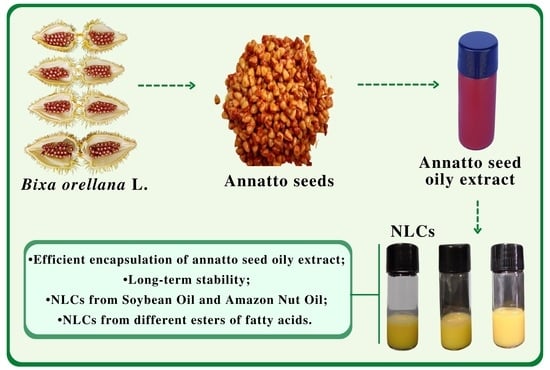

Green Extraction of Annatto Seed Oily Extract and Its Use as a Pharmaceutical Material for the Production of Lipid Nanoparticles

Abstract

:1. Introduction

2. Results

2.1. Characterization of Annatto Seed Oily Extract (ASE)

2.1.1. Fatty Acid Composition of the Vegetable Oils

2.1.2. Fourier Transform Infrared Spectroscopy Analysis

2.2. Physical Characterization and Evaluation of the Stability of NLCs from Annatto Seed Oily Extract

2.3. Physical Properties and Evaluation of the Stability of Nanoemulsions (Nn) Based on Myristic Acid Esters (Co-Lipids)

2.4. UV-VIS Characterization of Annatto Nn and NLC Formulations

3. Materials and Methods

3.1. Materials

3.2. Production of Annatto Seed Oily Extract (ASE)

3.3. Synthesis of Methyl, Ethyl, Isopropyl, and Butyl Esters from Myristic Acid Catalyzed by Oxone Salt

3.4. Fourier Transform Infrared Spectroscopy Analysis

3.5. Preparation of Nanostructured Lipid Carriers (NLC) from Annatto Seed Oily Extract

3.6. Preparation of Nanoemulsions with Myristic Acid Esters (Co-Lipids)

3.7. NLC and Nn Characterization

3.7.1. Physical and Visual Evaluations

3.7.2. Particle Size Distribution

3.7.3. Zeta Potential

3.8. UV-VIS Characterization of Annamato Seed Oil Formulations

3.9. Statistical Procedures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Rodrigues, L.; Alcázar Alay, S.C.; Petenate, A.; Meireles, M.A. Bixin Extraction from Defatted Annatto Seeds. Comptes Rendus Chim. 2014, 17, 268–283. [Google Scholar] [CrossRef]

- Teixeira da Silva, J.A.; Zeng, S.; Godoy-Hernández, G.; Rivera-Madrid, R.; Dobránszki, J. Bixa orellana L. (Achiote) Tissue Culture: A Review. In Vitro Cell.Dev.Biol.-Plant 2019, 55, 231–241. [Google Scholar] [CrossRef]

- Vilar, D.; Vilar, M.; Moura, T.F.A.L.; Raffin, F.; Oliveira, M.; Franco, C.; Athayde-Filho, P.; Diniz, M.; Barbosa Filho, J. Traditional Uses, Chemical Constituents, and Biological Activities of Bixa orellana L.: A Review. Sci. World J. 2014, 2014, 857292. [Google Scholar] [CrossRef]

- Chisté, R.C.; Mercadante, A.Z.; Gomes, A.; Fernandes, E.; da Costa Lima, J.L.F.; Bragagnolo, N. In Vitro Scavenging Capacity of Annatto Seed Extracts against Reactive Oxygen and Nitrogen Species. Food Chem. 2011, 127, 419–426. [Google Scholar] [CrossRef]

- Mohd Mutalip, S.S.; Rajikin, M.H.; Ab Rahim, S.; Mohamed Noor Khan, N. Annatto (Bixa orellana) δ-TCT Supplementation Protection against Embryonic Malformations through Alterations in PI3K/Akt-Cyclin D1 Pathway. Biomolecules 2019, 9, E19. [Google Scholar] [CrossRef]

- Stringheta, P.; Silva, P.; Costa, A. Annatto/Urucum-Bixa Orellana. In Exotic Fruits; Rodrigues, S., Silva, E.D.O., Brito, E.S.D., Eds.; Academic Press Inc.: Cambridge, MA, USA, 2018; pp. 23–30. ISBN 978-0-12-803138-4. [Google Scholar]

- Cardarelli, C.; Benassi, M.; Mercadante, A. Characterization of Different Annatto Extracts Based on Antioxidant and Color Properties. LWT-Food Sci. Technol. 2008, 41, 1689–1693. [Google Scholar] [CrossRef]

- Taham, T.; Cabral, F.; Barrozo, M. Extraction of Bixin from Annatto Seeds Using Combined Technologies. J. Supercrit. Fluids 2015, 100, 175–183. [Google Scholar] [CrossRef]

- Rao, M.; Manjunath, K.; Bhagawati, S.; Boreddy Shivanandappa, T. Bixin Loaded Solid Lipid Nanoparticles for Enhanced Hepatoprotection-Preparation, Characterisation and in Vivo Evaluation. Int. J. Pharm. 2014, 473, 485–492. [Google Scholar] [CrossRef]

- Ferreira, L.; Pereira, R.; Carvalho, F.; Santos, A.; Ribeiro-Costa, R.; Junior, J. Green Extraction by Ultrasound, Microencapsulation by Spray Drying and Antioxidant Activity of the Tucuma Coproduct (Astrocaryum vulgare Mart.) Almonds. Biomolecules 2021, 11, 545. [Google Scholar] [CrossRef]

- Momchev, P.; Ciganović, P.; Jug, M.; Marguí, E.; Jablan, J.; Zovko Končić, M. Comparison of Maceration and Ultrasonication for Green Extraction of Phenolic Acids from Echinacea purpurea Aerial Parts. Molecules 2020, 25, 5142. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Cravotto, G. Green Extraction of Natural Products: Concept and Principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef]

- Chemat, F.; Abert Vian, M.; Ravi, H.K.; Khadhraoui, B.; Hilali, S.; Perino, S.; Tixier, A.-S.F. Review of Alternative Solvents for Green Extraction of Food and Natural Products: Panorama, Principles, Applications and Prospects. Molecules 2019, 24, 3007. [Google Scholar] [CrossRef]

- Istrati, D.; Lacatusu, I.; Bordei, N.; Badea, G.; Oprea, O.; Stefan, L.M.; Stan, R.; Badea, N.; Meghea, A. Phyto-Mediated Nanostructured Carriers Based on Dual Vegetable Actives Involved in the Prevention of Cellular Damage. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 64, 249–259. [Google Scholar] [CrossRef]

- Singh, Y.; Meher, J.; Raval, K.; Khan, F.; Chaurasia, M.; Jain, N.; Chourasia, M. Nanoemulsion: Concepts, Development and Applications in Drug Delivery. J. Control. Release 2017, 252, 28–49. [Google Scholar] [CrossRef]

- Subramaniam, B.; Siddik, Z.; Nagoor, N. Optimization of Nanostructured Lipid Carriers: Understanding the Types, Designs, and Parameters in the Process of Formulations. J. Nanopart. Res. 2020, 252, 28–49. [Google Scholar] [CrossRef]

- Rocha-filho, P.; Ferrari, M.; Maruno, M.; Souza, O.; Gumiero, V. In Vitro and In Vivo Evaluation of Nanoemulsion Containing Vegetable Extracts. Cosmetics 2017, 4, 32. [Google Scholar] [CrossRef]

- Pereira, R.; Gomes, A.T.; Testi, M.; Bianchera, A.; Ribeiro-Costa, R.; Padula, C.; Júnior, J.; Sonvico, F. Ucuúba Fat Characterization and Use to Obtain Lipid Nanoparticles by HPH Using Full Factorial Design. Chem. Eng. Technol. 2021, 44, 1009–1016. [Google Scholar] [CrossRef]

- Contente, D.; Pereira, R.; Rodrigues, A.; Silva, E.; Ribeiro-Costa, R.; Silva-Júnior, J. Nanoemulsions of Açai Oil: Physicochemical Characterization for Topical Delivery Antifungal Drug. Chem. Eng. Technol. 2020, 43, 1424–1432. [Google Scholar] [CrossRef]

- Gomes, A.T.; Pereira, R.; Junior, A.; Rodrigues, A.; Remédios, C.; Brasil, D.; Morais, L.; Silva-Júnior, J.; Ribeiro-Costa, R. Tucumã (Astrocaryum vulgare) Fat: An Amazonian Material as a Pharmaceutical Input for Lipid Nanoparticle Production. J. Therm. Anal. Calorim. 2020, 147, 1–11. [Google Scholar] [CrossRef]

- Quitian-Useche, Y.F.; Sánchez-Ortiz, B.L.; Borges, S.F.; Ramos, B.; de Souza, G.C.; Batista, M.A.; da Silva Hage Melim, L.I.; Ferreira, I.M.; Carvalho, J.C.T.; Borges, R.S. Fatty Ethanolamide of Bertholletia excelsa Triglycerides (Brazil Nuts): Anti-Inflammatory Action and Acute Toxicity Evaluation in Zebrafish (Danio rerio). Inflammopharmacology 2021, 29, 1519–1537. [Google Scholar] [CrossRef]

- Vasquez-Rojas, W.V.; Martín, D.; Miralles, B.; Recio, I.; Fornari, T.; Cano, M.P. Composition of Brazil Nut (Bertholletia excelsa HBK), Its Beverage and By-Products: A Healthy Food and Potential Source of Ingredients. Foods 2021, 10, 3007. [Google Scholar] [CrossRef]

- Barata, P.H.S.; Sarquis, Í.R.; Carvalho, H.O.; Barros, A.S.; Rodrigues, A.B.; Galue-Parra, A.J.; Silva, E.O.; Carvalho, J.C.T.; Ferreira, I.M. Chemoenzymatic Synthesis and Anti-Inflammatory Activity of Fatty Acid Amides Prepared from Bertholletia Excelsa (Brazil Nut) Triglycerides. J. Braz. Chem. Soc. 2020, 31, 1557–1565. [Google Scholar] [CrossRef]

- Kharat, M.; McClements, D.J. Fabrication and Characterization of Nanostructured Lipid Carriers (NLC) Using a Plant-Based Emulsifier: Quillaja Saponin. Food Res. Int. 2019, 126, 108601. [Google Scholar] [CrossRef]

- Hunter, J.E.; Zhang, J.; Kris-Etherton, P.M. Cardiovascular Disease Risk of Dietary Stearic Acid Compared with Trans, Other Saturated, and Unsaturated Fatty Acids: A Systematic Review. Am. J. Clin. Nutr. 2010, 91, 46–63. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, A.; Sena, I.; Magalhaes, K.; Oliveira, S.; Ferreira, I.; Porto, A. Amazon Oils from Andiroba (Carapa sp.) and Babassu (Orbignya sp.) for Preparation Biodiesel by Enzymatic Catalysis. Curr. Biotechnol. 2019, 7, 428–437. [Google Scholar] [CrossRef]

- Lima, R.; da Luz, P.; Braga, M.; Batista, P.; Costa, C.; Zamian, J.; Nascimento, L.; Da Rocha Filho, G. Murumuru (Astrocaryum murumuru Mart.) Butter and Oils of Buriti (Mauritia flexuosa Mart.) and Pracaxi (Pentaclethra macroloba (Willd.) Kuntze) Can Be Used for Biodiesel Production: Physico-Chemical Properties and Thermal and Kinetic Studies. Ind. Crop. Prod. 2017, 97, 536–544. [Google Scholar] [CrossRef]

- Lobato, K.; Paese, K.; Forgearini, J.; Guterres, S.; Jablonski, A.; Rios, A. Evaluation of Stability of Bixin in Nanocapsules in Model Systems of Photosensitization and Heating. LWT-Food Sci. Technol. 2015, 60, 8–14. [Google Scholar] [CrossRef]

- Pereira, R.; Testi, M.; Rossi, F.; Junior, J.; Ribeiro-Costa, R.; Bettini, R.; Santi, P.; Padula, C.; Sonvico, F. Ucuùba (Virola surinamensis) Fat-Based Nanostructured Lipid Carriers for Nail Drug Delivery of Ketoconazole: Development and Optimization Using Box-Behnken Design. Pharmaceutics 2019, 11, 284. [Google Scholar] [CrossRef]

- AlZahabi, S.; Sakr, O.; Ramadan, A. Nanostructured Lipid Carriers Incorporating Prickly Pear Seed Oil for the Encapsulation of Vitamin A. J. Cosmet. Dermatol. 2019, 18, 1875–1884. [Google Scholar] [CrossRef] [PubMed]

- Krasodomska, O.; Paolicelli, P.; Cesa, S.; Casadei, M.; Jungnickel, C. Protection and Viability of Fruit Seeds Oils by Nanostructured Lipid Carrier (NLC) Nanosuspensions. J. Colloid Interface Sci. 2016, 479, 25–33. [Google Scholar] [CrossRef]

- Pinto, F.; Barros, D.; Reis, C.; Fonseca, L. Optimization of Nanostructured Lipid Carriers Loaded with Retinoids by Central Composite Design. J. Mol. Liq. 2019, 293, 111468. [Google Scholar] [CrossRef]

- Lin, Y.; Yin, W.; Li, Y.; Liu, G. Influence of Different Solid Lipids on the Properties of a Novel Nanostructured Lipid Carrier Containing Antarctic Krill Oil. Int. J. Food Sci. Technol. 2022, 57, 2886–2895. [Google Scholar] [CrossRef]

- Aryani, N.L.D.; Soeratri, W.; Putri, D.Y.; Puspitasarini, P.D. Development, Characterization in vitro and in Silico of Coenzyme Q10 Loaded Myristic Acid with Different Liquid Lipids Nanostructured Lipid Carriers. J. Pharm. Pharmacol. 2021, 9, 573–583. [Google Scholar]

- Clayton, K.; Salameh, J.; Wereley, S.; Kinzer-Ursem, T. Physical Characterization of Nanoparticle Size and Surface Modification Using Particle Scattering Diffusometry. Biomicrofluidics 2016, 10, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Cheong, A.M.; Tan, C.; Nyam, K. Physicochemical, Oxidative and Anti-Oxidant Stabilities of Kenaf Seed Oil-in-Water Nanoemulsions under Different Storage Temperatures. Ind. Crop. Prod. 2016, 95, 374–382. [Google Scholar] [CrossRef]

- Bhattacharjee, S. DLS and Zeta Potential-What They Are and What They Are Not? J. Control. Release 2016, 235, 337–351. [Google Scholar] [CrossRef]

- Makoni, P.; Wa Kasongo, K.; Walker, R. Short Term Stability Testing of Efavirenz-Loaded Solid Lipid Nanoparticle (SLN) and Nanostructured Lipid Carrier (NLC) Dispersions. Pharmaceutics 2019, 11, 397. [Google Scholar] [CrossRef]

- Witayaudom, P.; Klinkesorn, U. Effect of Surfactant Concentration and Solidification Temperature on the Characteristics and Stability of Nanostructured Lipid Carrier (NLC) Prepared from Rambutan (Nephelium lappaceum L.) Kernel Fat. J. Colloid Interface Sci. 2017, 505, 1082–1092. [Google Scholar] [CrossRef]

- Zhang, X.; Gan, Y.; Li, G.P.; Nie, S.; Pan, W. PEGylated Nanostructured Lipid Carriers Loaded with 10-Hydroxycamptothecin: An Efficient Carrier with Enhanced Anti-Tumour Effects against Lung Cancer. J. Pharm. Pharmacol. 2008, 60, 1077–1087. [Google Scholar] [CrossRef]

- Badawi, N.; Teaima, M.; El-Say, K.; Attia, D.; El-Nabarawi, M.; Elmazar, M. Pomegranate Extract-Loaded Solid Lipid Nanoparticles: Design, Optimization, and in Vitro Cytotoxicity Study. Int. J. Nanomed. 2018, 13, 1313–1326. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, A.C.; Yañez, O.; Salas-Huenuleo, E.; Morales, J.O. Development of a Nanostructured Lipid Carrier (NLC) by a Low-Energy Method, Comparison of Release Kinetics and Molecular Dynamics Simulation. Pharmaceutics 2021, 13, 531. [Google Scholar] [CrossRef]

- Souto, E.B.; Baldim, I.; Oliveira, W.P.; Rao, R.; Yadav, N.; Gama, F.M.; Mahant, S. SLN and NLC for Topical, Dermal, and Transdermal Drug Delivery. Expert Opin. Drug Deliv. 2020, 17, 357–377. [Google Scholar] [CrossRef]

- Karimi, N.; Ghanbarzadeh, B.; Hamishehkar, H.; Mehramuz, B.; Kafil, H. Antioxidant, Antimicrobial and Physicochemical Properties of Turmeric Extract-Loaded Nanostructured Lipid Carrier (NLC). J. Colloid Interface Sci. 2018, 22, 18–24. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, J.; Watanabe, W. Physical and Chemical Stability of Drug Nanoparticles. Adv. Drug Deliv. Rev. 2011, 63, 456–469. [Google Scholar] [CrossRef] [PubMed]

- Rahmalia, W.; Fabre, J.-F.; Usman, T.; Mouloungui, Z. Bixin adsorption characteristic on TIO2. WINDA RAHMALIA. In Proceedings of the IRES 28th International Conference, Jakarta, Indonesia, 6 February 2016. [Google Scholar]

- Rios, A.; Mercadante, A. Otimização Das Condições Para Obtenção de Padrão de Bixin e Das Etapas de Extração e Saponificação Para Quantificação de Bixina Em “Snakcs” Extrusados Por HPLC. Aliment. E Nutr. 2008, 15, 1–9. [Google Scholar]

- Lopes, S.; Holanda, F.; Jimenez, E.; Nascimento, L.; Oliveira, A.; Ferreira, I. Use of Oxone® as a Potential Catalyst in Biodiesel Production from Palm Fatty Acid Distillate (PFAD). Catal. Lett. 2022, 152, 1009–1019. [Google Scholar] [CrossRef]

- Penido, C.; Pacheco, M.; Novotny, E.; Lednev, I.; Silveira, L. Quantification of Cocaine in Ternary Mixtures Using Partial Least Squares Regression Applied to Raman and Fourier Transform Infrared Spectroscopy. J. Raman Spectrosc. 2017, 48, 1732–1743. [Google Scholar] [CrossRef]

- Pinto, F.; Barros, D.; Fonseca, L. Design of Multifunctional Nanostructured Lipid Carriers Enriched with α-Tocopherol Using Vegetable Oils. Ind. Crop. Prod. 2018, 118, 149–159. [Google Scholar] [CrossRef]

| Oil | Fatty Acid (%) | Density (g/mL) * | |||||

|---|---|---|---|---|---|---|---|

| Palmitic (C16:0) | Linoleic (C 18:2 ω-6) | Oleic (C 18:1 ω-9) | Linolenic (C 18:1 ω-7) | Stearic (C 18:0) | Unidentified | ||

| Brazil nut | 19 | 29 | 32 | 2 | 16 | 2 | 0.89456 (±0.008) |

| Soybean | 11 | 54 | 22 | 1.2 | 4.55 | 7.25 | 0.87850 (±0.048) |

| Sample | Total Lipids, wt% | Tween 80, wt% | Water, wt% |

|---|---|---|---|

| ASE + BNO | 4.0 | 2.5 | 93.5 |

| ASE + SO | 4.0 | 2.5 | 93.5 |

| BNONLC | 4.0 | 2.5 | 93.5 |

| SONLC | 4.0 | 2.5 | 93.5 |

| Sample | Lipid, wt% | Ester, wt% | Tween 80, wt% | Water, wt% |

|---|---|---|---|---|

| (ASE + BNO)Nn-MM | 2.4 | 1.6 | 2.5 | 93.5 |

| (ASE + BNO)Nn-EM | 2.4 | 1.6 | 2.5 | 93.5 |

| (ASE + BNO)Nn-PM | 2.4 | 1.6 | 2.5 | 93.5 |

| (ASE + BNO)Nn-BM | 2.4 | 1.6 | 2.5 | 93.5 |

| (BNO)Nn-MM | 2.4 | 1.6 | 2.5 | 93.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, S.d.S.d.C.; Sarmento, E.d.S.; Marinho, V.H.; Pereira, R.R.; Fonseca, L.P.; Ferreira, I.M. Green Extraction of Annatto Seed Oily Extract and Its Use as a Pharmaceutical Material for the Production of Lipid Nanoparticles. Molecules 2022, 27, 5187. https://doi.org/10.3390/molecules27165187

Oliveira SdSdC, Sarmento EdS, Marinho VH, Pereira RR, Fonseca LP, Ferreira IM. Green Extraction of Annatto Seed Oily Extract and Its Use as a Pharmaceutical Material for the Production of Lipid Nanoparticles. Molecules. 2022; 27(16):5187. https://doi.org/10.3390/molecules27165187

Chicago/Turabian StyleOliveira, Sônia do Socorro do C., Edmilson dos S. Sarmento, Victor H. Marinho, Rayanne R. Pereira, Luis P. Fonseca, and Irlon M. Ferreira. 2022. "Green Extraction of Annatto Seed Oily Extract and Its Use as a Pharmaceutical Material for the Production of Lipid Nanoparticles" Molecules 27, no. 16: 5187. https://doi.org/10.3390/molecules27165187