1. Introduction

The continuously growing demand for electricity in the world encourages the rational use of energy resources. The extraction of hard coal from thin seams is one of the possibilities for the rational management of natural resources, particularly in those countries where the deposits that are the most attractive in terms of extraction profitability, i.e., those located in medium and thick seams, have already been partially or completely mined. In recent years, the coal reserve of medium-thick and thick coal seams, which are thicker than 2 m, has decreased significantly [

1].

Since no available energy source can be ignored, the possibility of the economically viable exploitation of thin deposits has received increasing attention in recent years [

2,

3,

4]. Satisfactory technical and economic results are possible to obtain with the use of fully mechanized equipment [

5].

In some countries, it is assumed that the lower limit of deposit thickness for thin seams is 0.4–0.5 m. In Ukrainian coal mining, the assumed thickness is 0.7–1.2 m [

6,

7,

8], with a lower technical limit of 0.65 m [

9]. In Chinese conditions, thin seams are those with a thickness of 0.8–1.3 m, while seams thinner than 0.8 m are classified as extremely thin [

10]. In the case of Poland, thin seams are those with a thickness of 1–1.5 m.

The exploitation of thin seams is a point of focus not only for users but also for mining machinery manufacturers. Decades of efforts resulted in significant achievements, and the automation level of thin coal seam mining has been gradually improving. Currently, longwall shearers or static coal plows are most commonly used to mine thin seams. Their advantages, disadvantages, and adaptability for different geological conditions can be found in the literature [

11,

12]. A longwall shearer is a component of a mechanized longwall system that is also equipped with a face conveyor and powered roof support. The mechanized longwall system enables the execution of the mining process and the loading and haulage of the excavated material from the longwall. Currently, regardless of the thickness of the seam, the most popular of the produced mining machines are two-arm, two-unit shearers moving on the conveyor by means of a chainless haulage system. A unique solution used for two-way, noncavity mining and loading of coal in thin seams is the Mikrus system, which is equipped with a GUŁ-500 mining and loading head. The data used for this study were acquired from the Mikrus system, for the period in which the shearer was tested under actual working conditions.

The use of the right mining machines for mining low seams is crucial to an efficient coal mining process. The possibility of obtaining relevant data from them is also important. The intensive digitization of the mining process is creating tremendous opportunities for mining companies. These opportunities are related to the collection, storage, and processing of massive amounts of data that can be used to derive new and useful knowledge about processes taking place in a mining company. Digitization of the mining industry translates into significant improvements in productivity [

13].

The proper use of low-level data obtained from existing monitoring systems is very important. Properly used data analysis should result in the optimization of business management processes and procedures. Heterogeneous data are most often generated by a series of low-level sensors that monitor the operation of machines and equipment that are part of a larger process. The data must be preprocessed and supplemented with specific knowledge from the domain of processes. Additionally, sensor data need to be translated into a higher-level representation, e.g., event log [

14,

15,

16]. Event logs are comprised of activities that have occurred during the execution of a process. They enable a process analyst to explore the process which generated a particular event log. In other words, the event log is the evidence of the process that produced it [

17]. When making their decisions, managers of modern mining companies use data from different areas of the company as well as from other sources. Process data can come from multiple sources: for example, enterprise resource planning (ERP) systems, machinery and equipment monitoring systems, the work environment, or employee location. Different origins of data result in varying degrees of detail: from the most general (e.g., geometric dimensions of the excavation), through more detailed operating states of machines (work, alarm, standstill), to simple measurements (e.g., methane, currents in motors, transformer switching) [

18]. It is essential that all data are assigned to a specific process and analyzed in its context to provide an in-depth analysis of performance and security.

There are several different approaches to analyzing data related to work environment processes and conditions in the scientific literature. Many authors favor an approach that includes a broad spectrum of data mining algorithms that are used in the classification of phenomena [

19,

20,

21], prediction [

22,

23,

24,

25], and description tasks [

26,

27,

28]. For process improvement, process-oriented methods should be used, such as process mining (PM), which is derived from workflow analysis. Process mining is most commonly used in business process management. Tools used in PM include such techniques as process model discovery, compliance verification, process model repair, role discovery, bottleneck analysis, and prediction of the remaining flow time [

18,

29].

In real-world conditions, we do not always obtain all the data we need to determine the process flow, and thus we do not have the complete information needed to optimize the process. This can be caused by sensor misalignment, sensor failure, disrupted data transfer, or, finally, incorrect readings. This paper presents an algorithm for reconstructing the original data layout using the R programming language and discovering parts of the process based on other parameters, i.e., presentation of a set of results showing the structure of a machine’s operating states based on readings of changes in current intensities. This approach allows new information to be acquired, existing information to be verified, and further process analysis to be conducted.

The article is structured as follows: the second section presents the description and characteristics of the “Mikrus” longwall system from which the analyzed data were derived. The section also presents the R language functions used in the calculations. The next section presents the data used for the analysis and how they were prepared. The section also contains the author’s analysis of shearer states and the structure of the machine operating states. The final section presents a summary of the work and prospects for further research in this area.

3. Results and Discussion

The data used for the calculations were obtained when the shearer was tested under actual working conditions. They cover a period of two months and describe the values of the currents flowing through the windings of four shearer motors. One of the motors drives the cutting organs, two other motors are used to drive the shearer’s feed, and the fourth one drives the mechanism responsible for properly laying the power cables.

3.1. Data Preparation

The original data format contained 554,352 records with information about changes in current intensities, the time of their occurrence, and the code of the motor to which the change pertained, which appropriately reduced the amount of transmitted and collected data, but for its analysis, the original data layout had to be reconstructed.

R language functions were used to recreate the original data layout.

The processed dataset includes 5,254,993 records containing a timestamp, and four records containing the corresponding information about current. A fragment of the reconstructed set is shown in

Table 2.

In

Table 2, the column headings indicate, respectively:

Tsu—time (unix timestamp);

ouf—current of the shearing organ motor A;

npf—current of the auxiliary drive motor A;

ngf—current of the main drive motor A;

nuf—current of the stacker motor A.

The data thus prepared were the basis for further calculations.

3.2. Preliminary Data Analysis—A Study of Current Intensity Distributions

Calculations were performed to determine histograms of current intensities for each motor. This allowed for revealing the nature of data variability. Calculation results are illustrated in

Figure 2.

As can be seen in

Figure 2, a significant portion of the measured values of the cutting organ current (ouf) is at the lower end of the range of observed intensities, with outliers as high as 600 [A]. These are isolated situations associated with the starting of a particular motor. In order to better illustrate the variation of the remaining parameters, the values of current exceeding 200 [A] and equal to zero were eliminated from the graph, and another graph was then created (

Figure 3).

An analysis of the graph in

Figure 3 reveals that the ranges of current intensities of the motors (ngf, npf) are very close to each other. The average value of these intensities is approximatly 42 A, and the interquartile range is ca. 24 A. The range of currents flowing through the motor of the cutting drive (ngf) is much larger and reaches up to 600 A (

Figure 1), while the interquartile range is smaller than that of the drive motors and amounts to 17 A, and the mean of the observed values is ca. 35 A. As can be seen from the analysis of distributions, it should be noted that the terms ‘main engine’ and ‘auxiliary engine’ are conventional because the observed currents flowing through these engines are similar, and, moreover (as can be seen from other analyses), they operated simultaneously throughout the analyzed period.

3.3. Data Illustration

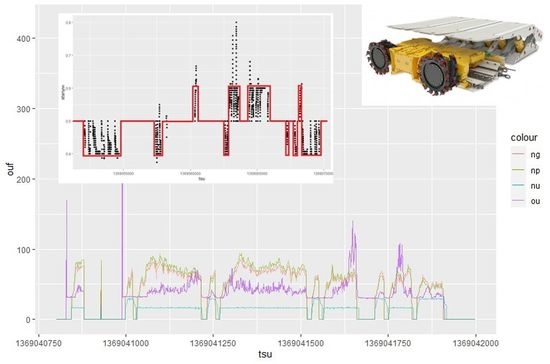

Using the ggplot function available in the R language, it is possible to generate graphs that can be customized in any possible way. A graph mapping the changes in currents as a function of time, recorded in the database, is presented below (

Figure 4).

In

Figure 4, one can observe the periods of both work and standstill of the shearer. Purple is used for the values of current of the cutting unit motor (ou). In the presented period, there is a peak reaching the value exceeding 400 [A] connected with the starting of this motor. This is confirmed by the different increases in the currents flowing through the other motors. This figure illustrates the mutual similarity of the current values flowing through the two feed drive motors and the relatively constant current values flowing through the stacker drive motor.

3.4. Shearer Status Analysis

To investigate the nature of the load distribution of shearer motors in more detail, histograms of the values of the currents flowing through the main drive motor (

Figure 5) and through the main feed drive motor (

Figure 6) were generated.

Figure 5 presents a large number of observed zero values associated with device stoppage. In addition, there is a large number of observations of 30 [A] values which correspond to the movement of the cutting organ without the mining load. Higher values are observed during cutting.

In interpreting the distribution of current intensities in

Figure 6, we can observe, similarly as before, a large number of zero value occurrences. However, in this case, it is difficult to clearly distinguish the values of current intensity corresponding to driving the shearer’s feed without the use of a cutting unit.

A better understanding of the operating state of the shearer can be obtained when the above histograms are overlayed.

Figure 7 presents a graph resulting from superimposing the observations in the space formed by the currents of the cutter motor and the currents of the feed motor.

The number of observations corresponding to the values of these currents is mapped by the degree of blackness of a point in this coordinate system. This was accomplished by overlapping points with a high degree of transparency. In

Figure 6, four operating states of the machine can be distinguished. The first one, in which the currents of both motors are zero, is the machine shutdown state. The second state is the idle state, which is a situation where the current of the feed motor is zero, while the current of the cutting unit motor is approximately 30 [A]. The third state is the maneuvering state. In this state, a current equal to approximately 30 [A] passes through both motors. It stands out in

Figure 6 as a dark circle at the bottom of the point cloud. The last operating state of the shearer is the cutting state. In this state, the current of both the motor driving the cutting unit and the feed mechanism exceeds 30 [A].

Based on the boundaries assumed above, it is possible to assign the recorded readings of current intensity to the distinguished shearer working states and then to calculate the percentage structure of these states in the analyzed period of time. Taking economic calculations into account, the state of cutting is expected to occupy the largest part in this structure. The rules for assigning cutter operating states are summarized in

Table 3.

The state marked with an “X” in

Table 3 deserves an additional comment. It is a prohibited state. In this state, the shearer would mine coal without feed. Observations of this state are possible but only to analyze the incorrect operation of the shearer. An example would be to start the drive of the cutting organ that is hogged into a coal bed. This action can very likely result in damage to the machine.

The operation of the feed drive motors is analyzed in the next part of the study. Observations of the distributions of currents flowing through these motors and their waveforms observed on the graphs suggest a high similarity of these values. To confirm this, a graph was constructed (

Figure 8) whose axes mark the currents of both motors.

In

Figure 8, it can be seen that the points align along two distinct straight lines. The top line represents the cases where the power consumed by the main motor is greater than the power consumed by the auxiliary motor, while the bottom line represents the opposite case. It can also be seen that the difference between the currents flowing through the motors increases proportionally to their load. To better understand the structure of these cases, their percentages were calculated. The results are shown in

Table 4. This list, as well as the rest of the analysis, does not include cases in which the feed drives were not working, because it concerns the states of a device in motion.

Since the structure of these cases turned out to be uniform, a histogram was determined in the next step (

Figure 9) which shows the distribution of differences between the currents of the two motors.

The values to the right of zero are cases where the main motor draws more power than the auxiliary motor. This histogram is characterized by high symmetry, which, together with the percentage distribution calculated earlier, suggests that, to a significant extent, these motors swap roles in driving the shearer’s feed.

This observation is the basis for the hypothesis that shearer working directions can be distinguished. Since a significant longwall slope is likely to occur, there may be differences in loads between the motors driving the shearer feed. These differences may be increased by the activity of loading the excavated material onto a scraper conveyor, which is additionally performed by the moving shearer, and which may depend on the direction of the feed. Similar differences resulting from the direction of the shearer’s movement, but observed in the engines of the cutting units, were described in [

37].

Partial confirmation of this hypothesis can be provided by the graph shown in

Figure 10.

Figure 10 was developed by introducing an additional variable (state) into the data set, based on the intervals determined in

Figure 9. This variable takes values according to

Table 5.

To increase the clarity of the graph, the values of this variable were averaged within a fifteen-second window. The graph in

Figure 10 covers a period of 5 h 30 min. The red line indicates the probable directions of the shearer’s movement (values of 0.4 and 0.6), and a value of 0.5 indicates its standstill.

3.5. Structure of Machine Operating States

Based on the rules determined in the analysis and collected in

Table 3, a set of results (

Table 6) was generated, showing the percentage structure of the machine operating states observed on consecutive days.

Table 6 presents the results of one week of observations. On all days, the vast majority of the time structure is occupied by the Off state. The largest share during the operation of the shearer is occupied by extraction activity (E) and the smallest share by the Idle (I) state. The maneuvering state is shown in column M. It should be recalled that the recorded data pertain to the period of implementation and testing of the shearer, and therefore, the results may significantly differ from those obtained in the conditions of industrial exploitation of the deposit.

4. Conclusions

The proposed method can serve as a verification tool for progress reported by employees. In a mine setting, the reporting of work through numbers provided by supervisory personnel is still used. The method described in this study enables a comparison of these values with the values calculated based on the analysis of current intensities, and thus, objective values can be obtained.

The results presented here do not include the shearer direction component, as the relationships discovered in the analysis must be further verified as a continuation of this work.

The presented analysis can also be an example of the fact that, in cases when the required process parameters are not available, they can be discovered based on other available parameters, which facilitates further analysis.

The authors believe that there is the need to develop a method to automatically separate groups of observations based on the shape of the histograms. Past considerations lead to determining the zero positions of the first derivative function approximating the quantitative distribution of observations.

The presented method can be implemented in information systems reporting the course of the production process in hard coal mines.

The calculations described in this paper are in line with the authors’ earlier works on monitoring the operation of machines. Issues related to identifying deviations from the norms of machine operation are presented in [

38]. The subject of monitoring the analysis of the effectiveness of machine use in hard coal exploitation by generating reports enabling the analysis of the degree of machine use is presented in [

39].