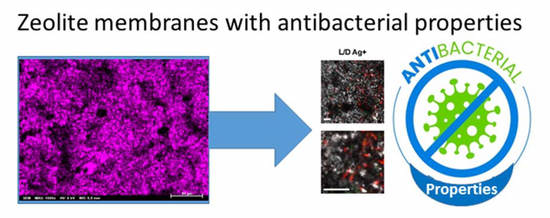

Synthesis of FAU-Type Zeolite Membranes with Antimicrobial Activity

Abstract

:1. Introduction

2. Results and Discussion

2.1. Hydrothermal Synthesis of FAU-Type Zeolite Membranes

2.2. Ion-Exchange

2.3. Antibacterial Activity of the Zeolitic Membrane

2.3.1. Inhibition through Diffusion

2.3.2. Impact on the Colony Forming Activity of a Bacterial Suspension

2.3.3. Live and Dead Bacteria Quantification on the Zeolite Surfaces

3. Materials and Methods

3.1. Materials and Reagents

3.2. Pretreatment of the Support

3.3. Hydrothermal Synthesis of FAU-Type Zeolite Membranes

3.4. Ion-Exchange

3.5. Agarose Diffusion Assay

3.6. Colony Forming Unit Assay

3.7. Live/Dead Assay

3.8. Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Striebel, C.H.; Hoffmann, K.; Marlow, F. The microcrystal prism method for refractive index measurements on zeolite-based nanocomposites. Microporous Mater. 1997, 9, 43–50. [Google Scholar] [CrossRef]

- Ferch, H. Zeolites and clay minerals as sorbents and molecular sieves. Von, R.M. Barrer. Academic Press, London—New York 1978. 1. Aufl., VII, 497 S., zahlr. Abb. u. Tab., Ln. Chem. Ing. Tech. 1980, 52, 366. [Google Scholar] [CrossRef]

- Jiraroj, D.; Tungasmita, S.; Tungasmita, D.N. Silver ions and silver nanoparticles in zeolite a composites for antibacterial activity. Powder Tech. 2014, 264, 418–422. [Google Scholar] [CrossRef]

- Saint-Cricq, P.; Kamimura, Y.; Itabashi, K.; Sugawara-Narutaki, A.; Shimojima, A.; Okudo, T. Antibacterial activity of silver-loaded “green zeolites”. Eur. J. Inorg. Chem. 2012, 21, 3398–3402. [Google Scholar] [CrossRef]

- Lalueza, P.; Monzon, M.; Arruebo, M.; Santamaria, J. Antibacterial action of Ag-containing MFI zeolite at low Ag loadings. J. Chem. Com. 2011, 47, 680–682. [Google Scholar] [CrossRef]

- Tosheva, L.; Belkhair, S.; Gackowski, M.; Malica, S.; Al-Shanti, N.; Verran, J. Rapid screening of the antimicrobial efficacy of Ag zeolites. J. Coll. Surf. B 2017, 157, 254–260. [Google Scholar] [CrossRef]

- Jędrzejczyk, R.J.; Turnau, K.; Jodłowski, P.J.; Chlebda, D.K.; Łojewski, T.; Łojewska, J. Antimicrobial properties of silver cations substitutedto faujasite mineral. Nanomaterials 2017, 7, 240. [Google Scholar] [CrossRef] [Green Version]

- Bedi, R.S.; Cai, R.; O’Neill, C.; Beving, D.E.; Foster, S.; Guthrie, S.; Chen, W.; Yan, Y. Hydrophilic and antimicrobial Ag-exchanged zeolite a coatings: A year-longdurability study and preliminary evidence for their general microbiocidal efficacyto bacteria, fungus and yeast. Microporous Mesoporous Mater. 2012, 151, 352–357. [Google Scholar] [CrossRef]

- Milenkovic, J.; Hrenovic, J.; Matijasevic, D.; Niksic, M.; Rajic, N. Bactericidal Activity of Cu-, Zn-, and Ag-containing zeolites toward escherichia coli isolates. Environ. Sci. Pollut. Res. 2017, 24, 20273–20281. [Google Scholar] [CrossRef]

- Cho, C.H.; Oh, K.Y.; Kim, S.K.; Yeo, J.G.; Sharma, P. Pervaporative seawater desalination using NaA zeolite membrane: Mechanisms of high water flux and high salt rejection. J. Membr. Sci. 2011, 371, 226–238. [Google Scholar] [CrossRef]

- Duke, M.C.; O’Brien-Abraham, J.; Milne, N.; Zhu, B.; Lin, J.Y.S.; Diniz da Costa, J.C. Seawater desalination performance of MFI type membranes made by secondary growth. Sep. Purif. Technol. 2009, 68, 343–350. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, M.; Mao, Q.; Yue, J.; Wang, X. Novel NaY zeolite-supported nanoscale zero-valent iron as an efficient heterogeneous Fenton catalyst. Catal. Commun. 2010, 11, 937–941. [Google Scholar] [CrossRef]

- McLeary, E.E.; Jansen, J.C.; Kapteijn, F. Zeolite based films, membranes and membrane reactors: Progress and prospects. Microporous Mesoporous Mater. 2006, 90, 198–220. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H.; Mitra, A.; Huang, L.; Yan, Y. 20-P-11 Pure-silica zeolite low-k dielectric thin films by spin-on process. In Studies in Surface Science and Catalysis; Elsevier: Montpellier, France, 2001; Volume 135, p. 292. [Google Scholar]

- Caro, J.; Noack, M. Zeolite membranes—Recent developments and progress. Microporous Mesoporous Mater. 2008, 115, 215–233. [Google Scholar] [CrossRef]

- Yu, L.; Korelskiy, D.; Grahn, M.; Hedlund, J. Very high flux MFI membranes for alcohol recovery via pervaporation at high temperature and pressure. Sep. Purif. Technol. 2015, 153, 138–145. [Google Scholar] [CrossRef]

- Lai, Z.; Bonilla, G.; Diaz, I.; Nery, J.G.; Sujaoti, K.; Amat, M.A.; Kokkoli, E.; Terasaki, O.; Thompson, R.W.; Tsapatsis, M.; et al. Microstructural optimization of a zeolite membrane for organic vapor separation. Science 2003, 300, 456–460. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Y.; Huang, A.; Caro, J. Hydrophilic SOD and LTA membranes for membrane-supported methanol, dimethylether and dimethylcarbonate synthesis. Microporous Mesoporous Mater. 2015, 207, 33–38. [Google Scholar] [CrossRef]

- Covarrubias, C.; García, R.; Yánez, J.; Arriagada, R. Preparation of CPB-modified FAU zeolite for the removal of tannery wastewater contaminants. J. Porous Mater. 2008, 15, 491–498. [Google Scholar] [CrossRef]

- Zhu, G.; Li, Y.; Chen, H.; Liu, J.; Yang, W. An in situ approach to synthesize pure phase FAU-type zeolite membranes: Effect of aging and formation mechanism. J. Mater. Sci. 2008, 43, 3279–3288. [Google Scholar] [CrossRef]

- Dhainaut, J.; Daou, T.J.; Chappaz, A.; Bats, N.; Harbuzaru, B.; Lapisardi, G.; Chaumeil, H.; Defoin, A.; Rouleau, L.; Patarin, J. Synthesis of FAU and EMT-type zeolites using structure-directing agents specifically designed by molecular modelling. Microporous Mesoporous Mater. 2013, 174, 117–125. [Google Scholar] [CrossRef]

- Gascon, J.; Kapteijn, F.; Zornoza, B.; Sebastián, V.; Casado, C.; Coronas, J. Practical Approach to Zeolitic Membranes and Coatings: State of the Art, Opportunities, Barriers, and Future Perspectives. Chem. Mater. 2012, 24, 2829–2844. [Google Scholar] [CrossRef]

- Shan, L.; Shao, J.; Wang, Z.; Yan, Y. Preparation of zeolite MFI membranes on alumina hollow fibers with high flux for pervaporation. J. Membr. Sci. 2011, 378, 319–329. [Google Scholar] [CrossRef]

- Said, A.; Nouali, H.; Limousy, L.; Dutournié, P.; Josien, L.; Toufaily, J.; Hamieh, T.; Daou, T.J. Synthesis of mono- and bi-layer zeolite films on alumina substrates. C. R. Chim. 2016, 19, 486–495. [Google Scholar] [CrossRef] [Green Version]

- Nikolakis, V.; Xomeritakis, G.; Abibi, A.; Dickson, M.; Tsapatsis, M.; Vlachos, D.G. Growth of a faujasite-type zeolite membrane and its application in the separation of saturated/unsaturated hydrocarbon mixtures. J. Membr. Sci. 2001, 184, 209–219. [Google Scholar] [CrossRef]

- Lassinantti, M.; Hedlund, J.; Sterte, J. Faujasite-type films synthesized by seeding. Microporous Mesoporous Mater. 2000, 38, 25–34. [Google Scholar] [CrossRef]

- Kita, H.; Fuchida, K.; Horita, T.; Asamura, H.; Okamoto, K. Preparation of faujasite membranes and their permeation properties. Sep. Purif. Technol. 2001, 25, 261–268. [Google Scholar] [CrossRef]

- Huang, A.; Wang, N.; Caro, J. Seeding-free synthesis of dense zeolite FAU membranes on 3-aminopropyltriethoxysilane-functionalized alumina supports. J. Membr. Sci. 2012, 389, 272–279. [Google Scholar] [CrossRef]

- Huang, A.; Wang, N.; Caro, J. Stepwise synthesis of sandwich-structured composite zeolite membranes with enhanced separation selectivity. Chem. Commun. 2012, 48, 3542–3544. [Google Scholar] [CrossRef] [Green Version]

- Zhou, C.; Zhou, J.; Huang, A. Seeding-free synthesis of zeolite FAU membrane for seawater desalination by pervaporation. Microporous Mesoporous Mater. 2016, 234, 377–383. [Google Scholar] [CrossRef]

- Zhou, C.; Yuan, C.; Zhu, Y.; Caro, J.; Huang, A. Facile synthesis of zeolite FAU molecular sieve membranes on bio-adhesive polydopamine modified Al2O3 tubes. J. Membr. Sci. 2015, 494, 174–181. [Google Scholar] [CrossRef]

- Borel, M.; Dodin, M.; Daou, T.J.; Bats, N.; Harbuzaru, B.; Patarin, J. SDA-free hydrothermal synthesis of high-silica ultra-nanosized zeolite Y. Cryst. Growth Des. 2017, 17, 1173–1179. [Google Scholar] [CrossRef]

- Tahraoui, Z.; Nouali, H.; Marichal, C.; Forler, P.; Klain, J.; Daou, T.J. Influence of the compensating cation nature on the water adsorption properties of zeolites. Molecules 2020, 25, 944. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Borel, M.; Dodin, M.; Daou, T.J.; Bats, N.; Patarin, J. Formation domain of SDA-free Y faujasite small crystals. New J. Chem. 2017, 41, 13260–13267. [Google Scholar] [CrossRef]

- Said, A.; Limousy, L.; Nouali, H.; Michelin, L.; Halawani, J.; Toufaily, J.; Hamieh, T.; Dutournié, P.; Daou, T.J. Synthesis of mono- and bi-layer MFI zeolite films on macroporous alumina tubular supports: Application to nanofiltration. J. Cryst. Growth 2015, 428, 71–79. [Google Scholar] [CrossRef]

- Boultif, A.; Louër, D.J. Indexing of powder diffraction patterns for low-symmetry lattices by the successive dichotomy method. Appl. Crystallogr. 1991, 24, 987–993. [Google Scholar] [CrossRef]

- Breck, D.W.; Flanigen, E.M. Molecular Sieves; Barrer, R.M., Ed.; The Society of Chemical Industry: London, UK, 1968; p. 47. [Google Scholar]

- Lauridant, N.; Daou, T.J.; Arnold, G.; Soulard, M.; Nouali, H.; Patarin, J.; Faye, D. Key steps influencing the formation of ZSM-5 films on aluminum substrates. Microporous Mesoporous Mater. 2012, 152, 1–8. [Google Scholar] [CrossRef]

- Lauridant, N.; Daou, T.J.; Arnold, G.; Nouali, H.; Patarin, J.; Faye, D. Zeolite hybrid films for space decontamination. Microporous Mesoporous Mater. 2013, 172, 36–43. [Google Scholar] [CrossRef]

- Daou, T.J.; Lauridant, N.; Arnold, G.; Josien, L.; Faye, D.; Patarin, J. Synthesis of MFI/EMT zeolite bi-layer films for molecular decontamination. Chem. Eng. J. 2013, 234, 66–73. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Mosca, A.; Öhrman, O.; Hedlund, J.; Perdana, I.; Creaser, D. NO2 and N2 sorption in MFI films with varying Si/Al and Na/Al ratios. Microporous Mesoporous Mater. 2009, 120, 195–205. [Google Scholar] [CrossRef]

- Song, H.; Jiang, B.-L.; Song, H.-L.; Jin, Z.-S.; Sun, X.-L. Preparation of AgY zeolite and study on its adsorption equilibrium and kinetics. Res. Chem. Intermed. 2015, 41, 3837–3854. [Google Scholar] [CrossRef]

- Xu, K.; Yuan, C.; Caro, J.; Huang, A. Silver-exchanged zeolite LTA molecular sieving membranes with enhanced hydrogen selectivity. J. Membr. Sci. 2016, 511, 1–8. [Google Scholar] [CrossRef]

- Henao-Sierra, W.; Romero-Sáez, M.; Gracia, F.; Cacua, K.; Buitrago-Sierra, R. Water vapor adsorption performance of Ag and Ni modified 5A zeolite. Microporous Mesoporous Mater. 2018, 265, 250–257. [Google Scholar] [CrossRef]

- Golbad, S.; Khoshnoud, P.; Abu-Zahra, N. Synthesis of 4A Zeolite and Characterization of Calcium- and Silver-Exchanged Forms. J. Miner. Mater. Charact. Eng. 2017, 5, 237–251. [Google Scholar] [CrossRef] [Green Version]

- Price, L.; Leung, K.M.; Sartbaeva, A. Local and Average Structural Changes in Zeolite A upon Ion Exchange. Magnetochemistry 2017, 3, 42. [Google Scholar] [CrossRef] [Green Version]

- Chandwadkar, A.J.; Chandwadkar, J.G.; Kulkarni, S.B. The influence of the size and concentration of alkaline earth ions on the structural and sorption properties of faujasites. J. Colloid Interface Sci. 1984, 97, 435–445. [Google Scholar] [CrossRef]

- Zhu, G.; Li, Y.; Zhou, H.; Liu, J.; Yang, W. FAU-type zeolite membranes synthesized by microwave assisted in situ crystallization. Mater. Lett. 2008, 62, 4357–4359. [Google Scholar] [CrossRef]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| Zeolite-Type | Adsorbed Volume a (cm3/gsample STP) | Vmicro b Zeolite Layer (cm3/gsample) | Zeolite Weight on Support c (mg) |

|---|---|---|---|

| FAU | 1.04 | 1.6 × 10−3 | ~22.9 |

| Chemical Component | Mass Fraction (%) |

|---|---|

| Al2O3 | 98.63 |

| ZrO2 | 0.64 |

| SiO2 | 0.30 |

| CaO | 0.12 |

| Fe2O3 | 0.09 |

| K2O | 0.06 |

| Na2O | 0.05 |

| Others | <0.01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daou, T.J.; Dos Santos, T.; Nouali, H.; Josien, L.; Michelin, L.; Pieuchot, L.; Dutournie, P. Synthesis of FAU-Type Zeolite Membranes with Antimicrobial Activity. Molecules 2020, 25, 3414. https://doi.org/10.3390/molecules25153414

Daou TJ, Dos Santos T, Nouali H, Josien L, Michelin L, Pieuchot L, Dutournie P. Synthesis of FAU-Type Zeolite Membranes with Antimicrobial Activity. Molecules. 2020; 25(15):3414. https://doi.org/10.3390/molecules25153414

Chicago/Turabian StyleDaou, T. Jean, Thomas Dos Santos, Habiba Nouali, Ludovic Josien, Laure Michelin, Laurent Pieuchot, and Patrick Dutournie. 2020. "Synthesis of FAU-Type Zeolite Membranes with Antimicrobial Activity" Molecules 25, no. 15: 3414. https://doi.org/10.3390/molecules25153414