Restoring Pre-Industrial CO2 Levels While Achieving Sustainable Development Goals

Abstract

:1. Introduction

- (1)

- Total ecosystem aquaculture (TEA) was developed by Capron and his colleagues [15,16,17,18,19,20,21,22,23], based on decades of work on integrated multi-trophic aquaculture (IMTA) (see Chambers [24] and Knowler [25] and references therein) during a techno-economic analysis funded by the U.S. Department of Energy (DOE) Advanced Research Projects Agency—Energy (ARPA-E) MacroAlgae Research Inspiring Novel Energy Resources (MARINER) program [26]. TEA systems consist of permanent, flexible reefs floating at ocean depths for optimal growth of cultured macroalgae species. Primary productivity is optimized by returning just as much nutrients as extracted, unless the reef is extracting excessive anthropogenic nutrients. That is, primary productivity is not nutrient limited. Initially TEA produces finfish, shellfish, crustaceans, and other high-protein seafood with some boutique harvesting of macroalgae. Seafood-producing reefs directly address SDGs 1–3, 8, 10, and 14 and indirectly address most of the others. Some seafood reefs can expand tropical fisheries in the face of climate change, substitute for natural reefs so that natural marine areas can be protected and facilitate research and development on growing macroalgae-for-biofuel. Macroalgae-for-biofuel requires an energy conversion process that recycles nutrients to support complete ecosystems similar to seafood-production reefs. Although full TEA is not yet demonstrated, most components and technologies are proven in other forms of aquaculture, including integrated multi-trophic aquaculture (IMTA). In addition, Laurens et al. [27] make the case for greatly expanded biofuels production from macroalgae.

- (2)

- Hydrothermal liquefaction (HTL) [28,29,30] uses a combination of high temperature (350 °C, 660 °F) and pressure (2 MPa, 3,000 psi) to convert wet biomass and some plastics to a biocrude oil in about 30 min. Because the reaction temperature is <400 °C, all nutrients can be recovered and used to grow more plants. Several companies [31,32,33] have systems operating at 1–10 wet tonnes of biomass/day. Using wet organic wastes mixed with select plastics to make biofuels addresses SDGs 7, 12, 13, and 14. Like many biofuel technologies, HTL deployment has been interrupted by several global oil price drops including the 2008 recession, the 2014 oil glut, and the 2020 SARS-COV-2 pandemic.

- (3)

- Allam Cycle electricity production [34,35,36,37] combines pure O2, gaseous fuel, and recirculating CO2. The combustion product is a supercritical fluid (viscosity like a gas, density like a liquid) that exits the turbine at 3 MPa (as a gas). The CO2 is compressed to become a sequestration-ready gas or supercritical fluid at 10 MPa with no efficiency penalty. Economic costs or benefits depend primarily on fuel price. The fuel can be natural gas, gasified coal, or gasified dry biomass (including crop residues and other dry wastes). With fossil fuel, electricity production can be carbon-neutral, addressing SDGs 7, 12, and 13. With gasified dry biomass, the electricity produced can be carbon-neutral or carbon-negative. 8 Rivers Capital has operated a 50-MW natural gas Allam Cycle plant for over two years [38]. They plan to be mass-producing 300-MW natural gas units by 2022 [37], and gasified coal units after demonstration of a 300-MW unit expected by 2026 [35].

- (1)

- Install TEA on floating, flexible, fishing reefs with macroalgae forests to produce seafood while returning nutrients for sustainability.

- (2)

- Install solid-waste collection systems that produce bioenergy (as opposed to deposition in landfills). Simultaneously install electrical power plants that can be upgraded easily to capture and compress CO2 emissions. As soon as possible, switch to capture-and-compression of CO2 from biomass combustion.

- (3)

- Sequester the captured fossil- and bio-CO2. Increase the amount of biomass (such as macroalgae, Miscanthus, and other sustainable biomass crops) to make carbon-negative liquid fossil fuels (using the HTL process, which in itself captures some CO2). Gradually increase the ratio of biomass-fueled to fossil-fueled electricity.

2. Methods

- (a)

- An integrated system design that includes seeding, growing, and harvesting.

- (b)

- Use of any reasonably foreseeable technology such as autonomous operation.

- (c)

- A minimum, but not necessarily continuous, 100,000 hectare (ha) seaweed farm.

- (d)

- A location that will support the concept, including nutrients.

- (e)

- A reasonable expected economic life of the capital investment.

- (a)

- Costs are estimated for production from the nth macroalgae grow-harvest unit (after the learning curve to install automated harvesting and economies of scale).

- (b)

- Nutrient recycling calculations focus on nitrogen (N) (in protein, ammonium, nitrates, etc.). Phosphorus (P) and other nutrients are assumed to be roughly proportional when recycling waste (such as sewage or crop residues). However, if relying on excess nutrients (mainly N), as from a dead zone, the P may become a limiting factor)

- (c)

- Macroalgae productivity per area is not nutrient-limited (due to nutrient recycling). Of course, nutrient recycling per area is limited to less than that which would adversely affect local biodiversity and ecosystem balance.

- (d)

- High-protein seafood (shellfish, finfish, crustaceans, etc.) production per area is estimated from a mass balance of N and information on the insolation-limited primary productivity.

- (e)

- The technology issues and life-cycle cost for gasified dry biomass-fired Allam Cycle electricity will be like those for gasified coal-fired Allam Cycle electricity.

- (f)

- The paths shown in Figure 2 are based on values at three points: (1) 2018 emissions, (2) net zero CO2 emissions (assigned to 2050), and (3) calculated maximum CDR (assigned to 2070).

- (g)

- Only CO2 emissions and CDR from energy production and use are calculated. Other CO2eq causes of climate change such as methane will need to be addressed separately from energy production (although the elimination of fossil fuel production will considerably reduce methane emissions).

- (h)

- The amount of CDR is dependent on the energy demand from sequestering sources burning biofuels, such as HTL and Allam Cycle. If these are replaced by wind, solar, etc. CDR will cease.

- (i)

- The calculations do not include CDR from other sources, such as trees, soils, etc. If these remove significant carbon, that could speed up the timetable in this paper and spreadsheet.

3. Results

3.1. Overview of Two Bracketing Paths

3.2. Overview Calculation Results for Net Zero Emissions and Maximum Net CDR

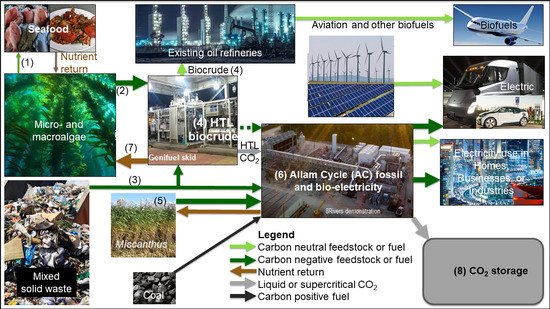

- (1)

- Increasing seafood production can start now with excess and artificial nutrients (Section 3.3; SMS#18).

- (2)

- Ocean (aquatic) plants produce wet biomass feedstock for food and energy (Section 3.3; SMS# 4, 6).

- (3)

- Wet solid waste is the initial feedstock for HTL biofuel. Dry solid waste can be the initial biomass feedstock for Allam Cycle electricity (Section 3.3, Section 3.5 and Section 3.6; SMS#4).

- (4)

- About 60% of the carbon in biomass or most plastics becomes biocrude oil during HTL. Biocrude can be refined at existing refineries. About 40% of the carbon can be recovered as a mixture of fuel gas and CO2 for Allam Cycle (or other) electricity and heat co-generation or the CO2 can be separated and sequestered (see Section 3.5 and Section 3.6; SMS#11, 12; SMD Section 3.5 and Section 3.6).

- (5)

- Dry terrestrial biomass can be gasified for Allam Cycle electricity production with carbon capture and sequestration (Section 3.6; SMD Section 3.6).

- (6)

- The Allam Cycle produces electricity from gasified coal, gasified biomass, or natural gas at 40–60% efficiency while also producing pure CO2 compressed to 100-bar ready for sequestration (Section 3.6; SMD Section 3.6).

- (7)

- Nutrient recycling is essential for sustained production of seafood and energy (Section 3.4, SMS#18, 19; SMD Section 3.4).

- (8)

3.3. Biomass Production Details

- There is more than enough organic solid waste (including mixed biosolids, paper, plastic, food waste, etc.) [49] for 20 million barrels/day (by 2050) of sweet biocrude oil (see SMS#4, 7, 11, 12).

- Every kind of biomass or waste (wet or dry) can contribute, which means most countries can participate in some form of biomass production.

- While there are obvious differences in maximum scale and cost, most biomass sources can be turned into a viable industry.

- These numbers are speculative in that macroalgae projections are based on theoretical studies, not physical demonstration projects.

3.4. Nutrient Recycling Details

- Terrestrial and oceanic biomass increase food and reduce waste by moving to a circular economy, as explained in “The End of Trash” [107].

- Buying ammonia would add $24/tonne to the cost of oceanic biomass, (i.e., add US$22/barrel to the cost of biocrude oil produced by HTL) based on values used by Jiang et al. [28]. There are additional costs for other nutrients, such as phosphates.

- If nutrients after energy production were not recycled, waste-treatment costs using conventional “wastewater” biologic nutrient removal processes would increase the cost of bio-oil by $60/barrel.

- Removing 1.2 billion tonnes of inorganic nitrogen (and other nutrients) from a few million km3 of deep ocean water each year [110] is not sustainable (see SMS#19). Temporarily upwelling a smaller amount of deep ocean water to start and expand primary production until recycled nutrients are available may be acceptable.

- Several processes (in addition to HTL, such as anaerobic digestion [27,115]) convert macroalgae to energy with good efficiency while separating most of the carbon from the nutrients. These separated nutrients can be returned to the macroalgae ecosystem during harvesting without significant cost [16,42].

3.5. HTL Details

3.6. Allam Cycle Details

3.7. CO2 Sequestration Details

3.8. Costs of CDR

- $150/tonne for direct air capture (in 2019 USD) [143];

3.8.1. Capture

3.8.2. Compression

- CO2 capture from Allam cycle—Each 300 MW coal- or biomass-fired power plant compresses 4600 tonnes/h of CO2 from 30 to 150 bar. Most of the CO2 is recirculated working fluid. About 230 tonnes/h is produced from coal for sale or sequestration. The energy required to compress CO2 from a gas at 30 bar to a supercritical fluid at 100 to 150 bar is small, about 9 kWh/tonne [124]. The combined compression energy plus other operating and capital costs are near $1/tonne of CO2 for coal or $2/tonne for natural gas. This is based on data from Fernandes et al. [36], Atlas Copco CO2 compressors [144], Allam et al. [34], and 8 Rivers Capital [124] presented in SMS#14.

- CO2 capture from HTL—HTL produces bio-crude plus fuel gas that could be combusted with air such that it produces gas with a high fraction of CO2 (10 to 20%) at 1 bar. Capturing >95% of the CO2 costs about $40/tonne of CO2. Compressing CO2 from 1 to 100 bar requires about 130 kWh/tonne of CO2. The combined capture, energy plus other operating, and capital costs are near $65/tonne of CO2. Most of the cost is for capture and compressing energy, which varies significantly by location, by technology, and over time, as indicated in Table 5.

- Hybrid of HTL co-located with Allam Cycle—HTL’s byproduct fuel gas and CO2 at 1 bar could be blended and provided as fuel (low-grade fuel gas) to the Allam Cycle. Its value as fuel should cover the cost of compressing it to the required fuel pressure. This situation’s capture and compression cost should be similar to the $1 or $2/tonne of CO2 for the Allam Cycle situation (SMS#14).

3.8.3. Transportation

3.8.4. Storage

3.8.5. Input Fuel Cost

3.8.6. Process Cost

3.8.7. Total Cost

- Waste can be converted to inexpensive energy with CO2 capture and sequestration because disposal fees decrease the cost of fuel.

- Terrestrial (dry) biomass (agricultural residues and purpose-grown biomass) costs roughly the same as coal, which might be $1.9/GJ in some countries (such as US) and $4.7/GJ in other countries (such as Japan which is dependent on imported coal at about $100/tonne).

- The hybrid of HTL co-located with Allam Cycle has about the same added cost for sequestering CO2 as does Allam Cycle alone, which greatly reduces the sequestration cost for the byproduct fuel gas and CO2 generated during HTL.

- HTL biocrude and biogas made from purpose-grown biomass are likely to cost much more than coal or natural gas as shown in the bottom two rows of Table 5. Therefore, we assume essentially no HTL biocrude-from-macroalgae will be fed into Allam Cycle plants for electricity production; it will be used for transportation fuels.

- Process cost explained

- Putting the cost of sequestering CO2 in perspective

- Lower costs for early adopters

- Allocating costs for removing legacy CO2

- Examples of fossil-CO2 fees and sequestration payments

- Comparison of carbon fee and regulation options.

3.9. SDGs Details

3.9.1. Food Systems with Lower CO2eq Emissions (SDGs 1, 2, 3, 13, 14, and 15)

3.9.2. Human Waste Resource Recovery Systems (SDGs 3, 6, 12, and 14)

3.9.3. Solid Waste Resource Recovery Systems (SDGs 3, 6, 12, and 14)

3.9.4. Sustainable Energy Systems (SDGs 7 and 13)

3.9.5. Sustainable Ocean Biomass-For-Energy (SDGs 7 and 13)

3.9.6. CO2 Sequestration Systems (SDG 13)

3.9.7. Floating Land Systems (SDG 11)

3.9.8. Other Public Health Systems (SDG 3)

3.9.9. All Human Systems Be Sustainable (All SDGs)

4. Conclusions and Recommendations

4.1. Summary

4.2. Needed Research

- Life-cycle costs, planetary boundaries [167], energy, and emissions analyses for all the mechanisms and technologies included, such as emissions during soil preparation, cultivation, collection and processing of dry biomass and the equivalent for oceanic biomass. Macroalgae-for-biofuel scale production requires a planetary boundary check on ozone layer depletion from gases emitted by micro- and macroalgae ([168,169] and references therein).

- Total-ecosystem aquaculture must be designed for continued biodiversity and seafood production even with some fish species moving toward the poles as the tropical oceans become too warm [170].

- The United Nations Decade of Ocean Science for Sustainable Development [172] could use the above framework to focus on supporting sustainable management of the oceans to achieve the UN SDGs.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pope Francis. Encyclical Letter Laudato Si’ of the Holy Father Francis on Care for Our Common Home. 2015. Available online: http://www.vatican.va/content/francesco/en/encyclicals/documents/papa-francesco_20150524_enciclica-laudato-si.html (accessed on 10 April 2020).

- Sorondo, M.S.; Ramanathan, V. Pursuit of integral ecology. Science 2016, 352, 747. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- UNFCCC. What is the Paris Agreement? 2015. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/what-is-the-paris-agreement (accessed on 14 April 2020).

- IPCC. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- United Nations. Sustainable Development Goals. 2016. Available online: https://sustainabledevelopment.un.org (accessed on 10 April 2020).

- UNEP. Emissions Gap Report 2019. Available online: https://www.unenvironment.org/resources/emissions-gap-report-2019 (accessed on 9 September 2020).

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- National Academies of Sciences, Engineering, and Medicine. Negative Emissions Technologies and Reliable Sequestration: A Research Agenda.; The National Academies Press: Washington, DC, USA, 2019; ISBN 978-0-309-48452-7. [Google Scholar]

- Minx, J.C.; Lamb, W.F.; Callaghan, M.W.; Bornmann, L.; Fuss, S. Fast growing research on negative emissions. Environ. Res. Lett. 2017, 12. [Google Scholar] [CrossRef]

- Fuss, S.; Lamb, W.F.; Callaghan, M.W.; Hilaire, J.; Creutzig, F.; Amann, T.; Beringer, T.; De Oliveira Garcia, W.; Hartmann, J.; Khanna, T.; et al. Negative emissions-Part 2: Costs, potentials and side effects. Environ. Res. Lett. 2018, 13. [Google Scholar] [CrossRef] [Green Version]

- Nemet, G.F.; Callaghan, M.W.; Creutzig, F.; Fuss, S.; Hartmann, J.; Hilaire, J.; Lamb, W.F.; Minx, J.C.; Rogers, S.; Smith, P. Negative emissions—Part 3: Innovation and upscaling. Environ. Res. Lett. 2018, 13, 63003. [Google Scholar] [CrossRef] [Green Version]

- Flannery, T. Atmosphere of Hope: Searching for Solutions to the Climate Crisis.; Atlantic Monthly Press: Boston, MA, USA, 2015. [Google Scholar]

- Flannery, T. Sunlight and Seaweed, an Argument for How to Feed, Power and Clean Up the World.; The Text Publishing Company: Melbourne, Australia, 2017. [Google Scholar]

- Wilkinson, K. The Drawdown Review 2020: Climate Solutions for a New Decade. Available online: https://drawdown.org/drawdown-framework/drawdown-review-2020 (accessed on 10 April 2020).

- Capron, M.E.; Blaylock, R.; Lucas, K.; Chambers, M.D.; Stewart, J.R.; DiMarco, S.F.; Whilden, K.; Wang, B.; Kim, M.H.; Moscicki, Z.; et al. Ocean Forests: Breakthrough Yields for Macroalgae. In Proceedings of the OCEANS 2018 MTS/IEEE Charleston, Charleston, SC, USA, 22–25 October 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Lucas, K.; Capron, M.E.; Blaylock, R.; Chambers, M.D.; Stewart, J.R.; DiMarco, S.F.; Whilden, K.; Kim, M.H.; Moscicki, Z.; Sullivan, C.; et al. AdjustaDepth Phase 1 Final Report to ARPA-E, DE-AR0000916. 2019. Available online: https://www.researchgate.net/publication/341997484_AdjustaDepth_Phase_1_Final_Report_DE-AR0000916_Feed_the_world_on_the_way_to_abundant_biofuels (accessed on 9 September 2020).

- Lucas, K.; Capron, M.E.; Blaylock, R.; Chambers, M.D.; Stewart, J.R.; DiMarco, S.F.; Whilden, K.; Wang, B.; Kim, M.H.; Moscicki, Z.; et al. Ocean Forests: Feeding the World with Floating Artificial Reefs. In Proceedings of the World Aquaculture Society, #666, New Orleans, LA, USA; 2019. Available online: https://wasblobstorage.blob.core.windows.net/meeting-abstracts/AQ2019AbstractBook.pdf (accessed on 9 September 2020).

- Capron, M.E. Centuries of Food and Job Security for Coastal Peoples. 2019. Available online: https://challenges.openideo.com/challenge/2019-bridgebuilder-challenge/ideas/centuries-of-food-and-job-security-for-coastal-peoples (accessed on 4 April 2020).

- Capron, M.E.; Piper, D. Abundant Food and Export Income with Total ecosystem Aquaculture. 2019. Available online: https://www.climatecolab.org/contests/2019/reshapingdevelopmentpathwaysinLDCs/c/proposal/1334620 (accessed on 9 September 2020).

- Capron, M.E.; Lucas, K.; Chambers, M.D.; Lapointe, B.; N’Yeurt, A.d.R.; Krueger-Hadfield, S.A.; James, S.C.; Blaylock, R.; Stewart, J.R.; Piper, D.; et al. Building New Fishery Ecosystems: The Science of Flexible Floating Fishing Reefs. In Proceedings of the International Symposium on Stock Enhancement & Sea Ranching; 2019. Available online: https://mote.org/media/uploads/contact/ISSESR-Wednesday-1150-Piper.pdf (accessed on 9 September 2020).

- Capron, M.E.; N’Yeurt, A.d.R.; Kim, J.K.; Pichach, C.; Chambers, M.D.; Fuhrman, R.; Jones, A.T.; Stewart, J.R.; Blaylock, R.; Hasan, M.A.; et al. Reversing Climate Change within 100 Years: The Scale to Restore Natural CO2 Levels. In Proceedings of the Ocean Sciences Meeting Presentation SI41A-02; 2020. Available online: https://agu.confex.com/agu/osm20/meetingapp.cgi/Paper/648119 (accessed on 9 September 2020).

- Capron, M.E.; Prasad, R.; N’Yeurt, A.d.R.; Hopkins, K.; Stewart, J.R.; Harris, G.; Hasan, M.A.; Piper, D. Increasing South Pacific aquaculture with complete ecosystems. Ocean Sciences Meeting Presentation SI12A-05. 2020. Available online: https://agu.confex.com/agu/osm20/meetingapp.cgi/Paper/649244 (accessed on 9 September 2020).

- Capron, M.E.; Prasad, R.; N’Yeurt, A.d.R.; Hewavitharane, C.; Stewart, J.R. Total Ecosystem Aquaculture—Sustainable Seafood Production for Fiji, the Pacific, and then the World. 2020. Available online: https://challenges.openideo.com/challenge/food-system-vision-prize/open-submission/restorative-aquaculture-sustainable-seafood-production-for-the-world (accessed on 9 March 2020).

- Chambers, M.D. Integrated Multi-Trophic Aquaculture of Steelhead, Blue Mussels and Sugar Kelp. Ph.D. Dissertation, University of New Hampshire, Durham, NH, USA, 2013. [Google Scholar]

- Knowler, D.; Chopin, T.; Martínez-Espiñeira, R.; Neori, A.; Nobre, A.; Noce, A.; Reid, G. The economics of Integrated Multi-Trophic Aquaculture: Where are we now and where do we need to go? Rev. Aquac. 2020. [Google Scholar] [CrossRef]

- Advanced Research Projects Agency—Energy (ARPA-E)—U.S. Department of Energy. MacroAlgae Research Inspiring Novel Energy Resources (MARINER) Program Overview. Available online: https://arpa-e.energy.gov/sites/default/files/documents/files/MARINER_ProgramOverview_FINAL.pdf (accessed on 10 April 2020).

- Laurens, L.M.L.; Nelson, R.S. Chapter 21—Sustainable technologies for seaweed conversion to biofuels and bioproducts. In Advances in Green Chemistry; Torres, M.D., Kraan, S., Dominguez, H.B.T.-S.S.T., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 643–661. ISBN 978-0-12-817943-7. [Google Scholar]

- Jiang, Y.; Jones, S.B.; Zhu, Y.; Snowden-Swan, L.; Schmidt, A.J.; Billing, J.M.; Anderson, D. Techno-economic uncertainty quantification of algal-derived biocrude via hydrothermal liquefaction. Algal Res. 2019, 39, 101450. [Google Scholar] [CrossRef]

- Jiao, J.-L.; Wang, F.; Duan, P.-G.; Xu, Y.-P.; Yan, W.-H. Catalytic hydrothermal gasification of microalgae for producing hydrogen and methane-rich gas. Energy Sources Part Recovery Util. Environ. Eff. 2017, 39, 851–860. [Google Scholar] [CrossRef]

- Pichach, C. CleanCarbon Energy: Carbon Balanced Renewable Energy, Plus Private Communication. Available online: https://www.f6s.com/cleancarbonenergy (accessed on 10 April 2020).

- Genifuel. Clean Conversion of Wet Waste to Fuel. Available online: https://www.genifuel.com/ (accessed on 4 April 2020).

- Steeper Energy. Hydrofaction Technology. Available online: https://steeperenergy.com/ (accessed on 4 April 2020).

- ReNew ELP. Unlocking the Value in Plastic Waste. Available online: https://renewelp.co.uk/ (accessed on 4 April 2020).

- Allam, R.; Martin, S.; Forrest, B.; Fetvedt, J.; Lu, X.; Freed, D.; Brown, G.W.; Sasaki, T.; Itoh, M.; Manning, J. Demonstration of the Allam Cycle: An Update on the Development Status of a High Efficiency Supercritical Carbon Dioxide Power Process Employing Full Carbon Capture. Energy Procedia 2017, 114, 5948–5966. [Google Scholar] [CrossRef]

- 8 Rivers Capital. Allam Cycle Zero Emission Coal Power Plant DOE Grant Proposal 89243319CFE000015. 2020. Available online: https://www.netl.doe.gov/coal/tpg/coalfirst/concept-reports (accessed on 10 April 2020).

- Fernandes, D.; Wang, S.; Xu, Q.; Buss, R.; Chen, D. Process and Carbon Footprint Analyses of the Allam Cycle Power Plant Integrated with an Air Separation Unit. Clean Technol. 2019, 1, 325–340. [Google Scholar] [CrossRef] [Green Version]

- McMahon, J. Multiple Zero-Carbon Natural-Gas Plants Planned at Lower Cost Than Conventional Plants. Forbes Mag. 2019, 15, 3074–3098. [Google Scholar]

- Flin, D. First Fire for La Porte Carbon Capture demo. Gas Turbine World. Available online: https://gasturbineworld.com/first-fire-for-la-porte-carbon-capture-demo/ (accessed on 10 April 2020).

- N‘Yeurt, A.R.; Chynoweth, D.P.; Capron, M.E.; Stewart, J.R.; Hasan, M.A. Negative carbon via Ocean Afforestation. Process Saf. Environ. Prot. 2012, 90, 467–474. [Google Scholar] [CrossRef]

- U.S. Department of Energy Advanced Research Projects Agency-Energy. MacroAlgae Research Inspiring Novel Energy Resources (MARINER) Project Listing. 2017. Available online: https://arpa-e.energy.gov/?q=arpa-e-programs/mariner (accessed on 4 April 2020).

- U.S. Department of Energy. Department of Energy Announces $100M in Investments in Coal FIRST; U.S. Department of Energy: Washington, DC, USA, 2019.

- Capron, M.E.; Lucas, K.; Stewart, J.R.; Blaylock, R.; Howden, S.; Chambers, M.D.; James, S.C.; Brooks, M.T.; Lapointe, B.; N’Yeurt, A.d.R.; et al. AdjustaDepth TechnoEconomic Analysis for ARPA-E Phase 1 Contract DE-AR0000916. Available online: https://www.researchgate.net/publication/343697255_AdjustaDepth_TechnoEconomic_Analysis_for_ARPA-E_Phase_1_Contract_DE-AR0000916 (accessed on 9 September 2020).

- Gentry, R.R.; Froehlich, H.E.; Grimm, D.; Kareiva, P.; Parke, M.; Rust, M.; Gaines, S.D.; Halpern, B.S. Mapping the global potential for marine aquaculture. Nat. Ecol. Evol. 2017, 1, 1317–1324. [Google Scholar] [CrossRef]

- Lapointe, B.E.; Ryther, J.H. Some aspects of the growth and yield of Gracilaria tikvahiae in culture. Aquaculture 1978, 15, 185–193. [Google Scholar] [CrossRef]

- Lapointe, B.E. Strategies for pulsed nutrient supply to Gracilaria cultures in the Florida Keys: Interactions between concentration and frequency of nutrient pulses. J. Exp. Mar. Biol. Ecol. 1985, 93, 211–222. [Google Scholar] [CrossRef]

- Capo, T.R.; Jaramillo, J.C.; Boyd, A.E.; Lapointe, B.E.; Serafy, J.E. Sustained high yields of Gracilaria (Rhodophyta) grown in intensive large-scale culture. J. Appl. Phycol. 1999, 11, 143. [Google Scholar] [CrossRef]

- BP. BP Statistical Review of World Energy. 2019. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 8 August 2020).

- U.S. Energy Information Administration. Petroleum and other liquids. 2020. Available online: https://www.eia.gov/international/data/world/petroleum-and-other-liquids/annual-petroleum-and-other-liquids-production (accessed on 4 April 2020).

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018; ISBN 978-1-4648-1329-0. [Google Scholar]

- U.S. Department of Energy. 2016 Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy; U.S. Department of Energy: Washington, DC, USA, 2018. [CrossRef] [Green Version]

- Jolly, R. Dutch Industrial Waste Continues to Decrease. 2004. Available online: https://www.cbs.nl/en-gb/news/2004/42/industrial-waste-continues-to-decrease (accessed on 9 September 2020).

- CalRecycle. Disposal-Facility-Based Characterization of Solid Waste in California. 2015. Available online: https://www2.calrecycle.ca.gov/Publications/Details/1546 (accessed on 4 April 2020).

- U.S. Energy Information Administration (EIA). Average Heat Content of Selected Biomass Fuels. Renewable Energy Annual 2004. Available online: https://www.eia.gov/renewable/annual/ (accessed on 3 March 2020).

- Smil, V. Crop Residues: Agriculture’s Largest Harvest: Crop residues incorporate more than half of the world’s agricultural phytomass. BioScience 1999, 49, 299–308. [Google Scholar] [CrossRef] [Green Version]

- Daioglou, V.; Stehfest, E.; Wicke, B.; Faaij, A. Projections of the availability and cost of residues from agriculture and forestry. Bioenergy 2016, 8, 456–470. [Google Scholar] [CrossRef]

- Ravindra, K.; Singh, T.; Mor, S. Emissions of air pollutants from primary crop residue burning in India and their mitigation strategies for cleaner emissions. J. Clean. Prod. 2019, 208, 261–273. [Google Scholar] [CrossRef]

- Deng, Y.Y.; Koper, M.; Haigh, M.; Dornburg, V. Country-level assessment of long-term global bioenergy potential. Biomass Bioenergy 2015, 74, 253–267. [Google Scholar] [CrossRef] [Green Version]

- Devi, S.; Gupta, C.; Jat, S.L.; Parmar, M.S. Crop residue recycling for economic and environmental sustainability: The case of India. Open Agric. 2017, 2, 486–494. [Google Scholar] [CrossRef]

- Turner, P.A.; Mach, K.J.; Lobell, D.B.; Benson, S.M.; Baik, E.; Sanchez, D.L.; Field, C.B. The global overlap of bioenergy and carbon sequestration potential. Clim. Chang. 2018, 148, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Das, P.K.; Das, B.P.; Dash, P. Role of Energy Crops to Meet the Rural Energy Needs: An Overview. Biomass Valorization Bioenergy 2019. [Google Scholar] [CrossRef]

- Eisentraut, A. Sustainable Production of Second-Generation Biofuels: Potential and Perspectives in Major Economies and Developing Countries; IEA Energy Pap. No 201001; OECD Publ.: Paris, France, 2010. [Google Scholar] [CrossRef]

- Smeets, E.M.W.; Faaij, A.P.C.; Lewandowski, I.M.; Turkenburg, W.C. A bottom-up assessment and review of global bio-energy potentials to 2050. Prog. Energy Combust. Sci. 2007, 33, 56–106. [Google Scholar] [CrossRef] [Green Version]

- Daly, C.; Halbleib, M. Potential Yield Mapping of Dedicated Energy Crops. Available online: http://energy.gov/sites/prod/files/2014/11/f19/daly_biomass_2014.pdf (accessed on 4 April 2020).

- Buschmann, A.H.; Camus, C.; Infante, J.; Neori, A.; Israel, Á.; Hernández-González, M.C.; Pereda, S.V.; Gomez-Pinchetti, J.L.; Golberg, A.; Tadmor-Shalev, N.; et al. Seaweed production: Overview of the global state of exploitation, farming and emerging research activity. Eur. J. Phycol. 2017, 52, 391–406. [Google Scholar] [CrossRef]

- Kim, J.K.; Wu, H.; Shin, S.K.; Park, M.S.; Kim, Y.D.; Do, Y.H.; Kim, N.G.; Han, T. An effective integrated multi-trophic aquaculture system for Korean waters. In The 2nd International Integrated Multi-Trophic Aquaculture Symposium Book of Abstracts; Springer: New York, NY, USA, 2017; pp. 17–32. [Google Scholar]

- Kim, J.K.; Yarish, C.; Hwang, E.K.; Park, M.; Kim, Y. Seaweed aquaculture: Cultivation technologies, challenges and its ecosystem services. ALGAE 2017, 32, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Park, M.; Shin, S.K.; Do, Y.H.; Yarish, C.; Kim, J.K. Application of open water integrated multi-trophic aquaculture to intensive monoculture: A review of the current status and challenges in Korea. Aquaculture 2018, 497, 174–183. [Google Scholar] [CrossRef]

- Radulovich, R.; Umanzor, S.; Cabrera, R.; Mata, R. Tropical seaweeds for human food, their cultivation and its effect on biodiversity enrichment. Aquaculture 2015, 436, 40–46. [Google Scholar] [CrossRef] [Green Version]

- Shi, H.; Zheng, W.; Zhang, X.; Zhu, M.; Ding, D. Ecological–economic assessment of monoculture and integrated multi-trophic aquaculture in Sanggou Bay of China. Aquaculture 2013, 410–411, 172–178. [Google Scholar] [CrossRef]

- Froehlich, H.E.; Afflerbach, J.C.; Frazier, M.; Halpern, B.S. Blue Growth Potential to Mitigate Climate Change through Seaweed Offsetting. Curr. Biol. 2019, 29, 3087–3093. [Google Scholar] [CrossRef]

- Theuerkauf, S.J.; Morris, J.A., Jr.; Waters, T.J.; Wickliffe, L.C.; Alleway, H.K.; Jones, R.C. A global spatial analysis reveals where marine aquaculture can benefit nature and people. PLoS ONE 2019, 14, e0222282. [Google Scholar] [CrossRef] [PubMed]

- Dahlke, F.T.; Wohlrab, S.; Butzin, M.; Pörtner, H.O. Thermal bottlenecks in the life cycle define climate vulnerability of fish. Science 2020, 369, 65–70. [Google Scholar] [CrossRef] [PubMed]

- Hastings, R.A.; Rutterford, L.A.; Freer, J.J.; Collins, R.A.; Simpson, S.D.; Genner, M.J. Climate Change Drives Poleward Increases and Equatorward Declines in Marine Species. Curr. Biol. 2020, 30, 1572–1577. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Field, C.B.; Behrenfeld, M.J.; Randerson, J.T.; Falkowski, P. Primary Production of the Biosphere: Integrating Terrestrial and Oceanic Components. Science 1998, 281. [Google Scholar] [CrossRef] [Green Version]

- Hudiburg, T.W.; Luyssaert, S.; Thornton, P.E.; Law, B.E. Interactive Effects of Environmental Change and Management Strategies on Regional Forest Carbon Emissions. Environ. Sci. Technol. 2013, 47, 13132–13140. [Google Scholar] [CrossRef]

- Korai, M.S.; Mahar, R.B.; Uqaili, M.A. Assessment of Power Generation Potential from Municipal Solid Wastes: A Case Study of Hyderabad City, Sindh, Pakistan. Pak. J. Anal. Environ. Chem. 2014, 15, 18–27. [Google Scholar]

- Clarke, S.; Preto, F. Biomass Burn Characteristics. Available online: http://www.omafra.gov.on.ca/english/engineer/facts/11-033.pdf (accessed on 9 September 2020).

- Kumar, P.; Kumar, S.; Joshi, L. Socioeconomic and Environmental Implications of Stubble Burning in Punjab SpringerBriefs in Environmental Science. 2015, 156. [CrossRef]

- Faaij, A. Contribution of Bioenergy to the World’s Future Energy. 2007. Available online: https://www.ieabioenergy.com/publications/potential-contribution-of-bioenergy-to-the-worlds-future-energy-demand (accessed on 9 September 2020).

- Fischer, G.; Schrattenholzer, L. Global bioenergy potentials through 2050. Biomass Bioenergy 2001, 20, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Frank, A.B.; Berdahl, J.D.; Hanson, J.D.; Liebig, M.A.; Johnson, H.A. Biomass and Carbon Partitioning in Switchgrass. Crop Sci. 2004, 44, 1391–1396. [Google Scholar] [CrossRef] [Green Version]

- Hall, C.A.S.; Dale, B.E.; Pimentel, D. Seeking to understand the reasons for different energy return on investment (EROI) estimates for biofuels. Sustainability 2011, 3, 2413–2432. [Google Scholar] [CrossRef] [Green Version]

- Macreadie, P.I.; Anton, A.; Raven, J.A.; Beaumont, N.; Connolly, R.M.; Friess, D.A.; Kelleway, J.J.; Kennedy, H.; Kuwae, T.; Lavery, P.S.; et al. The future of Blue Carbon science. Nat. Commun. 2019, 10. [Google Scholar] [CrossRef] [Green Version]

- Hoogwijk, M.; Faaij, A.; de Vries, B.; Turkenburg, W. Exploration of regional and global cost–supply curves of biomass energy from short-rotation crops at abandoned cropland and rest land under four IPCC SRES land-use scenarios. Biomass Bioenergy 2009, 33, 26–43. [Google Scholar] [CrossRef] [Green Version]

- Eriksson, O.; Finnveden, G. Plastic waste as a fuel—CO2-neutral or not? Energy Environ. Sci. 2009, 2, 907–914. [Google Scholar] [CrossRef]

- Ioelovich, M. Recent Findings and the Energetic Potential of Plant Biomass as a Renewable Source of Biofuels—A Review. Bioresources 2015, 10, 1879–1914. [Google Scholar]

- Kostecki, J.; Greinert, A.; Drab, M.; Wasylewicz, R.; Szafraniec, M.; Stodulski, G.; Wypych, M. The total content of nitrogen in leaves and wood of trees growing in the area affected by the Głogów Copper Smelter. J. Elem. 2015, 20, 137–148. [Google Scholar] [CrossRef]

- Reinhart, D. Estimation of Energy Content of Municipal Solid Waste. 2004. Available online: http://msw.cecs.ucf.edu/wastecharacterization.html (accessed on 2 February 2020).

- Milledge, J.J.; Harvey, P.J. Potential process ‘hurdles’ in the use of macroalgae as feedstock for biofuel production in the British Isles. J. Chem. Technol. Biotechnol. 2016, 91, 2221–2234. [Google Scholar] [CrossRef] [PubMed]

- Penniman, C.A.; Mathieson, A.C. Variation in Chemical Composition of Gracilaria tikvahiae McLachlan (Gigartinales, Rhodophyta) in the Great Bay Estuary, New Hampshire. Bot. Mar. 1987, 30, 525–534. [Google Scholar] [CrossRef]

- Lee, M.-S.; Wycislo, A.; Guo, J.; Lee, D.K.; Voigt, T. Nitrogen Fertilization Effects on Biomass Production and Yield Components of Miscanthus ×giganteus. Front. Plant Sci. 2017, 8, 544. [Google Scholar] [CrossRef] [Green Version]

- Tanger, P.; Field, J.; Jahn, C.; DeFoort, M.; Leach, J. Biomass for thermochemical conversion: Targets and challenges. Front. Plant Sci. 2013, 4, 218. [Google Scholar] [CrossRef] [Green Version]

- UNEP. Waste-to-Energy: Considerations for Informed Decision-Making. 2019. Available online: http://wedocs.unep.org/bitstream/handle/20.500.11822/28413/WTEfull.pdf (accessed on 9 September 2020).

- Sherman, M.T.; Blaylock, R.; Lucas, K.; Capron, M.E.; Stewart, J.R.; DiMarco, S.F.; Thyng, K.; Hetland, R.; Kim, M.H.; Sullivan, C.; et al. SeaweedPaddock: Initial Modeling and Design for a Sargassum Ranch. In Proceedings of the OCEANS 2018 MTS/IEEE Charleston, Charleston, SC, USA, 22–25 October 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Wilcox, B. Biofuel Production from Kelp. 2017. Available online: https://arpa-e.energy.gov/?q=slick-sheet-project/biofuel-production-kelp (accessed on 9 September 2020).

- Huesemann, M.; Mumford, T.; Wood, G.; Quinn, J.; Wang, T.; Yang, Z. Nautical Offshore Macroalgal Autonomous Device (NOMAD). Available online: https://arpa-e.energy.gov/?q=slick-sheet-project/nautical-offshore-macroalgal-autonomous-device (accessed on 4 April 2020).

- Stekoll, M. Scalable Coastal and Offshore Macroalgal Farming (SCOMF). 2017. Available online: https://arpa-e.energy.gov/?q=slick-sheet-project/scalable-coastal-and-offshore-macroalgal-farming (accessed on 9 September 2020).

- Lombardelli, G.; Pirone, R.; Ruggeri, B. LCA Analysis of Different MSW Treatment Approaches in the Light of Energy and Sustainability Perspectives. Chem. Eng. Trans. 2017, 57, 469–474. [Google Scholar] [CrossRef]

- Zaimes, G.G.; Khanna, V. Microalgal biomass production pathways: Evaluation of life cycle environmental impacts. Biotechnol. Biofuels 2013, 6, 88. [Google Scholar] [CrossRef] [Green Version]

- Pandur, Z.; Šušnjar, M.; Zorić, M.; Nevečerel, H.; Horvat, D. Energy Return on Investment (EROI) of Different Wood Products. In Precious Forests—Precious Earth; Zlatic, M., Ed.; IntertechOpen: London, UK, 2015. [Google Scholar]

- Environmental Research & Education Foundation. Analysis of MSW Tipping Fees. 2019. Available online: http://www.erefdn.org (accessed on 4 April 2020).

- REN21. Renewables 2019 Global Status Report. Available online: https://www.ren21.net/gsr-2019/ (accessed on 11 April 2020).

- Schiener, P.; Black, K.D.; Stanley, M.S.; Green, D.H. The seasonal variation in the chemical composition of the kelp species Laminaria digitata, Laminaria hyperborea, Saccharina latissima and Alaria esculenta. J. Appl. Phycol. 2015, 27, 363–373. [Google Scholar] [CrossRef]

- Sims, N.A.; Vollbrecht, L.; Bullock, M.; Martin, K. Ocean Era Blue Fields Offshore Macroalgae Demonstration Project. 2019. Available online: http://ocean-era.com/projects (accessed on 4 April 2020).

- Wesseler, S. In King County, Washington, Human Waste Is a Climate Solution. Available online: https://www.yaleclimateconnections.org/2019/11/in-king-county-washington-human-waste-is-a-climate-solution/ (accessed on 4 April 2020).

- Pan, W.L.; Port, L.E.; Xiao, Y.; Bary, A.I.; Cogger, C.G. Soil Carbon and Nitrogen Fraction Accumulation with Long-Term Biosolids Applications. Soil Sci. Soc. Am. J. 2017, 81, 1381–1388. [Google Scholar] [CrossRef] [Green Version]

- Kunzig, R. Is a World without Trash Possible? Natl. Geogr. March 2020. Available online: https://www.nationalgeographic.com/magazine/2020/03/ (accessed on 9 September 2020).

- Brown, T. Ammonia Production Causes 1% of Total Global GHG Emissions. 2016. Available online: https://ammoniaindustry.com/ammonia-production-causes-1-percent-of-total-global-ghg-emissions/ (accessed on 4 April 2020).

- FAO. World fertilizer Trends and Outlook to 2018; FAO: Roma, Italy, 2015; ISBN 9789251086926. [Google Scholar]

- Monterey Bay Aquarium Research Institute (MBARI) Ocean Data FloatViz 6.0. Available online: https://www.mbari.org/science/upper-ocean-systems/chemical-sensor-group/floatviz (accessed on 11 November 2019).

- Chan, F.; Barth, J.A.; Blanchette, C.A.; Byrne, R.H.; Chavez, F.; Cheriton, O.; Feely, R.A.; Friederich, G.; Gaylord, B.; Gouhier, T.; et al. Persistent spatial structuring of coastal ocean acidification in the California Current System. Sci. Rep. 2017, 7, 2526. [Google Scholar] [CrossRef]

- Feely, R.A.; Sabine, C.L.; Hernandez-Ayon, J.M.; Ianson, D.; Hales, B. Evidence for Upwelling of Corrosive “Acidified” Water onto the Continental Shelf. Science 2008, 320, 1490–1492. [Google Scholar] [CrossRef] [Green Version]

- Köhn, E.E.; Thomsen, S.; Arévalo-Martinez, D.L.; Kanzow, T. Submesoscale CO2 variability across an upwelling front off Peru. Ocean Sci. 2017, 13, 1017–1033. [Google Scholar] [CrossRef] [Green Version]

- Ries, J.B. Review: Geological and experimental evidence for secular variation in seawater Mg/Ca (calcite-aragonite seas) and its effects on marine biological calcification. Biogeosciences 2010, 7, 2795–2849. [Google Scholar] [CrossRef] [Green Version]

- Melara, A.J.; Singh, U.; Colosi, L.M. Is aquatic bioenergy with carbon capture and storage a sustainable negative emission technology? Insights from a spatially explicit environmental life-cycle assessment. Energy Convers. Manag. 2020, 224, 113300. [Google Scholar] [CrossRef]

- Watson, J.; Wang, T.; Si, B.; Chen, W.T.; Aierzhati, A.; Zhang, Y. Valorization of hydrothermal liquefaction aqueous phase: Pathways towards commercial viability. Prog. Energy Combust. Sci. 2020, 77. [Google Scholar] [CrossRef]

- Cheng, F.; Porter, M.D.; Colosi, L.M. Is hydrothermal treatment coupled with carbon capture and storage an energy-producing negative emissions technology? Energy Convers. Manag. 2020, 203, 112252. [Google Scholar] [CrossRef]

- American Chemistry Council. U.S. Resin Production & Sales 2018 vs. 2017; American Chemistry Council: Washington, DC, USA, 2017. [Google Scholar]

- Bruun, J. Revolutionizing the Way We Manage Waste. 2019. Available online: https://eng.au.dk/en/news-and-events/news/show/artikel/revolutionising-the-way-we-manage-waste-a-danish-researcher-is-developing-a-pioneering-new-technolo-1/ (accessed on 4 April 2020).

- U.S. Department of Energy. U.S. Department of Energy Invests $7 Million for Projects to Advance Coal Power Generation under Coal FIRST Initiative. 2019. Available online: https://www.energy.gov/fe/articles/us-department-energy-invests-7-million-projects-advance-coal-power-generation-under-coal (accessed on 4 April 2020).

- U.S. Department of Energy. Reports for the Coal FIRST concepts of interest; 2020. Available online: https://netl.doe.gov/coal/tpg/coalfirst/concept-reports (accessed on 4 January 2020).

- James, R.E.; Kearins, D.; Turner, M.; Woods, M.; Kuehn, N.; Zoelle, A. Cost and Performance Baseline for Fossil Energy Plants Volume 1: Bituminous Coal and Natural Gas to Electricity; NETL: Washington, DC, USA, 2019. [CrossRef]

- Irlam, L. Global Costs of Carbon Capture and Storage. 2017. Available online: https://www.globalccsinstitute.com/archive/hub/publications/201688/global-ccs-cost-updatev4.pdf (accessed on 4 April 2020).

- 8 Rivers Capital. Direct Supercritical Carbon Dioxide Power Plant System. 2020. Available online: https://www.netl.doe.gov/coal/tpg/coalfirst/DirectSupercriticalCo2 (accessed on 9 September 2020).

- Melzer, L.S. Carbon Dioxide Enhanced Oil Recovery (CO2 EOR): Factors Involved in Adding Carbon Capture, Utilization and Storage (CCUS) to Enhanced Oil Recovery. 2012. Available online: https://carboncapturecoalition.org/wp-content/uploads/2018/01/Melzer_CO2EOR_CCUS_Feb2012.pdf (accessed on 4 April 2020).

- Sepulveda, N.A.; Jenkins, J.D.; de Sisternes, F.J.; Lester, R.K. The Role of Firm Low-Carbon Electricity Resources in Deep Decarbonization of Power Generation. Joule 2018, 2, 2403–2420. [Google Scholar] [CrossRef] [Green Version]

- Deng, H.; Bielicki, J.M.; Oppenheimer, M.; Fitts, J.P.; Peters, C.A. Leakage risks of geologic CO2 storage and the impacts on the global energy system and climate change mitigation. Clim. Chang. 2017, 144, 151–163. [Google Scholar] [CrossRef] [Green Version]

- Alcalde, J.; Flude, S.; Wilkinson, M.; Johnson, G.; Edlmann, K.; Bond, C.E.; Scott, V.; Gilfillan, S.M.V.; Ogaya, X.; Haszeldine, R.S. Estimating geological CO2 storage security to deliver on climate mitigation. Nat. Commun. 2018, 9, 2201. [Google Scholar] [CrossRef]

- Montserrat, F.; Renforth, P.; Hartmann, J.; Leermakers, M.; Knops, P.; Meysman, F.J.R. Olivine Dissolution in Seawater: Implications for CO2 Sequestration through Enhanced Weathering in Coastal Environments. Environ. Sci. Technol. 2017, 51, 3960–3972. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Strefler, J.; Amann, T.; Bauer, N.; Kriegler, E.; Hartmann, J. Potential and costs of carbon dioxide removal by enhanced weathering of rocks. Environ. Res. Lett. 2018, 13. [Google Scholar] [CrossRef]

- Project Vesta. Available online: https://projectvesta.org/ (accessed on 9 September 2020).

- Kelemen, P.; Benson, S.M.; Pilorgé, H.; Psarras, P.; Wilcox, J. An Overview of the Status and Challenges of CO2 Storage in Minerals and Geological Formations. Front. Clim. 2019, 1, 9. [Google Scholar] [CrossRef]

- Snæbjörnsdóttir, S.Ó.; Sigfússon, B.; Marieni, C.; Goldberg, D.; Gislason, S.R.; Oelkers, E.H. Carbon dioxide storage through mineral carbonation. Nat. Rev. Earth Environ. 2020, 1, 90–102. [Google Scholar] [CrossRef] [Green Version]

- Moran, K.; Crawford, C.; Webb, R.; Holmes, G.; Paulson, M.; Rankin, M. Solid Carbon: A Climate Mitigation Partnership Advancing Stable Negative Emissions. Available online: https://www.solidcarbon.ca/ (accessed on 12 April 2020).

- Caserini, S.; Dolci, G.; Azzellino, A.; Lanfredi, C.; Rigamonti, L.; Barreto, B.; Grosso, M. Evaluation of a new technology for carbon dioxide submarine storage in glass capsules. Int. J. Greenh. Gas Control 2017, 60, 140–155. [Google Scholar] [CrossRef]

- Brewer, P.G.; Orr Franklin, M.; Friederich, G.; Kvenvolden, K.A.; Orange, D.L. Gas Hydrate Formation in the Deep Sea: In Situ Experiments with Controlled Release of Methane, Natural Gas, and Carbon Dioxide. Energy Fuels 1998, 12, 183–188. [Google Scholar] [CrossRef]

- Brewer, P.G. Roger Revelle commemorative lecture contemplating action: Storing carbon dioxide in the ocean. Oceanography 2000, 13, 84–92. [Google Scholar] [CrossRef] [Green Version]

- Capron, M.E.; Stewart, J.R.; Rowe, R. Secure Seafloor Container CO2 Storage. In Proceedings of the OCEANS’13 MTS/IEEE San Diego Technical Program #130503-115, San Diego, CA, USA, 23–27 September 2013. [Google Scholar]

- McGrail, B.P.; Schaef, H.T.; Spane, F.A.; Horner, J.A.; Owen, A.T.; Cliff, J.B.; Qafoku, O.; Thompson, C.J.; Sullivan, E.C. Wallula Basalt Pilot Demonstration Project: Post-injection Results and Conclusions. Energy Procedia 2017, 114, 5783–5790. [Google Scholar] [CrossRef]

- Gunnarsson, I.; Aradóttir, E.S.; Oelkers, E.H.; Clark, D.E.; Arnarson, M.Þ.; Sigfússon, B.; Snæbjörnsdóttir, S.Ó.; Matter, J.M.; Stute, M.; Júlíusson, B.M.; et al. The rapid and cost-effective capture and subsurface mineral storage of carbon and sulfur at the CarbFix2 site. Int. J. Greenh. Gas Control 2018, 79, 117–126. [Google Scholar] [CrossRef] [Green Version]

- Friedlingstein, P.; Jones, M.W.; O’Sullivan, M.; Andrew, R.M.; Hauck, J.; Peters, G.P.; Peters, W.; Pongratz, J.; Sitch, S.; Le Quéré, C.; et al. Global Carbon Budget 2019. Earth Syst. Sci. Data 2019, 11, 1783–1838. [Google Scholar] [CrossRef] [Green Version]

- Knutti, R.; Rogelj, J. The legacy of our CO2 emissions: A clash of scientific facts, politics and ethics. Clim. Chang. 2015, 133, 361–373. [Google Scholar] [CrossRef]

- Baker, S.E.; Stolaroff, J.K.; Peridas, G.; Pang, S.H.; Goldstein, H.M.; Lucci, F.R.; Li, W.; Slesarev, E.W.; Pett-Ridge, P.; Ryerson, F.J.; et al. Getting to Neutral: Options for Negative Carbon Emissions in California; Lawrence Livermore National Laboratory: Livermore, CA, USA, 2020.

- Atlas-Copco CO2 Compressors. Available online: https://www.atlascopco.com/en-us/compressors/products/gas-compressors/co2-compressor (accessed on 1 April 2020).

- Rubin, E.S.; Davison, J.E.; Herzog, H.J. The cost of CO2 capture and storage. Int. J. Greenh. Gas Control 2015, 40, 378–400. [Google Scholar] [CrossRef]

- Investopedia. What Percentage of the Global Economy Consists of the Oil and Gas Drilling Sector? Available online: https://www.investopedia.com/ask/answers/030915/what-percentage-global-economy-comprised-oil-gas-drilling-sector.asp (accessed on 11 April 2020).

- Ibisworld. Global Coal Mining Industry—Market Research Report. 2019. Available online: https://www.ibisworld.com/global/market-research-reports/global-coal-mining-industry (accessed on 12 April 2020).

- USGCRP. Impacts, Risks, and Adaptation in the United States: Fourth National Climate Assessment, Volume II. Available online: https://nca2018.globalchange.gov/ (accessed on 10 April 2020).

- FAO. The State of World Fisheries and Aquaculture 2018—Meeting the Sustainable Development Goals; FAO: Roma, Italy, 2018. [Google Scholar]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [Green Version]

- Ritchie, H.; Roser, M. Global “Meat and Dairy Production” for 2018. Available online: https://ourworldindata.org/meat-production (accessed on 8 September 2020).

- MacLeod, M.J.; Hasan, M.R.; Robb, D.H.F.; Mamun-Ur-Rashid, M. Quantifying greenhouse gas emissions from global aquaculture. Sci. Rep. 2020, 10, 11679. [Google Scholar] [CrossRef]

- Parker, R.W.R.; Blanchard, J.L.; Gardner, C.; Green, B.S.; Hartmann, K.; Tyedmers, P.H.; Watson, R.A. Fuel use and greenhouse gas emissions of world fisheries. Nat. Clim. Chang. 2018, 8, 333–337. [Google Scholar] [CrossRef]

- Porter, J.R.; Xie, L.; Challinor, A.J.; Cochrane, K.; Howden, S.M.; Iqbal, M.M.; Lobell, D.B.; Travasso, M.I.; Aggarwal, P.; Hakala, K.; et al. Food security and food production systems. In Climate Change 2014: Impacts, Adaptation, and Vulnerability. Part A: Global and Sectoral Aspects; Cambridge University Press: Cambridge, UK, 2015; pp. 485–534. [Google Scholar] [CrossRef] [Green Version]

- Tigchelaar, M.; Battisti, D.S.; Naylor, R.L.; Ray, D.K. Future warming increases probability of globally synchronized maize production shocks. Proc. Natl. Acad. Sci. USA 2018, 115, 6644–6649. [Google Scholar] [CrossRef] [Green Version]

- Tirado-von der Pahlen, C. Sustainable Diets for Healthy People and a Healthy Planet. 2017. Available online: https://www.unscn.org/uploads/web/news/document/Climate-Nutrition-Paper-EN-.pd (accessed on 3 August 2020).

- Zhu, C.; Kobayashi, K.; Loladze, I.; Zhu, J.; Jiang, Q.; Xu, X.; Liu, G.; Seneweera, S.; Ebi, K.L.; Drewnowski, A.; et al. Carbon dioxide levels this century will alter the protein, micronutrients, and vitamin content of rice grains with potential health consequences for the poorest rice-dependent countries. Sci. Adv. 2018, 4, eaaq1012. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chumley, H.; Hewlings, S. The effects of elevated atmospheric carbon dioxide [CO2] on micronutrient concentration, specifically iron (Fe) and zinc (Zn) in rice; a systematic review. J. Plant Nutr. 2020, 43, 1571–1578. [Google Scholar] [CrossRef]

- FAO. World Aquaculture 2015: A Brief Overview; FAO: Roma, Italy, 2017; Volume 1140. [Google Scholar]

- Mohanty, B.P.; Sankar, T.V.; Ganguly, S.; Mahanty, A.; Anandan, R.; Chakraborty, K.; Paul, B.N.; Sarma, D.; Dayal, J.S.; Mathew, S.; et al. Micronutrient Composition of 35 Food Fishes from India and Their Significance in Human Nutrition. Biol. Trace Elem. Res. 2016, 174, 448–458. [Google Scholar] [CrossRef]

- Hicks, C.C.; Cohen, P.J.; Graham, N.A.J.; Nash, K.L.; Allison, E.H.; D’Lima, C.; Mills, D.J.; Roscher, M.; Thilsted, S.H.; Thorne-Lyman, A.L.; et al. Harnessing global fisheries to tackle micronutrient deficiencies. Nature 2019, 574, 95–98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guarino, B. As Seas Rise, the U.N. Explores a Bold Plan: Floating Cities. Available online: https://www.washingtonpost.com/science/2019/04/05/seas-rise-un-explores-bold-plan-floating-cities/ (accessed on 4 April 2020).

- West, J.J.; Smith, S.J.; Silva, R.A.; Naik, V.; Zhang, Y.; Adelman, Z.; Fry, M.M.; Anenberg, S.; Horowitz, L.W.; Lamarque, J.-F. Co-benefits of mitigating global greenhouse gas emissions for future air quality and human health. Nat. Clim. Chang. 2013, 3, 885–889. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morrow, D.R.; Thompson, M.S.; Anderson, A.; Batres, M.; Buck, H.J.; Dooley, K.; Geden, O.; Ghosh, A.; Low, S.; Njamnshi, A.; et al. Principles for Thinking about Carbon Dioxide Removal in Just Climate Policy. One Earth 2020, 3, 150–153. [Google Scholar] [CrossRef]

- Quirion, P.; Rozenberg, J.; Sassi, O.; Vogt-Schilb, A. How CO2 Capture and Storage Can Mitigate Carbon Leakage. SSRN Electron. J. 2012. [Google Scholar] [CrossRef] [Green Version]

- Otto, I.M.; Donges, J.F.; Cremades, R.; Bhowmik, A.; Hewitt, R.J.; Lucht, W.; Rockström, J.; Allerberger, F.; McCaffrey, M.; Doe, S.S.P.; et al. Social tipping dynamics for stabilizing Earth’s climate by 2050. Proc. Natl. Acad. Sci. USA 2020, 117, 2354–2365. [Google Scholar] [CrossRef] [Green Version]

- Algunaibet, I.M.; Pozo, C.; Galán-Martín, Á.; Huijbregts, M.A.J.; Mac Dowell, N.; Guillén-Gosálbez, G. Powering sustainable development within planetary boundaries. Energy Environ. Sci. 2019, 12, 1890–1900. [Google Scholar] [CrossRef] [Green Version]

- Stemmler, I.; Hense, I.; Quack, B. Marine sources of bromoform in the global open ocean—Global patterns and emissions. Biogeosciences 2015, 12, 1967–1981. [Google Scholar] [CrossRef] [Green Version]

- Mehlmann, M.; Quack, B.; Atlas, E.; Hepach, H.; Tegtmeier, S. Natural and anthropogenic sources of bromoform and dibromomethane in the oceanographic and biogeochemical regime of the subtropical North East Atlantic. Environ. Sci. Process. Impacts 2020, 22, 679–707. [Google Scholar] [CrossRef] [PubMed]

- Morley, J.W.; Selden, R.L.; Latour, R.J.; Frölicher, T.L.; Seagraves, R.J.; Pinsky, M.L. Projecting shifts in thermal habitat for 686 species on the North American continental shelf. PLoS ONE 2018, 13, e0196127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Buck, H.J. How to Decolonize the Atmosphere. 2020. Available online: https://progressive.international/blueprint/46253391-5b3d-4e68-bd3f-d53dc54180fd-holly-jean-buck-how-to-decolonize-the-atmosphere/en (accessed on 8 September 2020).

- Intergovernmental Oceanographic Commission. United Nations Decade of Ocean Science for Sustainable Development. 2020. Available online: https://oceandecade.org (accessed on 9 September 2020).

| Metric | Units | Pfuel: Low Bio-Electricity, High Biofuel | Pelectric: High Bio-Electricity, Low Biofuel |

|---|---|---|---|

| Global fossil oil and natural gas use without sequestering the CO2. | Billion barrels/yr (energy equiv.) | 33 1 | 10 |

| Global negative emissions biofuel production for non-electric use (transportation, industry, heating) | 7 | 0 | |

| Global carbon neutral electricity (solar, wind, nuclear, fossil fuel with emissions capture, etc.) | Billion MWh/yr | 15 | 56 |

| Global carbon negative electricity (biomass with carbon capture and sequestration) | 35 | 14 | |

| Biomass production at net zero (mix of waste, Miscanthus and similar, and macroalgae) | billion dry tonnes/yr | 13 | 3 |

| Resulting approximation of fossil- and bio-CO2 sequestration (at net zero) | billion tonnes/yr | 26 | 28 |

| Computed net CO2 emissions | billion tonnes/yr | 0 | 0 |

| Metric | Units | Pfuel | Pelectric |

|---|---|---|---|

| Global population | Billion | 10 | 10 |

| Projected global average electricity generation in 2070 * (2018 world average: 3.5 MWh/capita, China: 5.0, US: 13.6, Japan: 8.3 [47]) | MWh/yr/person | 5 | 7 |

| Projected global electricity generation in 2070 (2018 global electricity generation was 27 billion MWh per year [47]) | Billion MWh/yr | 50 | 70 |

| Fraction of global electricity production projected to be BECCS with the remainder nuclear or renewable: solar PV, solar thermal, wind, hydro, wave, geothermal, etc. | % | 22% | 67% |

| Global non-electric HTL-produced biofuel use (transportation, industry, heating) (global oil demand of 100 million barrels/day (14 million tonnes/day) or 37 billion barrels/yr in 2018 [48] | Billion barrels/yr | 40 | 10 |

| Global biomass production for Allam Cycle electricity BECCS | Billion dry tonnes/yr | 4 | 17 |

| Global biomass production for non-electric biofuel | 35 | 9 | |

| Global biomass production for HTL bio-construction materials (asphalt, plastic, carbon fiber, textiles, etc.) | 4 | 4 | |

| Total global biomass production (well past net zero, perhaps 2070) | 43 | 30 | |

| Mass of bio-CO2 captured and stored (well past net zero, perhaps 2070) | Billion tonnes of CO2/yr | 28 | 38 |

| Year when 3 trillion tonnes of CO2 are removed from atmosphere and ocean and permanently sequestered | Year | 2170 | 2140 |

| Metric | Estimated Global Scale at Indicated Cost 1 | Estimated Cost Delivered to Energy Process 1 | Estimated Energy-Return Ratio 2 |

|---|---|---|---|

| Billions of Dry Tonnes/yr | $/dry Tonne | Eout/Ein | |

| Organic waste including mixed biosolids, paper, plastic, food waste, etc. 3 | 5 to 7 | $(200) to $20 | 4 to 20 |

| Terrestrial agriculture residues and purpose-grown biomass-for-energy (Miscanthus, etc.) 4 | 6 to 20 | $0 to $400 | 1 to 50 |

| Macroalgae with total ecosystem aquaculture 5 paying for the structure | 0.1 to 0.3 | $40 to $70 | 20 to 50 |

| Microalgae, mixed species, microbes, and plants 6 | Small, due to high cost | $400 to $2000 | 0.4 to 1.1 |

| Macroalgae, anchored systems 7 | 10 to 15 | $125 to $145 | 8 to 20 |

| Macroalgae, free-floating systems 8 | 40 to 60 | $75 to $180 | 4 to 12 |

| Metric | Global Scale of Potential Storage 1 | Global Scale of Injection Rate | Cost for Injecting into Sequestration Process with Permanent Monitoring and Occasional Repairs 2 | Leakage Rate 3 | |

|---|---|---|---|---|---|

| Billions of Tonnes of CO2 | Billions of Tonnes of CO2/yr | US$/Tonne 4 of CO2 | US$/MWh 5 with CO2 from Allam Cycle | % | |

| Geologic sequestration 6 in emptied oil wells, gas wells, and brine aquifers (negative costs are for enhanced oil recovery (EOR) | 2000 to 5800 | large uncertainty | −$40 to $56 most w/o EOR below $8 | −$27 to $40 most below $5 | <0.9% of total per 1000 years |

| Mineralization sequestration in on land basalt and peridotite rocks 7 | more than 1000 | more than 10 | $10 to $30 | $7 to $20 | Negligible |

| Mineralization sequestration in subsea basalt rocks 7 | more than 20,000 | much more than 20 | $200 to $400 | $140 to $300 | Negligible |

| Contained CO2-hydrate storage on the seafloor or liquid CO2 in glass containers 8 | more than 20,000 | much more than 20 | $5 to $17 | $3 to $12 | <0.06% per 1000 years |

| Metric | Additional $/Tonne of CO2 | Comment |

|---|---|---|

| Allam Cycle power plant gasifying $0/GJ ($0/MMBTU) dry waste in place of $7.6/GJ ($8/MMBTU) LNG, including income from sales of argon and nitrogen plus CO2 for EOR | −$260 | Lower electricity fuel cost possible when retaining solid waste disposal fees to offset Allam capital and operating costs. |

| Allam Cycle power plant gasifying $0/GJ ($0/MMBTU) dry waste in place of $2.5/GJ Illinois coal delivered in US, including income from gas sales | −$45 | |

| Allam Cycle power plant burning terrestrial biomass delivered for the same $2.5/GJ as for US coal, no gas sales | $26 | When fuel costs the same, all the additional cost is process change ($15/tonne), compressing ($1/tonne), transporting, and sequestering liquid CO2 ($10/tonne). |

| Allam Cycle power plant burning $11/GJ HTL biocrude instead of fossil oil for the same $11/GJ, no gas sales | $26 | |

| Hybrid co-located HTL and fossil-fired (some HTL biogas) Allam Cycle capturing and compressing CO2 from both processes. Same $/GJ for biomass or fossil fuel, no gas sales | $26 | |

| Standalone HTL facility using by-product biogas internally with internal capture and compression of by-product CO2, no gas sales | $75 | Using historic capture and compression average cost of $65/tonne plus the same $10/tonne for sequestration. |

| Allam Cycle power plant burning $11/GJ HTL biocrude in place of $7.6/GJ LNG (approximate), no gas sales | $90 | Higher fuel cost increasing electricity price is most of the added expense. |

| Allam Cycle power plant burning $11/GJ HTL biocrude in place of $2.5/GJ coal (approximate), no gas sales | $180 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capron, M.E.; Stewart, J.R.; de Ramon N’Yeurt, A.; Chambers, M.D.; Kim, J.K.; Yarish, C.; Jones, A.T.; Blaylock, R.B.; James, S.C.; Fuhrman, R.; et al. Restoring Pre-Industrial CO2 Levels While Achieving Sustainable Development Goals. Energies 2020, 13, 4972. https://doi.org/10.3390/en13184972

Capron ME, Stewart JR, de Ramon N’Yeurt A, Chambers MD, Kim JK, Yarish C, Jones AT, Blaylock RB, James SC, Fuhrman R, et al. Restoring Pre-Industrial CO2 Levels While Achieving Sustainable Development Goals. Energies. 2020; 13(18):4972. https://doi.org/10.3390/en13184972

Chicago/Turabian StyleCapron, Mark E., Jim R. Stewart, Antoine de Ramon N’Yeurt, Michael D. Chambers, Jang K. Kim, Charles Yarish, Anthony T. Jones, Reginald B. Blaylock, Scott C. James, Rae Fuhrman, and et al. 2020. "Restoring Pre-Industrial CO2 Levels While Achieving Sustainable Development Goals" Energies 13, no. 18: 4972. https://doi.org/10.3390/en13184972