1. Introduction

Large-scale axial-flow and mixed flow pumps are typically used for a variety of purposes such as irrigation, drainage, water treatment, thermal and nuclear power plants, steelworks, petrochemical plants and even in the shipbuilding industry. Developed specifically for large-capacity low-head applications, these pumps’ operating conditions are highly influenced by flow conditions in the intake structures. Unfortunately, the proper design of these intake structures is also the most overlooked aspect when designing a pumping station. Poorly designed intake structures are those that fail to control any possible harmful formation of free-surface and submerged vortices. These vortices tend to result in energy loss, reduced flow rate, vibration, surging, structural damage, cavitation and safety hazards. A 3% to 4% air entrainment due to these vortices may produce a small but continuous decrease in pump efficiency. Fundamentally, for a 1% drop in efficiency, only a small amount of entrained air is necessary [

1]. A loss in efficiency by this relatively small rate may lead to losses in profit which, in a few years, can exceed the initial capital cost of the pump [

2].

Specifically, for pump bays, vortices are caused by the swirl that is formed at the hydraulic intakes due to a non-uniform approach flow. This swirl can be defined as the tendency of the fluid to move with a twisting or rotating motion. By itself, this swirling motion is oftentimes unavoidable and is not considered an engineering problem. Rather it is the degree of this swirling motion that determines the detrimental effect and possibility of vortex formation.

For pump installations experiencing these problems, the most commonly suggested solution is to increase the submergence of the vertical pump’s inlet bellmouth. In most cases, this solution often results in largely oversized and expensive structures. Since the cost of a typical pump structure grows directly with its size, site excavation issues and economic constraints requires pump intake size to be kept as small as possible. This naturally limits the application of this solution. Reducing the pump speed is still another common remedy. Although this implies sacrificing pump efficiency by operating the structure below its rated flow capacity. This in turn increases the long-term operating costs.

In general, no amount of engineering can produce an ideal design that ensures that the intake will be free from any swirl or vortices. As a solution, the American National Standard Institute Hydraulic Institute Standard for Intake Design (ANSI/HI) [

3] established strict conditions on when pump stations designs should undergo physical model testing prior to construction or rehabilitation. Among the conditions that necessitate a physical model test are when:

an individual pump or total station flow exceeds 9085 m3/h (40,000 gpm) and 22,710 m3/h (100,000 gpm) respectively;

intake or pump bay designs that deviate from standards, pump compartments with non-symmetrical approach flows;

pump stations whose operation is critical and prolonged outages due to maintenance are unacceptable.

These physical models allow visual observation of the flow as well as collection of data such as velocity distribution, pressure gradients, depth of flow, and prerotation. Such a test presents a reliable method to identify unacceptable flow patterns. Unfortunately, these physical models are also site-specific, time-consuming and costly to perform and often add very low economic value to the project. Therefore, development of alternative tools or methods for evaluating sump performance is highly demanded in the pump design industry. One such tool that deserves attention is the numerical simulation of computerized models representing the system that needs to be studied. Such simulation, termed Computational Fluid Dynamics (CFD), uses the general fluid flow equations to predict the flow field, turbulence, mass transfer, and other related hydraulic phenomena. In contrast to the cost of conducting a scaled physical model experiment, the lower operating cost together with the current advances in numerical simulations position CFD as an ideal alternative tool for pump designers.

For the past few decades, the ever lower cost coupled with the advancement in computing technology had constantly driven the pump industry to look into Computational Fluid Dynamics as an alternative means of developing better, least expensive, and more reliable pumps [

4,

5,

6]. CFD coupled with stress analysis had been efficiently used in the design of various pump components like shafts, seals, impellers, diffusers and casings among others. But for intake structure design, physical model experiments had still remained as a primary mandatory requirement as per existing codes and standards. The capability of CFD to consistently provide information about the vortex strength and temporal variation in these structures had remained a debatable topic. Also, additional difficulties associated with modelling free surfaces and predicting vortex phenomena oftentimes forces designers and CFD analysts to avoid the use of multiphase flow models and instead enforce a free-slip wall on the free-surface. For this reason, various investigations and researches had been conducted aiming to validate the accuracy and suitability of numerical models as compared to physical model studies.

Among the early studies in using CFD for the investigation of flow problems at pump intakes were those conducted by Constantinescu and Patel [

7]. A numerical model of a simple water-intake bay was developed to simulate the three-dimensional flow field and to study the formation of free-surface and submerged vortices. The analysis solves the Reynolds-averaged Navier-Stokes equation with a two-layer

turbulence model. Symmetric vortex formations were observed in the numerical solution. It was highlighted that this symmetry is rarely observed in reality and was only present in the numerical results due to the idealized flow and boundary conditions. It was reported that the CFD model was able to predict in detail the location, size and strength of the vortices.

Later, as part of an extensive experimental study of pump-bay flow phenomena, Rajendran and Patel [

8], conducted a simplified laboratory experiment specifically to validate the numerical model presented by Constantinescu and Patel. A model of a 0.003 m

3/s rectangular pump sump was constructed and velocity fields were measured using particle-image velocimetry (PIV). Comparing the CFD results, it was confirmed that the results for the position, number and overall structure for both the free-surface and subsurface vortices were in good agreement with the physical model. However, with the exception of the strongest vortex, the calculated vortices were more diffused and less intense than the vortices observed in the experiment.

Since both the physical experiments [

8] and the numerical model [

7] was conducted using simplified laboratory model, several limitations were noted. Among these are:

no inlet suction bell was used in the experimental sump, instead a straight vertical column was used;

the flow condition was limited to a very low Reynolds number (= 60,000);

the numerical model was not able to handle flows with high Reynolds numbers;

the intake column was modelled using zero-thickness walls since the numerical model was not able to handle complicated geometries (suction bellmouths);

the numerical results did not report neither the velocity distribution nor the swirl angle at the pipe column which are both vital for inlet structure design.

To address these limitations, Li et al. [

9] conducted a CFD model study based on an actual water pump intake structure. Their study applied higher Reynolds number to mimic a more practical pump-station. The simulation involved a more complex intake bellmouth geometry based on the 1:10 undistorted model of Union Electric’s Labadie Power Plant on the Missouri River near St. Louis, MO, USA. The model was based on the works of Lai et al. [

10] utilizing finite-volume-based unstructured grid technology that allowed the use of flexible mesh cell shapes. Similar to the previous studies, the simulation solves the RANS equation with the

turbulence model with wall functions. Two incoming flow conditions, designated as “cross-flow” and “no-cross-flow” were simulated to eliminate the limitations present in the first study [

8]. It was reported that the pertinent flow patterns in the forebay for both “no-cross-flow” and “cross-flow” conditions observed in the scaled model experiment were well captured by the numerical model. For “no-cross-flow” conditions, the calculated axial velocity at the throat of the suction bell showed good agreement with experimental data except for points near the pipe wall. Inversely, for “cross-flow” conditions, the steady state solution gave relatively low agreement with experiment data. As such, an unsteady-state solution is recommended for such scenario. Taking these issues into considerations, the study concluded that CFD may be used as a cost-effective tool for preliminary engineering designs.

Recognizing the impact of conducting physical model studies on the development cost of pumps, Okamura et al. [

11], carried out a study on the accuracy and reliability of various CFD codes in predicting vortices in sumps. The assessment was carried out by validating the results obtained from current commercially available CFD codes like STAR-CD, ANSYS CFX, Virtual Fluid Systems 3D and SCRYU/TETRA against results from a physical sump model. The benchmarks were conducted under three different discharge conditions and submergence level. Due to the difference in software capability, the CFD models varied in grid structure and mesh density. The turbulence model also varied across all numerical model with STAR-CD using

RNG,

for CFX, and

SST being used for SCRYU/TETRA. Point velocities from numerical results were compared from experiment results acquired through PIV and LLS. Stream lines and vortex core lines taken using video and still cameras were also compared to those obtained from the numerical models. It was concluded that some CFD codes are able to predict the vortex formation with enough accuracy for industrial applications [

11]. The results for both the physical model and the CFD code agrees qualitatively in terms of velocity distributions in the intake bellmouth. However, the agreement is poor in terms of magnitude and distribution patterns for the vorticity.

Wicklein et al. [

12] are among those who have successfully utilized steady state RANS models to optimize the design of a wastewater treatment plant influent pump station. The original proposed pump station design was developed using extensive scale physical model test to verify hydraulic performance. Unfortunately, subsequent changes to the pump station’s operating condition required a revised influent sewer design. With the goal of evaluating the effect of the proposed upstream sewer changes, Wicklean et al. utilized CFD to verify and refine the hydraulic design of the proposed pump station. Numerical results showed that surface vortex formation was very dependent on geometry. For this reason, proposed modifications were simulated using CFD. The aim of which is improving sump performance by reducing the potential for vortices to develop, improve velocity distribution and reduced pre-swirl. For this pump station, CFD models were used for design optimization and later for additional changes at the time of construction. Satisfactory results were reported in using CFD highlighting its advantage over physical model studies. One major advantage being that results produced are digital and can be kept to investigate changes at time of construction or any point in the future.

Similarly, the use of CFD in evaluating pump performance is being continuously developed and investigated in line with advancements in numerical methods. One such study was made by Shukla and Kshirsagar [

13] on a vertical axis, single stage centrifugal pump. The study compared the numerical results with those obtained from a physical model test of a pump rated at 0.508 m

3/s at 60 m head running at 1450 rpm with an impeller eye of 330 m. The multiphase flow was modelled using Eulerian approach while the mass transfer through cavitation used Rayleigh-Plesset equation. Standard

turbulence model with scalable wall functions was selected for the numerical analysis. NPSH results obtained from Ansys CFX showed a good matching trend with those obtained from the physical experiment. Furthermore, the numerical model was able to predict the formation and growth of vapor bubbles on the impeller making CFD a viable tool in predicting pump performance deterioration caused by cavitation

Nagahara et al. [

14] investigated a detailed velocity distribution around the submerged vortex cavitation in a pump intake by means of PIV utilizing a pressurized tank to control the main inlet velocity. They believed that there have been no quantitative data concerning submerged vortex cavitation in particular. Thus, it is necessary to investigate its effects to establish reliable guidelines for the design of trouble-free pumps and intakes.

Most previous studies in predicting vortex formation deals with either treating the calculation domain as a single phase model applying symmetry boundary condition on the free surface [

15,

16] or through high-fidelity multiphase simulations requiring highly intensive calculations [

17,

18] which becomes unacceptable for industrial application. The goal of this paper is to provide a practical CFD method to augment existing pump intake design procedures in terms for predicting and minimizing vortex formation and swirl. The method should be optimized in terms of computational efforts but with sufficient accuracy as compared with physical model test results.

In this study, an implicit volume of fluid (VOF) multiphase numerical model of a 530 mm wide rectangular intake sump housing a 116 m3/h pump with a 260 mm diameter inlet bellmouth is analyzed using ANSYS Fluent. The flow conditions, vortex formation and inlet swirl are compared to the results obtained from a physical model test. The aim of this study is to validate the use of CFD as an alternative method of evaluating flow behavior in pump sumps concentrating mainly on vortex prediction, anti-vortex devices and related prerotation.

The novelty of this work is the investigation of various sump floor configurations showing their effects on reducing the entrained vortices developed within the suction lines.

2. Experimental Setup

In conducting any CFD simulations, it is vital that numerical accuracy be demonstrated by either comparing results to a well-established analytical model or to the results acquired from conducting a physical model experiment. In this paper, photographs and plot data taken from the baseline test of a 1:10 undistorted scale hydraulic model is presented as reference in evaluating the numerical results. These data are lifted from a recent pump project supplying cooling water to a thermal power plant and are presented here with implicit permission from Hitachi Plant Technologies, Ltd. PBO. (Makati City, Philippines). The prototype model consisted of two 5.3 m wide by 14 m long pump bay and one 2.0 m wide auxiliary channel. The 5.3 m wide pump bay feeds two vertical axis mixed flow pumps each rated at 36,700 m

3/h with a total dynamic head (TDH) of 15 m. The auxiliary channel feeds a smaller auxiliary pump rated at 4400 m

3/h against a TDH of 12.5 m. For this study, the focus will be on the main pumps since these are the crucial components for this pump station. For open channel flows such as these sump, gravity and inertial forces play a more dominant role than viscous or turbulent shear forces. As such, dynamic similarity during the test was maintained by keeping the Froude number

between the model and the prototype constant. Furthermore, ANSI/HI recommends a minimum value for both the Reynolds number

and Weber number

to avoid any scale effects and surface tension effects in the model. A minimum

is necessary in order to ensure that the flow condition in the model is as turbulent as that of the prototype. While a minimum

is recommended in order to avoid surface tension effects particularly in fully developed stage where the vortices start to draw in air from the surface.

Table 1 shows the

and

numbers calculated at the 260 mm diameter suction bell. These values justify and prove that the selected scale (1:10) is sufficient for the physical model test. Using this scale, the model capacity based on the 36,700 m

3/h maximum flow capacity of the prototype is taken as 116.07 m

3/h.

In order to protect proprietary data, a 3D representation of the hydraulic test model is presented in

Figure 1 in lieu of a picture of the actual setup. A centrifugal pump was used to recirculate water through a diffuser that spreads the flow over the entire width of the forebay. Orifice plates and control valves were installed to control the individual pump flows as well as the total model flow. Straightening devices were installed in the model head-box representing the trash racks and travelling screens in the prototype. This is to ensure that flow entering from the forebay is as uniform and as steady as possible. Typically for hydraulic model studies, impeller induced flows are not considered. This is mainly due to the fact that the main focus of the test is to verify the flow conditions and vortex formations in the sump as the fluid enters the pump and not the performance of the pump. Hence in this case, the 116 m

3/h vertical axis semi-axial pump is represented using a 130 mm diameter vertical pipe with a 260 mm diameter suction bellmouth. The bellmouth was fabricated from transparent polyvinyl chloride to facilitate visual observation.

All other aspects of the hydraulic model test comply with the latest ANSI/HI 9.8 test standards in terms of acceptance criteria, scale selection, data collection and instrumentation. Specifically, the pump model flow rates were determined using an ASME standard orifice meter with an accuracy of ±2%. The water level in the pump sump were recorded with a staff gauge referenced from the sump floor with a minimum accuracy of 3-mm. Velocity probe with a repeatability of ±2% was installed to measure point velocities at specific points along the throat of the suction bell. Typically, measurements of swirl in sump model test are done through visual inspection. The number of revolutions made by the swirl meter are counted and related to the flow rate. For the physical model test discussed in this paper, a swirl meter consisting of four straight vanes mounted on a shaft with low friction bearings was installed at a height of four suction pipe diameters downstream from the bell mouth to measure the level of pre-swirl as flow enters the pump.

The swirl angle is calculated by:

where

average axial velocity,

diameter of the pipe in which the swirl meter is installed and

revolutions per second of the swirl meter

The design specifications for the physical model is outlined in

Table 2.

5. Conclusions

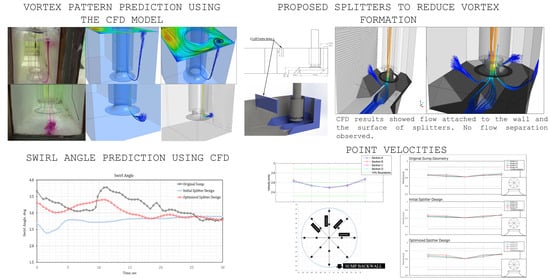

This paper presented results of numerical simulation as compared with data from reduced-scale physical model test of pump sump focusing on vortex prediction and swirl angle at intakes.

The numerical model was able to accurately predict the formation, size and location of the type 3 surface vortex that was observed in the physical experiment. Similar to the experiment, the predicted surface vortex was intermittent and was not able to draw in any air to the suction bell mouth.

The strong backwall and floor vortices observed in the physical model test were also replicated in the numerical results. Numerical results showed that the flow separation along the side walls of the sump as well as high turbulence at the back of the pump to be the primary cause of this submerged vortices.

Point velocity data from the numerical analysis showed a good agreement with those measured at several points along the bellmouth throat during the physical model test. Both numerical data and experimental data displayed acceptable similarity in terms of magnitude and trend.

On the other hand, numerical results showed a 30-s maximum short-term swirl angle of 3.75° at a location where the pump impeller was supposed to be. This value is lower than the maximum short-term swirl of 7.5° obtained from the physical model test. The discrepancy between the numerical and the experimental results may be attributed to the difference in the measurement method used. The physical model test measures swirl angle using a rotameter which can change rotation direction depending on the flow. In general, any change in direction of rotation introduces errors or uncertainties. On the contrary, assuming correct tangential and axial velocities, CFD results provides exact conditions.

For the model used for the baseline test, the strength of the submerged side wall and floor vortices observed both in the physical model test and CFD simulation rendered the initial design unacceptable as per established performance criteria. However, additional CFD simulation showed that the strong vortices can be successfully suppressed by the installation of a trident-shaped triangular floor baffle and 45° corner fillets.

Based on the comparison of these results, it can be concluded that CFD simulation can serve as a viable means of evaluating sump performance. CFD could provide the necessary insight in the flow performance within pump sump thereby possibly reducing the need for extensive physical experiments.

Lastly, it was observed that CFD could provide results within a shorter period of time with a lower financial impact but the speed at which design revision can be made in CFD compared with the physical model is debatable. CFD design revision often requires new geometries and meshes and various pre-processing steps which are considered as the most time-consuming process. While the physical model test merely requires the installation of dummy geometries (e.g., fillet, splitters, AVDs) during each test iteration. Nevertheless, even at least from a financial perspective, CFD may still be a viable option in developing optimum intake designs.