Potential Applications of Biogas Produced in Small-Scale UASB-Based Sewage Treatment Plants in Brazil

Abstract

:1. Introduction

2. Material and Methods

2.1. Identification of Rural Agglomerations: Secondary Data

2.2. Energy Assessment and Carbon Emissions Evaluation

3. Results and Discussion

3.1. Rural Agglomerations in Brazil

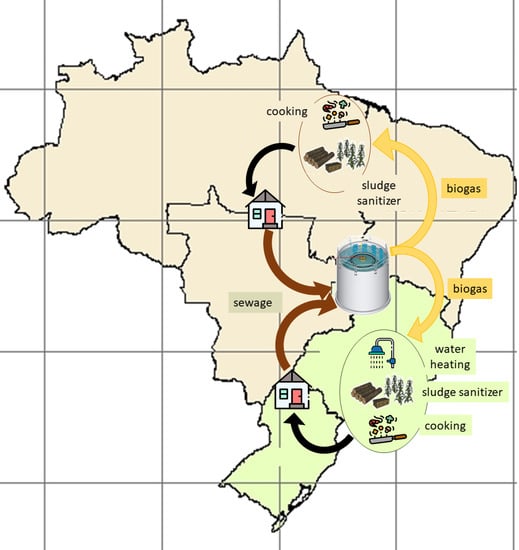

3.2. Proposed Flowsheet for Sewage Treatment and by-Products Recovery/Use

3.3. Potential Uses of the Biogas Produced in Small-Scale Anaerobic-Based STPs in the Northern and Southern Regions of Brazil

3.3.1. Use of Biogas for Sludge Sanitization

3.3.2. Use of Biogas for Cooking and Water Heating

3.3.3. Avoided Emissions of GHG

3.4. Comparison with Biogas Use in Other Rural Contexts

4. Final Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations General Assembly (UNGA). Human Right to Water and Sanitation; UN Document A/RES/64/292, UNGA: Geneva, Switzerland, 2010; Available online: https://undocs.org/en/A/RES/64/292 (accessed on 17 November 2019).

- Presidência da República, Casa Civil, Subchefia para Assuntos Jurídicos. LEI N° 11.445, DE 5 DE JANEIRO DE 2007. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2007/lei/l11445.htm (accessed on 21 November 2019).

- Chernicharo, C.A.L.; Bressani-Ribeiro, T.; Garcia, G.B.; Lermontov, A.; Pereira, C.B.; Platzer, C.J.; Possetti, G.R.C.; Leites, M.A.L.; Rosseto, R. Panorama do tratamento de esgoto sanitário nas regiões Sul, Sudeste e Centro-Oeste do Brasil: Tecnologias mais empregadas (Overview of sewage treatment in the south, south-east and center-west regions of Brazil: Most employed technologies). Rev. DAE 2018, 213, 5–19. [Google Scholar]

- Noyola, A.; Padilla-Rivera, A.; Morgan-Sagastume, J.M.; Güereca, L.P.; Hernández-Padilla, F. Typology of Municipal Wastewater Treatment Technologies in Latin America. Clean Soil Air Water 2012, 40, 926–932. [Google Scholar] [CrossRef]

- Seghezzo, L.; Zeeman, Z.; Van Lier, J.B.; Hamelers, H.V.M.; Lettinga, L. A reiview: The anaerobic treatment of sewage in UASB and EGSB reactors. Bioresour. Technol. 1998, 65, 175–190. [Google Scholar] [CrossRef]

- Chernicharo, C.A.L.; Bressani-Ribeiro, T.; von Sperling, M. Introduction to anaerobic sewage treatment. In Anaerobic Reactors for Sewage Treatment: Design, Construction and Operation; Chernicharo, C.A.L., Bressani-Ribeiro, T., Eds.; IWA Publishing: London, UK, 2019; pp. 1–7. [Google Scholar]

- Possetti, G.R.C.; Rietow, J.; Cabral, C.B.G.; Moreira, H.C.; Platzer, C.; Bressani-Ribeiro, T.; Chernicharo, C.A.L. Energy recovery from biogas in UASB reactors treating sewage. In Anaerobic Reactors for Sewage Treatment: Design, Construction and Operation; Chernicharo, C.A.L., Bressani-Ribeiro, T., Eds.; IWA Publishing: London, UK, 2019; pp. 194–236. [Google Scholar]

- IBGE. 2010 Population Census. Results of the Universe; IBGE: Rio de Janeiro, Brazil, 2011. [Google Scholar]

- National Rural Sanitation Program. Available online: http://www.funasa.gov.br/documents/20182/38564/MNL_PNSR_2019.pdf/08d94216-fb09-468e-ac98-afb4ed0483eb (accessed on 12 November 2019).

- INMET (National Institute of Meteorology). Average Annual Temperature. Available online: http://www.inmet.gov.br/portal/index.php?r=clima/page&page=anomaliaTempMediaAnual (accessed on 17 March 2020). (In Portuguese)

- Bressani-Ribeiro, T.; Lobato, L.C.S.; Chamhum-Silva, L.A.; Chernicharo, C.A.L. Sustainable STPs and public policies. In Soluções Baseadas na Natureza e os Desafios das Águas: Acelerando a Transição Para Cidades Mais Sustentáveis; Herzog, H., Freitas, T., Wiedman, G., Eds.; European Commission—Directorate-General for Research and Innovation: Brussels, Belgium, 2020. [Google Scholar]

- Soares, A.; Mota, C.R.; Fdz-Polanco, F.; Huang, X.; Passos, F.; Bressani-Ribeiro, T.; Chernicharo, C.A.L. Closing cycles in anaerobic-based sewage treatment systems. In Anaerobic Reactors for Sewage Treatment: Design, Construction and Operation; Chernicharo, C.A.L., Bressani-Ribeiro, T., Eds.; IWA Publishing: London, UK, 2019; pp. 379–406. [Google Scholar]

- Von Sperling, M.; Chernicharo, C.A.L. Biological Wastewater Treatment in Warm Climate Regions (2 vols); IWA Publishing: London, UK, 2005. [Google Scholar]

- Jiménez, F.M.; Zambrano, D. A Consumo de biogas en hogares rurales y sus implicaciones económicas y ambientales. Caso El Porvenir, Limón. RedBioLAC 2018, 2, 52–58. [Google Scholar]

- Lobato, L.C.S.; Chernicharo, C.A.L.; Souza, C.L. Estimates of methane loss and energy recovery potential in anaerobic reactors treating domestic wastewater. Water Sci. Technol. 2012, 66, 2745–2753. [Google Scholar] [CrossRef] [PubMed]

- Cabral, B.G.C.; Chernicharo, C.A.L.; Hoffmann, H.; Neves, P.N.P.; Platzer, C.; Bressani-Ribeiro, T.; Rosenfeldt, S. Resultados do Projeto de Medições de Biogás em Reatores Anaeróbios/Probiogás (Results of the Biogas Measurement Project in Anaerobic Reactors/Probiogás); Deutsche Gesellschaf für Internationale Zusammenarbeit GmbH, Ed.; GIZ/Ministério das Cidades: Brasília, Brazil, 2016. [Google Scholar]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 8th ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Andreoli, C.V.; von Sperling, M.; Fernandes, F. Lodo de Esgoto: Tratamento e Disposição Final (Sewage Sludge: Treatment and Final Disposal); Department of Sanitary and Environmental Engineering of UFMG: Curitiba, Brazil, 2001; Volume 6, p. 484. [Google Scholar]

- Borges, E.S.M.; Godinho, V.M.; Chernicharo, C.A.L. Thermal higienization of excess anaerobic sludge: A possible self-sustained application of biogas produced in UASB reactors. Water Sci. Technol. 2005, 52, 227–234. [Google Scholar] [CrossRef] [PubMed]

- Chernicharo, C.A.L.; Bressani-Ribeiro, T. Anaerobic Reactors for Sewage Treatment: Design, Construction and Operation; IWA Publishing: London, UK, 2019; p. 420. ISBN 9781780409221. [Google Scholar]

- U.S. EPA. 2014 Emission Factors for Greenhouse Gas Inventories. In Report of the United States Environmental Protection Agency; United States Environmental Protection Agency: Washington, DC, USA, 2014. [Google Scholar]

- Ministério da Ciência, Tecnologia e Inovação. Brasil 2017 Annual Estimates of Greenhouse Gas Emissions in Brazil (Estimativas Anuais de Emissões de Gases de Efeito Estufa no Brasil), 2nd ed.; Ministério da Ciência, Tecnologia e Inovação: Brasília, Brazil, 2017. (In Portuguese) [Google Scholar]

- Chernicharo, C.A.L.; Brandt, E.M.F.; Bressani-Ribeiro, T.; Melo, V.R.; Bianchetti, F.J.; Mota Filho, C.; McAdam, E. Development of a tool for improving the management of gaseous emissions in UASB-based sewage treatment plants. Water Pract. Technol. 2017, 12, 917–926. [Google Scholar] [CrossRef] [Green Version]

- Bressani-Ribeiro, T.; Mota Filho, C.R.; Melo, V.R.; Bianchetti, F.J.; Chernicharo, C.A.L. Planning for achieving low carbon and integrated resources recovery from sewage treatment plants in Minas Gerais, Brazil. J. Environ. Manag. 2018, 242, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Garfí, M.; Martí-Herrero, J.; Garwood, A.; Ferrer, I. Household anaerobic digesters for biogas production in Latin America: A review. Renew. Sustain. Energy Rev. 2016, 60, 599–614. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Yang, G.; Sweeney, S.; Feng, Y. Household biogas use in rural China: A study of opportunities and constraints. Renew. Sustain. Energy Rev. 2010, 14, 545–549. [Google Scholar] [CrossRef]

- Von Sperling, M.; Almeida, P.G.S.; Bressani-Ribeiro, T.; Chernicharo, C.A.L. Post-treatment of anaerobic effluents. In Anaerobic Reactors for Sewage Treatment: Design, Construction and Operation; Chernicharo, C.A.L., Bressani-Ribeiro, T., Eds.; IWA Publishing: London, UK, 2019; pp. 285–348. [Google Scholar]

| Population Category | Description | Recommended Sanitation Solutions |

|---|---|---|

| A | Peripheric agglomerations in urban territory | The same as those practiced in cities (urban areas) |

| B | Isolated agglomerations with urban characteristics | Economy of scale justify the use of decentralised solutions and self-sufficient management model |

| C | Isolated agglomerations with rural characteristics | Individual and collective actions coexist; the management may require external support |

| D | Dispersed rural settlements | Individual actions prevail |

| Geographic Region | Population Category | Recommended/Potential Biogas End Uses |

|---|---|---|

| North | A, B and C | Sludge sanitization Cooking |

| South | A, B and C | Sludge sanitization Water heating |

| Parameters | Variable Name | Unit | Value | Reference |

|---|---|---|---|---|

| Daily per capita sewage generation | QPC | L PE−1 d−1 | 160 | [13] |

| Daily biogas consumption for cooking | BCcooking | Nm3 biogas family−1 d−1 | 0.25 | [14] |

| Unitary methane yield | YCH4 | NL CH4 m−3sewage | 64 | [15] |

| Methane content in biogas | %CH4 | % | 75 | [16] |

| Lower calorific value of methane | LCVCH4 | MJ Nm−3CH4−1 | 35.8 | [17] |

| Lower calorific value of LPG1 | LCVLPG | MJ Nm−3CH4−1 | 120.4 | [17] |

| Daily per capita sludge (as DS2) generation in UASB reactors | DSPE | gDS PE−1 d−1 | 15 | [18] |

| Water specific heat | Hw | kJ kg−1 °K-1 | 4.18 | [17] |

| Sludge specific heat | Hs | kJ kg−1 °K−1 | 1.05 | [12] |

| Sludge temperature | Ts | °C | 20 | [19] |

| Sanitized sludge temperature | Tss | °C | 70 | [19] |

| Excess sludge concentration | Csludge | % | 4 | [20] |

| Sludge specific mass | γs | kg m−3 | 1020 | [18] |

| Energy loss through the walls of the sanitizing tank | ELsanit-tank | % | 15 | [12] |

| Difference between tap water and bath temperatures | Δw | °C | 30 | Assumed value |

| Thermal efficiency of boilers | TEboilers | % | 90 | Standard engine reference |

| Emission factor for LPG burn | ÈFLPG | kgCO2 eq m−3 LPG | 1507.1 | [21] |

| Emission factor for the electricity generation in Brazil | EFelec | gCO2 eq kW−1 h−1 | 125 | [22] |

| Geographic Region | Population Category | Population Equivalent (Inhabitants) | By-Products end Uses | ||

|---|---|---|---|---|---|

| Biogas | Sludge | Effluent | |||

| North | A | 3,021,261 | Sludge sanitization Cooking | Agriculture | Fertirrigation |

| B | 272,638 | ||||

| C | 2,277,349 | ||||

| Total | 5,571,248 | ||||

| South | A | 2,259,180 | Sludge sanitization Water heating | Agriculture | Fertirrigation |

| B | 300,177 | ||||

| C | 153,760 | ||||

| Total | 2,713,117 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Passos, F.; Bressani-Ribeiro, T.; Rezende, S.; Chernicharo, C.A.L. Potential Applications of Biogas Produced in Small-Scale UASB-Based Sewage Treatment Plants in Brazil. Energies 2020, 13, 3356. https://doi.org/10.3390/en13133356

Passos F, Bressani-Ribeiro T, Rezende S, Chernicharo CAL. Potential Applications of Biogas Produced in Small-Scale UASB-Based Sewage Treatment Plants in Brazil. Energies. 2020; 13(13):3356. https://doi.org/10.3390/en13133356

Chicago/Turabian StylePassos, Fabiana, Thiago Bressani-Ribeiro, Sonaly Rezende, and Carlos A. L. Chernicharo. 2020. "Potential Applications of Biogas Produced in Small-Scale UASB-Based Sewage Treatment Plants in Brazil" Energies 13, no. 13: 3356. https://doi.org/10.3390/en13133356