Effects of Biostimulants on the Chemical Composition of Essential Oil and Hydrosol of Lavandin (Lavandula x intermedia Emeric ex Loisel.) Cultivated in Tuscan-Emilian Apennines

Abstract

:1. Introduction

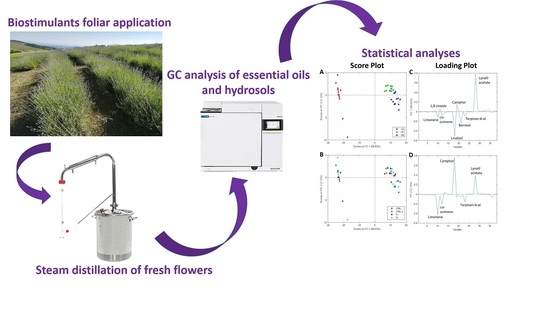

2. Results and Discussion

2.1. EO Content in Fresh Lavandin Flowers

2.2. Chemical Composition of the EOs

2.3. Hydrosol Characterization

3. Materials and Methods

3.1. Materials

3.2. Growing Conditions and Experimental Design

3.3. Steam Distillation

3.4. Hydrosol Extraction

3.5. Analysis

3.5.1. GC-MS Analysis

3.5.2. GC-FID Analysis

3.6. Statistical Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, L.; Yao, L. Antiviral Effects of Plant-Derived Essential Oils and Their Components: An Updated Review. Molecules 2020, 25, 2627. [Google Scholar] [CrossRef]

- Amorati, R.; Foti, M.C.; Valgimigli, L. Antioxidant activity of essential oils. J. Agric. Food Chem. 2013, 61, 10835–10847. [Google Scholar] [CrossRef] [PubMed]

- de Lavor, É.M.; Fernandes, A.W.C.; de Andrade Teles, R.B.; Leal, A.E.B.P.; de Oliveira, R.G., Jr.; Silva, M.G.; de Oliveira, A.P.; Silva, J.C.; de Moura Fontes Araújo, M.T.; Coutinho, H.D.M.; et al. Essential Oils and Their Major Compounds in the Treatment of Chronic Inflammation: A Review of Antioxidant Potential in Preclinical Studies and Molecular Mechanisms. Oxidative Med. Cell. Longev. 2018, 2018, 1–23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mongiano, G.; Zampieri, E.; Morcia, C.; Titone, P.; Volante, A.; Terzi, V.; Tamborini, L.; Valé, G.; Monaco, S. Application of plant-derived bioactive compounds as seed treatments to manage the rice pathogen Fusarium fujikuroi. Crop. Prot. 2021, 148, 105739. [Google Scholar] [CrossRef]

- Chivandi, E.; Dangarembizi, R.; Nyakudya, T.T.; Erlwanger, K.H. Use of Essential Oils as a Preservative of Meat. In Essential Oils in Food Preservation, Flavor and Safety; Elsevier: Amsterdam, The Netherlands, 2016; pp. 85–91. ISBN 9780124166448. [Google Scholar]

- Karam, L.; Chehab, R.; Osaili, T.M.; Savvaidis, I.N. Antimicrobial effect of thymol and carvacrol added to a vinegar-based marinade for controlling spoilage of marinated beef (Shawarma) stored in air or vacuum packaging. Int. J. Food Microbiol. 2020, 332, 108769. [Google Scholar] [CrossRef] [PubMed]

- Pavela, R.; Benelli, G. Essential Oils as Ecofriendly Biopesticides? Challenges and Constraints. Trends Plant Sci. 2016, 21, 1000–1007. [Google Scholar] [CrossRef]

- Essential Oils Market Outlook Report 2026 | Growth Statistics. Available online: https://www.gminsights.com/industry-analysis/essential-oil-market (accessed on 20 April 2021).

- Verrillo, M.; Cozzolino, V.; Spaccini, R.; Piccolo, A. Humic substances from green compost increase bioactivity and antibacterial properties of essential oils in Basil leaves. Chem. Biol. Technol. Agric. 2021, 8, 1–14. [Google Scholar] [CrossRef]

- Golubkina, N.; Logvinenko, L.; Novitsky, M.; Zamana, S.; Sokolov, S.; Molchanova, A.; Shevchuk, O.; Sekara, A.; Tallarita, A.; Caruso, G. Yield, Essential Oil and Quality Performances of Artemisia dracunculus, Hyssopus officinalis and Lavandula angustifolia as Affected by Arbuscular Mycorrhizal Fungi under Organic Management. Plants 2020, 9, 375. [Google Scholar] [CrossRef] [Green Version]

- Sangwan, R.S.; Farooqi, A.; Shabih, F. Regulation of essential oil production in plants. Plant Growth Regul. 2001, 34, 3–21. [Google Scholar] [CrossRef]

- Barra, A. Factors Affecting Chemical Variability of Essential Oils: A Review of Recent Developments. Nat. Prod. Commun. 2009, 4, 1147–1154. [Google Scholar] [CrossRef] [Green Version]

- Nia, A.F.; Badi, H.N.; Mehrafarin, A.; Bahman, S.; Sahandi, M.S. Changes in the essential oil content and terpene composition of rosemary (Rosmarinus officinalis L.) by using plant biostimulants. Acta Agric. Slov. 2016, 107, 147–157. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, A.A.; El-Hefny, M.; El-Shanhorey, N.A.; Ali, H.M. Foliar Application of Bio-Stimulants Enhancing the Production and the Toxicity of Origanum majorana Essential Oils Against Four Rice Seed-Borne Fungi. Molecules 2020, 25, 2363. [Google Scholar] [CrossRef] [PubMed]

- Poorghadir, M.; Torkashvand, A.M.; Mirjalili, S.A.; Moradi, P. Interactions of amino acids (proline and phenylalanine) and biostimulants (salicylic acid and chitosan) on the growth and essential oil components of savory (Satureja hortensis L.). Biocatal. Agric. Biotechnol. 2020, 30, 101815. [Google Scholar] [CrossRef]

- Godlewska, K.; Ronga, D.; Michalak, I. Plant extracts - importance in sustainable agriculture. Ital. J. Agron. 2021, 16. [Google Scholar] [CrossRef]

- Kauffman, G.L.; Kneivel, D.P.; Watschke, T.L. Effects of a Biostimulant on the Heat Tolerance Associated with Photosynthetic Capacity, Membrane Thermostability, and Polyphenol Production of Perennial Ryegrass. Crop Sci. 2007, 47, 261–267. [Google Scholar] [CrossRef]

- Halpern, M.; Bar-Tal, A.; Ofek, M.; Minz, D.; Muller, T.; Yermiyahu, U. The Use of Biostimulants for Enhancing Nutrient Uptake. Adv. Agron. 2015, 130, 141–174. [Google Scholar] [CrossRef]

- Colla, G.; Rouphael, Y.; Canaguier, R.; Svecova, E.; Cardarelli, M. Biostimulant action of a plant-derived protein hydrolysate produced through enzymatic hydrolysis. Front. Plant Sci. 2014, 5, 448. [Google Scholar] [CrossRef] [Green Version]

- Ronga, D.; Biazzi, E.; Parati, K.; Carminati, D.; Carminati, E.; Tava, A. Microalgal Biostimulants and Biofertilisers in Crop Productions. Agronomy 2019, 9, 192. [Google Scholar] [CrossRef] [Green Version]

- Wally, O.S.D.; Critchley, A.T.; Hiltz, D.; Craigie, J.S.; Han, X.; Zaharia, L.I.; Abrams, S.R.; Prithiviraj, B. Regulation of Phytohormone Biosynthesis and Accumulation in Arabidopsis Following Treatment with Commercial Extract from the Marine Macroalga Ascophyllum nodosum. J. Plant Growth Regul. 2013, 32, 324–339. [Google Scholar] [CrossRef]

- du Jardin, P. Plant biostimulants: Definition, concept, main categories and regulation. Sci. Hortic. 2015, 196, 3–14. [Google Scholar] [CrossRef] [Green Version]

- Hammad, S.A.; Ali, O.A. Physiological and biochemical studies on drought tolerance of wheat plants by application of amino acids and yeast extract. Ann. Agric. Sci. 2014, 59, 133–145. [Google Scholar] [CrossRef] [Green Version]

- Mannino, G.; Campobenedetto, C.; Vigliante, I.; Contartese, V.; Gentile, C.; Bertea, C.M. The Application of a Plant Biostimulant Based on Seaweed and Yeast Extract Improved Tomato Fruit Development and Quality. Biomolecules 2020, 10, 1662. [Google Scholar] [CrossRef] [PubMed]

- Tanase, C.; Ștefănescu, R.; Darkó, B.; Muntean, D.L.; Fărcaş, A.C.; Socaci, S.A. Biochemical and Histo-Anatomical Responses of Lavandula angustifolia Mill. to Spruce and Beech Bark Extracts Application. Plants 2020, 9, 859. [Google Scholar] [CrossRef]

- Wise, K.; Gill, H.; Selby-Pham, J. Willow bark extract and the biostimulant complex Root Nectar® increase propagation efficiency in chrysanthemum and lavender cuttings. Sci. Hortic. 2020, 263, 109108. [Google Scholar] [CrossRef]

- Wells, R.; Truong, F.; Adal, A.M.; Sarker, L.S.; Mahmoud, S.S. Lavandula Essential Oils: A Current Review of Applications in Medicinal, Food, and Cosmetic Industries of Lavender. Nat. Prod. Commun. 2018, 13, 1403–1417. [Google Scholar] [CrossRef] [Green Version]

- Germinara, G.S.; Giovanna, M.; Stefano, D.I.; De Acutis, L.; Pati, S.; Delfine, S.; De Cristofaro, A.; Rotundo, G. Bioactivities of Lavandula angustifolia essential oil against the stored grain pest Sitophilus granarius. Bull. Insectol. 2017, 70, 129–138. [Google Scholar]

- Olanya, O.M.; Larkin, R.P. Efficacy of essential oils and biopesticides on Phytophthora infestans suppression in laboratory and growth chamber studies. Biocontrol Sci. Technol. 2006, 16, 901–917. [Google Scholar] [CrossRef]

- Khater, H.F.; Ali, A.M.; Abouelella, G.A.; Marawan, M.A.; Govindarajan, M.; Murugan, K.; Abbas, R.Z.; Vaz, N.P.; Benelli, G. Toxicity and growth inhibition potential of vetiver, cinnamon, and lavender essential oils and their blends against larvae of the sheep blowfly, Lucilia sericata. Int. J. Dermatol. 2018, 57, 449–457. [Google Scholar] [CrossRef] [PubMed]

- Baydar, H.; Kineci, S. Scent Composition of Essential Oil, Concrete, Absolute and Hydrosol from Lavandin (LavandulaxintermediaEmeric ex Loisel.). J. Essent. Oil Bear. Plants 2009, 12, 131–136. [Google Scholar] [CrossRef]

- Usano-Alemany, J.; Herraiz Peñalver, D.; Cuadrado Ortiz, J.; De López, B.B.; Ruiz, O.S.; Palá-Paúl, J. Ecological production of lavenders in Cuenca province (Spain)–A study of yield production and quality of the essential oils. Bot. Complut. 2011, 35, 147–152. [Google Scholar]

- Giannoulis, K.; Evangelopoulos, V.; Gougoulias, N.; Wogiatzi, E. Lavender organic cultivation yield and essential oil can be improved by using bio-stimulants. Acta Agric. Scand. Sect. B Plant Soil Sci. 2020, 70, 648–656. [Google Scholar] [CrossRef]

- Carrasco, A.; Martinez-Gutierrez, R.; Tomas, V.; Tudela, J. Lavandin (Lavandula × intermedia Emeric ex Loiseleur) essential oil from Spain: Determination of aromatic profile by gas chromatography–mass spectrometry, antioxidant and lipoxygenase inhibitory bioactivities. Nat. Prod. Res. 2015, 30, 1123–1130. [Google Scholar] [CrossRef] [PubMed]

- Bombarda, I.; Dupuy, N.; Le Van Da, J.-P.; Gaydou, E. Comparative chemometric analyses of geographic origins and compositions of lavandin var. Grosso essential oils by mid infrared spectroscopy and gas chromatography. Anal. Chim. Acta 2008, 613, 31–39. [Google Scholar] [CrossRef]

- Barocelli, E.; Calcina, F.; Chiavarini, M.; Impicciatore, M.; Bruni, R.; Bianchi, A.; Ballabeni, V. Antinociceptive and gastroprotective effects of inhaled and orally administered Lavandula hybrida Reverchon “Grosso” essential oil. Life Sci. 2004, 76, 213–223. [Google Scholar] [CrossRef] [PubMed]

- Truzzi, E.; Marchetti, L.; Bertelli, D.; Benvenuti, S. Attenuated total reflectance–Fourier transform infrared (ATR–FTIR) spectroscopy coupled with chemometric analysis for detection and quantification of adulteration in lavender and citronella essential oils. Phytochem. Anal. 2021, 3034. [Google Scholar] [CrossRef]

- Silva, S.M.; Luz, J.M.Q.; Nogueira, P.A.M.; Blank, A.F.; Sampaio, T.S.; Pinto, J.A.O.; Junior, A.W. Organo-mineral fertilization effects on biomass and essential oil of lavender (Lavandula dentata L.). Ind. Crop. Prod. 2017, 103, 133–140. [Google Scholar] [CrossRef]

- Ahmed, A.; Elkady, F.; Khalid, K.A.T. Morphological and Chemical Characters of Petroselinum crispum (Mill) Subjected to Some Biostimulants. Asian J. Plant Sci. 2018, 17, 96–106. [Google Scholar] [CrossRef] [Green Version]

- Elansary, H.O.; Yessoufou, K.; Shokralla, S.; Mahmoud, E.; Skalicka-Woźniak, K. Enhancing mint and basil oil composition and antibacterial activity using seaweed extracts. Ind. Crop. Prod. 2016, 92, 50–56. [Google Scholar] [CrossRef]

- Hassiotis, C.; Ntana, F.; Lazari, D.; Poulios, S.; Vlachonasios, K. Environmental and developmental factors affect essential oil production and quality of Lavandula angustifolia during flowering period. Ind. Crop. Prod. 2014, 62, 359–366. [Google Scholar] [CrossRef]

- Fernández-Sestelo, M.; Carrillo, J. Environmental Effects on Yield and Composition of Essential Oil in Wild Populations of Spike Lavender (Lavandula latifolia Medik.). Agriculture 2020, 10, 626. [Google Scholar] [CrossRef]

- Moghaddam, M.; Mehdizadeh, L. Chemistry of Essential Oils and Factors Influencing Their Constituents. In Soft Chemistry and Food Fermentation; Academic Press: Cambridge, MA, USA, 2017; pp. 379–419. [Google Scholar] [CrossRef]

- Arabaci, O.; Bayram, E.; Baydar, H.; Ferhan Savran, A.; Karadogan, T.; Ozay, N. Chemical Composition, Yield and Contents of Essential Oil of Lavandula hybrida Reverchon Grown under Different Nitrogen Fertilizer, Plant Density and Location. Asian J. Chem. 2007, 19, 2184–2192. [Google Scholar]

- Carrubba, A.; Catalano, C. Essential Oil Crops for Sustainable Agriculture–A Review. In Climate Change, Intercropping, Pest Control and Beneficial Microorganisms; Springer: Cham, Switzerland, 2009; pp. 137–187. [Google Scholar]

- Pistelli, L.; Najar, B.; Giovanelli, S.; Lorenzini, L.; Tavarini, S.; Angelini, L. Agronomic and phytochemical evaluation of lavandin and lavender cultivars cultivated in the Tyrrhenian area of Tuscany (Italy). Ind. Crop. Prod. 2017, 109, 37–44. [Google Scholar] [CrossRef]

- Dellacecca, V. Ricerche sulla menta piperita (Mentha x piperita L.). In Proceedings of the Coltivazione e miglioramento di piante officinali, Trento, Italy, 2–3 July 1994; pp. 201–212. [Google Scholar]

- Schuh, G.; Heiden, A.C.; Hoffmann, T.; Kahl, J.; Rockel, P.; Rudolph, J.; Wildt, J. Emissions of Volatile Organic Compounds from Sunflower and Beech: Dependence on Temperature and Light Intensity. J. Atmospheric Chem. 1997, 27, 291–318. [Google Scholar] [CrossRef]

- Sharma, P.; Jha, A.B.; Dubey, R.S.; Pessarakli, M. Reactive Oxygen Species, Oxidative Damage, and Antioxidative Defense Mechanism in Plants under Stressful Conditions. J. Bot. 2012, 2012. [Google Scholar] [CrossRef] [Green Version]

- Sharkey, T.; Loreto, F. Water stress, temperature, and light effects on the capacity for isoprene emission and photosynthesis of kudzu leaves. Oecologia 1993, 95, 328–333. [Google Scholar] [CrossRef] [PubMed]

- Figueiredo, A.C.; Barroso, J.G.; Pedro, L.G.; Scheffer, J.J.C. Factors affecting secondary metabolite production in plants: Volatile components and essential oils. Flavour Fragr. J. 2008, 23, 213–226. [Google Scholar] [CrossRef]

- Boncan, D.A.T.; Tsang, S.S.; Li, C.; Lee, I.H.; Lam, H.-M.; Chan, T.-F.; Hui, J.H. Terpenes and Terpenoids in Plants: Interactions with Environment and Insects. Int. J. Mol. Sci. 2020, 21, 7382. [Google Scholar] [CrossRef]

- Šilha, D.; Švarcová, K.; Bajer, T.; Královec, K.; Tesařová, E.; Moučková, K.; Pejchalová, M.; Bajerová, P. Chemical Composition of Natural Hydrolates and Their Antimicrobial Activity on Arcobacter-like Cells in Comparison with Other Microorganisms. Molecules 2020, 25, 5654. [Google Scholar] [CrossRef]

- Pharmacopoeia, J. European Pharmacopoeia, 10th ed.; Council of Europe: Strasbourg, France, 2021. [Google Scholar]

- Adams, R. Identification of Essential Oil Components by Gas Chromatography/Mass Spectrometry, 4th ed.; Allured Pub. Corp.: Carol Stream, IL, USA, 2007. [Google Scholar]

| Farm | Treatment | Yield w/w % (Mean ± SD) | Yield g per Plant (Mean ± SD) | ||

|---|---|---|---|---|---|

| CA | CTRL | 1.04 ± 0.04 | a | 4.14 ± 0.49 | d |

| CA | CTRL W | 1.30 ± 0.20 | a | 6.38 ± 0.52 | d |

| CA | T1 | 1.11 ± 0.13 | a | 5.22 ± 1.22 | d |

| CA | T2 | 1.22 ± 0.29 | a | 5.28 ± 0.99 | d |

| PE | CTRL | 2.42 ± 0.24 | b | 3.97 ± 0.47 | d |

| PE | CTRL W | 2.32 ± 0.20 | b | 3.90 ± 1.21 | d |

| PE | T1 | 2.48 ± 0.08 | b | 5.09 ± 0.64 | d |

| PE | T2 | 2.60 ± 0.10 | b | 4.40 ± 0.58 | d |

| PR | CTRL | 2.66 ± 0.03 | b | 13.23 ± 1.46 | c |

| PR | CTRL W | 2.80 ± 0.13 | b | 15.04 ± 2.81 | bc |

| PR | T1 | 2.45 ± 0.43 | b | 18.44 ± 3.63 | ab |

| PR | T2 | 2.34 ± 0.06 | b | 21.03 ± 0.95 | a |

| CA | PE | PR | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LRI | CTRL | CTRL W | T1 | T2 | CTRL | CTRL W | T1 | T2 | CTRL | CTRL W | T1 | T2 | |

| 2-hexenal | 865 | 0.34 ± 0.13 | 0.36 ± 0.05 | 0.33 ± 0.09 | 0.35 ± 0.11 | - | - | - | - | - | - | - | - |

| α-thujene | 925 | 0.13 ± 0.03 | 0.13 ± 0.01 | 0.12 ± 0.01 | 0.15 ± 0.03 | - | - | - | - | - | - | - | - |

| α-pinene | 932 | 0.54 ± 0.07 | 0.54 ± 0.02 | 0.51 ± 0.04 | 0.58 ± 0.11 | 0.48 ± 0.09 | 0.46 ± 0.05 | 0.43 ± 0.04 | 0.41 ± 0.03 | 0.49 ± 0.05 | 0.61 ± 0.08 | 0.58 ± 0.05 | 0.61 ± 0.09 |

| Camphene | 946 | 0.46 ± 0.02 | 0.47 ± 0.02 | 0.45 ± 0.02 | 0.50 ± 0.10 | 0.35 ± 0.05 | 0.34 ± 0.02 | 0.32 ± 0.03 | 0.30 ± 0.02 | 0.34 ± 0.02 | 0.36 ± 0.03 | 0.36 ± 0.01 | 0.38 ± 0.05 |

| Sabinene | 972 | 0.16 ± 0.04 | 0.16 ± 0.02 | 0.15 ± 0.01 | 0.19 ± 0.05 | 0.14 ± 0.02 | 0.13 ± 0.02 | 0.13 ± 0.01 | 0.12 ± 0.01 | 0.15 ± 0.02 | 0.21 ± 0.02 | 0.19 ± 0.02 | 0.21 ± 0.01 |

| β-pinene | 975 | 0.15 ± 0.03 | 0.15 ± 0.01 | 0.15 ± 0.01 | 0.17 ± 0.02 | 0.45 ± 0.09 | 0.45 ± 0.07 | 0.43 ± 0.03 | 0.40 ± 0.04 | 0.49 ± 0.09 | 0.69 ± 0.09 | 0.61 ± 0.07 | 0.65 ± 0.08 |

| oct-1-en-3-ol | 978 | 0.91 ± 0.09 | 0.97 ± 0.06 | 0.82 ± 0.05 | 0.99 ± 0.07 | 0.29 ± 0.04 | 0.27 ± 0.02 | 0.23 ± 0.06 | 0.23 ± 0.02 | 0.25 ± 0.05 | 0.18 ± 0.08 | 0.14 ± 0.00 | 0.19 ± 0.09 |

| Myrcene | 991 | 1.14 ± 0.17 | 1.08 ± 0.08 | 1.02 ± 0.13 | 1.20 ± 0.21 | 1.65 ± 0.74 | 1.43 ± 0.25 | 1.16 ± 0.23 | 1.08 ± 0.05 | 1.28 ± 0.15 | 1.17 ± 0.23 | 1.30 ± 0.23 | 1.32 ± 0.23 |

| α-phellandrene | 1004 | 0.15 ± 0.02 | 0.14 ± 0.01 | 0.14 ± 0.02 | 0.15 ± 0.03 | 0.07 ± 0.01 | 0.08 ± 0.01 | 0.07 ± 0.01 | 0.06 ± 0.00 | 0.07 ± 0.00 | 0.08 ± 0.00 | 0.08 ± 0.00 | 0.08 ± 0.01 |

| δ-3-carene | 1009 | 0.26 ± 0.07 | 0.25 ± 0.03 | 0.25 ± 0.01 | 0.30 ± 0.09 | 0.11 ± 0.02 | 0.11 ± 0.02 | 0.10 ± 0.01 | 0.09 ± 0.01 | 0.14 ± 0.03 | 0.19 ± 0.04 | 0.17 ± 0.02 | 0.17 ± 0.04 |

| α-terpinene | 1015 | 0.21 ± 0.05 | 0.20 ± 0.02 | 0.20 ± 0.04 | 0.23 ± 0.05 | 0.20 ± 0.07 | 0.24 ± 0.01 | 0.19 ± 0.02 | 0.17 ± 0.03 | 0.16 ± 0.02 | 0.20 ± 0.04 | 0.17 ± 0.02 | 0.19 ± 0.04 |

| p-cymene | 1023 | 0.08 ± 0.02 | 0.08 ± 0.01 | 0.08 ± 0.01 | 0.10 ± 0.03 | - | - | - | - | - | - | - | - |

| Limonene | 1028 | 5.68 ± 1.43 | 5.38 ± 0.59 | 5.09 ± 0.38 | 6.46 ± 2.06 | 0.96 ± 0.16 | 1.02 ± 0.12 | 0.84 ± 0.11 | 0.80 ± 0.03 | 0.93 ± 0.10 | 0.86 ± 0.13 | 0.90 ± 0.07 | 0.74 ± 0.59 |

| 1,8-cineole | 1031 | 2.83 ± 0.29 | 2.85 ± 0.10 | 3.04 ± 0.22 | 3.25 ± 0.15 | 4.61 ± 0.49 | 4.57 ± 0.62 | 4.69 ± 0.19 | 4.27 ± 0.34 | 4.75 ± 0.71 | 6.42 ± 0.44 | 5.76 ± 0.30 | 6.48 ± 0.57 |

| cis-ocimene | 1038 | 4.36 ± 0.65 | 4.16 ± 0.31 | 4.02 ± 0.31 | 4.75 ± 1.17 | 1.43 ± 0.27 | 1.39 ± 0.08 | 1.19 ± 0.11 | 1.14 ± 0.04 | 1.54 ± 0.12 | 1.37 ± 0.08 | 1.58 ± 0.15 | 1.62 ± 0.16 |

| trans-ocimene | 1048 | 1.47 ± 0.31 | 1.28 ± 0.14 | 1.39 ± 0.17 | 1.39 ± 0.29 | 0.73 ± 0.22 | 0.76 ± 0.14 | 0.58 ± 0.13 | 0.53 ± 0.03 | 0.65 ± 0.09 | 0.55 ± 0.13 | 0.63 ± 0.13 | 0.66 ± 0.12 |

| γ-terpinene | 1058 | 0.26 ± 0.05 | 0.25 ± 0.03 | 0.25 ± 0.05 | 0.26 ± 0.06 | 0.13 ± 0.03 | 0.14 ± 0.02 | 0.12 ± 0.02 | 0.11 ± 0.01 | 0.13 ± 0.02 | 0.13 ± 0.02 | 0.14 ± 0.01 | 0.13 ± 0.03 |

| trans-sabinene hydrate | 1065 | 0.13 ± 0.05 | 0.13 ± 0.07 | 0.12 ± 0.05 | 0.17 ± 0.05 | 0.09 ± 0.03 | 0.08 ± 0.02 | 0.09 ± 0.02 | 0.11 ± 0.03 | 0.11 ± 0.02 | 0.15 ± 0.05 | 0.13 ± 0.02 | 0.16 ± 0.05 |

| cis-linalool oxide | 1072 | 0.14 ± 0.00 | 0.13 ± 0.01 | 0.13 ± 0.01 | 0.13 ± 0.01 | 0.15 ± 0.01 | 0.15 ± 0.01 | 0.15 ± 0.01 | 0.15 ± 0.02 | 0.14 ± 0.01 | 0.13 ± 0.00 | 0.15 ± 0.02 | 0.15 ± 0.02 |

| trans-linalool oxide | 1087 | 0.56 ± 0.06 | 0.50 ± 0.02 | 0.51 ± 0.05 | 0.54 ± 0.09 | 0.48 ± 0.06 | 0.49 ± 0.04 | 0.44 ± 0.04 | 0.42 ± 0.02 | 0.45 ± 0.02 | 0.42 ± 0.03 | 0.44 ± 0.01 | 0.45 ± 0.05 |

| Linalool | 1108 | 46.98 ± 3.01 | 50.21 ± 2.16 | 49.45 ± 0.82 | 46.61 ± 6.86 | 33.43 ± 1.00 | 33.87 ± 1.53 | 33.72 ± 0.83 | 32.58 ± 0.59 | 31.05 ± 0.25 | 27.82 ± 1.24 | 29.73 ± 1.33 | 28.99 ± 1.19 |

| Fenchol | 1115 | - | - | - | - | 0.55 ± 0.05 | 0.52 ± 0.03 | 0.42 ± 0.12 | 0.45 ± 0.02 | 0.40 ± 0.16 | 0.35 ± 0.18 | 0.23 ± 0.01 | 0.32 ± 0.18 |

| trans-rose oxide | 1130 | 0.14 ± 0.01 | 0.17 ± 0.07 | 0.13 ± 0.02 | 0.15 ± 0.04 | - | - | - | - | - | - | - | - |

| Camphor | 1144 | 2.22 ± 0.17 | 1.74 ± 0.18 | 1.94 ± 0.14 | 2.17 ± 0.68 | 6.62 ± 0.13 | 6.43 ± 0.55 | 6.30 ± 0.18 | 6.31 ± 0.44 | 6.97 ± 0.14 | 7.67 ± 0.16 | 7.40 ± 0.18 | 7.70 ± 0.21 |

| trans-verbenol | 1151 | 0.15 ± 0.02 | 0.17 ± 0.01 | 0.15 ± 0.00 | 0.17 ± 0.03 | 0.11 ± 0.01 | 0.10 ± 0.01 | 0.09 ± 0.00 | 0.10 ± 0.01 | 0.09 ± 0.00 | 0.09 ± 0.01 | 0.10 ± 0.01 | 0.11 ± 0.01 |

| Borneol | 1167 | 11.65 ± 0.77 | 11.09 ± 1.31 | 11.86 ± 0.86 | 10.95 ± 1.81 | 3.78 ± 0.30 | 3.98 ± 0.50 | 4.15 ± 0.17 | 3.98 ± 0.31 | 3.01 ± 0.02 | 2.60 ± 0.16 | 2.55 ± 0.03 | 2.46 ± 0.15 |

| lavandulol | 1171 | 0.66 ± 0.09 | 0.55 ± 0.08 | 0.63 ± 0.09 | 0.70 ± 0.04 | 0.45 ± 0.02 | 0.51 ± 0.05 | 0.45 ± 0.04 | 0.46 ± 0.01 | 0.48 ± 0.03 | 0.38 ± 0.01 | 0.38 ± 0.00 | 0.37 ± 0.03 |

| Terpinen-4-ol | 1181 | 5.58 ± 0.64 | 5.30 ± 0.37 | 5.29 ± 0.35 | 5.35 ± 0.79 | 1.95 ± 0.02 | 1.95 ± 0.06 | 1.96 ± 0.05 | 1.98 ± 0.16 | 2.05 ± 0.05 | 1.90 ± 0.09 | 2.07 ± 0.04 | 1.97 ± 0.05 |

| p-cymen-8-ol | 1187 | 0.30 ± 0.03 | 0.27 ± 0.03 | 0.29 ± 0.03 | 0.35 ± 0.15 | - | - | - | - | - | - | - | - |

| α-terpineol | 1191 | 0.29 ± 0.06 | 0.25 ± 0.03 | 0.26 ± 0.04 | 0.27 ± 0.01 | 0.71 ± 0.17 | 0.72 ± 0.12 | 0.71 ± 0.14 | 0.64 ± 0.08 | 0.70 ± 0.10 | 0.78 ± 0.13 | 0.67 ± 0.08 | 0.78 ± 0.13 |

| Myrtenal | 1194 | 0.49 ± 0.04 | 0.52 ± 0.02 | 0.52 ± 0.02 | 0.50 ± 0.04 | 0.25 ± 0.01 | 0.25 ± 0.02 | 0.24 ± 0.01 | 0.24 ± 0.01 | 0.20 ± 0.01 | 0.18 ± 0.01 | 0.21 ± 0.02 | 0.20 ± 0.01 |

| Nerol | 1230 | 0.16 ± 0.01 | 0.16 ± 0.02 | 0.15 ± 0.01 | 0.16 ± 0.01 | 0.09 ± 0.03 | 0.09 ± 0.02 | 0.09 ± 0.03 | 0.07 ± 0.01 | 0.08 ± 0.02 | 0.09 ± 0.02 | 0.07 ± 0.01 | 0.08 ± 0.03 |

| Pulegone | 1242 | 0.34 ± 0.03 | 0.32 ± 0.01 | 0.31 ± 0.01 | 0.37 ± 0.09 | - | - | - | - | - | - | - | - |

| Carvone | 1247 | 0.14 ± 0.00 | 0.14 ± 0.00 | 0.14 ± 0.00 | 0.15 ± 0.01 | 0.13 ± 0.00 | 0.12 ± 0.00 | 0.12 ± 0.01 | 0.13 ± 0.01 | 0.11 ± 0.00 | 0.11 ± 0.00 | 0.11 ± 0.01 | 0.11 ± 0.01 |

| Linalyl acetate | 1263 | 5.25 ± 0.82 | 4.70 ± 0.42 | 4.75 ± 0.29 | 4.81 ± 0.84 | 30.16 ± 2.26 | 29.89 ± 1.75 | 30.94 ± 0.80 | 32.60 ± 0.49 | 32.02 ± 1.62 | 33.04 ± 2.00 | 33.17 ± 1.27 | 32.42 ± 1.50 |

| Lavandulyl acetate | 1293 | 1.27 ± 0.10 | 1.10 ± 0.11 | 1.23 ± 0.01 | 1.19 ± 0.24 | 2.87 ± 0.17 | 2.94 ± 0.10 | 2.88 ± 0.02 | 2.97 ± 0.12 | 3.12 ± 0.17 | 3.06 ± 0.12 | 2.64 ± 0.04 | 2.75 ± 0.18 |

| Neryl acetate | 1367 | 0.07 ± 0.01 | 0.05 ± 0.01 | 0.05 ± 0.01 | 0.05 ± 0.00 | 0.29 ± 0.06 | 0.30 ± 0.05 | 0.26 ± 0.05 | 0.24 ± 0.02 | 0.28 ± 0.05 | 0.25 ± 0.05 | 0.26 ± 0.05 | 0.28 ± 0.06 |

| α-copaene | 1383 | - | - | - | - | 0.09 ± 0.00 | 0.09 ± 0.01 | 0.09 ± 0.00 | 0.09 ± 0.00 | 0.11 ± 0.01 | 0.13 ± 0.01 | 0.11 ± 0.01 | 0.12 ± 0.01 |

| β-cubebene | 1386 | 0.10 ± 0.04 | 0.07 ± 0.02 | 0.07 ± 0.02 | 0.08 ± 0.01 | 0.60 ± 0.13 | 0.65 ± 0.10 | 0.54 ± 0.09 | 0.54 ± 0.03 | 0.61 ± 0.09 | 0.56 ± 0.12 | 0.57 ± 0.11 | 0.58 ± 0.10 |

| Geranyl acetate | 1424 | 0.14 ± 0.01 | 0.13 ± 0.02 | 0.14 ± 0.00 | 0.15 ± 0.04 | - | - | - | - | - | - | - | - |

| β-caryophyllene | 1439 | 0.47 ± 0.06 | 0.41 ± 0.05 | 0.44 ± 0.01 | 0.46 ± 0.08 | 1.55 ± 0.08 | 1.62 ± 0.15 | 1.47 ± 0.12 | 1.57 ± 0.06 | 1.78 ± 0.09 | 1.87 ± 0.13 | 1.72 ± 0.19 | 1.81 ± 0.18 |

| α-bergamotene | 1460 | 0.06 ± 0.00 | 0.05 ± 0.00 | 0.05 ± 0.00 | 0.07 ± 0.01 | 0.12 ± 0.01 | 0.13 ± 0.01 | 0.12 ± 0.01 | 0.13 ± 0.01 | 0.16 ± 0.02 | 0.18 ± 0.02 | 0.16 ± 0.02 | 0.16 ± 0.02 |

| β-farnesene | 1487 | 2.15 ± 0.14 | 1.99 ± 0.32 | 2.18 ± 0.04 | 2.23 ± 0.48 | 1.13 ± 0.13 | 1.18 ± 0.15 | 1.17 ± 0.07 | 1.26 ± 0.06 | 1.30 ± 0.07 | 1.33 ± 0.07 | 1.24 ± 0.11 | 1.24 ± 0.17 |

| ar-curcumene | 1511 | 0.20 ± 0.02 | 0.16 ± 0.04 | 0.18 ± 0.02 | 0.20 ± 0.07 | 0.66 ± 0.10 | 0.65 ± 0.07 | 0.68 ± 0.05 | 0.75 ± 0.04 | 0.88 ± 0.08 | 0.92 ± 0.01 | 0.87 ± 0.10 | 0.86 ± 0.14 |

| δ-cadinene | 1521 | 0.49 ± 0.12 | 0.46 ± 0.10 | 0.46 ± 0.04 | 0.48 ± 0.12 | 0.52 ± 0.08 | 0.55 ± 0.11 | 0.53 ± 0.04 | 0.58 ± 0.05 | 0.58 ± 0.05 | 0.53 ± 0.15 | 0.58 ± 0.06 | 0.60 ± 0.10 |

| γ-cadinene | 1529 | - | - | - | - | 0.36 ± 0.05 | 0.39 ± 0.07 | 0.34 ± 0.03 | 0.38 ± 0.03 | 0.32 ± 0.07 | 0.40 ± 0.12 | 0.29 ± 0.06 | 0.34 ± 0.07 |

| Total | 99.36 ± 0.36 | 99.3 ± 0.36 | 99.52 ± 0.18 | 99.51 ± 0.37 | 98.47 ± 0.42 | 98.71 ± 0.42 | 98.16 ± 0.29 | 98.11 ± 0.23 | 98.07 ± 0.31 | 97.64 ± 0.24 | 98.23 ± 0.44 | 98.18 ± 0.24 | |

| monoterpene hydrocarbons | 15.4 ± 3.03 | 14.63 ± 1.22 | 14.16 ± 1.25 | 16.77 ± 4.00 | 6.7 ± 1.73 | 6.54 ± 0.69 | 5.58 ± 0.69 | 5.22 ± 0.28 | 6.35 ± 0.5 | 6.42 ± 0.83 | 6.71 ± 0.75 | 6.77 ± 1.12 | |

| ethers | 3.66 ± 0.35 | 3.66 ± 0.18 | 3.81 ± 0.17 | 4.07 ± 0.24 | 5.24 ± 0.55 | 5.22 ± 0.63 | 5.28 ± 0.22 | 4.83 ± 0.37 | 5.33 ± 0.72 | 6.97 ± 0.46 | 6.35 ± 0.28 | 7.09 ± 0.58 | |

| alcohols | 66.82 ± 3.03 | 69.09 ± 1.37 | 69.03 ± 0.65 | 65.72 ± 5.97 | 41.46 ± 0.92 | 42.09 ± 1.14 | 41.9 ± 0.96 | 40.58 ± 0.59 | 38.22 ± 0.31 | 34.34 ± 1.59 | 36.07 ± 1.26 | 35.43 ± 1.29 | |

| ketones and aldehydes | 3.18 ± 0.17 | 2.72 ± 0.15 | 2.9 ± 0.11 | 3.19 ± 0.74 | 7 ± 0.12 | 6.81 ± 0.56 | 6.67 ± 0.18 | 6.67 ± 0.45 | 7.29 ± 0.15 | 7.97 ± 0.15 | 7.72 ± 0.18 | 8.01 ± 0.2 | |

| esters | 6.68 ± 0.89 | 5.93 ± 0.52 | 6.11 ± 0.28 | 6.13 ± 1.09 | 33.39 ± 2.38 | 33.19 ± 1.71 | 34.14 ± 0.76 | 35.88 ± 0.58 | 35.47 ± 1.75 | 36.41 ± 2.04 | 36.14 ± 1.24 | 35.52 ± 1.65 | |

| sesquiterpenes | 3.61 ± 0.35 | 3.27 ± 0.51 | 3.52 ± 0.04 | 3.65 ± 0.75 | 4.67 ± 0.31 | 4.86 ± 0.57 | 4.59 ± 0.32 | 4.93 ± 0.16 | 5.41 ± 0.37 | 5.53 ± 0.23 | 5.25 ± 0.58 | 5.37 ± 0.66 | |

| LRI | CA | PE | PR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CTRL az | CTRL H2O | T1 | T2 | CTRL az | CTRL H2O | T1 | T2 | CTRL az | CTRL H2O | T1 | T2 | ||

| β-pinene | 978 | 0.56 ± 0.04 | 0.98 ± 0.07 | 0.81 ± 0.09 | 0.84 ± 0.39 | 0.39 ± 0.06 | 0.42 ± 0.05 | 0.27 ± 0.06 | 0.22 ± 0.01 | 0.47 ± 0.15 | 0.22 ± 0.08 | 0.19 ± 0.01 | 0.35 ± 0.01 |

| 1,8-cineole | 1029 | 0.46 ± 0.10 | 0.6 ± 0.14 | 0.86 ± 0.23 | 1.17 ± 0.04 | 1.16 ± 1.47 | 0.7 ± 0.12 | 0.8 ± 0.3 | 0.77 ± 0.1 | 0.44 ± 0.2 | 1.10 ± 0.21 | 0.6 ± 0.40 | 0.4 ± 0.02 |

| cis-linalool oxide | 1071 | 0.7 ± 0.04 | 0.57 ± 0.06 | 0.65 ± 0.01 | 0.64 ± 0.17 | 2.08 ± 0.58 | 1.74 ± 0.17 | 2.31 ± 0.18 | 2.17 ± 0.14 | 1.55 ± 0.18 | 2.24 ± 0.67 | 2.36 ± 0.88 | 2.11 ± 0.19 |

| trans-linalool oxide | 1087 | 0.82 ± 0.05 | 0.57 ± 0.06 | 0.62 ± 0.02 | 0.67 ± 0.11 | 2.14 ± 0.53 | 1.74 ± 0.15 | 2.47 ± 0.23 | 2.32 ± 0.2 | 1.59 ± 0.2 | 2.31 ± 0.67 | 2.49 ± 0.85 | 2.13 ± 0.3 |

| Linalool | 1101 | 34.23 ± 1.72 | 43.81 ± 4.72 | 39.6 ± 3.95 | 42.12 ± 10.33 | 43.2 ± 10.3 | 47.5 ± 0.83 | 41.53 ± 2.73 | 40.3 ± 2.68 | 46.28 ± 2.56 | 38.74 ± 2.84 | 43.1 ± 1.44 | 39.12 ± 0.14 |

| Camphor | 1143 | 3.27 ± 0.29 | 2.76 ± 0.01 | 3.55 ± 0.51 | 3.06 ± 0.15 | 11.78 ± 0.53 | 14.78 ± 1.18 | 12.8 ± 0.68 | 11.8 ± 2.67 | 15.11 ± 0.53 | 18.76 ± 0.88 | 15.44 ± 0.02 | 13.36 ± 1.68 |

| Borneol | 1166 | 31.94 ± 1.65 | 26.85 ± 2.14 | 30.82 ± 3.21 | 30.49 ± 7.93 | 12.3 ± 1.13 | 13.09 ± 0.64 | 14.25 ± 0.29 | 14.43 ± 1.41 | 11.59 ± 0.15 | 10.64 ± 0.69 | 10.04 ± 0.63 | 10.31 ± 0.17 |

| Neomenthol | 1168 | 2.51 ± 0.62 | 1.93 ± 0.92 | 2.04 ± 0.44 | 1.97 ± 0.35 | 1.77 ± 0.10 | 1.79 ± 0.16 | 2.05 ± 0.2 | 2.2 ± 0.27 | 1.8 ± 0.13 | 1.73 ± 0.11 | 1.79 ± 0.06 | 1.86 ± 0.07 |

| Lavandulol | 1175 | 0.25 ± 0.56 | 0.19 ± 0.21 | 0.19 ± 0.1 | 0.19 ± 0.09 | 0.52 ± 0.09 | 0.4 ± 0.07 | 0.63 ± 0.16 | 0.7 ± 0.16 | 0.42 ± 0.06 | 0.49 ± 0.10 | 0.59 ± 0.09 | 0.65 ± 0.06 |

| Terpinen-4-ol | 1178 | 10.97 ± 1.47 | 8.7 ± 0.54 | 9.6 ± 0.68 | 8.87 ± 0.55 | 5.12 ± 0.67 | 4.8 ± 0.04 | 4.88 ± 0.09 | 5.22 ± 0.34 | 5.43 ± 0.06 | 5.3 ± 0.13 | 6.02 ± 0.06 | 5.4 ± 0.14 |

| Menthol | 1183 | 0.55 ± 0.03 | 0.29 ± 0.04 | 0.42 ± 0.09 | 0.33 ± 0.12 | 0.55 ± 0.12 | 0.5 ± 0.06 | 0.78 ± 0.12 | 0.81 ± 0.09 | 0.5 ± 0.01 | 0.61 ± 0.06 | 0.61 ± 0.02 | 0.7 ± 0.11 |

| p-cymen-8-ol | 1186 | 3.69 ± 0.5 | 2.23 ± 0.2 | 2.85 ± 0.6 | 2.66 ± 1.26 | 0.7 ± 0.08 | 0.67 ± 0.11 | 0.97 ± 0.23 | 1.12 ± 0.26 | 0.81 ± 0.03 | 1.06 ± 0.07 | 0.84 ± 0.06 | 1.05 ± 0.13 |

| α-terpineol | 1190 | 2.53 ± 0.52 | 1.71 ± 0.38 | 1.92 ± 0.1 | 1.93 ± 0.23 | 7 ± 1.62 | 7.04 ± 0.19 | 7.66 ± 0.73 | 8.3 ± 0.18 | 7.39 ± 0.03 | 7.8 ± 0.10 | 7.88 ± 0.94 | 8.73 ± 1.17 |

| Nerol | 1232 | 0.73 ± 0.11 | 0.44 ± 0.1 | 0.59 ± 0.08 | 0.48 ± 0.05 | 1.09 ± 0.18 | 1.06 ± 0.1 | 1.13 ± 0.22 | 1.29 ± 0.05 | 1.12 ± 0.04 | 0.88 ± 0.06 | 1.08 ± 0.17 | 0.99 ± 0.09 |

| Piperitone | 1259 | 0.86 ± 0.43 | 0.65 ± 0.02 | 0.74 ± 0.06 | 0.55 ± 0.18 | 2.48 ± 1.06 | 1.83 ± 0.25 | 2.51 ± 0.47 | 2.87 ± 0.01 | 2.05 ± 0.36 | 2.12 ± 0.14 | 2.12 ± 0.36 | 2.55 ± 0.33 |

| Lavandulyl acetate | 1292 | 0.69 ± 0.23 | 0.27 ± 0.07 | 0.67 ± 0.3 | 0.51 ± 0.4 | 0.25 ± 0.10 | 0.25 ± 0.03 | 0.37 ± 0.07 | 0.36 ± 0.07 | 0.25 ± 0.1 | 0.34 ± 0.01 | 0.56 ± 0.33 | 0.96 ± 0.85 |

| Total | 91.56 ± 2.35 | 95.9 ± 2.01 | 93.53 ± 1.47 | 94.2 ± 1.19 | 83.53 ± 6.49 | 91.31 ± 1.11 | 87.3 ± 1.61 | 85.51 ± 2.38 | 89.16 ± 2.83 | 87.47 ± 1.66 | 87.84 ± 2.02 | 82.23 ± 2.38 | |

| monoterpene hydrocarbons | 0.56 ± 0.04 | 0.98 ± 0.07 | 0.81 ± 0.09 | 0.84 ± 0.39 | 0.39 ± 0.06 | 0.42 ± 0.05 | 0.27 ± 0.06 | 0.22 ± 0.01 | 0.47 ± 0.15 | 0.22 ± 0.08 | 0.19 ± 0.01 | 0.35 ± 0.01 | |

| ethers | 2 ± 0.09 | 1.73 ± 0.09 | 2.19 ± 0.19 | 2.4 ± 0.26 | 5.98 ± 2.1 | 4.08 ± 0.36 | 5.61 ± 0.09 | 4.83 ± 0.17 | 3.72 ± 0.47 | 5.71 ± 1.09 | 5.95 ± 1.74 | 4.63 ± 0.63 | |

| alcohols | 84.4 ± 1.68 | 89.5 ± 1.98 | 85.94 ± 0.56 | 86.83 ± 0.96 | 62.42 ± 9.79 | 69.75 ± 0.22 | 65.75 ± 1.64 | 66.05 ± 0.90 | 67.41 ± 1.82 | 58.69 ± 2.63 | 63.58 ± 1.7 | 60 ± 0.24 | |

| ketones | 3.96 ± 0.59 | 3.42 ± 0.59 | 4.39 ± 0.36 | 3.62 ± 0.03 | 14.64 ± 1.29 | 16.83 ± 0.75 | 15.27 ± 0.17 | 14.04 ± 2.17 | 17.37 ± 0.72 | 21.12 ± 0.84 | 17.48 ± 0.31 | 16.22 ± 1.1 | |

| esters | 0.69 ± 0.23 | 0.27 ± 0.07 | 0.67 ± 0.3 | 0.51 ± 0.4 | 0.25 ± 0.10 | 0.25 ± 0.03 | 0.37 ± 0.07 | 0.36 ± 0.07 | 0.25 ± 0.1 | 0.34 ± 0.01 | 0.56 ± 0.33 | 0.96 ± 0.85 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truzzi, E.; Benvenuti, S.; Bertelli, D.; Francia, E.; Ronga, D. Effects of Biostimulants on the Chemical Composition of Essential Oil and Hydrosol of Lavandin (Lavandula x intermedia Emeric ex Loisel.) Cultivated in Tuscan-Emilian Apennines. Molecules 2021, 26, 6157. https://doi.org/10.3390/molecules26206157

Truzzi E, Benvenuti S, Bertelli D, Francia E, Ronga D. Effects of Biostimulants on the Chemical Composition of Essential Oil and Hydrosol of Lavandin (Lavandula x intermedia Emeric ex Loisel.) Cultivated in Tuscan-Emilian Apennines. Molecules. 2021; 26(20):6157. https://doi.org/10.3390/molecules26206157

Chicago/Turabian StyleTruzzi, Eleonora, Stefania Benvenuti, Davide Bertelli, Enrico Francia, and Domenico Ronga. 2021. "Effects of Biostimulants on the Chemical Composition of Essential Oil and Hydrosol of Lavandin (Lavandula x intermedia Emeric ex Loisel.) Cultivated in Tuscan-Emilian Apennines" Molecules 26, no. 20: 6157. https://doi.org/10.3390/molecules26206157