Instantaneous Electromagnetic Torque Components in Synchronous Motors Fed by Load-Commutated Inverters

Abstract

:1. Introduction

1.1. Classification of Variable Frequency Drive (VFD) Applications: Power Ratings

1.2. Motivation, Purpose and Organization of This Paper

1.3. Notes on Alternative Method to Evaluate Air-Gap Torque

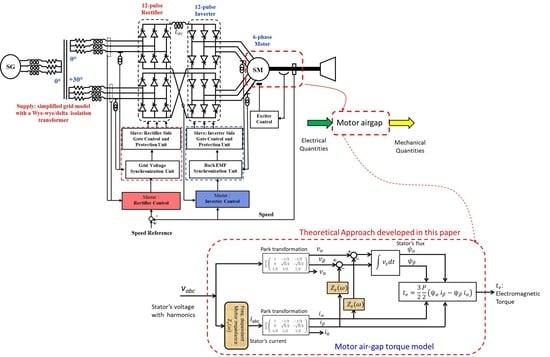

2. LCI Systems for Synchronous Motors

2.1. Operating Range of LCIs in O&G Industry

- Liquefied Natural Gas plants, with a speed between 3000 and 3600 rpm, and a power range between 10 and 80 MW.

- Pipeline recompression and decompression, with speed between 4000 and 8000 rpm, and a power range between 10 and 40 MW.

- Storage recompression and decompression, with speed between 8000 and 18,000 rpm, and a power range between 15 and 20 MW.

- Gas refrigeration with a speed between 15,000 and 20,000 rpm, and a power range between 0.75 and 4 MW.

2.2. Engineering Challenges of LCIs

2.2.1. Input Power Quality

2.2.2. Machine Compatibility: Induction vs. Synchronous Machines

2.2.3. Reliability

2.2.4. Torsional Excitation and Low-Torque Ripple

2.3. LCI System Configurations

2.4. Advantages and Drawbacks of LCIs

3. Instantaneous Electromagnetic Torque Harmonics in LCI Systems

3.1. Assumptions

3.2. LCI Current Harmonic Performance

3.3. LCI Current Harmonic Performance

3.4. Torque Harmonic Families for a 6/6-Pulse LCI System

3.5. Torque Harmonic Families for a 12/12-Pulse LCI System

3.6. Torque Harmonic Families for a 24/24-Pulse LCI System

3.7. Campbell Diagrams of LCI Systems

4. Numerical Validation of the Theoretical Results

4.1. Simulated Systems

4.2. Validation Method

4.2.1. Principle of Validation

4.2.2. Frequency Domain Validation

4.2.3. Confirmation of the Robustness of the Results

4.3. Selected Simulation Results of a 6/6-Pulse LCI System

4.3.1. Simulation Results in Time and Frequency Domains

4.3.2. Detailed Analysis of Harmonic Families

- Baseband harmonic family of stator current are located at : (i) and ; (ii) and ; (iii) and .

- Sideband harmonic family of stator current located around are given in the form of : (i) and ; (ii) and ; (iii) and ; (iv) and ; (v) and ; (vi) and ; (vii) and .

- Sideband harmonic family of stator current located around are given in the form of : (i) and ; (ii) and ; (iii) and ; (iv) and ; (v) and .

- Sideband harmonic family of stator current located around are given in the form of : (i) and .

- Baseband harmonic family of torque current are located at : (i) ; (ii) ; (iii) .

- Sideband harmonic family of torque current located around are given in the form of : (i) ; (ii) ; (iii) ; (iv) ; (v) ; (vi) ; (vii) .

- Sideband harmonic family of torque current located are given in the form of : (i) ; (ii) ; (iii) ; (iv) ; (v) .

- Sideband harmonic family of stator current located around are given in the form of : (i) .

4.3.3. Reconstruction of the Instantaneous Electromagnetic Air-Gap Torque Waveform

4.3.4. Campbell Diagram and Relevant Air-Gap Torque Harmonic Families and Their Magnitude

4.4. Selected Simulation Results of a 12/12-Pulse LCI System

4.4.1. 12/12-Pulse LCI System Operation at 40 Hz

4.4.2. Detailed Analysis of Harmonic Families

- Baseband harmonic family of stator current are located at : (i) and ; (ii) and ; (iii) and .

- Sideband harmonic family of stator current located around are given in the form of : (i) and ; (ii) and ; (iii) and .

- Sideband harmonic family of stator current located are given in the form of : (i) and ; (ii) and ; (iii) and .

- Baseband harmonic family of torque current are located at : (i) ; (ii) ; (iii) .

- Sideband harmonic family of torque current located around are given in the form of : (i) ; (ii) ; (iii) .

- Sideband harmonic family of torque current located are given in the form of : (i) ; (ii) ; (iii) .

4.4.3. Reconstruction of the Instantaneous Air-Gap Torque Waveform

4.4.4. Summary: Campbell Diagram and Relevant Air-Gap Torque Harmonic Families and Their Magnitudes

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Campbell, J.M. The Basic Principle. In Gas Conditioning and Processing, 8th ed.; John Campbell and Company: Norman, OK, USA, February 2004; Volume 1. [Google Scholar]

- Campbell, J.M. The Equipment Modules. In Gas Conditioning and Processing, 8th ed.; John Campbell and Company: Norman, OK, USA, February 2004; Volume 2. [Google Scholar]

- Hutten, V.; Zurowski, R.M.; Hilsher, M. Torsional interharmonic interaction study of 75 MW direct-driven VSDS motor compressor trains for LNG duty. In Proceedings of the 37th Turbomachery and Pump Symposia, College Station, TX, USA, 8–11 September 2008; pp. 57–66. [Google Scholar]

- Schramm, S.; Sihler, C.; Song-Manguelle, J.; Rotondo, P. Damping Torsional Interharmonic Effects of Large Drives. IEEE Trans. Power Electron. 2010, 25, 1090–1098. [Google Scholar] [CrossRef]

- API. API Standard 617, Axial and Centrifugal Compressors and Expander-Compressors, 8th ed.; API: Englewood, CO, USA, 2016. [Google Scholar]

- API. API Standard 672, Packaged, Integrally Geared Centrifugal Air Compressors for Petroleum, Chemical, and Gas Industry Services, 5th ed.; API: Englewood, CO, USA, August 2019. [Google Scholar]

- API. API Standard 673, Centrifugal Fans for Petroleum, Chemical and Gas Industry Services, 3rd ed.; API: Englewood, CO, USA, December 2014. [Google Scholar]

- API. API Standard 684, Paragraphs Rotodynamic Tutorial: Lateral Critical Speeds, Unbalance Response, Stability, Train Torsional, and Rotor Balancing, 2nd ed.; API Recommended Practice 684; API: Englewood, CO, USA, August 2005. [Google Scholar]

- Toliyat, H.A.; Nandi, S.; Choi, S.; Meshgin-Kelk, H. Electric Machines: Modelling, Condition Monitoring, and Fault Diagnosis; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2013; pp. 83–85. [Google Scholar]

- Rotondo, P.; Andreao, D.; Famoli, S.; Jörg, P.; Lenzi, A.; Hattenbach, T.; Fioravanti, D.; de Franciscis, S. Combined Torsional and Electromagnetic Analysis of an LNG Compression Train with Variable Speed Drive System. In Proceedings of the 38th Turbo Machinery Symposium, College Station, TX, USA, 14–17 September 2009; pp. 93–102. [Google Scholar]

- Song-Manguelle, J.; Sihler, C.; Schramm, S. A General Approach of Damping Torsional Resonance Modes in Multi-megawatt Applications. IEEE Trans. Ind. Appl. 2011, 47, 1390–1399. [Google Scholar] [CrossRef]

- Baccani, R.; Zhang, R.; Toma, T.; Iuretig, A.; Perna, M. Electric Systems for High Power Compressor Trains in Oil and Gas Applications—System Design, Validation Approach and Performance. In Proceedings of the 36th Turbo Machinery Symposium, College Station, TX, USA, 11–13 September 2007; pp. 61–68. [Google Scholar]

- Lipo, T.A. Introduction to AC Machine Design; Series on Power Engineering; Wiley-IEEE Press: Hoboken, NJ, USA, 2017. [Google Scholar]

- IEEE. Std 519-2014 Recommended Practice and Requirements for Harmonic Control in Electric Power Systems; IEEE: Piscataway, NJ, USA, 2014. [Google Scholar]

- Mohamadian, S.; Castellan, S.; Tessarolo, A.; Ferrari, G.; Shoulaie, A. An Algebraic Algorithm for Motor Voltage Waveform Prediction in Dual-LCI Drives with Interconnected DC-Links. IEEE Trans. Energy Convers. 2016, 31, 506–519. [Google Scholar] [CrossRef]

- Muetze, A.; Binder, A. Practical Rules for Assessment of Inverter-Induced Bearing Currents in Inverter-Fed AC Motors up to 500 Kw. IEEE Trans. Ind. Electron. 2007, 54, 1614–1622. [Google Scholar] [CrossRef]

- Mon-Nzongo, D.; Ekemb, G.; Song-Manguelle, J. LCIs and PWM-VSIs for the Petroleum Industry: A Torque Oriented Evaluation for Torsional Analysis Purposes. IEEE Trans. Power Electron. 2019, 34, 8956–8970. [Google Scholar] [CrossRef]

- Mohamadian, S.; Tessarolo, A.; Castellan, S.; Shoulaie, A. Steady-State Simulation of LCI-Fed Synchronous Motor Drives Through a Computationally Efficient Algebraic Method. Power Electron. IEEE Trans. 2017, 32, 452–470. [Google Scholar] [CrossRef]

- ABB Medium Voltage Drives. MEGADRIVE-LCI: Large Adjustable-Speed Synchronous Motor Drives, Power Range 2000 to 80000 kW; ABB Publication: Turgi, Switzerland, 2003. [Google Scholar]

- Bianchi, N.; Bolognani, S. Reducing torque ripple in PM synchronous motors. In Proceedings of the International Conference on Electrical Machines, ICEM 2000, Helsinki, Finland, 28–30 August 2000; pp. 1222–1226. [Google Scholar]

- Song-Manguelle, J.; Ekemb, G.; Mon-Nzongo, D.L.; Jin, T.; Doumbia, M.L. A Theoretical Analysis of Pulsating Torque Components in AC Machines with Variable Frequency Drives and Dynamic Mechanical Loads. IEEE Trans. Ind. Electron. 2018, 65, 9311–9324. [Google Scholar] [CrossRef]

| Parameters | 3-Phase (SM) | 6-Phase (SM) |

|---|---|---|

| Pn | 1.85 MW | 1.85 MW |

| Vllrms | 6000 V | 6000 V |

| fn | 50 Hz | 50 Hz |

| poles | 3 | 3 |

| Power Factor | 0.85 | 0.85 |

| Rs | 0.0085 pu | 0.0085 pu |

| Lls | 0.13 pu | 0.13 pu |

| Rf | 0.00218 | 0.005 pu |

| Llfd | 0.307 pu | 0.307 pu |

| Rkd | 0.0915 pu | 0.0915 pu |

| Llkd | 0.208 pu | 0.208 pu |

| Rkq | 0.079 pu | 0.079 pu |

| Llkq | 0.185 pu | 0.185 pu |

| Lmd | 1.26 pu | 1.29 pu |

| Lmq | 0.695 pu | 0.695 pu |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ekemb, G.; Slaoui-Hasnaoui, F.; Song-Manguelle, J.; Lingom, P.M.; Fofana, I. Instantaneous Electromagnetic Torque Components in Synchronous Motors Fed by Load-Commutated Inverters. Energies 2021, 14, 3223. https://doi.org/10.3390/en14113223

Ekemb G, Slaoui-Hasnaoui F, Song-Manguelle J, Lingom PM, Fofana I. Instantaneous Electromagnetic Torque Components in Synchronous Motors Fed by Load-Commutated Inverters. Energies. 2021; 14(11):3223. https://doi.org/10.3390/en14113223

Chicago/Turabian StyleEkemb, Gabriel, Fouad Slaoui-Hasnaoui, Joseph Song-Manguelle, P. M. Lingom, and Issouf Fofana. 2021. "Instantaneous Electromagnetic Torque Components in Synchronous Motors Fed by Load-Commutated Inverters" Energies 14, no. 11: 3223. https://doi.org/10.3390/en14113223