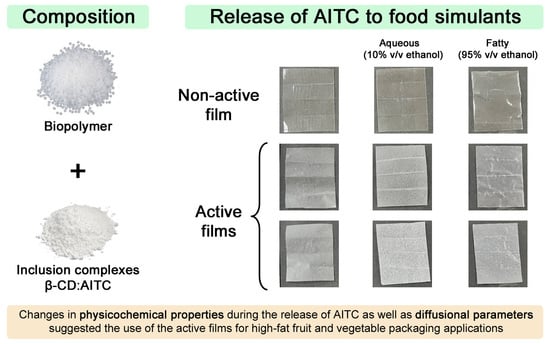

Development and Evaluation of the Properties of Active Films for High-Fat Fruit and Vegetable Packaging

Abstract

:1. Introduction

2. Results and Discussion

2.1. Surface Properties

2.2. Liquid Absorption Capacity

2.3. Thermal Properties

2.4. AITC Release

3. Materials and Methods

3.1. Materials and Reagents

3.2. Inclusion Complexes Preparation

3.3. Film Preparation

3.4. Film Characterization

3.4.1. Surface Properties

3.4.2. Liquid Absorption Capacity

3.4.3. Differential Scanning Calorimetry (DSC)

3.5. Release of AITC from Active Films

3.5.1. Experimental

3.5.2. Data Modelling and Determination of the Diffusion (D) and Partition Coefficient (Kp)

3.6. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

Appendix A

| Liquid | γL (mN m−1) | γLP (mN m−1) | γLD (mN m−1) |

|---|---|---|---|

| Water | 72.8 | 51.0 | 21.8 |

| Ethanol | 21.4 | 18.8 | 2.6 |

| Ethylene glycol | 48.8 | 32.8 | 16.0 |

| Glycerol | 63.4 | 26.4 | 37.0 |

| Diiodomethane | 50.8 | 2.3 | 48.5 |

Appendix B

| First Heating | ||||

| Ethanol in Simulant | P0 | P5 | P10 | |

| (% v/v) | ||||

| Tg (°C) | ||||

| Dry film | - | 59.18 ± 1.00 | 60.58 ± 0.01 | 60.19 ± 0.11 |

| In aqueous simulant | 10 | 56.29 ± 0.87 | 53.15 ± 0.26 | 51.54 ± 0.16 |

| In fatty simulant | 95 | 53.14 ± 1.69 | 63.51 ± 0.14 | 58.07 ± 1.45 |

| Tcc (°C) | ||||

| Dry film | - | 114.73 ± 0.51 | 118.89 ± 0.16 | 116.40 ± 0.61 |

| In aqueous simulant | 10 | 113.65 ± 0.71 | 118.25 ± 0.33 | 117.51 ± 0.31 |

| In fatty simulant | 95 | 123.55 ± 2.83 | 118.42 ± 1.50 | - |

| ΔHcc (J g−1) | ||||

| Dry film | - | 23.40 ± 0.23 | 23.26 ± 0.15 | 27.42 ± 0.14 |

| In aqueous simulant | 10 | 23.45 ± 0.34 | 22.95 ± 0.48 | 18.57 ± 1.38 |

| In fatty simulant | 95 | 5.82 ± 0.01 | 2.38 ± 0.26 | - |

| Tm (°C) | ||||

| Dry film | - | 148.35 ± 0.18 | 149.75 ± 0.36 | 148.07 ± 0.16 |

| In aqueous simulant | 10 | 147.50 ± 1.66 | 148.84 ± 0.47 | 149.14 ± 0.91 |

| In fatty simulant | 95 | 149.39 ± 0.63 | 149.75 ± 0.18 | 149.86 ± 0.54 |

| ΔHm (J g−1) | ||||

| Dry film | - | 31.33 ± 0.53 | 29.35 ± 0.62 | 30.44 ± 0.23 |

| In aqueous simulant | 10 | 32.45 ± 0.25 | 30.66 ± 0.63 | 29.71 ± 0.82 |

| In fatty simulant | 95 | 23.41 ± 0.04 | 27.03 ± 1.19 | 27.75 ± 2.51 |

| Xc (%) | ||||

| Dry film | - | 8.52 ± 0.33 | 6.89 ± 0.86 | 3.61 ± 0.44 |

| In aqueous simulant | 10 | 9.68 ± 0.09 | 8.72 ± 0.17 | 13.32 ± 0.67 |

| In fatty simulant | 95 | 18.92 ± 0.04 | 27.91 ± 1.05 | 33.15 ± 3.00 |

| Second Heating | ||||

| Ethanol in Simulant | P0 | P5 | P10 | |

| (% v/v) | ||||

| Tg (°C) | ||||

| Dry film | - | 57.53 ± 0.08 | 58.74 ± 0.15 | 57.96 ± 0.15 |

| In aqueous simulant | 10 | 58.33 ± 0.28 | 57.80 ± 0.01 | 58.39 ± 0.12 |

| In fatty simulant | 95 | 58.53 ± 0.018 | 58.57 ± 0.05 | 57.09 ± 0.22 |

| Tcc (°C) | ||||

| Dry film | - | 115.39 ± 0.04 | 122.62 ± 0.29 | 119.65 ± 0.02 |

| In aqueous simulant | 10 | 115.73 ± 0.11 | 125.97 ± 1.19 | 127.09 ± 0.64 |

| In fatty simulant | 95 | 115.60 ± 0.46 | 123.29 ± 0.40 | 126.71 ± 0.37 |

| ΔHcc (J g−1) | ||||

| Dry film | - | 18.36 ± 0.24 | 20.29 ± 0.04 | 25.05 ± 0.07 |

| In aqueous simulant | 10 | 23.49 ± 0.41 | 10.05 ± 1.84 | 7.95 ± 1.44 |

| In fatty simulant | 95 | 24.18 ± 0.48 | 17.52 ± 0.16 | 8.40 ± 0.13 |

| Tm (°C) | ||||

| Dry film | - | 147.24 ± 0.28 | 149.34 ± 0.28 | 148.15 ± 0.20 |

| In aqueous simulant | 10 | 147.15 ± 0.47 | 149.55 ± 0.27 | 150.02 ± 0.66 |

| In fatty simulant | 95 | 147.28 ± 0.25 | 149.09 ± 0.06 | 149.55 ± 0.25 |

| ΔHm (J g−1) | ||||

| Dry film | - | 25.97 ± 0.41 | 20.85 ± 0.13 | 26.27 ± 0.11 |

| In aqueous simulant | 10 | 28.17 ± 0.72 | 14.24 ± 2.45 | 11.64 ± 1.32 |

| In fatty simulant | 95 | 25.96 ± 0.14 | 18.93 ± 0.25 | 10.73 ± 0.23 |

| Xc (%) | ||||

| Dry film | - | 8.18 ± 0.18 | 0.64 ± 0.18 | 1.46 ± 0.05 |

| In aqueous simulant | 10 | 5.03 ± 1.22 | 4.74 ± 0.70 | 4.40 ± 0.14 |

| In fatty simulant | 95 | 1.92 ± 0.67 | 1.60 ± 0.46 | 2.79 ± 0.42 |

References

- Panwar, S.; Duggirala, K.S.; Yadav, P.; Debnath, N.; Yadav, A.K.; Kumar, A. Advanced diagnostic methods for identification of bacterial foodborne pathogens: Contemporary and upcoming challenges. Crit. Rev. Biotechnol. 2022, 2022, 1–19. [Google Scholar] [CrossRef]

- Kuswandi, B. Jumina Active and intelligent packaging, safety, and quality controls. In Fresh-Cut Fruits and Vegetables: Technologies and Mechanisms for Safety Control; Wasim Siddiqui, M., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 243–294. ISBN 9780128161845. [Google Scholar]

- Wyrwa, J.; Barska, A. Innovations in the food packaging market: Active packaging. Eur. Food Res. Technol. 2017, 243, 1681–1692. [Google Scholar] [CrossRef]

- Ataei, S.; Azari, P.; Hassan, A.; Pingguan-Murphy, B.; Yahya, R.; Muhamad, F. Essential Oils-Loaded Electrospun Biopolymers: A Future Perspective for Active Food Packaging. Adv. Polym. Technol. 2020, 2020, 9040535. [Google Scholar] [CrossRef]

- Ribeiro-Santos, R.; Andrade, M.; de Melo, N.R.; Sanches-Silva, A. Use of essential oils in active food packaging: Recent advances and future trends. Trends Food Sci. Technol. 2017, 61, 132–140. [Google Scholar] [CrossRef]

- Ugolini, L.; Pagnotta, E.; Matteo, R.; Malaguti, L.; Di Francesco, A.; Lazzeri, L. Brassica meal-derived allyl-isothiocyanate postharvest application: Influence on strawberry nutraceutical and biochemical parameters. J. Sci. Food Agric. 2019, 99, 4235–4241. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Zhang, X.; Zhang, G.-A.A.; Zeng, S.-Y.Y.; Lin, K.-C.C. Antifungal Vapour-phase Activity of a Combination of Allyl Isothiocyanate and Ethyl Isothiocyanate against Botrytis cinerea and Penicillium expansum Infection on Apples. J. Phytopathol. 2011, 159, 450–455. [Google Scholar] [CrossRef]

- Hussein, K.N.; Friedrich, L.; Kiskó, G.; Ayari, E.; Németh, C.; Dalmadi, I. Use of allyl-isothiocyanate and carvacrol to preserve fresh chicken meat during chilling storage. Czech J. Food Sci. 2019, 37, 417–424. [Google Scholar] [CrossRef] [Green Version]

- Chai, H.E.; Sheen, S. Effect of high pressure processing, allyl isothiocyanate, and acetic acid stresses on Salmonella survivals, storage, and appearance color in raw ground chicken meat. Food Control 2021, 123, 107784. [Google Scholar] [CrossRef]

- Otoni, C.G.; Espitia, P.J.P.; Avena-Bustillos, R.J.; McHugh, T.H. Trends in antimicrobial food packaging systems: Emitting sachets and absorbent pads. Food Res. Int. 2016, 83, 60–73. [Google Scholar] [CrossRef]

- Bahmid, N.A.; Pepping, L.; Dekker, M.; Fogliano, V.; Heising, J. Using particle size and fat content to control the release of Allyl isothiocyanate from ground mustard seeds for its application in antimicrobial packaging. Food Chem. 2020, 308, 125573. [Google Scholar] [CrossRef]

- Muñoz-Shugulí, C.; Patiño, C.; Cantero-López, P.; Lopez-Polo, J. Encapsulation of plant extract compounds using cyclodextrin inclusion complexes, liposomes, electrospinning and their combinations for food purposes. Trends Food Sci. Technol. 2021, 108, 177–186. [Google Scholar] [CrossRef]

- Szente, L.; Fenyvesi, É. Cyclodextrin-Enabled Polymer Composites for Packaging. Molecules 2018, 23, 1556. [Google Scholar] [CrossRef] [Green Version]

- Patiño Vidal, C.; López de Dicastillo, C.; Rodríguez-Mercado, F.; Guarda, A.; Galotto, M.J.; Muñoz-Shugulí, C. Electrospinning and cyclodextrin inclusion complexes: An emerging technological combination for developing novel active food packaging materials. Crit. Rev. Food Sci. Nutr. 2021, 62, 5495–5510. [Google Scholar] [CrossRef]

- Muñoz-Shugulí, C.; Rodríguez-Mercado, F.; Mascayano, C.; Herrera, A.; Bruna, J.E.; Guarda, A.; Galotto, M.J. Development of Inclusion Complexes with Relative Humidity Responsive Capacity as Novel Antifungal Agents for Active Food Packaging. Front. Nutr. 2022, 8, 1091. [Google Scholar] [CrossRef] [PubMed]

- Moustafa, H.; Youssef, A.M.; Darwish, N.A.; Abou-Kandil, A.I. Eco-friendly polymer composites for green packaging: Future vision and challenges. Compos. Part B Eng. 2019, 172, 16–25. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Rojas, A.; Velásquez, E.; Patiño, C.; Guarda, A.; Galotto, M.J.; López de Dicastillo, C. Active PLA Packaging Films: Effect of Processing and the Addition of Natural Antimicrobials and Antioxidants on Physical Properties, Release Kinetics, and Compostability. Antioxidants 2021, 10, 1976. [Google Scholar] [CrossRef]

- Kara, H.H.; Xiao, F.; Sarker, M.; Jin, T.Z.; Sousa, A.M.M.; Liu, C.K.; Tomasula, P.M.; Liu, L. Antibacterial poly(lactic acid) (PLA) films grafted with electrospun PLA/allyl isothiocyanate fibers for food packaging. J. Appl. Polym. Sci. 2016, 133, 42475. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, C.; Narsimhan, G.; Jin, Z. Preparation and Characterization of Ternary Antimicrobial Films of β-Cyclodextrin/Allyl Isothiocyanate/Polylactic Acid for the Enhancement of Long-Term Controlled Release. Materials 2017, 10, 1210. [Google Scholar] [CrossRef] [Green Version]

- Sonchaeng, U.; Auras, R.; Selke, S.; Rubino, M.; Lim, L.T. In-situ changes of thermo-mechanical properties of poly(lactic acid) film immersed in alcohol solutions. Polym. Test. 2020, 82, 106320. [Google Scholar] [CrossRef]

- Vogler, E.A. Structure and reactivity of water at biomaterial surfaces. Adv. Colloid Interface Sci. 1998, 74, 69–117. [Google Scholar] [CrossRef] [PubMed]

- Karbowiak, T.; Debeaufort, F.; Voilley, A. Importance of Surface Tension Characterization for Food, Pharmaceutical and Packaging Products: A Review. Crit. Rev. Food Sci. Nutr. 2007, 46, 391–407. [Google Scholar] [CrossRef]

- Gutierrez-Villarreal, M.H.; Rodríguez-Gonzalez, F.J.; Perera-Mercado, Y. Estimation of Surface Free Energy of Poly(lactic acid) during UV-Grafting with N-Vinylpyrrolidone. Macromol. Symp. 2017, 374, 1600130. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. Effect of starch type on the physico-chemical properties of edible films. Int. J. Biol. Macromol. 2017, 98, 348–356. [Google Scholar] [CrossRef]

- Hajji, S.; Kchaou, H.; Bkhairia, I.; Ben Slama-Ben Salem, R.; Boufi, S.; Debeaufort, F.; Nasri, M. Conception of active food packaging films based on crab chitosan and gelatin enriched with crustacean protein hydrolysates with improved functional and biological properties. Food Hydrocoll. 2021, 116, 106639. [Google Scholar] [CrossRef]

- Kurek, M.; Guinault, A.; Voilley, A.; Galić, K.; Debeaufort, F. Effect of relative humidity on carvacrol release and permeation properties of chitosan based films and coatings. Food Chem. 2014, 144, 9–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, Y.; Lee, T.R. Contact angle and wetting properties. Springer Ser. Surf. Sci. 2013, 51, 3–34. [Google Scholar] [CrossRef]

- Yousefzade, O.; Jeddi, J.; Vazirinasab, E.; Garmabi, H. Poly(lactic acid) phase transitions in the presence of nano calcium carbonate: Opposing effect of nanofiller on static and dynamic measurements. J. Thermoplast. Compos. Mater. 2018, 32, 312–327. [Google Scholar] [CrossRef]

- Orue, A.; Jauregi, A.; Peña-Rodriguez, C.; Labidi, J.; Eceiza, A.; Arbelaiz, A. The effect of surface modifications on sisal fiber properties and sisal/poly (lactic acid) interface adhesion. Compos. Part B Eng. 2015, 73, 132–138. [Google Scholar] [CrossRef]

- Kchaou, H.; Jridi, M.; Benbettaieb, N.; Debeaufort, F.; Nasri, M. Bioactive films based on cuttlefish (Sepia officinalis) skin gelatin incorporated with cuttlefish protein hydrolysates: Physicochemical characterization and antioxidant properties. Food Packag. Shelf Life 2020, 24, 100477. [Google Scholar] [CrossRef]

- Snowdon, M.R.; Mohanty, A.K.; Misra, M. Miscibility and Performance Evaluation of Biocomposites Made from Polypropylene/Poly(lactic acid)/Poly(hydroxybutyrate-cohydroxyvalerate) with a Sustainable Biocarbon Filler. ACS Omega 2017, 2, 6446–6454. [Google Scholar] [CrossRef] [PubMed]

- Ščetar, M.; Kurek, M.; Režek Jambrak, A.; Debeaufort, F.; Galić, K. Influence of high power ultrasound on physical–chemical properties of polypropylene films aimed for food packaging: Barrier and contact angle features. Polym. Int. 2017, 66, 1572–1578. [Google Scholar] [CrossRef]

- Xu, D.; Auras, R.A.; Sonchaeng, U.; Rubino, M.; Lim, L.-T. The effect of alcoholic solutions on the thermomechanical properties of immersed poly(lactic acid) films. J. Appl. Polym. Sci. 2022, 140, e53489. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Kim, K.H.; Park, J.W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Iñiguez-Franco, F.; Auras, R.; Burgess, G.; Holmes, D.; Fang, X.; Rubino, M.; Soto-Valdez, H. Concurrent solvent induced crystallization and hydrolytic degradation of PLA by water-ethanol solutions. Polymer 2016, 99, 315–323. [Google Scholar] [CrossRef] [Green Version]

- Dias, M.V.; Sousa, M.M.; Lara, B.R.B.; de Azevedo, V.M.; de Fátima Ferreira Soares, N.; Borges, S.V.; Queiroz, F. Thermal and morphological properties and kinetics of diffusion of antimicrobial films on food and a simulant. Food Packag. Shelf Life 2018, 16, 15–22. [Google Scholar] [CrossRef]

- Ramos, M.; Fortunati, E.; Beltrán, A.; Peltzer, M.; Cristofaro, F.; Visai, L.; Valente, A.J.M.; Jiménez, A.; María Kenny, J.; Carmen Garrigós, M. Controlled Release, Disintegration, Antioxidant, and Antimicrobial Properties of Poly (Lactic Acid)/Thymol/Nanoclay Composites. Polymers 2020, 12, 1878. [Google Scholar] [CrossRef]

- Iglesias-Montes, M.L.; Soccio, M.; Luzi, F.; Puglia, D.; Gazzano, M.; Lotti, N.; Manfredi, L.B.; Cyras, V.P. Evaluation of the Factors Affecting the Disintegration under a Composting Process of Poly(lactic acid)/Poly(3-hydroxybutyrate) (PLA/PHB) Blends. Polymers 2021, 13, 3171. [Google Scholar] [CrossRef]

- Otero-Pazos, P.; Rodriguez-Bernaldo De Quiros, A.; Sendón, R.; Benito-Peña, E.; González-Vallejo, V.; Moreno-Bondi, M.C.; Angulo, I.; Paseiro-Losada, P. Active food packaging based on molecularly imprinted polymers: Study of the release kinetics of ferulic acid. J. Agric. Food Chem. 2014, 62, 11215–11221. [Google Scholar] [CrossRef]

- Chen, J.; Li, Y.; Shi, W.; Zheng, H.; Wang, L.; Li, L.; Zhou, X. Release of Cinnamaldehyde and Thymol from PLA/Tilapia Fish Gelatin-Sodium Alginate Bilayer Films to Liquid and Solid Food Simulants, and Japanese Sea Bass: A Comparative Study. Molecules 2021, 26, 7140. [Google Scholar] [CrossRef]

- Tawakkal, I.S.M.A.; Cran, M.J.; Bigger, S.W. Release of thymol from poly(lactic acid)-based antimicrobial films containing kenaf fibres as natural filler. LWT-Food Sci. Technol. 2016, 66, 629–637. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Liu, Y.; Liu, Z.; Fan, L.; Dong, T.; Jin, Y.; Saldaña, M.D.A.; Sun, W. Sustained-release antibacterial pads based on nonwovens polyethylene terephthalate modified by β-cyclodextrin embedded with cinnamaldehyde for cold fresh pork preservation. Food Packag. Shelf Life 2020, 26, 100554. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Zisman, W.A. Relation of the Equilibrium Contact Angle to Liquid and Solid Constitution. Adv. Chem. 1964, 43, 1–51. [Google Scholar] [CrossRef]

- Xu, R.; Xie, J.; Lei, C. Influence of melt-draw ratio on the crystalline behaviour of a polylactic acid cast film with a chi structure. RSC Adv. 2017, 7, 39914–39921. [Google Scholar] [CrossRef] [Green Version]

- European-Commission. Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food. Off. J. Eur. Union 2011, 12, 1–89. [Google Scholar]

- Benbettaïeb, N.; Mahfoudh, R.; Moundanga, S.; Brachais, C.H.; Chambin, O.; Debeaufort, F. Modeling of the release kinetics of phenolic acids embedded in gelatin/chitosan bioactive-packaging films: Influence of both water activity and viscosity of the food simulant on the film structure and antioxidant activity. Int. J. Biol. Macromol. 2020, 160, 780–794. [Google Scholar] [CrossRef] [PubMed]

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Clarendon Press: Oxford, UK, 1975; ISBN 0198534116. [Google Scholar]

- Benbettaieb, N.; Nyagaya, J.; Seuvre, A.M.; Debeaufort, F. Antioxidant Activity and Release Kinetics of Caffeic and p-Coumaric Acids from Hydrocolloid-Based Active Films for Healthy Packaged Food. J. Agric. Food Chem. 2018, 66, 6906–6916. [Google Scholar] [CrossRef]

- Diversified Enterprises Surface Tension Components and Molecular Weight of Selected Liquids. Available online: http://www.accudynetest.com/surface_tension_table.html (accessed on 7 July 2022).

| Material | θw (°) | θEG (°) | θDM (°) | θG (°) |

|---|---|---|---|---|

| P0 | 74.5 ± 1.4 a | 51.7 ± 2.0 b | 44.8 ± 0.4 a | 68.5 ± 3.9 a |

| P5 | 70.0 ± 1.3 b | 53.9 ± 0.6 a,b | 40.4 ± 1.7 b | 63.9 ± 2.0 a |

| P10 | 69.9 ± 0.8 b | 55.5 ± 0.9 a | 37.7 ± 1.7 c | 66.3 ± 1.6 a |

| Ethanol in Simulant | P5 | P10 | |

|---|---|---|---|

| (% v/v) | |||

| Thickness (µm) | 83.6 ± 5.7 | 96.6 ± 5.6 | |

| D (m² s−1) × 1012 | |||

| In aqueous simulant | 10 | 4.6 ± 1.0 b,B | 14.4 ± 0.2 a,A |

| In fatty simulant | 95 | 8.1 ± 1.4 a,B | 11.6 ± 0.1 a,A |

| Kp | |||

| In aqueous simulant | 10 | 140.2 ± 4.9 a,A | 33.5 ± 1.1 a,B |

| In fatty simulant | 95 | 16.48 ± 1.7 b,B | 27.7 ± 2.4 b,A |

| Released AITC (%) | |||

| In aqueous simulant | 10 | 27.6 ± 1.5 b,B | 57.4 ± 1.7 b,A |

| In fatty simulant | 95 | 74.1 ± 5.0 a,A | 65.7 ± 1.0 a,B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muñoz-Shugulí, C.; Rodríguez-Mercado, F.; Benbettaieb, N.; Guarda, A.; Galotto, M.J.; Debeaufort, F. Development and Evaluation of the Properties of Active Films for High-Fat Fruit and Vegetable Packaging. Molecules 2023, 28, 3045. https://doi.org/10.3390/molecules28073045

Muñoz-Shugulí C, Rodríguez-Mercado F, Benbettaieb N, Guarda A, Galotto MJ, Debeaufort F. Development and Evaluation of the Properties of Active Films for High-Fat Fruit and Vegetable Packaging. Molecules. 2023; 28(7):3045. https://doi.org/10.3390/molecules28073045

Chicago/Turabian StyleMuñoz-Shugulí, Cristina, Francisco Rodríguez-Mercado, Nasreddine Benbettaieb, Abel Guarda, María José Galotto, and Frederic Debeaufort. 2023. "Development and Evaluation of the Properties of Active Films for High-Fat Fruit and Vegetable Packaging" Molecules 28, no. 7: 3045. https://doi.org/10.3390/molecules28073045