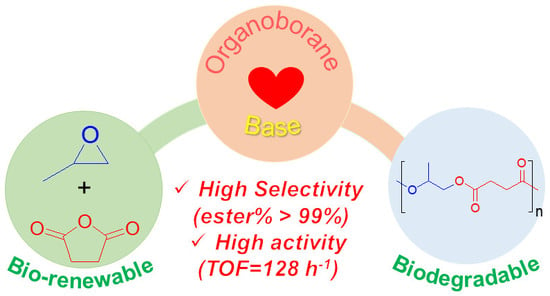

An Investigation of the Organoborane/Lewis Base Pairs on the Copolymerization of Propylene Oxide with Succinic Anhydride

Abstract

:1. Introduction

2. Results

3. Materials and Methods

3.1. Materials

3.2. Copolymerization of SA with PO, Experimental Details

3.3. Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human Consumption of Microplastics. Environ. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef] [Green Version]

- Allen, S.; Allen, D.; Phoenix, V.R.; Le Roux, G.; Jiménez, P.D.; Simonneau, A.; Binet, S.; Galop, D. Atmospheric transport and deposition of microplastics in a remote mountain catchment. Nat. Geosci. 2019, 12, 339–344. [Google Scholar] [CrossRef]

- Hillmyer, M.A.; Tolman, W.B. Aliphatic Polyester Block Polymers: Renewable, Degradable, and Sustainable. Acc. Chem. Res. 2014, 47, 2390–2396. [Google Scholar] [CrossRef] [PubMed]

- Hong, M.; Chen, E.Y. Towards Truly Sustainable Polymers: A Metal-Free Recyclable Polyester from Biorenewable Non-Strained γ-Butyrolactone. Angew. Chem. Int. Ed. 2016, 55, 4188–4193. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Hong, M.; Falivene, L.; Cavallo, L.; Chen, E.Y.-X. Closed-Loop Polymer Upcycling by Installing Property-Enhancing Comonomer Sequences and Recyclability. Macromolecules 2019, 52, 4570–4578. [Google Scholar] [CrossRef]

- Bechthold, I.; Bretz, K.; Kabasci, S.; Kopitzky, R.; Springer, A. Succinic Acid: A New Platform Chemical for Biobased Polymers from Renewable Resources. Chem. Eng. Technol. 2008, 31, 647–654. [Google Scholar] [CrossRef]

- Bikiaris, D.N.; Achilias, D.S. Synthesis of Poly(Alkylene Succinate) Biodegradable Polyesters I. Mathematical Modelling of the Esterification Reaction. Polymer 2006, 47, 4851–4860. [Google Scholar] [CrossRef]

- Paul, S.; Zhu, Y.; Saini, P.K.; Williams, C.K.; Romain, C.; Brooks, R. Ring-opening copolymerization (ROCOP): Synthesis and properties of polyesters and polycarbonates. Chem. Commun. 2015, 51, 6459–6479. [Google Scholar] [CrossRef] [Green Version]

- Longo, J.M.; Sanford, M.J.; Coates, G.W. Ring-Opening Copolymerization of Epoxides and Cyclic Anhydrides with Discrete Metal Complexes: Structure–Property Relationships. Chem. Rev. 2016, 116, 15167–15197. [Google Scholar] [CrossRef]

- Lanfang, H.; Zhang, X. Recent Progress in the Copolymerization of Cyclic Ethers and Cyclic Anhydrides Via Organocatalysts. J. Funct. Polym. 2019, 32, 259–270. [Google Scholar]

- Van Zee, N.J.; Coates, G.W. Alternating Copolymerization of Propylene Oxide with Biorenewable Terpene-Based Cyclic Anhydrides: A Sustainable Route to Aliphatic Polyesters with High Glass Transition Temperatures. Angew. Chem. Int. Ed. 2015, 54, 2665–2668. [Google Scholar] [CrossRef]

- Sanford, M.J.; Carrodeguas, L.P.; Van Zee, N.J.; Kleij, A.W.; Coates, G.W. Alternating Copolymerization of Propylene Oxide and Cyclohexene Oxide with Tricyclic Anhydrides: Access to Partially Renewable Aliphatic Polyesters with High Glass Transition Temperatures. Macromolecules 2016, 49, 6394–6400. [Google Scholar] [CrossRef]

- Carrodeguas, L.P.; Martín, C.; Kleij, A.W. Semiaromatic Polyesters Derived from Renewable Terpene Oxides with High Glass Transitions. Macromolecules 2017, 50, 5337–5345. [Google Scholar] [CrossRef]

- Robert, C.; De Montigny, F.; Thomas, C.M. Tandem synthesis of alternating polyesters from renewable resources. Nat. Commun. 2011. [Google Scholar] [CrossRef] [PubMed]

- Winkler, M.; Romain, C.; Meier, M.A.R.; Williams, C.K. Renewable polycarbonates and polyesters from 1,4-cyclohexadiene. Green Chem. 2015, 17, 300–306. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Zeikus, J.G.; Jain, M.K.; Elankovan, P. Biotechnology of succinic acid production and markets for derived industrial products. Appl. Microbiol. Biotechnol. 1999, 51, 545–552. [Google Scholar] [CrossRef]

- Longo, J.M.; DiCiccio, A.M.; Coates, G.W. Poly(propylene succinate): A New Polymer Stereocomplex. J. Am. Chem. Soc. 2014, 136, 15897–15900. [Google Scholar] [CrossRef] [Green Version]

- Suh, H.S.; Ha, J.Y.; Yoon, J.H.; Ha, C.-S.; Suh, H.; Kim, I. Polyester polyol synthesis by alternating copolymerization of propylene oxide with cyclic acid anhydrides by using double metal cyanide catalyst. React. Funct. Polym. 2010, 70, 288–293. [Google Scholar] [CrossRef]

- Takasu, A.; Bando, T.; Morimoto, Y.; Shibata, Y.; Hirabayashi, T. Asymmetric Epoxidation of α-Olefins Having Neighboring Sugar Chiral Templates and Alternating Copolymerization with Dicarboxylic Anhydrides. Biomacromolecules 2005, 6, 1707–1712. [Google Scholar] [CrossRef]

- DiCiccio, A.M.; Longo, J.M.; Rodríguez-Calero, G.G.; Coates, G.W. Development of Highly Active and Regioselective Catalysts for the Copolymerization of Epoxides with Cyclic Anhydrides: An Unanticipated Effect of Electronic Variation. J. Am. Chem. Soc. 2016, 138, 7107–7113. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Boopathi, S.K.; Hadjichristidis, N.; Gnanou, Y.; Feng, X. Metal-Free Alternating Copolymerization of CO2 with Epoxides: Fulfilling “Green” Synthesis and Activity. J. Am. Chem. Soc. 2016, 138, 11117–11120. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.-L.; Wu, H.-L.; Li, Y.; Zhang, X.-H.; Darensbourg, D.J. Perfectly Alternating and Regioselective Copolymerization of Carbonyl Sulfide and Epoxides by Metal-Free Lewis Pairs. Angew. Chem. 2017, 129, 5868–5873. [Google Scholar] [CrossRef]

- Zhang, C.-J.; Wu, H.-L.; Li, Y.; Yang, J.-L.; Zhang, X.-H. Precise synthesis of sulfur-containing polymers via cooperative dual organocatalysts with high activity. Nat. Commun. 2018. [Google Scholar] [CrossRef]

- Lin, B.; Waymouth, R.M. Urea Anions: Simple, Fast, and Selective Catalysts for Ring-Opening Polymerizations. J. Am. Chem. Soc. 2017, 139, 1645–1652. [Google Scholar] [CrossRef]

- Li, H.; Zhao, J.; Zhang, G. Self-Buffering Organocatalysis Tailoring Alternating Polyester. ACS Macro Lett. 2017, 6, 1094–1098. [Google Scholar] [CrossRef]

- Hu, L.-F.; Zhang, C.-J.; Wu, H.-L.; Yang, J.-L.; Liu, B.; Duan, H.-Y.; Zhang, X.-H. Highly Active Organic Lewis Pairs for the Copolymerization of Epoxides with Cyclic Anhydrides: Metal-Free Access to Well-Defined Aliphatic Polyesters. Macromolecules 2018, 51, 3126–3134. [Google Scholar] [CrossRef]

- Hošťálek, Z.; Trhlíková, O.; Walterová, Z.; Martinez, T.; Peruch, F.; Cramail, H.; Merna, J. Alternating copolymerization of epoxides with anhydrides initiated by organic bases. Eur. Polym. J. 2017, 88, 433–447. [Google Scholar] [CrossRef]

- Lin, L.; Liang, J.; Xu, Y.; Wang, S.; Xiao, M.; Sun, L.; Meng, Y. Fully alternating sustainable polyesters from epoxides and cyclic anhydrides: Economical and metal-free dual catalysis. Green Chem. 2019, 21, 2469–2477. [Google Scholar] [CrossRef]

- Kummari, A.; Pappuru, S.; Chakraborty, D.; Kanji, A. Fully alternating and regioselective ring-opening copolymerization of phthalic anhydride with epoxides using highly active metal-free Lewis pairs as a catalyst. Polym. Chem. 2018, 9, 4052–4062. [Google Scholar] [CrossRef]

- Ji, H.-Y.; Chen, X.-L.; Wang, B.; Pan, L.; Li, Y.-S. Metal-free, regioselective and stereoregular alternating copolymerization of monosubstituted epoxides and tricyclic anhydrides. Green Chem. 2018, 20, 3963–3973. [Google Scholar] [CrossRef]

- Zhang, C.-J.; Zhang, X.-H. Organocatalytic polymerization. Sci. China Ser. B Chem. 2019, 62, 1087–1089. [Google Scholar] [CrossRef]

- Luston, J.; Vass, F. Anionic Copolymerization of Cyclic Ethers with Cyclic Anhydrides. In Anionic Polymerization; Advances in Polymer Science; Springer: Berlin, Germany, 1984; Volume 56, pp. 91–133. [Google Scholar]

- Ji, H.-Y.; Wang, B.; Pan, L.; Li, Y.-S. Lewis Pairs for Ring-Opening Alternating Copolymerization of Cyclic Anhydrides and Epoxides. Green Chem. 2018, 20, 641–648. [Google Scholar] [CrossRef]

- Yang, J.-L.; Wang, H.-L.; Hu, L.-F.; Hong, X.; Zhang, X.-H. A double-site Lewis pair for highly active and living synthesis of sulfur-containing polymers. Polym. Chem. 2019, 10, 6555–6560. [Google Scholar] [CrossRef]

- Sivaev, I.B.; Bregadze, V.I. Lewis acidity of boron compounds. Coord. Chem. Rev. 2014, 270, 75–88. [Google Scholar] [CrossRef]

- Jiang, Y.; Hess, J.; Fox, T.; Berke, H. Rhenium Hydride/Boron Lewis Acid Cocatalysis of Alkene Hydrogenations: Activities Comparable to Those of Precious Metal Systems. J. Am. Chem. Soc. 2010, 132, 18233–18247. [Google Scholar] [CrossRef]

- Lin, B.; Waymouth, R.M. Organic Ring-Opening Polymerization Catalysts: Reactivity Control by Balancing Acidity. Macromolecules 2018, 51, 2932–2938. [Google Scholar] [CrossRef]

- Schwesinger, R.; Schlemper, H.; Hasenfratz, C.; Willaredt, J.; Dambacher, T.; Breuer, T.; Ottaway, C.; Fletschinger, M.; Boele, J.; Fritz, H.; et al. Extremely Strong, Uncharged Auxiliary Bases; Monomeric and Polymer-Supported Polyaminophosphazenes (P2–P5). Liebigs Annalen 1996, 1996, 1055–1081. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Liu, B.; Dong, X.; Kim, I.; Duan, Z.; Theato, P. Controllable Synthesis of Stereoregular Polyesters by Organocatalytic Alternating Copolymerizations of Cyclohexene Oxide and Norbornene Anhydrides. Macromolecules 2015, 48, 3431–3437. [Google Scholar] [CrossRef]

- Li, H.; He, G.; Chen, Y.; Zhao, J.; Zhang, G. One-Step Approach to Polyester–Polyether Block Copolymers Using Highly Tunable Bicomponent Catalyst. ACS Macro Lett. 2019, 8, 973–978. [Google Scholar] [CrossRef]

- Ji, H.-Y.; Wang, B.; Pan, L.; Li, Y.-S. One-Step Access to Sequence-Controlled Block Copolymers by Self-Switchable Organocatalytic Multicomponent Polymerization. Angew. Chem. Int. Ed. 2018, 57, 16888–16892. [Google Scholar] [CrossRef] [PubMed]

| Entry | LA | LB | Time (h) | SA Conv. (%) 2 | Ester (%) 2 | TOF (h−1) 3 | Mn (kg/mol) 4 | Đ4 |

|---|---|---|---|---|---|---|---|---|

| 1 | TEA | 48 | 55 | 86 | 1 | 3.5 | 1.20 | |

| 2 | TEB | TEA | 10 | 74 | 95 | 7 | 5.1 | 1.10 |

| 3 | TEEA | 48 | 62 | 93 | 1 | 3.0 | 1.22 | |

| 4 | TEB | TEEA | 10 | >99 | 97 | 10 | 6.4 | 1.15 |

| 5 | TBB | TEEA | 10 | 70 | 88 | 7 | 4.1 | 1.06 |

| 6 | TPB | TEEA | 10 | 48 | 85 | 5 | 3.3 | 1.12 |

| 7 | MDEB | TEEA | 10 | 92 | 94 | 9 | 5.0 | 1.11 |

| Entry | LB | [PO]:[SA]: [TEB]:]LB] | Time (h) | SA Conv. (%) 2 | Ester (%) 2 | TOF (h−1) 3 | Mn (kg/mol) 4 | Đ4 |

|---|---|---|---|---|---|---|---|---|

| 1 | t-BuP1 | 400:100:1:1 | 5 | 73 | >99 | 15 | 6.0 | 1.10 |

| 2 | t-BuP2 | 400:100:1:1 | 5 | 98 | 99 | 20 | 8.3 | 1.30 |

| 3 | DBU | 400:100:1:1 | 5 | 45 | 93 | 9 | 3.6 | 1.14 |

| 4 | MTBD | 400:100:1:1 | 5 | 57 | 98 | 11 | 4.2 | 1.13 |

| 5 5 | t-BuP1 | 400:100:4:1 | 0.5 | 64 | 96 | 128 | 1.7 | 1.24 |

| 6 6 | t-BuP1 | 400:200:1:1 | 84 | 98 | >99 | 1 | 20.4 | 1.42 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, L.-F.; Chen, D.-J.; Yang, J.-L.; Zhang, X.-H. An Investigation of the Organoborane/Lewis Base Pairs on the Copolymerization of Propylene Oxide with Succinic Anhydride. Molecules 2020, 25, 253. https://doi.org/10.3390/molecules25020253

Hu L-F, Chen D-J, Yang J-L, Zhang X-H. An Investigation of the Organoborane/Lewis Base Pairs on the Copolymerization of Propylene Oxide with Succinic Anhydride. Molecules. 2020; 25(2):253. https://doi.org/10.3390/molecules25020253

Chicago/Turabian StyleHu, Lan-Fang, Dan-Jing Chen, Jia-Liang Yang, and Xing-Hong Zhang. 2020. "An Investigation of the Organoborane/Lewis Base Pairs on the Copolymerization of Propylene Oxide with Succinic Anhydride" Molecules 25, no. 2: 253. https://doi.org/10.3390/molecules25020253