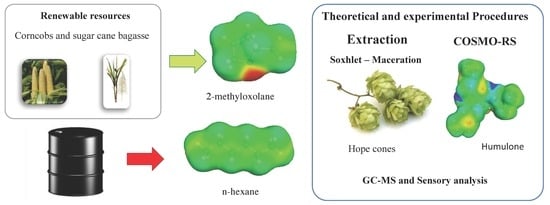

2-Methyloxolane as a Bio-Based Solvent for Green Extraction of Aromas from Hops (Humulus lupulus L.)

Abstract

:1. Introduction

- Use of a natural origin, renewable, or agro-sourced solvent

- Avoid the use of solvents which might affect the safety and health of production operators and consumers. It must not be a CMR (carcinogenic, mutagenic, reproductively-toxic) or toxic (or present low toxicity), it must not induce an allergenic effect, and not belong to endocrine disruptors.

- Use of solvent compatible with existing in industrial facilities

- Prefer a solvent with a high rate of recyclability

- High bio-degradability and no bio-accumulation, to limit global process impact on the environment

- Use of solvent which limits energy consumption and cost of global process (solvent with low boiling point, low specific heat capacity, and low enthalpy of vaporization)

- Ensure a maximal solvent recovery at the end of the process using various available techniques

2. Results and Discussion

2.1. Solubility Study: COSMO-RS

2.2. Extraction Yields

2.3. Chemical Compositions

2.4. Sensory Analysis

2.5. Techno-Economic Comparison

3. Materials and Methods

3.1. Plant Material and Chemicals

3.2. Computational Method: COSMO-RS Calculations

3.3. Extraction Yield

3.4. Solid–Liquid Extraction

3.5. Soxhlet Extraction

3.6. Production of Essential Oil

3.7. Identification of Aroma by GC-MS

3.8. Sensory Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Choi, Y.H.; Verpoorte, R. Metabolomics: What you see is what you extract. Phytochem. Anal. PCA 2014, 25, 289–290. [Google Scholar] [CrossRef] [PubMed]

- Sicaire, A.-G.; Vian, M.A.; Filly, A.; Li, Y.; Bily, A.; Chemat, F. 2-Methyltetrahydrofuran: Main Properties, Production Processes, and Application in Extraction of Natural Products. In Alternative Solvents for Natural Products Extraction; Chemat, F., Vian, M.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 253–268. [Google Scholar]

- Yuichiro, O.; Takeuchi, Y.; Hisanaga, N. Studies on the method of measuring nerve conduction velocity in rat’s tail and on the comparative toxicity of n-hexane, methyl n-butyl ketone, and 2,5-hexanedione. Sangyo Igaku 1979, 21, 528–538. [Google Scholar]

- Takeuchi, Y.; Ono, Y.; Hisanaga, N.; Kitoh, J.; Sugiura, Y. A comparative study on the neurotoxicity of n-pentane, n-hexane, and n-heptane in the rat. Br. J. Ind. Med. 1980, 37, 241–247. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chemat, F.; Abert Vian, M.; Ravi, H.K.; Khadhraoui, B.; Hilali, S.; Perino, S.; Tixier, A.-S.F. Review of Alternative Solvents for Green Extraction of Food and Natural Products: Panorama, Principles, Applications and Prospects. Molecules 2019, 24, 3007. [Google Scholar] [CrossRef] [Green Version]

- Pace, V.; Hoyos, P.; Castoldi, L.; Domínguez de María, P.; Alcántara, A.R. 2-Methyltetrahydrofuran (2-MeTHF): A Biomass-Derived Solvent with Broad Application in Organic Chemistry. Chem. Sus. Chem. 2012, 5, 1369–1379. [Google Scholar] [CrossRef]

- Aycock, D.F. Solvent Applications of 2-Methyltetrahydrofuran in Organometallic and Biphasic Reactions. Org. Process Res. Dev. 2007, 11, 156–159. [Google Scholar] [CrossRef]

- Geilen, F.M.A.; Engendahl, B.; Harwardt, A.; Marquardt, W.; Klankermayer, J.; Leitner, W. Selective and Flexible Transformation of Biomass-Derived Platform Chemicals by a Multifunctional Catalytic System. Angew. Chem. Int. Ed. 2010, 49, 5510–5514. [Google Scholar] [CrossRef]

- Zheng, H.-Y.; Zhu, Y.-L.; Teng, B.-T.; Bai, Z.-Q.; Zhang, C.-H.; Xiang, H.-W.; Li, Y.-W. Towards understanding the reaction pathway in vapour phase hydrogenation of furfural to 2-methylfuran. J. Mol. Catal. Chem. 2006, 246, 18–23. [Google Scholar] [CrossRef]

- Antonucci, V.; Coleman, J.; Ferry, J.B.; Johnson, N.; Mathe, M.; Scott, J.P.; Xu, J. Toxicological Assessment of 2-Methyltetrahydrofuran and Cyclopentyl Methyl Ether in Support of Their Use in Pharmaceutical Chemical Process Development. Org. Process Res. Dev. 2011, 15, 939–941. [Google Scholar] [CrossRef]

- Angles, E.; Jaouen, P.; Pruvost, J.; Marchal, L. Wet lipid extraction from the microalga Nannochloropsis sp.: Disruption, physiological effects and solvent screening. Algal Res. 2017, 21, 27–34. [Google Scholar] [CrossRef]

- Sicaire, A.-G.; Vian, M.; Fine, F.; Joffre, F.; Carré, P.; Tostain, S.; Chemat, F. Alternative Bio-Based Solvents for Extraction of Fat and Oils: Solubility Prediction, Global Yield, Extraction Kinetics, Chemical Composition and Cost of Manufacturing. Int. J. Mol. Sci. 2015, 16, 8430–8453. [Google Scholar] [CrossRef] [PubMed]

- Ravi, H.K.; Vian, M.A.; Tao, Y.; Degrou, A.; Costil, J.; Trespeuch, C.; Chemat, F. Alternative solvents for lipid extraction and their effect on protein quality in black soldier fly (Hermetia illucens) larvae. J. Clean. Prod. 2019, 238, 1–13. [Google Scholar] [CrossRef]

- De Jesus, S.S.; Ferreira, G.F.; Fregolente, L.V.; Maciel Filho, R. Laboratory extraction of microalgal lipids using sugarcane bagasse derived green solvents. Algal Res. 2018, 35, 292–300. [Google Scholar] [CrossRef]

- Yara-Varón, E.; Fabiano-Tixier, A.S.; Balcells, M.; Canela-Garayoa, R.; Bily, A.; Chemat, F. Is it possible to substitute hexane with green solvents for extraction of carotenoids? A theoretical versus experimental solubility study. RSC Adv. 2016, 6, 27750–27759. [Google Scholar] [CrossRef] [Green Version]

- Damergi, E.; Schwitzguébel, J.-P.; Refardt, D.; Sharma, S.; Holliger, C.; Ludwig, C. Extraction of carotenoids from Chlorella vulgaris using green solvents and syngas production from residual biomass. Algal Res. 2017, 25, 488–495. [Google Scholar] [CrossRef]

- Filly, A.; Fabiano-Tixier, A.-S.; Lemasson, Y.; Roy, C.; Fernandez, X.; Chemat, F. Extraction of aroma compounds in blackcurrant buds by alternative solvents: Theoretical and experimental solubility study. Comptes Rendus Chim. 2014, 17, 1268–1275. [Google Scholar] [CrossRef]

- Ozturk, B.; Winterburn, J.; Gonzalez-Miquel, M. Orange peel waste valorisation through limonene extraction using bio-based solvents. Biochem. Eng. J. 2019, 151, 1–9. [Google Scholar] [CrossRef]

- Kralj, D.; Zupanec, J.; Vasilj, D.; Kralj, S.; Pšeničnik, J. Variability of Essential Oils of Hops, Humulus Lupulus L. J. Inst. Brew. 1991, 97, 197–206. [Google Scholar] [CrossRef]

- Becker, L.; Boyer, I. Safety Assessment of Humulus Lupulus (Hops) - Extract and Oil as Used in Cosmetics. Cosmet. Ingred. Rev. 2017, 1, 1–27. [Google Scholar]

- Verzele, M.; De Keukeleire, D. Hops as a raw material in the brewery. In Chemistry and Analysis of Hop and Beer Bitter Acids; Elsevier Science Publishers B.V.: Amsterdam, The Netherlands, 1991; Volume 27, pp. 1–16. [Google Scholar]

- Algazzali, V.; Shellhammer, T. Bitterness Intensity of Oxidized Hop Acids: Humulinones and Hulupones. J. Am. Soc. Brew. Chem. 2016, 74, 36–43. [Google Scholar] [CrossRef]

- Eßlinger, H.M. Stability of beer. In Handbook of Brewing: Processes, Technology, Markets; Eßlinger, H.M., Ed.; John Wiley & Sons: Weinheim, Germany, 2009; Volume 1, pp. 399–426. [Google Scholar]

- Patouillard, N.; (Pennakem LLC, Memphis, TN, USA). A new eco-friendly breakthrough biobased solution for clean label oils and plant proteins. Personal communication, Food Ingredients Europe Fair: Paris, France, 12 April 2019. [Google Scholar]

- U.S. Environmental Protection Agency. Toxological Review of n-hexane, in Support of Summary Information on the Integrated Risk Information System (IRIS); U.S. Environmental Protection Agency: Washington, DC, USA, 2005.

- Slater, C.S.; Savelski, M.J.; Hitchcock, D.; Cavanagh, E.J. Environmental analysis of the life cycle emissions of 2-methyl tetrahydrofuran solvent manufactured from renewable resources. J. Environ. Sci. Health Part A 2016, 51, 487–494. [Google Scholar] [CrossRef]

- Haynes, W.M.; Lide, D.; Bruno, T.J. CRC Handbook of Chemistry and Physics, 97th ed.; CRC Press: Boca Raton, FL, USA, 2016; Volume 3, pp. 298–398. [Google Scholar]

- Klamt, A. Prediction of the mutual solubilities of hydrocarbons and water with COSMO-RS. Fluid Phase Equilib. 2003, 206, 223–235. [Google Scholar] [CrossRef] [Green Version]

- Filly, A.; Fabiano-Tixier, A.S.; Fernandez, X.; Chemat, F. Alternative solvents for extraction of food aromas. Experimental and COSMO-RS study. LWT Food Sci. Technol. 2015, 61, 33–40. [Google Scholar] [CrossRef]

- Sicaire, A.-G.; Abert Vian, M.; Fine, F.; Carré, P.; Tostain, S.; Chemat, F. Experimental approach versus COSMO-RS assisted solvent screening for predicting the solubility of rapeseed oil. OCL 2015, 22, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Chaabani, E.; Vian, M.A.; Bott, R.; Ginies, C.; Defoort, C.; Ksouri, R.; Chemat, F. Extraction of aromas from Pistacia lentiscus L. leaves using alternative solvents: COSMO-RS-assisted solvent screening and GC-MS metabolites profiling. Sep. Sci. Technol. 2020, 55, 716–727. [Google Scholar] [CrossRef]

- Breil, C.; Meullemiestre, A.; Vian, M.; Chemat, F. Bio-Based Solvents for Green Extraction of Lipids from Oleaginous Yeast Biomass for Sustainable Aviation Biofuel. Molecules 2016, 21, 196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cascant, M.M.; Breil, C.; Garrigues, S.; de la Guardia, M.; Fabiano-Tixier, A.S.; Chemat, F. A green analytical chemistry approach for lipid extraction: Computation methods in the selection of green solvents as alternative to hexane. Anal. Bioanal. Chem. 2017, 409, 3527–3539. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| Technic/Solvent | Hexane | 2-Methyloxolane |

|---|---|---|

| Maceration (2 h) | 12.7% +/− 0.7 | 16.6% +/− 0.5 |

| Soxhlet (6 h) | 17.9% +/− 0.2 | 20.2% +/− 0.3 |

| Compound | CAS | RI | EO | Hexane | 2-Methyloxolane |

|---|---|---|---|---|---|

| Methacrolein | 78-85-3 | 568 | n.d. | 0.63 | 1.25 |

| 2-methyl-3-Buten-2-ol | 115-18-4 | 606 | n.d. | 5.65 | 2.30 |

| Diethyl acetal | 105-57-7 | 717 | n.d. | 5.32 | 1.91 |

| β-Myrcene | 123-35-3 | 991 | 35.03 | n.d. | n.d. |

| Linalool | 78-70-6 | 1100 | 1.20 | n.d. | n.d. |

| 2,3,4-Trimethyl-2-pentanol | 66576-26-9 | / | n.d. | 2.55 | 1.45 |

| E-Caryophyllene | 87-44-5 | 1444 | 8.87 | n.d. | n.d. |

| E-β-Farnesene | 18794-84-8 | 1458 | 6.96 | n.d. | n.d. |

| α-Humulene | 6753-98-6 | 1467 | 22.34 | 1.42 | 1.16 |

| γ-Murolene | 30021-74-0 | 1475 | 1.28 | n.d. | n.d. |

| β-Selinene | 17066-67-0 | 1485 | 1.51 | 0.66 | 0.44 |

| Geranyl isobutanoate | 2345-26-8 | 1515 | 1.55 | n.d. | n.d. |

| α-Selinene | 473-13-2 | 1494 | 1.56 | n.d. | n.d. |

| γ-Cadinene | 39029-41-9 | 1512 | 1.05 | n.d. | n.d. |

| δ-cadinene | 483-76-1 | 1530 | 1.38 | n.d. | n.d. |

| Caryophyllene oxide | 1139-30-6 | 1573 | 1.61 | 2.40 | 2.07 |

| Humulene oxide II | 19888-34-7 | 1642 | 2.72 | 1.79 | 2.20 |

| E,Z-1,3-Cyclododecadiene | 1129-92-6 | / | 1.56 | n.d. | n.d. |

| Phytol | 150-86-7 | / | n.d. | 2.00 | 2.17 |

| Hulupone | 468-62-2 | / | n.d. | 9.30 | n.d. |

| Isohumulone | 25522-96-7 | 2715 | n.d. | 6.00 | 8.93 |

| R-Humulone | 26472-41-3 | 2740 | n.d. | 11.89 | 10.19 |

| Lupulone | 468-28-0 | / | n.d. | 41.34 | 60.22 |

| Limonin | 1180-71-8 | / | n.d. | 4.52 | 4.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rapinel, V.; Chemat, A.; Santerre, C.; Belay, J.; Hanaei, F.; Vallet, N.; Jacques, L.; Fabiano-Tixier, A.-S. 2-Methyloxolane as a Bio-Based Solvent for Green Extraction of Aromas from Hops (Humulus lupulus L.). Molecules 2020, 25, 1727. https://doi.org/10.3390/molecules25071727

Rapinel V, Chemat A, Santerre C, Belay J, Hanaei F, Vallet N, Jacques L, Fabiano-Tixier A-S. 2-Methyloxolane as a Bio-Based Solvent for Green Extraction of Aromas from Hops (Humulus lupulus L.). Molecules. 2020; 25(7):1727. https://doi.org/10.3390/molecules25071727

Chicago/Turabian StyleRapinel, Vincent, Aziadé Chemat, Cyrille Santerre, Justine Belay, Farnaz Hanaei, Nadine Vallet, Laurence Jacques, and Anne-Sylvie Fabiano-Tixier. 2020. "2-Methyloxolane as a Bio-Based Solvent for Green Extraction of Aromas from Hops (Humulus lupulus L.)" Molecules 25, no. 7: 1727. https://doi.org/10.3390/molecules25071727