Key-Marker Volatile Compounds in Aromatic Rice (Oryza sativa) Grains: An HS-SPME Extraction Method Combined with GC×GC-TOFMS

Abstract

:1. Introduction

2. Results and Discussion

2.1. Volatile Compounds from Indonesian Rice

2.2. Optimisation of HS-SPME for the Key-Markers in Aromatic Rice

2.3. Method Validation of HS-SPME GC×GC-TOFMS

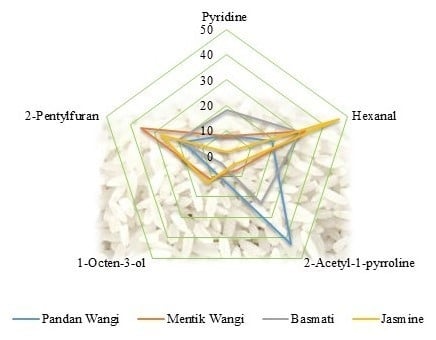

2.4. Real Rice Samples Application of HS-SPME

3. Materials and Methods

3.1. Chemicals and Reagents

3.2. Natural Source of 2-Acetyl-1-Pyrroline

3.3. Rice Grains and Sample Preparation

3.4. Headspace Solid-Phase Microextraction (HS-SPME)

3.5. GC×GC-TOFMS Analysis

3.6. Experimental Design and Optimisation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- FAOSTAT Food and Agricultural Commodities Production: Countries by Commodity (Rice, Paddy). Available online: http://faostat3.fao.org/browse/rankings/countries_by_commodity/E (accessed on 15 July 2015).

- Mishra, A.; Kumar, P.; Shamim, M.; Tiwari, K.K.; Fatima, P.; Srivastava, D.; Singh, R.; Yadav, P. Genetic diversity and population structure analysis of Asian and African aromatic rice (Oryza sativa L.) genotypes. J. Genet. 2019, 98, 92. [Google Scholar] [CrossRef] [PubMed]

- Ghiasvand, A.R.; Setkova, L.; Pawliszyn, J. Determination of flavour profile in Iranian fragrant rice samples using cold-fibre SPME–GC–TOF–MS. Flavour Fragr. J. 2007, 22, 377–391. [Google Scholar] [CrossRef]

- Shan, Q.; Zhang, Y.; Chen, K.; Zhang, K.; Gao, C. Creation of fragrant rice by targeted knockout of the OsBADH2 gene using TALEN technology. Plant Biotechnol. J. 2015, 13, 791–800. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Huang, M.; Crane, J.H.; Wang, Y. Characterization of key aroma-active compounds in lychee (Litchi chinensis Sonn.). J. food drug Anal. 2018, 26, 497–503. [Google Scholar] [CrossRef] [PubMed]

- Lim, D.K.; Mo, C.; Lee, J.H.; Long, N.P.; Dong, Z.; Li, J.; Lim, J.; Kwon, S.W. The integration of multi-platform MS-based metabolomics and multivariate analysis for the geographical origin discrimination of Oryza sativa L. J. Food Drug Anal. 2018, 26, 769–777. [Google Scholar] [CrossRef] [PubMed]

- Buttery, R.G.; Ling, L.C.; Juliano, B.O.; Turnbaugh, J.G. Cooked rice aroma and 2-acetyl-1-pyrroline. J. Agric. Food Chem. 1983, 31, 823–826. [Google Scholar] [CrossRef]

- Gay, F.; Maraval, I.; Roques, S.; Gunata, Z.; Boulanger, R.; Audebert, A.; Mestres, C. Effect of salinity on yield and 2-acetyl-1-pyrroline content in the grains of three fragrant rice cultivars (Oryza sativa L.) in Camargue (France). F. Crop. Res. 2010, 117, 154–160. [Google Scholar] [CrossRef]

- Maraval, I.; Sen, K.; Agrebi, A.; Menut, C.; Morere, A.; Boulanger, R.; Gay, F.; Mestres, C.; Gunata, Z. Quantification of 2-acetyl-1-pyrroline in rice by stable isotope dilution assay through headspace solid-phase microextraction coupled to gas chromatography-tandem mass spectrometry. Anal. Chim. Acta 2010, 675, 148–155. [Google Scholar] [CrossRef]

- Yahya, F.; Fryer, P.J.; Bakalis, S. The absorption of 2-acetyl-1-pyrroline during cooking of rice (Oryza sativa L.) with Pandan (Pandanus amaryllifolius Roxb.) leaves). Procedia Food Sci. 2011, 1, 722–728. [Google Scholar] [CrossRef]

- Grimm, C.C.; Bergman, C.; Delgado, J.T.; Bryant, R. Screening for 2-acetyl-1-pyrroline in the headspace of rice using SPME/GC-MS. J. Agric. Food Chem. 2001, 49, 245–249. [Google Scholar] [CrossRef]

- Mahatheeranont, S.; Keawsa-ard, S.; Dumri, K. Quantification of the rice aroma compound, 2-acetyl-1-pyrroline, in uncooked Khao Dawk Mali 105 brown rice. J. Agric. Food Chem. 2001, 49, 773–779. [Google Scholar] [CrossRef] [PubMed]

- Laohakunjit, N.; Kerdchoechuen, O. Aroma enrichment and the change during storage of non-aromatic milled rice coated with extracted natural flavor. Food Chem. 2006, 101, 339–344. [Google Scholar] [CrossRef]

- Ghiasvand, A.; Nasirian, A.; Koonani, S.; Nouriasl, K. A platinized stainless steel fiber with in-situ coated polyaniline/polypyrrole/graphene oxide nanocomposite sorbent for headspace solid-phase microextraction of aliphatic aldehydes in rice samples. Biomed. Chromatogr. 2017, 31, e4024. [Google Scholar] [CrossRef] [PubMed]

- Dymerski, T.; Chmiel, T.; Mostafa, A.; Sliwinska, M.; Wisniewska, P.; Wardencki, W.; Namiesnik, J.; Gorecki, T. Botanical and Geographical Origin Characterization of Polish Honeys by Headspace SPME-GC× GC-TOFMS. Curr. Org. Chem. 2013, 17, 853–870. [Google Scholar] [CrossRef]

- Abdulra’uf, L.B.; Tan, G.H. Chemometric approach to the optimization of HS-SPME/GC–MS for the determination of multiclass pesticide residues in fruits and vegetables. Food Chem. 2015, 177, 267–273. [Google Scholar] [CrossRef]

- Lim, D.K.; Mo, C.; Lee, D.-K.; Long, N.P.; Lim, J.; Kwon, S.W. Non-destructive profiling of volatile organic compounds using HS-SPME/GC-MS and its application for the geographical discrimination of white rice. J. Food Drug Anal. 2018, 26, 260–267. [Google Scholar] [CrossRef]

- Tankiewicz, M.; Morrison, C.; Biziuk, M. Application and optimization of headspace solid-phase microextraction (HS-SPME) coupled with gas chromatography-flame-ionization detector (GC-FID) to determine products of the petroleum industry in aqueous samples. Microchem. J. 2013, 108, 117–123. [Google Scholar] [CrossRef]

- Bianchin, J.N.; Nardini, G.; Merib, J.; Dias, A.N.; Martendal, E.; Carasek, E. Screening of volatile compounds in honey using a new sampling strategy combining multiple extraction temperatures in a single assay by HS-SPME-GC-MS. Food Chem. 2014, 145, 1061–1065. [Google Scholar] [CrossRef]

- Griglione, A.; Liberto, E.; Cordero, C.; Bressanello, D.; Cagliero, C.; Rubiolo, P.; Bicchi, C.; Sgorbini, B. High-quality Italian rice cultivars: Chemical indices of ageing and aroma quality. Food Chem. 2015, 172, 305–313. [Google Scholar] [CrossRef]

- Grimm, C.C.; Champagne, E.T.; Ohtsubo, K. Analysis of Volatile Compounds in the Headspace of Rice Using SPME/GC/MS. In Flavor, Fragrance, and Odor Analysis; Marsili, R., Ed.; CRC Press: New York, NY, USA, 2002; pp. 229–248. ISBN 0203908279. [Google Scholar]

- Lin, J.-Y.; Fan, W.; Gao, Y.-N.; Wu, S.-F.; Wang, S.-X. Study on volatile compounds in rice by HS-SPME and GC-MS. In Proceedings of the 10th International Working Conference on Stored Product Protection, Estoril, Portugal, 27 June–2 July 2010; pp. 125–134. [Google Scholar] [CrossRef]

- Weber, D.J.; Rohilla, R.; Singh, U.S. Chemistry and Biochemistry of Aroma in Scented Rice. In Aromatic Rices; Singh, R.K., Singh, U.S., Khush, G.S., Eds.; Oxford & IBH Publishing Co. Pvt. Ltd.: New Delhi, India, 2000; p. 300. ISBN 8120414209. [Google Scholar]

- Bryant, R.J.; McClung, A.M. Volatile profiles of aromatic and non-aromatic rice cultivars using SPME/GC–MS. Food Chem. 2011, 124, 501–513. [Google Scholar] [CrossRef]

- Buttery, R.G.; Turnbaugh, J.G.; Ling, L.C. Contribution of Volatiles to Rice Aroma. J. Agric. Food Chem. 1988, 36, 1006–1009. [Google Scholar] [CrossRef]

- Piyachaiseth, T.; Jirapakkul, W.; Chaiseri, S. Aroma Compounds of Flash-Fried Rice. Nat. Sci. 2011, 45, 717–729. [Google Scholar]

- Cho, S.; Nuijten, E.; Shewfelt, R.L.; Kays, S.J. Aroma chemistry of African Oryza glaberrima and Oryza sativa rice and their interspecific hybrids. J. Sci. Food Agric. 2014, 94, 727–735. [Google Scholar] [CrossRef] [PubMed]

- Nadaf, A.B.; Wakte, K.V.; Thengane, R.J.; Jawali, N. Review on Pandanus amaryllifolius Roxb.: The Plant with Rich Source of Principle Basmati Aroma Compound 2 Acetyl-1-Pyrroline. J. Biotechnol. 2008, 2, 61. [Google Scholar]

- Calingacion, M.; Fang, L.; Quiatchon-Baeza, L.; Mumm, R.; Riedel, A.; Hall, R.D.; Fitzgerald, M. Delving deeper into technological innovations to understand differences in rice quality. Rice 2015, 8, 43. [Google Scholar] [CrossRef] [PubMed]

- Givianrad, M.H. Characterization and assessment of flavor compounds and some allergens in three Iranian rice cultivars during gelatinization process by HS-SPME/GC-MS. E-Journal Chem. 2012, 9, 716–728. [Google Scholar] [CrossRef]

- Mahattanatawee, K.; Rouseff, R.L. Comparison of aroma active and sulfur volatiles in three fragrant rice cultivars using GC-Olfactometry and GC-PFPD. Food Chem. 2014, 154, 1–6. [Google Scholar] [CrossRef]

- Setyaningsih, W.; Saputro, I.E.; Palma, M.; Barroso, C.G. Optimisation and validation of the microwave-assisted extraction of phenolic compounds from rice grains. Food Chem. 2015, 169, 141–149. [Google Scholar] [CrossRef]

- Setyaningsih, W.; Saputro, I.E.; Palma, M.; Barroso, C.G. Pressurized liquid extraction of phenolic compounds from rice (Oryza sativa) grains. Food Chem. 2016, 192, 452–459. [Google Scholar] [CrossRef]

- Lloyd, S.W.; Grimm, C.C. Flavor Profiles of Aromatic and non-Aromatic Rice Varieties. In Proceedings of the PITTCON Conference and Expo 2010; Pittsburgh Conference, Orlando, FL, USA, 28 February–5 March 2010. [Google Scholar]

- Lee, G.W.; Lee, S.; Chung, M.-S.; Jeong, Y.S.; Chung, B.Y. Rice terpene synthase 20 (OsTPS20) plays an important role in producing terpene volatiles in response to abiotic stresses. Protoplasma 2014, 20, 997–1007. [Google Scholar] [CrossRef]

- Mathure, S.V.; Jawali, N.; Thengane, R.J.; Nadaf, A.B. Comparative quantitative analysis of headspace volatiles and their association with BADH2 marker in non-basmati scented, basmati and non-scented rice (Oryza sativa L.) cultivars of India. Food Chem. 2014, 142, 383–391. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.S.; Lee, K.-S.; Kays, S.J. Characterization and discrimination of premium-quality, waxy, and black-pigmented rice based on odor-active compounds. J. Sci. Food Agric. 2010, 90, 2595–2601. [Google Scholar] [CrossRef] [PubMed]

- Maraval, I.; Mestres, C.; Pernin, K.; Ribeyre, F.; Boulanger, R.; Guichard, E.; Gunata, Z. Odor-active compounds in cooked rice cultivars from Camargue (France) analyzed by GC-O and GC-MS. J. Agric. Food Chem. 2008, 56, 5291–5298. [Google Scholar] [CrossRef] [PubMed]

- Widjaja, R.; Craske, J.D.; Wootton, M. Comparative studies on volatile components of non-fragrant and fragrant rices. J. Sci. Food Agric. 1996, 70, 151–161. [Google Scholar] [CrossRef]

- Jezussek, M.; Juliano, B.O.; Schieberle, P. Comparison of key aroma compounds in cooked brown rice varieties based on aroma extract dilution analyses. J. Agric. Food Chem. 2002, 50, 1101–1105. [Google Scholar] [CrossRef] [PubMed]

- Cao, P.; Liu, C.; Liu, K. Aromatic constituents in fresh leaves of Lingtou Dancong tea induced by drought stress. Front. Agric. China 2007, 1, 81–84. [Google Scholar] [CrossRef]

- Karki, S.; Rizal, G.; Quick, W.P. Improvement of photosynthesis in rice (Oryza sativa L.) by inserting the C4 pathway. Rice 2013, 6, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Setyaningsih, W.; Hidayah, N.; Saputro, I.E.; Palma, M.; García Barroso, C. Profile of phenolic compounds in Indonesian rice (Oryza sativa) varieties throughout post-harvest practices. J. Food Compos. Anal. 2016, 54, 55–62. [Google Scholar] [CrossRef]

- ISO/IEC 17025:2017 General Requirements for the Competence of Testing and Calibration Laboratories. Available online: http://faostat3.fao.org/browse/rankings/countries_by_commodity/E (accessed on 15 November 2017).

- ICH Topic Q2 (R1) Validation of Analytical Procedures: Text and Methodology. 2005. Available online: https://database.ich.org/sites/default/files/Q2_R1__Guideline.pdf (accessed on 15 November 2005).

- Zakiyah, N.M.; Handoyo, T.; Kim, K.M. Genetic Diversity Analysis of Indonesian Aromatic Rice Varieties (Oryza sativa L.) Using RAPD. J. Crop. Sci. Biotechnol. 2019, 22, 55–63. [Google Scholar] [CrossRef]

- Giraud, G. The World Market of Fragrant Rice, Main Issues and Perspectives. Int. Food Agribus. Manag. Rev. 2013, 16, 1–20. [Google Scholar]

- Funsueb, S.; Krongchai, C.; Mahatheeranont, S.; Kittiwachana, S. Prediction of 2-acetyl-1-pyrroline content in grains of Thai Jasmine rice based on planting condition, plant growth and yield component data using chemometrics. Chemom. Intell. Lab. Syst. 2016, 156, 203–210. [Google Scholar] [CrossRef]

- Wakte, K.V.; Thengane, R.J.; Jawali, N.; Nadaf, A.B. Optimization of HS-SPME conditions for quantification of 2-acetyl-1-pyrroline and study of other volatiles in Pandanus amaryllifolius Roxb. Food Chem. 2010, 121, 595–600. [Google Scholar] [CrossRef]

Sample Availability: Samples are not available from the authors. |

| No | Compounds | Retention Time (s) | Mass 3 | References | Odour Strength 4 | Odour Description 4 | |

|---|---|---|---|---|---|---|---|

| 1D 1 | 2D 2 | ||||||

| 1 | Pentanal C1 | 435 | 2.11 | 58 | [20,21,22,23,24,25] | High, 1% | Bready; fruity; nutty; berry |

| 2 | Acetic acid | 455 | 4.41 | 60 | [21,22,26] | High, 10% | Pungent; sour; vinegar |

| 3 | 2-Methylfuran C2 | 495 | 2.59 | 53 | [22] | Medium, 1% | Ethereal; acetone; chocolate |

| 4 | Pyridine C3 | 505 | 2.60 | 79 | [21,23,25,27] | Very high, 0.01% | Sour; putrid; fishy; amine |

| 5 | 1-Pentanol C4 | 520 | 2.47 | 42 | [12,21,23,25] | High, 10% | Pungent; fermented; bread; yeasty; fusel; winey |

| 6 | Toluene C5 | 525 | 2.14 | 91 | [21,22,23] | Sweet | |

| 7 | 2-Hexanone | 540 | 2.16 | 43 | [23,28] | High, 1% | Fruity; fungal; meaty; buttery |

| 8 | Hexanal C6 | 550 | 2.17 | 56 | [12,20,21,22,23,24,25,26,27,29,30,31] | High, 1% | Fresh; green; fatty; grass; leafy; fruity; sweaty |

| 9 | Furfural C7 | 585 | 3.38 | 95 | [23,25,26,27,32,33] | Medium, 1% | Sweet; woody; almond; fragrant baked; bread |

| 10 | 2-Methylpyridine | 590 | 2.45 | 93 | [23,27] | Astringent; hazelnut | |

| 11 | 1,3-Octadiene * | 600 | 1.99 | 54 | |||

| 12 | 1-Hexanol C8 | 645 | 2.45 | 56 | [12,23,29] | Medium, 10% | Pungent; ethereal; fusel; oil; fruity; alcoholic; sweet with a green top note |

| 13 | 1,3-Dimethylbenzene | 655 | 2.14 | 91 | [12,23,29] | Fried; medicine; nut; plastic; rancid | |

| 14 | 2-Heptanone C9 | 665 | 2.18 | 58 | [20,21,22,23,26,27,29] | High, 10% | Cheesy; fruity; spicy; sweet; herbal; coconut; woody |

| 15 | 2-Butylfuran C10 | 680 | 2.09 | 81 | [21,23,29,30] | Medium | Mild; fruity; wine; sweet; spicy |

| 16 | Heptanal C11 | 680 | 2.17 | 70 | [20,21,22,23,24,25,26,27,29] | High, 1% | Fresh; fatty; green; herbal |

| 17 | Styrene | 680 | 2.30 | 104 | [21,26,27] | ||

| 18 | 1,2-Dimethylbenzene C12 | 685 | 2.18 | 91 | [12,21] | Geranium | |

| 19 | 2-Acetyl-1-pyrroline C13 | 700 | 2.45 | 43 | [12,20,21,23,24,25,30,31,34] | Medium, 1% | Popcorn; toasted; grain; malty |

| 20 | 2-Methyl-5-isopropenylfuran C14 | 730 | 2.18 | 122 | [22] | Medium | Sweet; spearmint; herbal |

| 21 | (Z)-2-heptenal C15 | 750 | 2.32 | 41 | [20,22,23,29] | High, 1% | Pungent; green; vegetable; fresh; fatty |

| 22 | Benzaldehyde C16 | 750 | 2.98 | 105 | [20,21,23,25,26,27,29,30] | High, 10% | Bitter; almond; burnt sugar; cherry; malt; roasted pepper |

| 23 | 1-Ethyl-4-methylbenzene | 775 | 2.14 | 105 | [21,23] | ||

| 24 | 1-Heptanol C17 | 775 | 2.39 | 70 | [12,22,27,30] | Medium, 10% | Musty; leafy; herbal; green; sweet; woody |

| 25 | Benzonitrile | 775 | 3.27 | 103 | [29] | ||

| 26 | 1-Octen-3-ol C19 | 785 | 2.43 | 57 | [20,22,23,24,25,27,30,31] | High, 10% | Earthy; green; oily; vegetative; fungal |

| 27 | 6-Methyl-5-hepten-2-one C18 | 785 | 2.26 | 43 | [20,21,23,24,25] | Medium, 10% | Citrus; green; musty; lemongrass |

| 28 | Phenol C20 | 790 | 2.99 | 66 | [12,23,26,29] | High, 0.01% | Phenolic |

| 29 | 2-Octanone C21 | 795 | 2.18 | 58 | [22,23,25] | Med, 10% | Earthy; weedy; natural; woody |

| 30 | 2,4,6-Trimethylpyridine ** | 800 | 2.30 | 121 | |||

| 31 | 2-Pentylfuran C22 | 805 | 2.09 | 81 | [20,21,22,23,24,27,29,30] | High, 10% | Fruity, green, earthy beany with vegetable-like nuances |

| 32 | α-Myrcene C23 | 810 | 2.02 | 93 | [35] | Med, 5% | Peppery; terpene; spicy; balsam |

| 33 | Octanal C24 | 810 | 2.17 | 43 | [20,21,22,23,24,25,27,29,30,31] | High, 1% | Waxy; citrus; orange peel; fatty |

| 34 | 1,2,3-Trimethylbenzene | 815 | 2.18 | 105 | [22,23] | Pesticide | |

| 35 | α-Phellandrene | 835 | 2.03 | 93 | [29] | Med, 5% | Citrus; herbal; terpene; green; woody; peppery |

| 36 | 1,2,4-Trimethyl benzene | 850 | 2.22 | 105 | [23,30] | pesticide, plastic | |

| 37 | 1-Nitro-hexane | 850 | 2.49 | 43 | [30] | ||

| 38 | 3-Octen-2-one C25 | 850 | 2.30 | 55 | [21,22,23,27] | High, 1% | Earthy; spicy; herbal; sweet; mushroom |

| 39 | Benzene acetaldehyde C26 | 850 | 3.00 | 91 | [21,22,25,27] | High, 2% | Honey; floral; rose; sweet; cocoa |

| 40 | 1-Ethyl-2-methylbenzene | 860 | 2.26 | 105 | [22] | ||

| 41 | Isobutyl nonyl ester oxalic acid | 860 | 2.16 | 57 | [24] | ||

| 42 | Eucalyptol C27 | 865 | 2.06 | 43 | [20,27] | High, 10% | Eucalyptus; herbal; camphor |

| 43 | (E)-2-octenal C28 | 875 | 2.30 | 70 | [20,21,22,23,24,25,26,27,29,30] | High, 1% | Fresh; cucumber; fatty; green; herbal |

| 44 | Indene | 875 | 2.46 | 115 | [26] | ||

| 45 | (Z)-3,7-Dimethyl-1,3,6-octatriene C29 | 880 | 2.05 | 93 | [26] | Medium | Tropical; green; woody with vegetable nuances |

| 46 | 1-Phenyl-ethanone C30 | 885 | 2.93 | 105 | [25,27,29] | ||

| 47 | Dihydromyrcenol | 900 | 2.26 | 59 | |||

| 48 | 1-Octanol C31 | 900 | 2.33 | 56 | [20,21,22,23,25,27,30,31] | Medium 10% | Waxy; green; orange; rose; mushroom |

| 49 | Decane | 910 | 2.11 | 57 | [21,22,23,30] | Alkane; odour | |

| 50 | 3,5-Octadien-2-one C32 | 915 | 2.52 | 95 | [34] | High, 1% | Fruity; fatty; mushroom |

| 51 | Guaiacol C33 | 915 | 3.57 | 109 | [32,36] | High, 1% | Phenolic; smoke; spice; vanilla woody |

| 52 | 2-Nonanone C34 | 920 | 2.17 | 58 | [20,22,23] | Medium | Fresh; sweet; green; weedy earthy herbal |

| 53 | 6-Methyl-3,5-heptadiene-2-one C35 | 930 | 2.54 | 109 | [22,25] | Citrus; fruits | |

| 54 | 1-octen-3-yl acetate * | 940 | 2.08 | 43 | Medium | Fresh; green; herbal; lavender; fruity oily | |

| 55 | α-Terpinolene | 935 | 2.06 | 93 | [35] | Medium, 1% | Sweet; fresh; piney; citrus with a woody old lemon peel nuance |

| 56 | Nonanal C36 | 935 | 2.17 | 57 | [12,20,21,22,23,25,26,27,30] | High, 1% | Aldehydic; citrus; cucumber fattiness |

| 57 | Linalool C37 | 935 | 2.33 | 93 | [23,27] | Medium | Citrus; floral; sweet; woody; green; blueberry |

| 58 | Decane | 940 | 2.08 | 57 | [22,23,26,30] | ||

| 59 | Tridecane | 950 | 1.93 | 43 | [23,29,30] | ||

| 60 | Tetradecane | 955 | 1.92 | 57 | [12,21,22,23,29,30] | ||

| 61 | o-Cymene C38 | 970 | 2.15 | 119 | [29] | ||

| 62 | (E)-2-nonenal C39 | 995 | 2.30 | 55 | [20,21,23,24,25,27,30,31] | High, 1% | Fatty; green cucumber; citrus |

| 63 | 1,2,3,4-tetramethyl-benzene | 1005 | 2.24 | 119 | [21,23] | ||

| 64 | 2-Decen-1-ol C40 | 1010 | 2.14 | 82 | [24] | Medium | Waxy; fresh air; citrus |

| 65 | 2-Pentylthiophene | 1010 | 2.17 | 97 | High 0.1% | Fruity; fatty; cranberry | |

| 66 | Ethyl ester benzoic acid C41 | 1010 | 2.53 | 105 | [25] | Medium | Fruity; dry musty; sweet; wintergreen |

| 67 | 1-Nonanol | 1015 | 2.30 | 56 | [12,22,23,27,30] | Medium | Fresh; fatty; floral; rose; orange; dusty; wet; oily |

| 68 | Undecane | 1025 | 1.94 | 43 | [21,22,23,29] | Alkane odour | |

| 69 | (+)-Isomenthol * | 1030 | 2.38 | 71 | Medium, 10% | Mentholic; musty; woody | |

| 70 | 2-Decanone | 1035 | 2.17 | 58 | [23,27] | Medium | Orange; floral; fatty; peach |

| 71 | Ethyl ester octanoic acid C42 | 1040 | 2.09 | 88 | [21] | Medium | Fruity; wine; waxy; sweet; apricot banana; brandy; pear |

| 72 | Naphthalene | 1040 | 2.73 | 128 | [21,23,24,26,27,29,30,34] | Naphthalene | |

| 73 | Estragole * | 1045 | 2.44 | 148 | Medium | Sweet; sassafrass; anise spice; green herbal; fennel | |

| 74 | Decanal C43 | 1050 | 2.17 | 57 | [20,21,23,25,26,27,29,30,31] | High, 1% | Sweet, aldehydic, orange, waxy and citrus rind |

| 75 | 2,4-Nonadienal C44 | 1055 | 2.50 | 81 | [21,22,23,30,31] | High, 0.1% | Fatty; green cucumber |

| 76 | Dodecane C45 | 1065 | 1.94 | 43 | [21,22,23,30] | Alkane odour | |

| 77 | Benzothiazole C46 | 1075 | 3.36 | 69 | [21,23,24,34] | High, 0.1% | Sulphur-like; rubbery; vegetable; Cooked; nutty; coffee; meat |

| 78 | (Z)-2-decenal C47 | 1110 | 2.28 | 70 | [22,23,31] | High, 0.1% | Waxy; fatty; earthy; green; mushroom |

| 79 | Citral C48 | 1115 | 2.41 | 69 | [22,23] | Medium | Sharp lemon; sweet |

| 80 | Ethyl ester decanoic acid | 1115 | 2.22 | 88 | [21] | Medium | Sweet; waxy; fruity; apple; grape; oily; brandy |

| 81 | Nonanoic acid | 1115 | 3.90 | 73 | [23,25,26] | Medium, 10% | Waxy; dirty; cheese cultured; dairy |

| 82 | 1-Decanol | 1130 | 2.02 | 83 | [23,24] | Medium | Fatty; waxy; floral; orange sweet; clean watery |

| 83 | Trans-anethole * | 1140 | 2.57 | 148 | High, 10% | Sweet anise; liquorice | |

| 84 | 1H-indole C49 | 1145 | 1.54 | 117 | [21,22,24,30] | High, 1% | Pungent; floral; animalic; musty; character |

| 85 | 2-Butyl-1-octanol | 1160 | 1.95 | 57 | [22] | Solvents | |

| 86 | Undecanal C50 | 1160 | 2.14 | 82 | [21,23] | High, 1% | Waxy; soapy; floral; aldehydic; citrus; green; fatty |

| 87 | 2,4-Decadienal C51 | 1165 | 2.46 | 81 | [23,25,26,27,30,31] | High, 1% | Orange; sweet; fresh; citrus fatty; green |

| 88 | 2,6-Dimethyl-heptadecane | 1180 | 1.95 | 57 | [22] | ||

| 89 | Dihydro-5-pentyl-2(3H)-furanone | 1200 | 2.95 | 85 | [21,26] | Medium | Creamy; oily with fatty nuances |

| 90 | Decanoic acid | 1215 | 3.74 | 60 | [25,26] | Medium, 1% | Unpleasant rancid; sour; fatty; citrus |

| 91 | E-2-undecenal | 1215 | 2.27 | 70 | [23,26,30] | High, 1% | Fresh fruity; citrus; orange peel |

| 92 | Pentadecane | 1220 | 1.94 | 57 | [21,22,23] | ||

| 93 | Geranyl acetate | 1230 | 2.22 | 69 | [20,23,31] | Medium, 5% | Floral; rosy; waxy; herbal and green with a slight cooling nuance |

| 94 | Hexadecane | 1365 | 1.94 | 57 | [21,22,23,30] | Alkane; root | |

| 95 | Biphenyl | 1240 | 2.72 | 154 | [30] | High, 0.1% | Pungent; rose; green; geranium |

| 96 | 1-ethyl-naphthalene | 1260 | 2.60 | 156 | [30] | fatty; earthy | |

| 97 | Dodecanal | 1260 | 2.16 | 57 | [26,31] | High, 10% | Soapy; waxy; aldehydic; citrus; green; floral |

| 98 | (E)-6,10-dimethyl-5,9-undecadien-2-one | 1300 | 2.26 | 43 | [21,25,30] | Medium | Fresh; rose; leaf; floral; green; magnolia; aldehydic |

| 99 | 1,3-dimethyl-naphthalene | 1305 | 2.71 | 141 | [30] | ||

| 100 | Trans-caryophyllene | 1305 | 2.08 | 93 | [21] | Medium | Spicy; woody and terpenic |

| 101 | α-Ionone | 1340 | 2.36 | 177 | [31] | Medium, 10% | Floral; woody; sweet; fruity; berry; tropical; beeswax |

| 102 | 2,4-Bis(1,1-dimethylethyl)-phenol | 1355 | 2.95 | 191 | [24] | Phenolic | |

| 103 | Methyl ester dodecanoic acid | 1365 | 2.123 | 74 | [21] | Medium | Waxy; soapy; creamy; coconut; mushroom |

| 104 | α-Copaene | 1370 | 2.11 | 105 | [35] | Medium | Woody; spicy; honey |

| 105 | Lilyall | 1370 | 2.46 | 189 | [30] | Medium | Floral; muguet; watery; green; powdery; cumin |

| 106 | 1S,cis-calamenene | 1385 | 2.19 | 159 | [21] | ||

| 107 | 2,3,6-Trimethyl-naphthalene | 1405 | 2.65 | 155 | [30] | Fruity; dry | |

| 108 | 2-Undecanone | 1515 | 2.18 | 58 | [20,21,22,23] | Waxy; fruity; creamy; fatty; floral | |

| 109 | Methyl ester decanoic acid | 1535 | 2.14 | 74 | [21] | Medium | Oily; wine; fruity; floral |

| 110 | 2,6-Diisopropylnaphthalene | 1555 | 2.42 | 197 | [21] | ||

| 111 | Tetradecanoic acid | 1560 | 3.22 | 60 | [25] | Low, 10% | Faint; waxy and fatty with a hint of pineapple and citrus peel |

| 112 | 2-Ethylhexyl salicylate | 1610 | 2.39 | 120 | [30] | Low | Mild; orchid; sweet; balsam |

| 113 | 6,10,14-Trimethyl-2-pentadecanone | 1630 | 2.16 | 58 | [22] | Low | Oily; herbal; jasmine; celery; woody |

| 114 | 2-Pentadecanone | 1670 | 2.25 | 58 | [30] | Medium, 10% | Fresh; jasmine; celery |

| 115 | Methyl ester hexadecanoic acid | 1690 | 2.22 | 74 | [21] | ||

| 116 | Hexadecanoic acid | 1715 | 3.67 | 60 | [21,23,30] | Low, 1% | Low heavy waxy with a creamy; candle waxy nuance |

| 117 | Hexadecanoic acid, ethyl ester | 1740 | 2.26 | 88 | [25] | Low | mild waxy; fruity; creamy milky balsam |

| 118 | 1-Hexadecanol | 1920 | 2.26 | 97 | [24] | Low | Waxy; floral |

| 119 | Heptacosane | 2215 | 2.45 | 71 | [22] | ||

| Factors | −1 | 0 | +1 | Unit |

|---|---|---|---|---|

| x1, sample mass | 0.5 | 1.5 | 2.5 | g |

| x2, water volume | 0 | 2.5 | 5.0 | mL |

| x3, adsorption temperature | 40 | 70 | 100 | °C |

| x4, pre-incubation time | 5 | 10 | 15 | min |

| x5, adsorption time | 10 | 30 | 50 | min |

| DOE | Extraction Variables | Extraction Yield (Relative % to Maximum Yield) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | x4 | x5 | PEN | HEX | PYR | 2AP | 2PF | OCT | OCA | NON | |

| 1 | 1 | 1 | 1 | 1 | 1 | 22.78 | 3.58 | 3.80 | 18.44 | 21.70 | 3.89 | 16.77 | 7.11 |

| 2 | −1 | −1 | 1 | 1 | −1 | 6.05 | 1.36 | 1.66 | 100.00 | 11.28 | 9.80 | 100.00 | 100.00 |

| 3 | −1 | −1 | −1 | 1 | 1 | 30.78 | 5.79 | 6.39 | 22.01 | 4.85 | 13.46 | 61.75 | 69.87 |

| 4 | −1 | 1 | 1 | −1 | −1 | 21.72 | 1.63 | 2.04 | 62.20 | 9.55 | 13.73 | 59.42 | 22.31 |

| 5 | −1 | 1 | −1 | −1 | 1 | 100.00 | 100.00 | 100.00 | 13.40 | 100.00 | 100.00 | 47.52 | 42.92 |

| 6 | 1 | −1 | −1 | −1 | −1 | 7.55 | 1.55 | 1.71 | 3.43 | 0.65 | 1.38 | 4.61 | 3.96 |

| 7 | 0 | 0 | 0 | 0 | 0 | 10.99 | 8.33 | 8.90 | 54.26 | 16.14 | 25.63 | 32.39 | 43.71 |

| 8 | 1 | 1 | −1 | 1 | −1 | 28.99 | 11.26 | 11.63 | 2.88 | 15.60 | 6.99 | 5.10 | 3.50 |

| 9 | 1 | −1 | 1 | −1 | 1 | 3.16 | 0.59 | 0.73 | 63.69 | 3.99 | 2.24 | 17.26 | 25.84 |

| 10 | 0 | 0 | 0 | 0 | 0 | 12.66 | 13.01 | 8.85 | 51.67 | 14.53 | 23.84 | 26.91 | 41.25 |

| 11 | 0 | 0 | 0 | 0 | 0 | 15.25 | 12.51 | 11.49 | 48.62 | 19.49 | 30.29 | 31.88 | 50.60 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Setyaningsih, W.; Majchrzak, T.; Dymerski, T.; Namieśnik, J.; Palma, M. Key-Marker Volatile Compounds in Aromatic Rice (Oryza sativa) Grains: An HS-SPME Extraction Method Combined with GC×GC-TOFMS. Molecules 2019, 24, 4180. https://doi.org/10.3390/molecules24224180

Setyaningsih W, Majchrzak T, Dymerski T, Namieśnik J, Palma M. Key-Marker Volatile Compounds in Aromatic Rice (Oryza sativa) Grains: An HS-SPME Extraction Method Combined with GC×GC-TOFMS. Molecules. 2019; 24(22):4180. https://doi.org/10.3390/molecules24224180

Chicago/Turabian StyleSetyaningsih, Widiastuti, Tomasz Majchrzak, Tomasz Dymerski, Jacek Namieśnik, and Miguel Palma. 2019. "Key-Marker Volatile Compounds in Aromatic Rice (Oryza sativa) Grains: An HS-SPME Extraction Method Combined with GC×GC-TOFMS" Molecules 24, no. 22: 4180. https://doi.org/10.3390/molecules24224180