyzer SARTORIUS MA150 (Sartorius, Goettingen, Germany). Using the IKA C200 calorimetric bomb (IKA, Lucknow, India), the higher heating value (HHV) was determined.

According to PN-EN ISO 18123:2016-01, the volatile matter content (VMC) in the pellets was determined.

Ultimate analysis was conducted using an organic elemental analyzer, FLASH 2000 CHNO/S (Thermo Fisher Scientific, Waltham, MA, USA).

3. Results and Discussion

3.1. Proximate and Ultimate Analysis

After the torrefaction, the caloric value of the pellets investigated increased significantly. At the temperature of torrefaction (200–300 °C), thermal decomposition of the organic material (biomass) takes place, leading to the partial release of volatiles, such as light hydrocarbons, hydrogen, carbon dioxide, etc. [

15]. At the same time, the percentage weight loss of the material is greater than the percentage loss of energy in the volatilized compounds, which explains the increase in the calorific value of the obtained torrificates.

Regarding the ash content, none of the tested pellets met the quality requirements for class A1; the ash content was greater than 0.7% [

32]. During torrefaction, the ash content (AC) increased, i.e., in the case of grass pellets, the values varied from 6.76% for dried material, to 15.75% for torrefaction at 200 °C, and 17.32% for torrefaction at 300 °C, which indicates a higher content of mineral fraction in fuel, which has no energetic value in terms of heat production [

33].

The volatile matter content (VMC) in the materials tested decreased, i.e., in the case of grass pellets the values varied from 76.91% for dried material, to 27.31% for torrefaction at 200 °C, and 22.60% for torrefaction at 300 °C. The torrefaction process at 200–300 °C caused the devolatilization of a significant amount of VMC. These results are consistent with the literature data [

15,

33,

34].

The biomass pellet torrefaction at 200 and 300 °C led to a significant increase in carbon content in the fuel. Simultaneously, a decrease of hydrogen and oxygen in the fuel was noted. The detailed results of the proximate and ultimate of each raw and torrefied pellet are shown in the

Supplementary Materials (Tables S1–S5).

3.2. Mechanical Durability

When analyzing the mechanical durability, it should be noted that high-quality pellets must be characterized by high mechanical durability. Their mechanical durability index should be higher than 97.5% according to PN-EN ISO 17831-1:2016-02 standard [

35].

In the results, for the investigated pellets (untreated), only sunflower husk pellet did not meet the standard (

DU = 95.28%). Other pellets had a

DU index at approximately 98%. The detailed results of the mechanical durability before and after torrefaction are shown in

Table 1. Applying the torrefaction process, the mechanical durability changed significantly. The

DU index varied from 73.50% (for beetroot at 200 °C) to 46.34% (for sunflower husk at 300 °C).

A significant decrease in the mechanical durability of pellets due to torrefaction is caused partly by the decomposition of lignocellulosic compounds (a component of biomass) under the influence of temperature. It translates into an increase in the brittleness of the material. At the same time, under the influence of temperature, there is an intense release of volatile matter, which escapes from the compacted material (pellets) under the influence of pressure, leading to swelling, tearing, and loosening of the particles. This decrease in the consistency of the material causes a decrease in mechanical durability, as confirmed by the results in

Table 1. The results also showed that an increase in the torrefaction temperature did not have a significant effect on the mechanical durability. The

DU indexes obtained for the torrefied pellets at temperatures of 200 and 300 °C showed no differences, or these differences were very small. For example, for grass pellets, the

DU index was 65.70% (torrefaction temperature 200 °C) and 63.78% (torrefaction temperature 300 °C). The statistical analysis confirmed the lack of significance of the change in torrefaction temperature on the

DU index (

Table 2). In the case of sunflower husk, beetroot pomace, grass, and pine pellets, there were no significant differences between pellets torrefied at 200 and 300 °C (

p-value > 0.05). It can be concluded that applying a treatment temperature greater than 200 °C does not affect significantly the mechanical durability. Only in the case of wheat straw pellets was the value statistically different (

p-value < 0.05).

This may have a significant practical meaning (if the objective is to reduce the mechanical durability), because the higher the torrefaction temperature, the higher costs of the technological process. Based on this study, it can be concluded that an appropriate sequence of technological processes (i.e., torrefaction process) is most important. The torrefaction process applied after pelletization may cause lower mechanical durability, The torrefaction of the agglomerated biomass causes devolatilization and devaporization of the material, thus creating free spaces in the pellets. In addition, between 200 and 300 °C starts the degradation of lignocellulose fibers, which are responsible for the biomass durability as well. Perhaps, it may be recommended to torificate biomass before pellet production in order to maintain better mechanical durability.

As biomass pellets are very often transported for much longer distances and undergo other intensive logistics operations, within this research the mechanical durability tests were performed beyond the ISO standard, with longer operation time. The results are shown in

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9. For all biomass pellets (as-received state, no torrefaction applied), the extension of the working chamber operation time (to 60 min) caused the further decrease of the

DU index, but these changes were not large. The lowest value was obtained for sunflower husk pellets and amounted to

DU = 87.17%. However, in the case of pellets after the torrefaction process, a significant decrease in

DU index was observed. High temperatures during the torrefaction process decomposed the fibrous structure of the biomass by the thermal degradation of hemicellulose, cellulose, and lignin. The moisture after torrefaction decreased because of the structure degradation caused by the evaporation and release of chemically bound water. These changes in biomass properties ultimately increased its brittleness, which leads to lower mechanical durability of pellets [

36]. As a result, the mechanical durability index

DU for all pellets dropped below 40%. Similarly, the lowest values were attained by sunflower husk pellets (

DU = 23.18%, torrefaction temperature 200 °C). In turn, the greatest value,

DU = 39.52% (torrefaction temperature 200 °C), was noted for beetroot pellets. The same trend was observed by Nobre et al. [

37], who investigated the pellets from industrial wood waste before and after thermal treatment (torrefaction temperature 250 °C, 60 min). The

DU index changed from

DU = 98.7% to

DU = 93.1%.

Furthermore, the result indicated that the torrefaction temperature did not affect the mechanical durability index

DU during the longer operation time of the working chamber. For the temperatures examined (200 °C and 300 °C), the values of the

DU index were very similar (

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9). For example, the mechanical durability index of wheat straw pellets was

DU = 27.24% ± 1.61% (at 200 °C) and

DU = 28.03% ± 2.61% (at 300 °C). It is also confirmed by the statistical analysis performed using ANOVA and post hoc tests (

Table 3). In the case of sunflower husk, beetroot pomace, and pine tree pellets, there were no significant differences between pellets torrefied at 200 and 300 °C (

p-value > 0.05). It can be concluded that applying a treatment temperature greater than 200 °C will not affect significantly the mechanical durability. Only in the case of grass and wheat straw pellets, in all time variants, were the values statistically different (

p-value < 0.05).

The results obtained also showed that the operation time of the working chamber affects the mechanical durability, and thus the number of fine particles separated from the pellet, which reduces its quality. The statistical analysis also indicated this relationship.

Analyzing the influence of the duration time of the mechanical durability test of the raw and torrefied pellets, interesting dependencies were found. In the case of thermally untreated pellets, the differences were smaller in comparison to the torrefied at 200 and 300 °C, where the differences were significant. The influence of the test operation time on the mechanical durability has been confirmed by the statistical analysis ANOVA and the post hoc test on the confidence level of 5% (p-value < 0.05). However, for longer operation time of the working chamber, the changes in the mechanical durability are not significant, which confirms the stabilization trend of the values obtained for the DU index.

This behavior is reflected in the actual conditions occurring during the transport of biomass pellets over longer distances or other logistic processes. The results suggest that the logistic supply chain should be kept to a minimum in order to maintain the high-performance quality of the pellets and to reduce material losses. Finally, it can be noted that the mechanical durability index DU did not change linearly with the extension of the working chamber operation time. The trend lines tend to reach a constant value. This can be explained by the limitation of direct impacts of the pellets against the walls of the working chamber due to the shock-absorbing effect of the previously separated fine particles from the compacted granulates. The gradual rounding of the initially sharp edges of the pellets also reduces the impact point both against the chamber walls and between the pellets.

3.3. Grindability

The investigated pellets were characterized by different grinding energy demands. Their grindability ranged from 16.28 kJ·kg

−1 for sunflower husk to 130.72 kJ·kg

−1 for beetroot.

Table 4 shows the energy demand for grinding of untreated (raw) and torrefied pellets at 200 and 300 °C. The beetroot pomace pellets needed the largest energy demand for grinding, whereas the sunflower husk pellets were the smallest. It should be noted that there is a relation between grindability and mechanical durability. The most durable pellets (with high mechanical durability) required the greatest grinding energy, and the least durable ones needed the least amount of energy.

Analyzing the data of grindability of the pellets, it was noted that torrefaction temperature influences the grindability. Only in the case of grass pellets were the values at all temperatures somewhat statistically different (p-value < 0.05). However, in the case of sunflower husk, beetroot pomace, pine tree, and wheat straw pellets, it was noted that there were no differences between energy demand for grindability torrefied at 200 and 300 °C, which may mean that the application of torrefaction temperature higher than 200 °C, does not affect significantly the improvement of the fuel grindability.

For the second analysis of ANOVA and influence of the type of pellets in the untreated forms, there were no statistically insignificant results; all values had a p-value < 0.05. Thus, the type of pellet material is important and may affect the grindability process, however only in the untreated form. Considering the torrefaction at 200 °C, there were no significant differences between sunflower husk pellet and pine tree and wheat straw pellet, grass and pine tree and wheat straw pellet, and between wheat straw and pine tree pellet (p-value > 0.05). After torrefaction at 300 °C, only wheat straw pellets were significantly different from the other pellets (p-value < 0.05). There were no differences between the sunflower husk, beetroot pomace, grass, and pine tree pellets.

The mechanical durability and grindability are close related to the natural fibers (hemicellulose, cellulose, and lignin) in the material. During the torrefaction and other thermal processes over 200 °C, the natural fiber hemicellulose begins to decompose [

16]. As result, the final torrefied product is characterized by lower mechanical durability and higher grindability (lower energy demand for grinding).

According to Williams et al. [

26], there is a relationship between the mechanical durability of the pellets and the energy consumption for the grinding process. Sunflower husk pellets were characterized by the lowest

DU index and the lowest energy demand for grinding. Pellets torrefied at 200 °C resulted in a significant reduction in energy consumption during the grinding of each of the five tested pellets. The energy demand for grinding of torrefied wheat straw pellets decreased by 94.5% compared to untreated wheat straw pellets. The smallest decrease in energy consumption was noticed for sunflower husk pellets; the difference amounted to 71.5%. For the remaining three pellets, the energy consumption was reduced by an average of 75% compared to the untreated state.

Phanphanich and Mani [

38] showed that an increase in the torrefaction temperature reduces the energy consumption of the grinding process. A linear decrease in energy consumption of the grinding process with increasing temperature was observed. The torrefaction processing of pine chips allowed for a tenfold reduction in energy consumption in the comminution process when compared to wood chips not subjected to thermal treatment. Reppelin et al. [

34] investigated the influence of torrefaction on the beech and pine tree wood energy demand used for grinding. It was also observed that the torrefaction process reduced the energy consumption of grinding. The greatest drops were observed for the biomass after torrefaction at the temperature of 200 °C. The torrefaction of beech sawdust at 280 °C allowed for reducing the grinding energy by 90%, from the value of 850 kWh∙Mg

−1 to about 100 kWh∙Mg

−1. According to Shang et al. [

16], along with the increase in weight loss (decrease of mechanical durability) of pellets, a decrease in energy consumption for grinding was observed as well. For a 40% loss in weight of pine pellets, a decrease in energy consumption by approximately 20 J∙g

−1 was noted. Moreover, Williams et al. [

26] revealed that dried pellets are characterized by a smaller energy consumption during the grinding process compared to raw pellets. The reduction of the water content reduces the plasticity of the granulate, making it more susceptible to grinding. Finally, the torrefaction destroys the fibrous structure of the biomass, making the biofuel brittle. The pores formed in the pellet make it less durable, which reduces the energy consumption of the grinding process [

39].

The amount of energy needed to comminute the torrefied pellets is determined by the properties of the biomass, i.e., water content, size, chemical composition, and torrefaction temperature, together with the properties and type of mill. Hence, it is difficult to compare the results directly with the data obtained by other authors. In terms of quality, however, the results obtained are fully consistent with the conclusions formulated in other research studies.

The study showed that pellets having much higher initial mechanical durability subjected to a longer mechanical test turn out to be characterized by lower mechanical durability. For this reason, it is not recommended to transport pellets over long distances, especially after torrefaction. Transport is associated with the exposure of pellets to numerous impacts and friction caused by the condition of the roads and logistic operations (loading, unloading). Long-term exposure of pellets to such conditions may reduce the safety of its storage (fire and explosion hazard) as well [

25].

Therefore, the two technological chains of torrefied pellets preparation/production can be adopted depending on the final consumer requirements or expectations.

The first includes the following order of the processes: biomass pelletization, torrefaction, and grinding. This order of biomass processing is justified if the biofuel has to be shredded/comminuted before being fed to the combustion chamber of the boiler. It takes place in the conventional industrial pulverized fuel boilers (PF boilers) used in power engineering. In this case, the final mechanical durability of pellets is low, and so is the energy demand for grinding. It reduces the energy consumption by biomass/coal mill and exploitation costs of the feeding system in the power plant.

The second consists of the following steps: shredded biomass torrefaction and pelletization of the torrefied biomass. This scheme is justified when the final form of the fuel to be burned in the boiler must be a pellet. Moreover, the high mechanical durability of the pellets is crucial to maintain the high combustion efficiency of the fuel. This situation occurs in the case of pellets combustion in the domestic boilers class 5 (ecodesign requirements).

4. Conclusions

Improvement of biomass properties by pelletization caused the development of the pellet market. Pelletization facilitates the processes of storage, transport, and feeding to the boiler. However, due to the hydrophilic properties of raw biomass and a lower calorific value (compared to coal), additional solutions are considered to improve these indicators. Raw pellets are also characterized by a high demand for regrinding. An interesting solution is torrefaction, which should improve energy parameters and resistance to moisture absorption, as well as grinding properties. However, the torrefaction of pellets can have a negative effect in terms of their mechanical durability.

This research clearly showed that the torrefaction process significantly reduces the amount of energy needed for pellet grinding, and affects the mechanical durability of pellets, causing durability to decrease. After torrefaction, the grindability index decreased by 4 to 18 times (depending on the material type of pellet). It was also noticed that long-term exposure of torrefied pellets to destructive conditions (imitating transport and other logistics activities) led to the decrease in mechanical durability by up to 50%, but with a tendency toward a stabilizing value of DU index. However, the increase of torrefaction temperature (from 200 to 300 °C) did not change significantly the grindability or the mechanical durability. Actually, only performance of the torrefaction process itself is important to cause the changes in the biomass pellets (the changes of process conditions are not crucial).

Based on this study, it may be recommended to appropriately design the chain technology process of torrefied pellet production, owing to the expected final properties of the alternative biomass fuel. It should be taken into account that the torrefaction causes the mechanical durability of the pellets to decrease. Application of the torrefaction before pelletization could be a better solution.

Therefore, further research could be focused on the assessing these processes in terms of effectiveness and economic profitability together with recommending a sequence of operations, depending on the purpose and necessary further processing of biomass pellets.