Analysis of the Fire Propagation in a Sublevel Coal Mine

Abstract

:1. Introduction

Mine Fires in Undergorund Coal Mines

2. Materials and Methods

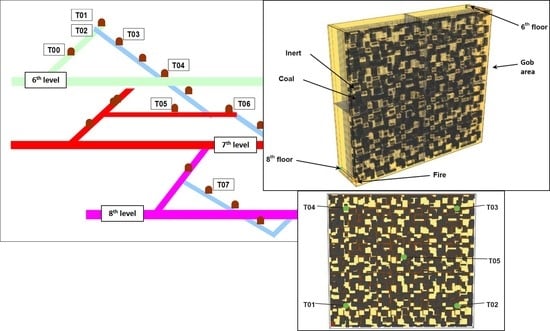

2.1. Case Study

- T00–6th level, sealing

- T01–6th level, inner part of the sealing, left side

- T02–6th level, inner part of the sealing, right side

- T03–Molino seam, 1st sublevel, between 6th and 7th levels

- T04–Molino seam, 3rd sublevel, between 6th and 7th levels

- T05–Drift in host rock, 7th level

- T06–Waste Molino, 7th level

- T07–Molino seam, 1st sublevel, between 7th and 8th levels

- Scenario 1: behavior of the fire without the implementation of any countermeasure. January.

- Scenario 2: sealing the access to the fire zone on the 5th level, which is above the affected area, the 6th level, and the 8th level. Applied in February.

- Scenario 3: Reduction of the airflow on the 7th level. Applied in June. The fire monitoring, applying both countermeasures, was done from June to December.

2.2. CFD Characteristics

3. Results and Discussion

3.1. Experimental Results

3.2. Ventilation Circuit

- Scenario 1. Development of the fire without countermeasures:

- Scenario 2. Fire developed and sealing of the levels

- Scenario 3. Fire developed, sealing and reduction of the airflow supply

3.3. CFD Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhu, Y.; Wang, D.; Shao, Z.; Xu, C.; Zhu, X.; Qi, X.; Liu, F. A statistical analysis of coalmine fires and explosions in China. Process Saf. Environ. Prot. 2019, 121, 357–366. [Google Scholar] [CrossRef]

- Smith, A.C.; Thimons, E.D. Summary of US Mine Fire Research. SME Annual Meeting and Exhibit; Society for Mining, Metallurgy, and Exploration, Inc.: Englewood, CO, USA, 2010; pp. 1–15. [Google Scholar]

- De Rosa, M.I. Analysis of Mine Fires for all USA Underground and Surface Coal Mining Categories; NIOSH: Pittsburgh, PA, USA, 2004.

- Grayson, L.R.; Kinilakodi, H.; Kecojevic, V. Pilot sample risk analysis for underground coal mine fires and explosions using MSHA citation data. Saf. Sci. 2009, 47, 1371–1378. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, S.; Ma, X.; Wu, Z.; Shao, H.; Zhang, W.; Cui, C. Information fusion of plume control and personnel escape during the emergency rescue of external-caused fire in a coal mine. Process Saf. Environ. Prot. 2016, 103, 46–59. [Google Scholar] [CrossRef]

- Sanmiquel-Pera, L.; Bascompta, M.; Anticoi, H.F. Analysis of a historical accident in a Spanish coal mine. Int. J. Environ. Res. Public Health 2019, 16, 3615. [Google Scholar] [CrossRef] [Green Version]

- Brake, D.J. Fire Modelling in Underground Mines using Ventsim Visual VentFIRE Software. In Proceedings of the Australian Mine Ventilation Conference, Adelaide, Australia, 1–3 July 2013. [Google Scholar]

- Morar, M.S.; Radu, S.M.; Cioclea, D.; Gherghe, I. Use of IT equipment and specialized programs for solving ventilation networks. Calitatea 2017, 18, 121–126. [Google Scholar]

- Edwards, J.C.; Hwang, C.C. CFD Modelling of Fire Spread Along Combustibles in a Mine Entry; NIOSH: Pittsburgh, PA, USA, 1990; pp. 4–8.

- Wang, Z.; Ren, T.; Ma, L.; Zhang, J. Investigations of ventilation airflow characteristics on a longwall face—A computational approach. Energies 2018, 11, 1564. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Zhang, Q. Analytical solution, experimental data and CFD simulation for longitudinal tunnel fire ventilation. Tunn. Undergr. Space Technol. 2014, 42, 307–313. [Google Scholar] [CrossRef]

- Haghighat, A.; Luxbacher, K. Tenability analysis for improvement of firefighters’ performance in a methane fire event at a coal mine working face. J. Fire Sci. 2018, 36, 256–274. [Google Scholar] [CrossRef]

- Du, T.; Yang, D.; Ding, Y. Driving force for preventing smoke backlayering in downhill tunnel fires using forced longitudinal ventilation. Tunn. Undergr. Space Technol. 2018, 79, 76–82. [Google Scholar] [CrossRef]

- Guansheng, Q.; Wei, L.; Xuyao, Q.; Xiaoxing, Z.; Weimin, C.; Fangming, L. Differences in smoldering characteristics of coal piles with different smoldering propagation directions. Fire Saf. J. 2018, 102, 77–82. [Google Scholar] [CrossRef]

- Sun, J.; Fang, Z.; Beji, T.; Merci, B. Interpretation of flow fields induced by water spray systems in reduced-scale tunnel fire experiments by means of CFD simulations. Tunn. Undergr. Space Technol. 2018, 81, 94–102. [Google Scholar] [CrossRef] [Green Version]

- Tewarson, A. Analysis of Full-Scale Timber Fire Tests in a Simulated Mine Gallery; Fifth Annual Report; Factory Mutual Research: Johnston, RI, USA, 1982. [Google Scholar]

- Ingason, H.; Nireus, K.; Werling, P. Fire Tests in Blasted Rock Tunnel; Report FOA-R97-00581-990-SE; FOA: Tumba, Sweden, 1997. [Google Scholar]

- Yuan, L.; Zhou, L.; Smith, A.C. Modeling carbon monoxide spread in underground mine fires. Appl. Therm. Eng. 2016, 100, 1319–1326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hansen, R. Fire behavior of mining vehicles in underground hard rock mines. Int. J. Min. Sci. Technol. 2018, 27, 627–634. [Google Scholar] [CrossRef]

- Fernández-Alaiz, F.; Castañón, A.M.; Gómez-Fernández, F.; Bascompta, M. Mine Fire Behavior under Different Ventilation Conditions: Real-Scale Tests and CFD Modeling. Appl. Sci. 2020, 10, 3380. [Google Scholar] [CrossRef]

- Yuan, L.; Smith, A.C. Effects of ventilation and gob characteristics on spontaneous heating in longwall gob areas. In Proceedings of the 12th U.S./North American Mine Ventilation Symposium, Reno, NV, USA, 9–11 June 2008. [Google Scholar]

- Carvel, R.; Beard, A.; Jowitt, P. How much do tunnels enhance the HRR of fires? In Proceedings of the 4th International Conference on Safety in Road and Rail Tunnels, Madrid, Spain, 2–6 April 2001; pp. 457–466. [Google Scholar]

- McPherson, M.J. Subsurface Ventilation and Environmental Engineering; Springer: Cham, Switzerland, 1993; ISBN 978-94-011-1550-6. [Google Scholar]

- Beard, A.; Carvel, R. The Handbook of Tunnel Fire Safety; Thomas Telford Ltd.: London, UK, 2005; ISBN 9780727731685. [Google Scholar]

- Wang, Y.; Li, X.; Wang, W.; Guo, Z. Experimental and in-situ estimation on hydrogen and methane emission from spontaneous gasification in coal fire. Int. J. Hydrog. Energy 2017, 42, 18728–18733. [Google Scholar] [CrossRef]

- Haghighat, A.; Gillies, S. Fire Behavior Analysis of a Mine Future Plan. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 20 June 2015; pp. 1–10. [Google Scholar]

- Ballesteros-Tajadura, R.; Santolaria-Morros, C.; Blanco-Marigorta, E. Influence of the slope in the ventilation semi-transversal system of an urban tunnel. Tunn. Undergr. Space Technol. 2006, 21, 21–28. [Google Scholar] [CrossRef]

- Grant, G.B.; Drysdale, D.D. Estimating heat release rates from large-scale tunnel fires. In Proceedings of the 5th International Symposium, Fire Safety Science, Melbourne, Australia, 3 March 1997; pp. 1213–1224. [Google Scholar]

- Wang, H.H.; Dlugogorski, B.Z.; Kennedy, E.M. Coal oxidation at low temperatures: Oxygen consumption, oxidation products, reaction mechanism and kinetic modelling. Prog. Energy Combust. Sci. 2003, 29, 487–513. [Google Scholar] [CrossRef]

- Gouws, M.J.; Knoetze, T.P. Coal self-heating and explosibility. J. S. Afr. Inst. Min. Metall. 1995, 95, 37–44. [Google Scholar]

- Tutak, M.; Brodny, J. The impact of the strength of roof rocks on the extent of the zone with a high risk of spontaneous coal combustion for fully powered longwalls ventilated with the Y-Type system-A case study. Appl. Sci. 2019, 9, 5315. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Li, X.; Shu, C.; Shen, W.; He, M.; Meng, J. Study of the influence of the characteristics of loose residual coal on the spontaneous combustion of coal gob. Energy Sci. Eng. 2020, 8, 689–701. [Google Scholar] [CrossRef] [Green Version]

- Morris, R.; Atkinson, T. Seam factor and the spontaneous heating of coal. Min. Sci. Technol. 1988, 7, 149–159. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, J.; Ren, T.; Wang, Z.; Song, S. Application of ventilation simulation to spontaneous combustion control in underground coal mine: A case study from Bulianta colliery. Int. J. Min. Sci. Technol. 2018, 28, 231–242. [Google Scholar] [CrossRef]

- Thyer, A. Development of a Fire and Explosion Risk Assessment Methodology for Underground Mines; Report HSL/2002/24; Science Group (Fire and Explosion), Health and Safety Laboratory: Buxton, UK, 2002. [Google Scholar]

- Adjiski, V.; Zubicek, V.; Despodov, Z. Monte Carlo simulation of uncertain parameters to evaluate the evacuation process in an underground mine fire emergency. S. Afr. Inst. Min. Metall. 2019, 119, 907–917. [Google Scholar] [CrossRef]

- Pach, G.; Różański, Z.; Wrona, P.; Niewiadomski, A.; Zapletal, P.; Zubíček, V. Reversal ventilation as a method of fire hazard mitigation in the mines. Energies 2020, 13, 1755. [Google Scholar] [CrossRef] [Green Version]

- Dong, S.; Lu, X.; Wang, D.; Wang, H.; Zheng, K.; Shi, Q.; Chen, M. Experimental investigation of the fire-fighting characteristics of aqueous foam in underground goaf. Process Saf. Environ. Prot. 2017, 106, 239–245. [Google Scholar] [CrossRef]

- Conti, R.S. Inflatable partitions for high-expansion foam generators. Min. Eng. 1995, 47, 561–566. [Google Scholar]

- Brune, J.F.; Saki, S.A. Prevention of gob ignitions and explosions in longwall mining using dynamic seals. Int. J. Min. Sci. Technol. 2017, 27, 999–1003. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Roy, P.; Ghosh, S.; Misra, S.; Obaidat, M.S. Wireless sensor network-based fire detection, alarming, monitoring and prevention system for Bord-and-Pillar coal mines. J. Syst. Softw. 2012, 85, 571–581. [Google Scholar] [CrossRef]

- Trevits, M.A.; Yuan, L.; Teacoach, K.; Valoski, M.P.; Urosek, J.E. Understanding Mine Fires By Determining The Characteristics Of Deep-Seated Fires; SME Annual Meeting; NIOSH: Pittsburgh, PA, USA, 2009.

- Zhang, H.T.; Gao, M.X. The Application of Support Vector Machine (SVM) Regression Method in Tunnel Fires. Procedia Eng. 2018, 211, 1004–1011. [Google Scholar] [CrossRef]

- Bustamante Rúa, M.O.; Daza Aragón, A.J.; Bustamante Baena, P. A study of fire propagation in coal seam with numerical simulation of heat transfer and chemical reaction rate in mining field. Int. J. Min. Sci. Technol. 2019, 29, 873–879. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, Y.; Wang, J.; Zhang, X.; Wang, J.; Zhou, C. Study on the effect of extraneous moisture on the spontaneous combustion of coal and its mechanism of action. Energies 2020, 13, 1969. [Google Scholar] [CrossRef]

| Coal Properties | Value | Units |

|---|---|---|

| Coal particle density | 1200 | kg/m3 |

| Coal bulk density | 870 | kg/m3 |

| Coal specific heat | 1.0 | kJ/(kg·K) |

| Conductivity | 0.2 | W/(m·K) |

| Heat of reaction | 209 | kJ/kg |

| Heat of combustion | 2.8402·104 | kJ/mol·O2 |

| Activation energy | 6.65·104 | kJ/kmol |

| Pre-exponential factor | 1.9·106 | K/s |

| Initial coal temperature | 20 | °C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernánez-Alaiz, F.; Castañón, A.M.; Gómez-Fernández, F.; Bernardo-Sánchez, A.; Bascompta, M. Analysis of the Fire Propagation in a Sublevel Coal Mine. Energies 2020, 13, 3754. https://doi.org/10.3390/en13143754

Fernánez-Alaiz F, Castañón AM, Gómez-Fernández F, Bernardo-Sánchez A, Bascompta M. Analysis of the Fire Propagation in a Sublevel Coal Mine. Energies. 2020; 13(14):3754. https://doi.org/10.3390/en13143754

Chicago/Turabian StyleFernánez-Alaiz, Florencio, Ana Maria Castañón, Fernando Gómez-Fernández, Antonio Bernardo-Sánchez, and Marc Bascompta. 2020. "Analysis of the Fire Propagation in a Sublevel Coal Mine" Energies 13, no. 14: 3754. https://doi.org/10.3390/en13143754