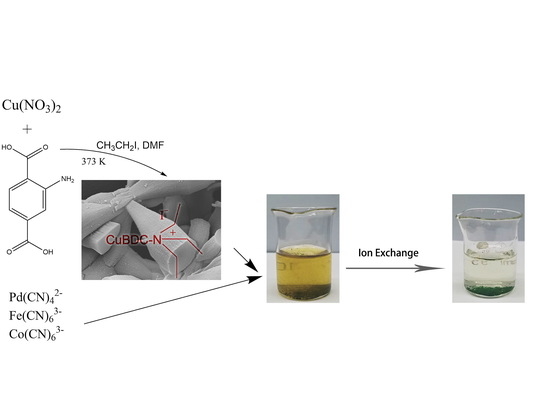

Highly Effective Removal of Metal Cyanide Complexes and Recovery of Palladium Using Quaternary-Ammonium-Functionalized MOFs

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization

2.1.1. FTIR Spectra

2.1.2. XRD spectra

2.1.3. SEM Analysis

2.1.4. TGA

2.1.5. N2 Adsorption–Desorption Isotherms

2.2. Effects of pH

2.3. Maximum Adsorption Capacities

2.4. Adsorption Kinetics

2.5. Sorption Isotherms

2.6. Thermodynamic Parameters

2.7. Removal of Metal Cyanide Complexes and Recovery of Pd(II)

2.8. Chemical Stability and Regeneration Experiment

3. Conclusions

4. Experimental

4.1. Reagents and Instruments

4.2. Adsorption Experiments

Author Contributions

Funding

Conflicts of Interest

References

- Parga, J.R.; Shukla, S.S.; Carrillo-Pedroza, F.R. Destruction of cyanide waste solutions using chlorine dioxide, ozone and titania sol. Waste Manag. 2003, 23, 183–191. [Google Scholar] [CrossRef]

- Chen, M.H.; Wu, S.J.; Huang, Z.J.; Chen, J.; Chen, M.J. Separation and recovery of Pd(II) and Pt(II) from cyanide liquors of Pd-Pt flotation concentrate via solvent extraction. J. Chem. Technol. Biot. 2017, 92, 1699–1709. [Google Scholar] [CrossRef]

- Dash, R.R.; Gaur, A.; Balomajumder, C. Cyanide in industrial wastewaters and its removal: A review on biotreatment. J. Hazard. Mater. 2009, 163, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.W.; Simons, A.; Breuer, P. A review of copper cyanide recovery technologies for the cyanidation of copper containing gold ores. Miner. Eng. 2012, 25, 1–13. [Google Scholar] [CrossRef]

- Yeddou, A.R.; Chergui, S.; Chergui, A.; Halet, F.; Hamza, A.; Nadjemi, B.; Ould-Dris, A.; Belkouch, J. Removal of cyanide in aqueous solution by oxidation with hydrogen peroxide in presence of copper-impregnated activated carbon. Miner. Eng. 2011, 24, 788–793. [Google Scholar] [CrossRef]

- Chen, J.; Huang, K. A new technique for extraction of platinum group metals by pressure cyanidation. Hydrometallurgy 2006, 82, 164–171. [Google Scholar] [CrossRef]

- Jha, M.K.; Lee, J.C.; Kim, M.S.; Jeong, J.; Kim, B.S.; Kumar, V. Hydrometallurgical recovery/recycling of platinum by the leaching of spent catalysts: A review. Hydrometallurgy 2013, 133, 23–32. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, W.; Lv, Y.; Li, B.; Ying, W. Enhanced carbon adsorption treatment for removing cyanide from coking plant effluent. J. Hazard. Mater. 2010, 184, 135–140. [Google Scholar] [CrossRef] [PubMed]

- Mpinga, C.N.; Bradshaw, S.M.; Akdogan, G.; Snyders, C.A.; Eksteen, J.J. The extraction of Pt, Pd and Au from an alkaline cyanide simulated heap leachate by granular activated carbon. Miner. Eng. 2014, 55, 11–17. [Google Scholar] [CrossRef]

- Lukey, G.C.; van Deventer, J.S.J.; Shallcross, D.C. The Effect of Functional Group Structure on the Elution of Metal Cyanide Complexes from Ion-Exchange Resins. Sep. Sci. Technol. 2007, 35, 2393–2413. [Google Scholar] [CrossRef]

- Schoeman, E.; Bradshaw, S.M.; Akdogan, G.; Snyders, C.A.; Eksteen, J.J. The elution of platinum and palladium cyanide from strong base anion exchange resins. Int. J. Miner. Process. 2017, 162, 19–26. [Google Scholar] [CrossRef]

- Schoeman, E.; Bradshaw, S.M.; Akdogan, G.; Snyders, C.A.; Eksteen, J.J. The extraction of platinum and palladium from a synthetic cyanide heap leach solution with strong base anion exchange resins. Int. J. Miner. Process. 2017, 162, 27–35. [Google Scholar] [CrossRef]

- Kobielska, P.A.; Howarth, A.J.; Farha, O.K.; Nayak, S. Metal–organic frameworks for heavy metal removal from water. Coordin. Chem. Rev. 2018, 358, 92–107. [Google Scholar] [CrossRef]

- Huang, L.; He, M.; Chen, B.; Hu, B. A mercapto functionalized magnetic Zr-MOF by solvent-assisted ligand exchange for Hg2+ removal from water. J. Mater. Chem. A. 2016, 4, 5159–5166. [Google Scholar] [CrossRef]

- Shi, Z.; Xu, C.; Guan, H.; Li, L.; Fan, L.; Wang, Y.; Liu, L.; Meng, Q.; Zhang, R. Magnetic metal organic frameworks (MOFs) composite for removal of lead and malachite green in wastewater. Colloid. Surface. A. 2018, 539, 382–390. [Google Scholar] [CrossRef]

- Yin, N.; Wang, K.; Xia, Y.; Li, Z. Novel melamine modified metal-organic frameworks for remarkably high removal of heavy metal Pb (II). Desalination 2018, 430, 120–127. [Google Scholar] [CrossRef]

- Halder, S.; Mondal, J.; Ortega-Castro, J.; Frontera, A.; Roy, P. A Ni-based MOF for selective detection and removal of Hg2+ in aqueous medium: A facile strategy. Dalton Trans. 2017, 46, 1943–1950. [Google Scholar] [CrossRef] [PubMed]

- Jamali, A.; Tehrani, A.A.; Shemirani, F.; Morsali, A. Lanthanide metal-organic frameworks as selective microporous materials for adsorption of heavy metal ions. Dalton Trans. 2016, 45, 9193–9200. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, A.; Bhattacharyya, S.; Hazra, A.; Ghosh, A.C.; Maji, T.K. Post-synthetic metalation in an anionic MOF for efficient catalytic activity and removal of heavy metal ions from aqueous solution. Chem. Commun. 2016, 52, 2831–2834. [Google Scholar] [CrossRef] [PubMed]

- Li, L.L.; Feng, X.Q.; Han, R.P.; Zang, S.Q.; Yang, G. Cr(VI) removal via anion exchange on a silver-triazolate MOF. J. Hazard. Mater. 2017, 321, 622–628. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Shen, W.; Wu, S.; Chen, C.; Luo, X.; Guo, L. Ion exchange induced removal of Pb(II) by MOF-derived magnetic inorganic sorbents. Nanoscale 2016, 8, 7172–7179. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Xie, Q.; Hu, Q.; Li, C.; Huang, Z.; Yang, X.; Guo, H. Surface modification of hollow magnetic Fe3O4@NH2-MIL-101(Fe) derived from metal-organic frameworks for enhanced selective removal of phosphates from aqueous solution. Sci. Rep. 2016, 6, 30651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, Q.; Li, Y.; Lv, Z.; Zhou, H.; Yang, X.; Chen, J.; Guo, H. Effective Adsorption and Removal of Phosphate from Aqueous Solutions and Eutrophic Water by Fe-based MOFs of MIL-101. Sci. Rep. 2017, 7, 3316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, C.; Liu, X.; Chen, J.P.; Li, K. Superior removal of arsenic from water with zirconium metal-organic framework UiO-66. Sci. Rep. 2015, 5, 16613. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hashemi, B.; Zohrabi, P.; Raza, N.; Kim, K.H. Metal-organic frameworks as advanced sorbents for the extraction and determination of pollutants from environmental, biological, and food media. Trend. Anal. Chem. 2017, 97, 65–82. [Google Scholar] [CrossRef]

- Oveisi, M.; Asli, M.A.; Mahmoodi, N.M. MIL-Ti metal-organic frameworks (MOFs) nanomaterials as superior adsorbents: Synthesis and ultrasound-aided dye adsorption from multicomponent wastewater systems. J. Hazard. Mater. 2018, 347, 123–140. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Pournara, A.; Kim, K.H.; Bansal, V.; Rapti, S.; Manos, M.J. Metal-organic frameworks: Challenges and opportunities for ion-exchange/sorption applications. Prog. Mater. Sci. 2017, 86, 25–74. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Z.J.; Li, J.F.; Chen, J. Solvent extraction of palladium(II) from alkaline cyanide solution by the dodecyldimethhy-2-phenoxyethyl ammonium bromide. J. Chil Chem. Soc. 2016, 61, 2864–2869. [Google Scholar] [CrossRef]

- Jiang, J.; Zhou, W.; Gao, H.; Wu, J.; Xu, G. Solvent extraction and stripping of gold(I) cyanide in the tetradecyldimethylbenzylammonium chloride system. Hydrometallurgy 2003, 70, 73–81. [Google Scholar] [CrossRef]

- Zhang, T.X.; Huang, B.G.; Zhou, W.J.; Gao, H.C.; Chen, J.; Wu, H.S.; Wu, J.G. Extraction and recovery of gold from KAu(CN)2 using cetyltrimethylammonium bromide microemulsions. J. Chem. Technol. Biot. 2001, 76, 1107–1111. [Google Scholar] [CrossRef]

- Lin, K.Y.A.; Yang, H.; Petit, C.; Hsu, F.K. Removing oil droplets from water using a copper-based metal organic frameworks. Chem. Eng. J. 2014, 249, 293–301. [Google Scholar] [CrossRef]

- Andrew Lin, K.Y.; Hsieh, Y.T. Copper-based metal organic framework (MOF), HKUST-1, as an efficient adsorbent to remove p-nitrophenol from water. J. Taiwan. Inst. Chem. E. 2015, 50, 223–228. [Google Scholar] [CrossRef]

- Hong, D.Y.; Hwang, Y.K.; Serre, C.; Férey, G.; Chang, J.S. Porous chromium terephthalate MIL-101 with coordinatively unsaturated sites: Surface functionalization, encapsulation, sorption and Catalysis. Adv. Funct. Mater. 2009, 19, 1537–1552. [Google Scholar] [CrossRef]

- Lin, Y.; Kong, C.; Chen, L. Direct synthesis of amine-functionalized MIL-101(Cr) nanoparticles and application for CO2 capture. Rsc Adv. 2012, 2, 6417–6419. [Google Scholar] [CrossRef]

- Serra-Crespo, P.; Ramos-Fernandez, E.V.; Gascon, J.; Kapteijn, F. Synthesis and Characterization of an Amino Functionalized MIL-101(Al): Separation and catalytic properties. Chem. Mater. 2011, 23, 2565–2572. [Google Scholar] [CrossRef]

- Yaghi, O.M.; Li, G.M.; Li, H.L. Selective binding and removal of guests in a microporous metal-organic framework. Nature 1995, 378, 703–706. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Li, Z.; Zhao, Q.; Zhou, Y.L.; Liu, H.W.; Zhang, X.X. A facilely synthesized amino-functionalized metal-organic framework for highly specific and efficient enrichment of glycopeptides. Chem. Comm. 2014, 50, 11504–11506. [Google Scholar] [CrossRef] [PubMed]

- Rostamnia, S.; Alamgholiloo, H.; Liu, X. Pd-grafted open metal site copper-benzene-1,4-dicarboxylate metal organic frameworks (Cu-BDC MOF’s) as promising interfacial catalysts for sustainable Suzuki coupling. J. Colloid Interf. Sci. 2016, 469, 310–317. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.G.; Li, X.Y.; Liu, B.J.; Zhao, Q.D.; Chen, G.H. Hexagonal microspindle of NH2-MIL-101(Fe) metal–organic frameworks with visible-light induced photocatalytic activity for the degradation of toluene. Rsc Adv. 2016, 6, 4289–4295. [Google Scholar] [CrossRef]

- Polowczyk, I.; Urbano, B.F.; Rivas, B.L.; Bryjak, M.; Kabay, N. Equilibrium and kinetic study of chromium sorption on resins with quaternary ammonium and N-methyl-d-glucamine groups. Chem. Eng. J. 2016, 284, 395–404. [Google Scholar] [CrossRef]

- Kim, Y.J.; Park, D.W. Functionalized IRMOF-3: An Efficient Heterogeneous Catalyst for the Cycloaddition of Allyl Glycidyl Ether and CO2. J. Nanosci. Nanotechnol. 2013, 13, 2307–2312. [Google Scholar] [CrossRef] [PubMed]

- Hibble, S.J.; Chippindale, A.M.; Bilbe, E.J.; Marelli, E.; Harris, P.J.; Hannon, A.C. Structures of Pd(CN)2 and Pt(CN)2: Intrinsically nanocrystalline materials? Inorg. Chem. 2011, 50, 104–113. [Google Scholar] [CrossRef] [PubMed]

- Carson, C.G.; Hardcastle, K.; Schwartz, J.; Liu, X.T.; Hoffmann, C.; Gerhardt, R.A.; Tannenbaum, R. Synthesis and structure characterization of copper terephthalate metal–organic frameworks. Eur. J. Inorg. Chem. 2009, 16, 2338–2343. [Google Scholar] [CrossRef]

- Dang, G.H.; Vu, Y.T.H.; Dong, Q.A.; Le, D.T.; Truong, T.; Phan, N.T.S. Quinoxaline synthesis via oxidative cyclization reaction using metal–organic framework Cu(BDC) as an efficient heterogeneous catalyst. Appl. Catal. A-Gen. 2015, 491, 189–195. [Google Scholar] [CrossRef]

- Alavi, M.A.; Morsali, A. Synthesis and characterization of different nanostructured copper(II) metal–organic frameworks by a ligand functionalization and modulation method. CrystEngComm 2014, 16, 2246–2250. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, H.; Emge, T.J.; Gong, Q.; Nijem, N.; Chabal, Y.J.; Kong, L.; Langreth, D.C.; Liu, H.; Zeng, H.; et al. Enhancing gas adsorption and separation capacity through ligand functionalization of microporous metal-organic framework structures. Chem. Eur. J. 2011, 17, 5101–5109. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhang, Y.; Yang, X.G.; Zhao, L.Z.; Wang, G.Y. Functionalized IRMOF-3 as efficient heterogeneous catalyst for the synthesis of cyclic carbonates. J. Mol. Catal. A Chem. 2012, 361, 12–16. [Google Scholar] [CrossRef]

- Chen, C.; Wu, Z.; Que, Y.; Li, B.; Guo, Q.; Li, Z.; Wang, L.; Wan, H.; Guan, G. Immobilization of a thiol-functionalized ionic liquid onto HKUST-1 through thiol compounds as the chemical bridge. RSC Adv. 2016, 6, 54119–54128. [Google Scholar] [CrossRef]

- Zhu, B.J.; Yu, X.Y.; Jia, Y.; Peng, F.M.; Sun, B.; Zhang, M.Y.; Luo, T.; Liu, J.H.; Huang, X.J. Iron and 1,3,5-benzenetricarboxylic metal−organic coordination polymers prepared by solvothermal method and their application in efficient As(V) removal from aqueous solutions. J. Phs. Chem. C. 2012, 116, 8601–8607. [Google Scholar] [CrossRef]

- Chui, S.S.Y.; Lo, S.M.F.; Charmant, J.P.H.; Orpen, A.G.; Williams, I.D. A Chemically functionalizable nanoporous material [Cu3(TMA)2(H2O)3]n. Science 1999, 283, 1148–1150. [Google Scholar] [CrossRef]

- Panella, B.; Hirscher, M.; Pütter, H.; Müller, U. Hydrogen adsorption in metal–organic frameworks: Cu-MOFs and Zn-MOFs Compared. Adv. Funct. Mater. 2006, 16, 520–524. [Google Scholar] [CrossRef]

- Carson, C.G.; Brunnello, G.; Lee, S.G.; Jang, S.S.; Gerhardt, R.A.; Tannenbaum, R. Structure solution from powder diffraction of copper1,4-benzenedicarboxylate. Eur. J. Inorg. Chem. 2014, 2140–2145. [Google Scholar] [CrossRef]

- Gong, W.P.; Chen, D.; Yang, S.J. Adsorption of methyl violet by an anionic metal-organic framework Cu(BDC-NH2)(4,4’-Bipy)0.5. Chin. J. Appl. Chem. 2017, 34, 1321–1328. (In Chinese) [Google Scholar]

- Can, M.; Bulut, E.; Özacar, M. Reduction of palladium onto pyrogallol-derived nano-resin and its mechanism. Chem. Eng. J. 2015, 275, 322–330. [Google Scholar] [CrossRef]

- Snyders, C.A.; Bradshaw, S.M.; Akdogan, G.; Eksteen, J.J. Factors affecting the elution of Pt, Pd and Au cyanide from activated carbon. Miner. Eng. 2015, 80, 14–24. [Google Scholar] [CrossRef]

- Snyders, C.A.; Bradshaw, S.M.; Akdogan, G.; Eksteen, J.J. The effect of temperature, cyanide and base metals on the adsorption of Pt, Pd and Au onto activated carbon. Hydrometallurgy 2014, 149, 132–142. [Google Scholar] [CrossRef]

- Deng, S.; Bai, R. Removal of trivalent and hexavalent chromium with aminated polyacrylonitrile fibers: Performance and mechanisms. Water Res. 2004, 38, 2424–2432. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.E.; Shan, X.Q.; Dong, D.M.; Hua, X.Y.; Owens, G. Kinetics and thermodynamics of sorption of nitroaromatic compounds to as-grown and oxidized multiwalled carbon nanotubes. J. Colloid Interface Sci. 2009, 330, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhong, L.J.; Zhang, J.Y.; Zhang, Q.; Chen, M.H.; Huang, Z.J. Novel poly(aniline-co-3-amino-4-methoxybenzoic acid) copolymer for the separation and recovery of Pd(II) from the leaching liquor of automotive catalysts. RSC Adv. 2017, 7, 39244–39257. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Sonu, C.H.; Lee, M.S. Separation of Ir(IV) and Rh(III) from strong hydrochloric acid solutions by solvent extraction with amines. J. Ind. Eng. Chem. 2016, 36, 245–250. [Google Scholar] [CrossRef]

- Jasuja, H.; Jiao, Y.; Burtch, N.C.; Huang, Y.G.; Walton, K.S. Synthesis of cobalt-, nickel-, Copper-, and Zinc-Based, water-stable, pillared metal−organic frameworks. Langmuir 2014, 30, 14300–14307. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, A.; Rahmani, H.; Zonouzi, A. Cu(BDC) as a catalyst for rapid reduction of methyl orange: Room temperature synthesis using recycled terephthalic acid. Chem. Pap. 2018, 72, 449–455. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.J. The method for enrichment of platinum and palladium from leaching solution of pressure cyanidation. China Patent 201210287951.2, 2012. [Google Scholar]

- Bae, J.H.; Lee, E.J.; Jeong, N.C. Metal coordination and metal activation abilities of commonly unreactive chloromethanes toward metal-organic frameworks. Chem. Commun. 2018, 25, 6421–6952. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.S.; Bae, J.H.; Lee, E.J.; Jeong, N.C. A chemical role for trichloromethane: Room-temperature removal of coordinated solvents from open metal sites in the copper-based metal− organic frameworks. Inorg. Chem. 2018, 57, 5225–5231. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are not available from the authors. |

| Sample | Surface Area of BET (m2 g−1) | Total Pore Volume (cm3 g−1) | Ref. |

|---|---|---|---|

| Cu-BTC | 692–2211 | ~0.81 | [48,50,51,52] |

| Cu(BDC)(DMF) | 241–903 | ~0.30 | [52] |

| Cu(BDC-NH2)(4,4’-Bipy)0.5 | 124 | - | [53] |

| Cu(BDC-NH2)(DMF) | 210.6 | 0.37 | present work |

| Et-N-Cu(BDC-NH2)(DMF) | 108.24 | 0.30 | present work |

| Metal Cyanide Complexes | qmax, Et-N-Cu(BDC-NH2) (DMF) | qmax, Cu(BDC-NH2) (DMF) | qmax, GAC |

|---|---|---|---|

| Pd(II) | 172.9 | 37.8 | 18.2 |

| Co(III) | 101.0 | 13.9 | 18.1 |

| Fe(III) | 102.6 | 20.6 | 20.7 |

| Pseudo-First-Order Model | Pseudo-Second-Order Model | Intra-Particle Diffusion Model | |||

|---|---|---|---|---|---|

| qe, exp. (mg g−1) | 124.4 | qe, exp. (mg g−1) | 124.4 | Kp (mg g−1 min−0.5) | 6.628 |

| qe, cal. (mg g−1) | 38.58 | qe, cal. (mg g−1) | 128.4 | C | 91.72 |

| k1 (min−1) | 0.17 | k2 (g mg−1 min−1) | 0.008 | R2 | 0.7705 |

| R2 | 0.9647 | R2 | 0.9991 | ||

| Metal | qma (mg g−1) | Langmuir Isotherm | Freundlich Isotherm | ||||

|---|---|---|---|---|---|---|---|

| qmb (mg g−1) | B (L mg−1) | R2 | Kf (L g−1) | n | R2 | ||

| Pd | 172.9 | 180.5 | 0.213 | 0.9995 | 44.98 | 3.16 | 0.9496 |

| Temperature (K) | △G (kJ mol−1) | △S (J mol−1 K−1) | △H (kJ mol−1) |

|---|---|---|---|

| 293.15 | −4.48 | −239.4 | −74.7 |

| 298.15 | −3.29 | ||

| 303.15 | −2.09 | ||

| 308.15 | −0.89 |

| Metal Cyanide Complexes | Pd(CN)42− | Co(CN)63− | Fe(CN)63− |

|---|---|---|---|

| Initial concentration (mg L−1) | 50.1 | 25.3 | 25.4 |

| Adsorption rate (%) | 99.1 | 98.7 | 98.3 |

| The first elution rate (%) | 1.9 | 98.2 | 98.8 |

| The second elution rate (%) | 97.2 | ||

| Recovery rate (%) | 96.3 |

| Adsorbent | Capacity (mg g−1) | Adsorption Time (h) | Optimum pH | Adsorption Selectivity | Refs. |

|---|---|---|---|---|---|

| Polymer resins | <80 | 8–48 h | 9–11 | Pd(CN)42− coexisting with other metal cyanide | [10,11,12,27] |

| Activated carbon | 8–25 | 2–12 h | 9–11 | Pd(CN)42− coexisting with other metal cyanide | [3,4,5,9,55,63] |

| Et-N-Cu(BDC-NH2) (DMF) | >100 | <0.5 | 7–8 | Pd(CN)42− can eluted separation from other metal cyanide | Present work |

| Samples | Iodine Content (w%) | Reaction 7ield (%) |

|---|---|---|

| Et-N-Cu(BDC-NH2) (DMF)-2d | 3.5 | ~14 |

| Et-N-Cu(BDC-NH2) (DMF)-4d | 6.3 | ~26 |

| Et-N-Cu(BDC-NH2) (DMF)-6d | 7.8 | ~32 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Chen, M.; Zhong, L.; Ye, Q.; Jiang, S.; Huang, Z. Highly Effective Removal of Metal Cyanide Complexes and Recovery of Palladium Using Quaternary-Ammonium-Functionalized MOFs. Molecules 2018, 23, 2086. https://doi.org/10.3390/molecules23082086

Zhang Q, Chen M, Zhong L, Ye Q, Jiang S, Huang Z. Highly Effective Removal of Metal Cyanide Complexes and Recovery of Palladium Using Quaternary-Ammonium-Functionalized MOFs. Molecules. 2018; 23(8):2086. https://doi.org/10.3390/molecules23082086

Chicago/Turabian StyleZhang, Qin, Muhan Chen, Lijiang Zhong, Qun Ye, Shaoshong Jiang, and Zhangjie Huang. 2018. "Highly Effective Removal of Metal Cyanide Complexes and Recovery of Palladium Using Quaternary-Ammonium-Functionalized MOFs" Molecules 23, no. 8: 2086. https://doi.org/10.3390/molecules23082086