Experimental Investigation of Desiccant Dehumidification Cooling System for Climatic Conditions of Multan (Pakistan)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Section

2.2. Data Processing

3. Proposed DAC System

3.1. Standalone DAC System

3.2. M-Cycle-Based DAC System

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ACS | air-conditioning systems |

| AC | air-conditioning |

| COP | coefficient of performance |

| specific heat capacity of air (kJ/kg-K) | |

| DAC | desiccant air-conditioning |

| DEC | direct evaporative cooling |

| EC | evaporative cooling |

| GW | global warming |

| h | enthalpy of air (kJ/kg) |

| HCFCS | hydrochlorofluorocarbons |

| HFCS | hydrofluorocarbons |

| HVAC | heating, ventilation, and air-conditioning |

| HX | heat exchanger |

| IEC | indirect evaporative cooling |

| MEC | Maisotsenko cycle evaporative cooling |

| MAC | Maisotsenko cycle-based air-conditioning |

| M-DAC | Maisotsenko cycle based desiccant air-conditioning |

| M-IEC | Maisotsenko cycle-based indirect evaporative cooling |

| independent variables in measuring uncertainty | |

| OD | ozone depletion |

| cooling capacity (kJ/kg) | |

| equivalent heat of adsorption (W) | |

| heat required for regeneration of desiccant (kW) | |

| isosteric heat of water vapor adsorption (kJ/kg) | |

| RH | relative humidity (%) |

| T | temperature (°C) |

| VCAC | vapor compression air-conditioning |

| humidity ratio (g/kg-DA) | |

| difference in humidity ratio (in–out) (g/kg-DA) | |

| slope of enthalpy line (-) | |

| slope of dehumidification line (-) | |

| effectiveness (-) | |

| uncertainties (-) | |

| mass flow rate of air (kg/s) | |

| total uncertainty in adsorption uptake | |

| uncertainty in measuring different variables | |

| total uncertainty (%) | |

| Subscripts | |

| calibr | calibration |

| daq | data acquisition system |

| db | dry bulb |

| in | inlet condition |

| out | outlet condition |

| PA | process air |

| RA | regeneration air |

| reg | regeneration |

| sen | sensor |

| wb | wet bulb |

Appendix A

References

- Sultan, M.; Miyazaki, T. Energy-Efficient Air-Conditioning Systems for Nonhuman Applications. Refrigeration 2017. [Google Scholar] [CrossRef] [Green Version]

- Sultan, M.T.; Miyazaki, T.; Saha, B.B.; Koyama, S. Steady-state investigation of water vapor adsorption for thermally driven adsorption based greenhouse air-conditioning system. Renew. Energy 2016, 86, 785–795. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. An overview of solid desiccant dehumidification and air conditioning systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Koyama, S.; Khan, Z.M. Performance evaluation of hydrophilic organic polymer sorbents for desiccant air-conditioning applications. Adsorpt. Sci. Technol. 2017, 36, 311–326. [Google Scholar] [CrossRef] [Green Version]

- Sultan, M.; I El-Sharkaw, I.; Miyazaki, T.; Saha, B.B.; Koyama, S. Experimental Study on Carbon Based Adsorbents for Greenhouse Dehumidification. Evergreen 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S. Desiccant Air-Conditioning System for Storage of Fruits and Vegetables: Pakistan Preview. Evergreen 2016, 3, 12–17. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V.S. Overview of the Maisotsenko cycle—A way towards dew point evaporative cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Cheng, F.; Li, Y.; Zhang, X.; Li, X. Effect of different absorbents on actual performance of the absorption air-conditioning system based on capacitive deionization regeneration method. Appl. Therm. Eng. 2020, 172, 115130. [Google Scholar] [CrossRef]

- Caliskan, H.; Dincer, I.; Hepbasli, A. Exergetic and sustainability performance comparison of novel and conventional air cooling systems for building applications. Energy Build. 2011, 43, 1461–1472. [Google Scholar] [CrossRef]

- Zhan, C.; Duan, Z.; Zhao, X.; Smith, S.; Jin, H.; Riffat, S. Comparative study of the performance of the M-cycle counter-flow and cross-flow heat exchangers for indirect evaporative cooling—Paving the path toward sustainable cooling of buildings. Energy 2011, 36, 6790–6805. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Xuan, Y.; Xiao, F.; Niu, X.; Huang, X.; Wang, S. Research and application of evaporative cooling in China: A review (I)—Research. Renew. Sustain. Energy Rev. 2012, 16, 3535–3546. [Google Scholar] [CrossRef]

- Kashif, M.; Sultan, M.; Khan, Z.M. Alternative Air-Conditioning Options for Developing Countries. Eur. J. Eng. Res. Sci. 2017, 2, 76–79. [Google Scholar] [CrossRef] [Green Version]

- Matsui, K.; Thu, K.; Miyazaki, T. A hybrid power cycle using an inverted Brayton cycle with an indirect evaporative device for waste-heat recovery. Appl. Therm. Eng. 2020, 170, 115029. [Google Scholar] [CrossRef]

- Duan, Z.; Zhan, C.; Zhang, X.; Mustafa, M.; Zhao, X.; Alimohammadisagvand, B.; Hasan, A. Indirect evaporative cooling: Past, present and future potentials. Renew. Sustain. Energy Rev. 2012, 16, 6823–6850. [Google Scholar] [CrossRef]

- Sultan, M.; Niaz, H.; Miyazaki, T. Investigation of Desiccant and Evaporative Cooling Systems for Animal Air-Conditioning. Low Temp. Technol. 2020. [Google Scholar] [CrossRef] [Green Version]

- Maheshwari, G.; Al-Ragom, F.; Suri, R. Energy-saving potential of an indirect evaporative cooler. Appl. Energy 2001, 69, 69–76. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S. Numerical analysis of the heat and mass transfer processes in selected M-Cycle heat exchangers for the dew point evaporative cooling. Energy Convers. Manag. 2015, 90, 62–83. [Google Scholar] [CrossRef]

- Enteria, N.; Mizutani, K. The role of the thermally activated desiccant cooling technologies in the issue of energy and environment. Renew. Sustain. Energy Rev. 2011, 15, 2095–2122. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S.; Worek, W.M. Comparison study of the counter-flow regenerative evaporative heat exchangers with numerical methods. Appl. Therm. Eng. 2015, 84, 211–224. [Google Scholar] [CrossRef]

- Lin, J.; Wang, R.; Li, C.; Wang, S.; Long, J.; Chua, K.J. Towards a thermodynamically favorable dew point evaporative cooler via optimization. Energy Convers. Manag. 2020, 203, 112224. [Google Scholar] [CrossRef]

- Arun, B.; Mariappan, V.; Maisotsenko, V.S. Experimental study on combined low temperature regeneration of liquid desiccant and evaporative cooling by ultrasonic atomization. Int. J. Refrig. 2020, 112, 100–109. [Google Scholar] [CrossRef]

- Anisimov, S.; Pandelidis, D.; Jedlikowski, A.; Polushkin, V. Performance investigation of a M (Maisotsenko)-cycle cross-flow heat exchanger used for indirect evaporative cooling. Energy 2014, 76, 593–606. [Google Scholar] [CrossRef]

- Delgado, J.M.P.Q.; de Lima, A.G.B.; da Silva, M.V. Numerical Analysis of Heat and Mass Transfer in Porous Media; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Khalatov, A.; Karp, I.; Isakov, B. Prospects of the maisotsenko thermodynamic cycle application in ukraine. Int. J. Energy Clean Environ. 2011, 12, 141–157. [Google Scholar] [CrossRef]

- Anisimov, S.; Pandelidis, D. Heat- and mass-transfer procesess in indirect evaporative air conditioners through the maisotsenko cycle. Int. J. Energy Clean Environ. 2011, 12, 273–286. [Google Scholar] [CrossRef] [Green Version]

- Tertipis, D.; Rogdakis, E. Maisotsenko cycle: Technology overview and energy-saving potential in cooling systems. Energy Emiss. Control. Technol. 2015, 2015, 15. [Google Scholar] [CrossRef] [Green Version]

- Anisimov, S.; Pandelidis, D.; Danielewicz, J. Numerical analysis of selected evaporative exchangers with the Maisotsenko cycle. Energy Convers. Manag. 2014, 88, 426–441. [Google Scholar] [CrossRef]

- Chua, K.; Chou, S.; Yang, W.; Yan, J. Achieving better energy-efficient air conditioning—A review of technologies and strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Anisimov, S.; Pandelidis, D. Numerical study of perforated indirect evaporative air cooler. Int. J. Energy Clean Environ. 2011, 12, 239–250. [Google Scholar] [CrossRef]

- Kojok, F.; Fardoun, F.; Younes, R.; Outbib, R. Hybrid cooling systems: A review and an optimized selection scheme. Renew. Sustain. Energy Rev. 2016, 65, 57–80. [Google Scholar] [CrossRef]

- Noor, S.; Ashraf, H.; Sultan, M.; Khan, Z.M. Evaporative cooling options for building air-conditioning: A comprehensive study for climatic conditions of Multan (Pakistan). Energies 2020, 13, 3061. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, X.; Zhan, C.; Dong, X.; Chen, H. Energy saving potential of a counter-flow regenerative evaporative cooler for various climates of China: Experiment-based evaluation. Energy Build. 2017, 148, 199–210. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Li, J.; Zhao, X. Energy savings of hybrid dew-point evaporative cooler and micro-channel separated heat pipe cooling systems for computer data centers. Energy 2018, 163, 629–640. [Google Scholar] [CrossRef] [Green Version]

- Farmahini-Farahani, M.; Delfani, S.; Esmaeelian, J. Exergy analysis of evaporative cooling to select the optimum system in diverse climates. Energy 2012, 40, 250–257. [Google Scholar] [CrossRef]

- Lin, J.; Bui, D.T.; Wang, R.; Chua, K. On the exergy analysis of the counter-flow dew point evaporative cooler. Energy 2018, 165, 958–971. [Google Scholar] [CrossRef]

- Alklaibi, A. Experimental and theoretical investigation of internal two-stage evaporative cooler. Energy Convers. Manag. 2015, 95, 140–148. [Google Scholar] [CrossRef]

- Fikri, B.; Sofia, E.; Putra, N. Experimental analysis of a multistage direct-indirect evaporative cooler using a straight heat pipe. Appl. Therm. Eng. 2020, 171, 115133. [Google Scholar] [CrossRef]

- Khalajzadeh, V.; Farmahini-Farahani, M.; Heidarinejad, G. A novel integrated system of ground heat exchanger and indirect evaporative cooler. Energy Build. 2012, 49, 604–610. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Rajput, S. Experimental analysis of an evaporative–vapour compression based combined air conditioning system for required comfort conditions. Appl. Therm. Eng. 2017, 115, 326–336. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, X.; Liu, J.; Zhang, Q. Dynamic simulation of a hybrid dew point evaporative cooler and vapour compression refrigerated system for a building using EnergyPlus. J. Build. Eng. 2019, 21, 287–301. [Google Scholar] [CrossRef]

- Zhou, S.; Gong, L.; Liu, X.; Shen, S. Mathematical modeling and performance analysis for multi-effect evaporation/multi-effect evaporation with thermal vapor compression desalination system. Appl. Therm. Eng. 2019, 159, 113759. [Google Scholar] [CrossRef]

- Fekadu, G.; Subudhi, S. Renewable energy for liquid desiccants air conditioning system: A review. Renew. Sustain. Energy Rev. 2018, 93, 364–379. [Google Scholar] [CrossRef]

- Qi, R.; Dong, C.; Zhang, L.-Z. A review of liquid desiccant air dehumidification: From system to material manipulations. Energy Build. 2020, 215, 109897. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Koyama, S. Optimization of adsorption isotherm types for desiccant air-conditioning applications. Renew. Energy 2018, 121, 441–450. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Experimental evaluation of desiccant dehumidification and air-conditioning system for energy-efficient storage of dried fruits. Build. Serv. Eng. Res. Technol. 2019, 41, 454–465. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Khan, Z.M. Solar assisted evaporative cooling based passive air-conditioning system for agricultural and livestock applications. J. Eng. Sci. Technol. 2018, 13, 693–703. [Google Scholar]

- Niaz, H.; Sultan, M.; Khan, A.A.; Miyazaki, T.; Feng, Y.; Khan, Z.M. Study on evaporative cooling assisted desiccant air conditioning system for livestock application in Pakistan. Fresenius Environ. Bull. 2019, 28, 8623–8633. [Google Scholar]

- Kashif, M.; Niaz, H.; Sultan, M.; Miyazaki, T.; Feng, Y.; Usman, M.; Shahzad, M.W.; Niaz, Y.; Waqas, M.M.; Ali, I. Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies 2020, 13, 2675. [Google Scholar] [CrossRef]

- Nagaya, K.; Senbongi, T.; Li, Y.; Zheng, J.; Murakami, I. High energy efficiency desiccant assisted automobile air-conditioner and its temperature and humidity control system. Appl. Therm. Eng. 2006, 26, 1545–1551. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, W.L. Site verification and modeling of desiccant-based system as an alternative to conventional air-conditioning systems for wet markets. Energy 2013, 55, 1076–1083. [Google Scholar] [CrossRef]

- Ismail, M.; Angus, D.; Thorpe, G. The performance of a solar-regenerated open-cycle desiccant bed grain cooling system. Sol. Energy 1991, 46, 63–70. [Google Scholar] [CrossRef]

- Guojie, Z.; Chaoyu, Z.; Guanghai, Y.; Chen, W. Development of a New Marine Rotary Desiccant Airconditioning System and its Energy Consumption Analysis. Energy Procedia 2012, 16, 1095–1101. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Chen, W. Energy and exergy performance analysis of a marine rotary desiccant air-conditioning system based on orthogonal experiment. Energy 2014, 77, 953–962. [Google Scholar] [CrossRef]

- Ascione, F.; Bellia, L.; Capozzoli, A.; Minichiello, F. Energy saving strategies in air-conditioning for museums. Appl. Therm. Eng. 2009, 29, 676–686. [Google Scholar] [CrossRef]

- Ascione, F.; Bellia, L.; Capozzoli, A. A coupled numerical approach on museum air conditioning: Energy and fluid-dynamic analysis. Appl. Energy 2013, 103, 416–427. [Google Scholar] [CrossRef]

- Daou, K.; Wang, R.; Xia, Z. Desiccant cooling air conditioning: A review. Renew. Sustain. Energy Rev. 2006, 10, 55–77. [Google Scholar] [CrossRef]

- La, D.; Dai, Y.; Li, Y.; Wang, R.; Ge, T. Technical development of rotary desiccant dehumidification and air conditioning: A review. Renew. Sustain. Energy Rev. 2010, 14, 130–147. [Google Scholar] [CrossRef]

- Mei, L.; Dai, Y. A technical review on use of liquid-desiccant dehumidification for air-conditioning application. Renew. Sustain. Energy Rev. 2008, 12, 662–689. [Google Scholar] [CrossRef]

- Saghafifar, M.; Gadalla, M. Innovative inlet air cooling technology for gas turbine power plants using integrated solid desiccant and Maisotsenko cooler. Energy 2015, 87, 663–677. [Google Scholar] [CrossRef]

- Gao, W.; Cheng, Y.; Jiang, A.; Liu, T.; Anderson, K. Experimental investigation on integrated liquid desiccant–Indirect evaporative air cooling system utilizing the Maisotesenko—Cycle. Appl. Therm. Eng. 2015, 88, 288–296. [Google Scholar] [CrossRef]

- Amer, O.; Boukhanouf, R.; Ibrahim, H.G. A Review of Evaporative Cooling Technologies. Int. J. Environ. Sci. Dev. 2015, 6, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Miyazaki, T.; Nikai, I.; Akisawa, A. Simulation analysis of an open-cycle adsorption air conditioning system—numeral modeling of a fixed bed dehumidification unit and the maisotsenko cycle cooling unit. Int. J. Energy Clean Environ. 2011, 12, 341–354. [Google Scholar] [CrossRef] [Green Version]

- Yaningsih, I.; Mahmood, M.H.; Wijayanta, A.T.; Miyazaki, T.; Koyama, S. Experimental Study on Dehumidification Technology using Honeycomb Desiccant Block. Evergreen 2018, 5, 11–18. [Google Scholar] [CrossRef]

- Kabeel, A. Solar powered air conditioning system using rotary honeycomb desiccant wheel. Renew. Energy 2007, 32, 1842–1857. [Google Scholar] [CrossRef]

- Yaningsih, I.; Wijayanta, A.T.; Miyazaki, T.; Koyama, S. Analysis of heat and mass transfer characteristics of desiccant dehumidifier system with honeycomb configuration. Appl. Therm. Eng. 2018, 144, 658–669. [Google Scholar] [CrossRef]

- Wrobel, J.; Ma, X.; Schmitz, G.; Grabe, J. A Desiccant Assisted Air Conditioning System with Use of Geothermal Energy. In Proceedings of the World Geothermal Congress, Bali, Indonesia, 25–30 April 2010. [Google Scholar]

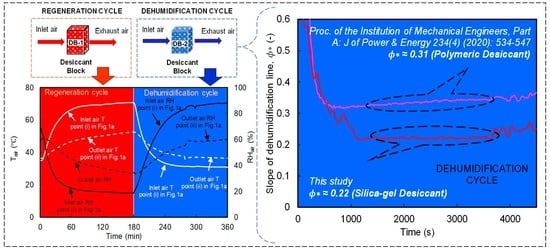

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Solid desiccant dehumidification-based air-conditioning system for agricultural storage application: Theory and experiments. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 234, 534–547. [Google Scholar] [CrossRef]

- ASHRAE. Handbook of Fundamentals; American Society of Heating, Refrigerating and Air-Conditioning Engineers. Inc.: Atlanta, GA, USA, 2013. [Google Scholar]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maruyama, T.; Maeda, S.; Nakamura, T. Water vapor sorption kinetics of polymer based sorbents: Theory and experiments. Appl. Therm. Eng. 2016, 106, 192–202. [Google Scholar] [CrossRef]

- Esen, H.; Inalli, M.; Esen, M. Technoeconomic appraisal of a ground source heat pump system for a heating season in eastern Turkey. Energy Convers. Manag. 2006, 47, 1281–1297. [Google Scholar] [CrossRef]

- Holman, J.P. Experimental Methods for Engineers; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Hepbasli, A.; Akdemir, O. Energy and exergy analysis of a ground source (geothermal) heat pump system. Energy Convers. Manag. 2004, 45, 737–753. [Google Scholar] [CrossRef]

- Uçkan, I.; Yılmaz, T.; Hürdoğan, E.; Büyükalaca, O. Experimental investigation of a novel configuration of desiccant based evaporative air conditioning system. Energy Convers. Manag. 2013, 65, 606–615. [Google Scholar] [CrossRef]

- Panaras, G.; Mathioulakis, E.; Belessiotis, V. Proposal of a control strategy for desiccant air-conditioning systems. Energy 2011, 36, 5666–5676. [Google Scholar] [CrossRef]

- Sultan, M.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Kil, H.-S.; Nakabayashi, K.; Miyawaki, J.; Yoon, S.-H. Adsorption of Difluoromethane (HFC-32) onto phenol resin based adsorbent: Theory and experiments. Int. J. Heat Mass Transf. 2018, 127, 348–356. [Google Scholar] [CrossRef]

- El-Agouz, S.A.; Sathyamurthy, R.; Manokar, A.M. Improvement of humidification–dehumidification desalination unit using a desiccant wheel. Chem. Eng. Res. Des. 2018, 131, 104–116. [Google Scholar] [CrossRef]

- Zhang, J.; Ge, T.; Dai, Y.; Zhao, Y.; Wang, R. Experimental investigation on solar powered desiccant coated heat exchanger humidification air conditioning system in winter. Energy 2017, 137, 468–478. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleem, M.; Hussain, G.; Sultan, M.; Miyazaki, T.; Mahmood, M.H.; Sabir, M.I.; Nasir, A.; Shabir, F.; Khan, Z.M. Experimental Investigation of Desiccant Dehumidification Cooling System for Climatic Conditions of Multan (Pakistan). Energies 2020, 13, 5530. https://doi.org/10.3390/en13215530

Aleem M, Hussain G, Sultan M, Miyazaki T, Mahmood MH, Sabir MI, Nasir A, Shabir F, Khan ZM. Experimental Investigation of Desiccant Dehumidification Cooling System for Climatic Conditions of Multan (Pakistan). Energies. 2020; 13(21):5530. https://doi.org/10.3390/en13215530

Chicago/Turabian StyleAleem, Muhammad, Ghulam Hussain, Muhammad Sultan, Takahiko Miyazaki, Muhammad H. Mahmood, Muhammad I. Sabir, Abdul Nasir, Faizan Shabir, and Zahid M. Khan. 2020. "Experimental Investigation of Desiccant Dehumidification Cooling System for Climatic Conditions of Multan (Pakistan)" Energies 13, no. 21: 5530. https://doi.org/10.3390/en13215530