Techno-Economic Investigation of an Integrated Boiler–Solar Water Heating/Cooling System: A Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Case Study

2.2. Heating/Cooling Energy Calculations

2.3. The Area of the Study

2.4. Experimental Set-Up

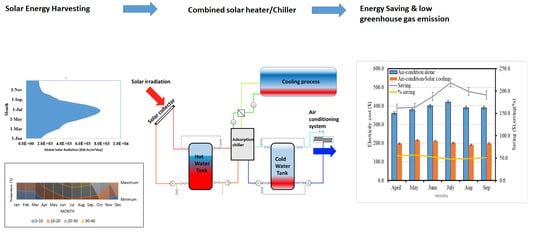

2.5. Process Performance and Energy Saving

2.6. Economic Analysis

3. Results and Discussion

3.1. Economic Analysis

3.2. Solar Cooling

3.3. CO2 Emission Benefit

3.4. Cost Analysis and Payback Period

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Qi | Absorbed solar energy (kJ) |

| Tam | Ambient temperature (°C) |

| Tav | Average annual temperature (°C) |

| SIIavg.,d | Average daily solar irradiation intensity (Kwh/m2/day) |

| tsun,m | Average monthly number of sunny hours (h) |

| Tavg., m | Average monthly temperature (°C) |

| COPcooling | Coefficient of performance of the solar cooling absorption cycle |

| Pc | Collected power (W), |

| Cooling efficiency (%) | |

| CCF | Cumulative cash flow |

| CDCF | Cumulative discounted cash flow |

| DTC | Differential temperature controller |

| me | Flow rate of refrigerant (L/s) |

| FHR | Heat removal factor |

| Qref | Heat removed by refrigerant (kJ) |

| Qr | Heat removed from a cold room (kJ) |

| HTPM | High temperature profile months |

| Iavg | Incident solar irradiation per unit area (W/m2) |

| Ti | inlet temperature of the water entering the collector (°C) |

| Log mean temperature (K) | |

| LTPM | Low temperature profile months |

| MTPM | Medium temperature profile months |

| Tout | Outlet temperature of water leaving the collector (°C) |

| UF-PSC | Overall heat loss coefficient (W/m2K) |

| U | Overall heat transfer coefficient (W/(m2K)) |

| %Es | Percentage energy saving (%) |

| %Echiller | Percentage of energy saving of the chiller (%) |

| %η | Percentage thermal performance (%) |

| Refrigerant Temperature (°C) | |

| Room Temperature (°C) | |

| Kcol | Solar collector absorption coefficient |

| SII | Solar irradiation intensities (W/m2) |

| Cp | Specific heat of the water (J/kg.°C), |

| ∆h | The enthalpy cooling fluid (kJ/kg) |

| A | Total area of the collector (m2). |

| Qw | Water flow rate (L/s) |

| Water mass flow rate (kg/s) | |

| Tw | Water temperature (°C) |

| Ws | wind speed (m/s) |

References

- Al-Qodah, Z.; Al-Shannag, M.; Amro, A.; Assirey, E.; Bob, M.; Bani-Melhem, K.; Alkasrawi, M. Impact of surface modification of green algal biomass by phosphorylation on the removal of copper(II) ions from water. Turk. J. Chem. 2017, 41, 190–208. [Google Scholar] [CrossRef]

- Al-Shannag, M.; Al-Qodah, Z.; Nawasreh, M.; Al-Hamamreh, Z.; Bani-Melhem, K.; Alkasrawi, M. On the performance of Ballota undulata biomass for the removal of cadmium(II) ions from water. Desalin. Water Treat. 2017, 67, 223–230. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Kafiah, F.; Tawalbeh, M.; Khraisheh, M.; Azzam, A.; Alzoubi, I.; Alkasrawi, M. Performance analysis of hybrid solar chimney–power plant for power production and seawater desalination: A sustainable approach. Int. J. Energy Res. 2020. [Google Scholar] [CrossRef]

- Almomani, F.; Al Ketife, A.; Judd, S.; Shurair, M.; Bhosale, R.R.; Znad, H.; Tawalbeh, M. Impact of CO2 concentration and ambient conditions on microalgal growth and nutrient removal from wastewater by a photobioreactor. Sci. Total. Environ. 2019, 662, 662–671. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Znad, H.; Al Ketife, A.M.; Judd, S.; Almomani, F.; Vuthaluru, H.B. Bioremediation and nutrient removal from wastewater by Chlorella vulgaris. Ecol. Eng. 2018, 110, 1–7. [Google Scholar] [CrossRef]

- Mohammed, H.; Al-Othman, A.; Nancarrow, P.; Tawalbeh, M.; Assad, M.E.H. Direct hydrocarbon fuel cells: A promising technology for improving energy efficiency. Energy 2019, 172, 207–219. [Google Scholar] [CrossRef]

- Bhosale, R.R.; Kumar, A.; Khraisheh, M.; Ghosh, U.; AlNouss, A.; Scheffe, J.; Gupta, R.B. CO2 Capture Using Aqueous Potassium Carbonate Promoted by Ethylaminoethanol: A Kinetic Study. Ind. Eng. Chem. Res. 2016, 55, 5238–5246. [Google Scholar] [CrossRef]

- Ashok, A.; Kumar, A.; Bhosale, R.; Saad, M.A.S.; Khraisheh, M.; Tarlochan, F. Study of ethanol dehydrogenation reaction mechanism for hydrogen production on combustion synthesized cobalt catalyst. Int. J. Hydrogen Energy 2017, 42, 23464–23473. [Google Scholar] [CrossRef]

- Al-Smairan, M.H. Investigation of a Hybrid Wind-Photovoltaic Electrical Energy System for a Remote Community. Ph.D. Thesis, Coventry University, Coventry, UK, 2006. [Google Scholar]

- Baumeister, C.; Kilian, L. Forty Years of Oil Price Fluctuations: Why the Price of Oil May Still Surprise Us. J. Econ. Perspect. 2016, 30, 139–160. [Google Scholar] [CrossRef] [Green Version]

- Al-Maamary, H.M.; Kazem, H.A.; Chaichan, M.T. The impact of oil price fluctuations on common renewable energies in GCC countries. Renew. Sustain. Energy Rev. 2017, 75, 989–1007. [Google Scholar] [CrossRef]

- Khatib, H. Oil and natural gas prospects: Middle East and North Africa. Energy Policy 2014, 64, 71–77. [Google Scholar] [CrossRef]

- Bhattacharyya, S.C.; Timilsina, G.R. Modelling energy demand of developing countries: Are the specific features adequately captured? Energy Policy 2010, 38, 1979–1990. [Google Scholar] [CrossRef]

- Akash, B.A.; Mohsen, M.S. Current situation of energy consumption in the Jordanian industry. Energy Convers. Manag. 2003, 44, 1501–1510. [Google Scholar] [CrossRef]

- Al-Ghandoor, A. Evaluation of energy use in Jordan using energy and exergy analyses. Energy Build. 2013, 59, 1–10. [Google Scholar] [CrossRef]

- Al-Ghandoor, A.; Al-Hinti, I.; Jaber, J.; Sawalha, S. Electricity consumption and associated GHG emissions of the Jordanian industrial sector: Empirical analysis and future projection. Energy Policy 2008, 36, 258–267. [Google Scholar] [CrossRef]

- Al-Bajjali, S.K.; Shamayleh, A.Y. Estimating the determinants of electricity consumption in Jordan. Energy 2018, 147, 1311–1320. [Google Scholar] [CrossRef]

- Siddiqi, A.; Anadón, L.D. The water–energy nexus in Middle East and North Africa. Energy Policy 2011, 39, 4529–4540. [Google Scholar] [CrossRef]

- Taib, M. The mineral industry of Jordan. In Minerals Yearbook: Area Reports: International Review 2012 Africa and the Middle East; U.S. Geological Survey: Reston, VA, USA, 2015; Volume 3, p. 43. [Google Scholar]

- Hrayshat, E.S. Oil Shale—An Alternative Energy Source for Jordan. Energy Sources Part A 2008, 30, 1915–1920. [Google Scholar] [CrossRef]

- Ali, H.H.; Al Nsairat, S.F. Developing a green building assessment tool for developing countries–Case of Jordan. Build. Environ. 2009, 44, 1053–1064. [Google Scholar] [CrossRef]

- Badeeb, R.A.; Lean, H.H.; Clark, J. The evolution of the natural resource curse thesis: A critical literature survey. Resour. Policy 2017, 51, 123–134. [Google Scholar] [CrossRef]

- Mason, M.; Al-Muhtaseb, M.A.; Al-Widyan, M. The Energy Sector in Jordan–Current Trends and the Potential for Renewable Energy. In Renewable Energy in the Middle East; Springer Science and Business Media LLC: Berlin/Heidelber, Germany, 2009; pp. 41–54. [Google Scholar]

- Al-Salaymeh, A.; Al-Rawabdeh, I.; Emran, S. Economical investigation of an integrated boiler–solar energy saving system in Jordan. Energy Convers. Manag. 2010, 51, 1621–1628. [Google Scholar] [CrossRef]

- Mohammed, H.; Al-Othman, A.; Nancarrow, P.; Elsayed, Y.; Tawalbeh, M. Enhanced proton conduction in zirconium phosphate/ionic liquids materials for high-temperature fuel cells. Int. J. Hydrogen Energy 2019. [Google Scholar] [CrossRef]

- Mamlook, R.; Akash, B.A.; Nijmeh, S. Fuzzy sets programming to perform evaluation of solar systems in Jordan. Energy Convers. Manag. 2001, 42, 1717–1726. [Google Scholar] [CrossRef]

- Badran, O. Study in industrial applications of solar energy and the range of its utilization in Jordan. Renew. Energy 2001, 24, 485–490. [Google Scholar] [CrossRef]

- Al-Soud, M.S.; Hrayshat, E.S. A 50 MW concentrating solar power plant for Jordan. J. Clean. Prod. 2009, 17, 625–635. [Google Scholar] [CrossRef]

- Al-Nimr, M.A.; Kiwan, S.; Sharadga, H. Simulation of a novel hybrid solar photovoltaic/wind system to maintain the cell surface temperature and to generate electricity. Int. J. Energy Res. 2018, 42, 985–998. [Google Scholar] [CrossRef]

- Hernandez, P.; Kenny, P. Net energy analysis of domestic solar water heating installations in operation. Renew. Sustain. Energy Rev. 2012, 16, 170–177. [Google Scholar] [CrossRef]

- Ruicheng, Z.; Tao, H.; Xinyu, Z.; Zhulian, H.; Yu, D. Developing Situation and Energy Saving Effects for Solar Heating and Cooling in China. Energy Procedia 2012, 30, 723–729. [Google Scholar] [CrossRef] [Green Version]

- Xuan, W.; Min, W.; Tao, H.; Ruicheng, Z.; Zhong, L.; Xinyu, Z.; Airong, F. Simulation of Annual Energy Saving Benefit of Solar Collector. Energy Procedia 2012, 30, 172–176. [Google Scholar] [CrossRef] [Green Version]

- Birdsall, B.; Buhl, W.F.; Ellington, K.L.; Erdem, A.E.; Winkelmann, F.C. Overview of the DOE-2 Building Energy Analysis Program, Version 2.1 D; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1990. [Google Scholar]

- Winkelmann, F.C.; Selkowitz, S. Daylighting simulation in the DOE-2 building energy analysis program. Energy Build. 1985, 8, 271–286. [Google Scholar] [CrossRef] [Green Version]

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Pedersen, C.O. EnergyPlus: New Capabilities in a Whole-Building Energy Simulation Program. In Proceeding of the 7th International IBPSA Conference, Rio de Janeiro, Brazil, 13–15 August 2001; pp. 51–58. [Google Scholar]

- Fisher, D.E.; Pedersen, C.O. Convective Heat Transfer in Building Energy and Thermal Load Calculations; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 1997. [Google Scholar]

- Pagliarini, G.; Corradi, C.; Rainieri, S. Hospital CHCP system optimization assisted by TRNSYS building energy simulation tool. Appl. Therm. Eng. 2012, 44, 150–158. [Google Scholar] [CrossRef]

- Asadi, E.; Da Silva, M.G.; Antunes, C.H.; Dias, L. A multi-objective optimization model for building retrofit strategies using TRNSYS simulations, GenOpt and MATLAB. Build. Environ. 2012, 56, 370–378. [Google Scholar] [CrossRef]

- Shariah, A.; Tashtoush, B.; Rousan, A. Cooling and heating loads in residential buildings in Jordan. Energy Build. 1997, 26, 137–143. [Google Scholar] [CrossRef]

- Yin, Y.; Song, Z.; Li, Y.; Wang, R.; Zhai, X. Experimental investigation of a mini-type solar absorption cooling system under different cooling modes. Energy Build. 2012, 47, 131–138. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, R.; Wang, H. Experimental evaluation of a variable effect LiBr–water absorption chiller designed for high-efficient solar cooling system. Int. J. Refrig. 2015, 59, 135–143. [Google Scholar] [CrossRef]

- Lin, L.; Tian, Y.; Luo, Y.; Chen, C.; Jiang, L. A novel solar system integrating concentrating photovoltaic thermal collectors and variable effect absorption chiller for flexible co-generation of electricity and cooling. Energy Convers. Manag. 2020, 206, 112506. [Google Scholar] [CrossRef]

- Martinopoulos, G.; Tsalikis, G. Diffusion and adoption of solar energy conversion systems—The case of Greece. Energy 2018, 144, 800–807. [Google Scholar] [CrossRef]

- Sami, S.; Semmar, D.; Hamid, A.; Mecheri, R.; Yaiche, M. Viability of integrating Solar Water Heating systems into High Energy Performance housing in Algeria. Energy 2018, 149, 354–363. [Google Scholar] [CrossRef]

- Benli, H. Potential application of solar water heaters for hot water production in Turkey. Renew. Sustain. Energy Rev. 2016, 54, 99–109. [Google Scholar] [CrossRef]

- Martinopoulos, G.; Tsalikis, G. Active solar heating systems for energy efficient buildings in Greece: A technical economic and environmental evaluation. Energy Build. 2014, 68, 130–137. [Google Scholar] [CrossRef]

- Abd-Ur-Rehman, H.M.; Al-Sulaiman, F.A. Optimum selection of solar water heating (SWH) systems based on their comparative techno-economic feasibility study for the domestic sector of Saudi Arabia. Renew. Sustain. Energy Rev. 2016, 62, 336–349. [Google Scholar] [CrossRef]

- Shirazi, A.; Taylor, R.A.; White, S.D.; Morrison, G.L. A systematic parametric study and feasibility assessment of solar-assisted single-effect, double-effect, and triple-effect absorption chillers for heating and cooling applications. Energy Convers. Manag. 2016, 114, 258–277. [Google Scholar] [CrossRef]

- Djelloul, A.; Draoui, B.; Moummi, N. Simulation of a solar driven air conditioning system for a house in dry and hot climate of Algeria. Courr. Savoir 2013, 15, 31–39. [Google Scholar]

- Alrwashdeh, S.S.; Alsaraireh, F.M.; Saraireh, M.A. Solar radiation map of Jordan governorates. Int. J. Eng. Technol. 2018, 7, 1664–1667. [Google Scholar] [CrossRef]

- Kiwan, S.; Venezia, L.; Montagnino, F.; Paredes, F.; Damseh, R. Techno-Economic Analysis of a Concentrated Solar Polygeneration Plant in Jordan. JJMIE 2018, 12, 1–6. [Google Scholar]

- Alrwashdeh, S.S.; Alsaraireh, F.M. Investigation of solar radiation distribution over three zones north, middle and south of Jordan. Int. J. Eng. Technol. 2018, 7, 5047–5050. [Google Scholar]

- Kong, W.; Wang, Z.; Fan, J.; Perers, B.; Chen, Z.; Furbo, S.; Andersen, E. Investigation of Thermal Performance of Flat Plate and Evacuated Tubular Solar Collectors According to a New Dynamic Test Method. Energy Procedia 2012, 30, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Al-Salaymeh, A.; Al-Salaymeh, M.; Rabah, M.; Abdelkader, M. Enhancement of the coefficient of performance in air conditioning systems by utilizing free cooling. In Proceeding of the 2nd International Conference on Thermal Engineering Theory and Applications, Al Ain, UAE, 3–6 January 2006; pp. 3–6. [Google Scholar]

- Rojas, D.; Beermann, J.; Klein, S.; Reindl, D. Thermal performance testing of flat-plate collectors. Sol. Energy 2008, 82, 746–757. [Google Scholar] [CrossRef]

- Kalogirou, S. Thermal performance, economic and environmental life cycle analysis of thermosiphon solar water heaters. Sol. Energy 2009, 83, 39–48. [Google Scholar] [CrossRef]

- Howell, J.R.; Bannerot, R.B.; Vliet, G.C. Solar-Thermal Energy Systems: Analysis and Design; Mcgraw-Hill College: New York, NY, USA, 1982. [Google Scholar]

- Stanciu, C.; Stanciu, D.; Gheorghian, A.-T. Thermal Analysis of a Solar Powered Absorption Cooling System with Fully Mixed Thermal Storage at Startup. Energies 2017, 10, 72. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Said, Z.; Issa, S. Performance evaluation and life cycle analysis of new solar thermal absorption air conditioning system. Energy Rep. 2020, 6, 673–679. [Google Scholar] [CrossRef]

- International Energy Agency. Emissions per kWh of Electricity and Heat Output; International Energy Agency: Paris, France, 2015. [Google Scholar]

- Paraschiv, S.; Bărbuţă-Mişu, N.; Paraschiv, L.S. Technical and economic analysis of a solar air heating system integration in a residential building wall to increase energy efficiency by solar heat gain and thermal insulation. Energy Rep. 2020, 6, 459–474. [Google Scholar] [CrossRef]

| Building Heat Transfer Parameters | Value (Std. Dev.) |

| Absorbance of the building (α) | 0.55 ± 0.05 (1.20) |

| Average area of the windows | 3.5 ± 0.05 (0.88) |

| Heat capacity of furniture (Cfur) | 2200 ± 20 (0.58) kJ/°C |

| Heat transfer coefficient of windows (hc,w) | 45 ± 5 (1.10) kJ/h.m2.°C |

| Heat loss coefficient through windows (Wl,win) | 25 ± 5 (2.5) kJ/h.m2.°C |

| Internal room diminution (L:W:H) | 12:8:3.5 m |

| Insight equipment heating duty (Qin) | 300 ± 30 (1.1) kJ/h |

| Internal reflection coefficient (Refin) | 0.65 ± 0.06 (0.09) |

| Input to TRNSYS 14.1 program | Value (Std. Dev.) |

| Heat capacity of air (Cair) | 2000 ± 20 (1.18) kJ/°C |

| Space heat gained- non-radiative (Qgain) | 500 ± 25 (0.88) kJ/h |

| Dehumidification coefficient (ωmax) | 0.55 ± 0.05 (0.19) |

| Humidification coefficient (ωmin) | 0.25 ± 0.05 (0.11) |

| Set point heating Temperature (TSp,C, °C) | 18 ± 0.5 (0.18) |

| Set point cooling Temperature (TSp,H, °C) | 27 ± 0.5 (0.18) |

| Radiation transmissivity of glass (Tg, °C) | 0.8 |

| Wind Speed (Swind, m/s ) | 3.5 ± 0.1 (0.23) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Smairan, M.; Shawaqfah, M.; AlMomani, F. Techno-Economic Investigation of an Integrated Boiler–Solar Water Heating/Cooling System: A Case Study. Energies 2021, 14, 1. https://doi.org/10.3390/en14010001

Al-Smairan M, Shawaqfah M, AlMomani F. Techno-Economic Investigation of an Integrated Boiler–Solar Water Heating/Cooling System: A Case Study. Energies. 2021; 14(1):1. https://doi.org/10.3390/en14010001

Chicago/Turabian StyleAl-Smairan, Mohammad, Moayyad Shawaqfah, and Fares AlMomani. 2021. "Techno-Economic Investigation of an Integrated Boiler–Solar Water Heating/Cooling System: A Case Study" Energies 14, no. 1: 1. https://doi.org/10.3390/en14010001