Bioinspired Polymers: Bridging Nature’s Ingenuity with Synthetic Innovation

Abstract

:1. Introduction

2. Biomimicry and Biomimetic Synthetic Polymers

3. Research Trends

4. Outcomes and Achievements

5. Testing and Evaluation of Bioinspired Polymer Composites

6. Limitations in Developing Bioinspired Synthetic Polymers

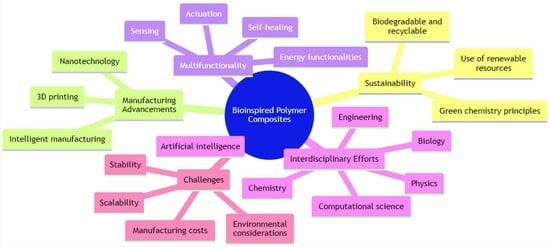

7. Future Directions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grindy, S.C.; Learsch, R.; Mozhdehi, D.; Cheng, J.; Barrett, D.G.; Guan, Z.; Messersmith, P.B.; Holten-Andersen, N. Control of hierarchical polymer mechanics with bioinspired metal-coordination dynamics. Nat. Mater. 2015, 14, 1210–1216. [Google Scholar] [CrossRef] [PubMed]

- Ludwigs, S.; Steiner, U.; Kulak, A.N.; Lam, R.; Meldrum, F.C. Bioinspired Polymer–Inorganic Hybrid Materials. Adv. Mater. 2006, 18, 2270–2273. [Google Scholar] [CrossRef]

- Xu, W.; Liu, J.; Chen, T.; Jiang, X.; Qian, X.; Zhang, Y.; Jiang, Z.; Zhang, Y. Bioinspired Polymer Nanocomposites Exhibit Giant Energy Density and High Efficiency at High Temperature. Small 2019, 15, e1901582. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Kong, K.; Tang, R.; Liu, Z. A Bioinspired Ultratough Composite Produced by Integration of Inorganic Ionic Oligomers within Polymer Networks. ACS Nano 2022, 16, 7926–7936. [Google Scholar] [CrossRef] [PubMed]

- Srivatsa, S.; Packo, P.; Mishnaevsky, L., Jr.; Uhl, T.; Grabowski, K. Deformation of Bioinspired MXene-Based Polymer Composites with Brick and Mortar Structures: A Computational Analysis. Materials 2020, 13, 19. [Google Scholar] [CrossRef] [PubMed]

- Amorim, L.; Santos, A.; Nunes, J.P.; Viana, J.C. Bioinspired approaches for toughening of fibre reinforced polymer composites. Mater. Des. 2021, 199, 24. [Google Scholar] [CrossRef]

- Lu, H.; Chen, Z.; Ma, C. Bioinspired approaches for optimizing the strength and toughness of graphene-based polymer nanocomposites. J. Mater. Chem. 2012, 22, 16182–16190. [Google Scholar] [CrossRef]

- Xu, Z.; Bykova, J.; Baniasadi, M.; Moreno, S.; Zhou, Z.; Das, N.; Bandi, S.; Xi, Y.; Qian, D.; Baughman, R.H.; et al. Bioinspired Multifunctional Ceramic Platelet-Reinforced Piezoelectric Polymer Composite. Adv. Eng. Mater. 2016, 19, 10. [Google Scholar] [CrossRef]

- Zhu, B.; Merindol, R.; Benitez, A.J.; Wang, B.; Walther, A. Supramolecular Engineering of Hierarchically Self-Assembled, Bioinspired, Cholesteric Nanocomposites Formed by Cellulose Nanocrystals and Polymers. ACS Appl. Mater. Interfaces 2016, 8, 11031–11040. [Google Scholar] [CrossRef]

- Ji, D.; Kim, J. Bioinspired Design and Fabrication of Polymer Composite Films Consisting of a Strong and Stiff Organic Matrix and Microsized Inorganic Platelets. ACS Nano 2019, 13, 2773–2785. [Google Scholar] [CrossRef]

- Johnson, J.R., 3rd; Spikowski, J.; Schiraldi, D.A. Mineralization of clay/polymer aerogels: A bioinspired approach to composite reinforcement. ACS Appl. Mater. Interfaces 2009, 1, 1305–1309. [Google Scholar] [CrossRef] [PubMed]

- Pang, C.; Kim, T.I.; Bae, W.G.; Kang, D.; Kim, S.M.; Suh, K.Y. Bioinspired reversible interlocker using regularly arrayed high aspect-ratio polymer fibers. Adv. Mater. 2012, 24, 475–479. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Wu, J.; Fang, X.; Guan, L.; Yao, N.; Yang, G.; Wang, Z.; Hua, Z.; Liu, G. Rational Design of Bioinspired Nucleobase-Containing Polymers as Tough Bioplastics and Ultra-Strong Adhesives. Adv. Funct. Mater. 2022, 32, 8. [Google Scholar] [CrossRef]

- Li, Z.-Z.; Li, M.; Feng, Y.-X.; Zhang, Z.; Wen, Y.-E.; Huang, Q.-Q.; Lu, Z.; Bai, H.; Wang, H.-L.; Xu, B.-B.; et al. Bioinspired Compartmentalization Strategy for Coating Polymers with Self-Organized Prismatic Films. Chem. Mat. 2021, 33, 9240–9251. [Google Scholar] [CrossRef]

- Das, C.; Patel, V.D.; Gupta, D.; Mahata, P. Cd-Based Coordination Polymer Using a Bioinspired Ligand: Studies Toward Turn-On Luminescence-Based Sensing and Schottky Diode Behavior through Device Fabrication. Cryst. Growth Des. 2022, 22, 7050–7061. [Google Scholar] [CrossRef]

- Gao, A.; Ma, T.; Li, M.; Chen, H.; Ju, M.; Hou, A.; Xie, K. Liquid Crystal Nanoparticle Actuator by Polymer Surfactant-Assisted Assembly for Fabricating Bioinspired Smart Interface with Adjustable Light and Changeable Color. ACS Appl. Nano Mater. 2022, 5, 15498–15506. [Google Scholar] [CrossRef]

- He, J.; Xiao, P.; Shi, J.; Liang, Y.; Lu, W.; Chen, Y.; Wang, W.; Théato, P.; Kuo, S.-W.; Chen, T. High Performance Humidity Fluctuation Sensor for Wearable Devices via a Bioinspired Atomic-Precise Tunable Graphene-Polymer Heterogeneous Sensing Junction. Chem. Mat. 2018, 30, 4343–4354. [Google Scholar] [CrossRef]

- Hu, Y.; Xu, A.; Liu, J.; Yang, L.; Chang, L.; Huang, M.; Gu, W.; Wu, G.; Lu, P.; Chen, W.; et al. Multifunctional Soft Actuators Based on Anisotropic Paper/Polymer Bilayer Toward Bioinspired Applications. Adv. Mater. Technol. 2019, 4, 11. [Google Scholar] [CrossRef]

- Huang, Z.; Tsui, G.C.-P.; Deng, Y.; Tang, C.-Y.; Yang, M.; Zhang, M.; Wong, W.-Y. Bioinspired near-infrared light-induced ultrafast soft actuators with tunable deformation and motion based on conjugated polymers/liquid crystal elastomers. J. Mater. Chem. C 2022, 10, 12731–12740. [Google Scholar] [CrossRef]

- Wang, T.; Huang, J.; Yang, Y.; Zhang, E.; Sun, W.; Tong, Z. Bioinspired Smart Actuator Based on Graphene Oxide-Polymer Hybrid Hydrogels. ACS Appl. Mater. Interfaces 2015, 7, 23423–23430. [Google Scholar] [CrossRef]

- Son, H.Y.; Ryu, J.H.; Lee, H.; Nam, Y.S. Bioinspired templating synthesis of metal-polymer hybrid nanostructures within 3D electrospun nanofibers. ACS Appl. Mater. Interfaces 2013, 5, 6381–6390. [Google Scholar] [CrossRef]

- Khetani, S.; Yong, K.W.; Ozhukil Kollath, V.; Eastick, E.; Azarmanesh, M.; Karan, K.; Sen, A.; Sanati-Nezhad, A. Engineering Shelf-Stable Coating for Microfluidic Organ-on-a-Chip Using Bioinspired Catecholamine Polymers. ACS Appl. Mater. Interfaces 2020, 12, 6910–6923. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Pardo, J.; Novio, F.; Nador, F.; Cavaliere, I.; Suarez-Garcia, S.; Lope-Piedrafita, S.; Candiota, A.P.; Romero-Gimenez, J.; Rodriguez-Galvan, B.; Bove, J.; et al. Bioinspired Theranostic Coordination Polymer Nanoparticles for Intranasal Dopamine Replacement in Parkinson’s Disease. ACS Nano 2021, 15, 8592–8609. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Chen, F.; Zhang, Y.; Wu, P.; Yang, Z.; Zhang, S.; Xiao, L.; Deng, Z.; Cai, L.; Wu, M. Facile fabrication of biomimetic silicified gelatin scaffolds for angiogenesis and bone regeneration by a bioinspired polymer-induced liquid precursor. Mater. Des. 2022, 222, 25. [Google Scholar] [CrossRef]

- Delesky, E.A.; Garcia, L.F.; Lobo, A.J.; Mikofsky, R.A.; Dowdy, N.D.; Wallat, J.D.; Miyake, G.M.; Srubar, W.V., 3rd. Bioinspired Threonine-Based Polymers with Potent Ice Recrystallization Inhibition Activity. ACS Appl. Polym. Mater. 2022, 4, 7934–7942. [Google Scholar] [CrossRef]

- Morozova, T.I.; Garcia, N.A.; Barrat, J.L.; Luengo, G.S.; Leonforte, F. Adsorption and Desorption of Polymers on Bioinspired Chemically Structured Substrates. ACS Appl. Mater. Interfaces 2021, 13, 30086–30097. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.L.; Huang, C.Y.; Xie, Y.T.; Chiang, Y.Y.; Chen, Y.M.; Hsueh, H.Y. Bioinspired Durable Superhydrophobic Surface from a Hierarchically Wrinkled Nanoporous Polymer. ACS Appl. Mater. Interfaces 2019, 11, 40875–40885. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Wang, J.; Zhang, Y. Bioinspired porous organic polymer-functionalized membranes for efficient CO2 capture. Sustain. Energy Fuels 2020, 4, 1191–1198. [Google Scholar] [CrossRef]

- Lim, N.K.; Kim, E.K.; Park, J.J.; Bae, S.J.; Woo, S.; Choi, J.H.; Song, W.J. Design of a Bioinspired Robust Three-Dimensional Cross-Linked Polymer Binder for High-Performance Li-Ion Battery Applications. ACS Appl. Mater. Interfaces 2023, 15, 54409–54418. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, H.; Li, B.; Yang, J.; Li, X.; Zhang, T.; He, C.; Duan, C.; Wang, L. Bioinspired Carboxylate–Water Coordination Polymers with Hydrogen-Bond Clusters and Local Coordination Flexibility for Electrochemical Water Splitting. ACS Appl. Energy Mater. 2020, 3, 10515–10524. [Google Scholar] [CrossRef]

- Patil, N.; Aqil, A.; Ouhib, F.; Admassie, S.; Inganas, O.; Jerome, C.; Detrembleur, C. Bioinspired Redox-Active Catechol-Bearing Polymers as Ultrarobust Organic Cathodes for Lithium Storage. Adv. Mater. 2017, 29, 9. [Google Scholar] [CrossRef] [PubMed]

- Shi, B.; Pang, X.; Wu, H.; Shen, J.; Guan, J.; Wang, X.; Fan, C.; Cao, L.; Zhu, T.; Yin, Z.; et al. Ultra-robust, highly proton-conductive polymer carbon dot membranes through bioinspired complexation. J. Mater. Chem. A 2022, 10, 16995–17000. [Google Scholar] [CrossRef]

- Zhu, M.; Zhao, L.; Ran, Q.; Zhang, Y.; Peng, R.; Lu, G.; Jia, X.; Chao, D.; Wang, C. Bioinspired Catechol-Grafting PEDOT Cathode for an All-Polymer Aqueous Proton Battery with High Voltage and Outstanding Rate Capacity. Adv. Sci. 2022, 9, e2103896. [Google Scholar] [CrossRef]

- Kim, M.; Butler, M.F.; Pramudya, I.; Lee, C.; Kim, S.; Chung, H. Metal-Free Electrically Conductive Bioinspired Adhesive Polymers. Chem. Mat. 2019, 31, 8358–8365. [Google Scholar] [CrossRef]

- Peng, W.; Zhang, G.; Liu, J.; Nie, S.; Wu, Y.; Deng, S.; Fang, G.; Zhou, J.; Song, J.; Qian, J.; et al. Light-Coded Digital Crystallinity Patterns Toward Bioinspired 4D Transformation of Shape-Memory Polymers. Adv. Funct. Mater. 2020, 30, 7. [Google Scholar] [CrossRef]

- Raeis Hosseini, N.; Lee, J.S. Resistive switching memory based on bioinspired natural solid polymer electrolytes. ACS Nano 2015, 9, 419–426. [Google Scholar] [CrossRef]

- Li, X.; Xiong, Y.; Qing, G.; Jiang, G.; Li, X.; Sun, T.; Liang, X. Bioinspired Saccharide-Saccharide Interaction and Smart Polymer for Specific Enrichment of Sialylated Glycopeptides. ACS Appl. Mater. Interfaces 2016, 8, 13294–13302. [Google Scholar] [CrossRef]

- Paes, G.; von Schantz, L.; Ohlin, M. Bioinspired assemblies of plant cell wall polymers unravel the affinity properties of carbohydrate-binding modules. Soft Matter 2015, 11, 6586–6594. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.-C.; Chu, Y.-L.; Huang, P.-H.; Yen, Y.-C.; Chu, C.-W.; Yang, A.C.M.; Ko, F.-H.; Chen, J.-K.; Chang, F.-C. Bioinspired hole-conducting polymers for application in organic light-emitting diodes. J. Mater. Chem. 2012, 22, 18127–18131. [Google Scholar] [CrossRef]

- Wang, L.; Meng, Y.; Zhang, C.; Xiao, H.; Li, Y.; Tan, Y.; Xie, Q. Improving Photovoltaic and Enzymatic Sensing Performance by Coupling a Core-Shell Au Nanorod@TiO(2) Heterostructure with the Bioinspired l-DOPA Polymer. ACS Appl. Mater. Interfaces 2019, 11, 9394–9404. [Google Scholar] [CrossRef]

- Dalsin, J.L.; Messersmith, P.B. Bioinspired antifouling polymers. Mater. Today 2005, 8, 38–46. [Google Scholar] [CrossRef]

- Ishihara, K. Bioinspired phospholipid polymer biomaterials for making high performance artificial organs. Sci. Technol. Adv. Mater. 2000, 1, 131–138. [Google Scholar] [CrossRef]

- Krannig, K.S.; Schlaad, H. Emerging bioinspired polymers: Glycopolypeptides. Soft Matter 2014, 10, 4228–4235. [Google Scholar] [CrossRef] [PubMed]

- Xi, S.; Tian, F.; Wei, G.; He, X.; Shang, Y.; Ju, Y.; Li, W.; Lu, Q.; Wang, Q. Reversible Dendritic-Crystal-Reinforced Polymer Gel for Bioinspired Adaptable Adhesive. Adv. Mater. 2021, 33, e2103174. [Google Scholar] [CrossRef] [PubMed]

- Aqil, A.; Ouhib, F.; Detrembleur, C.; Moreno-Couranjou, M. Atmospheric plasma deposition of bioinspired catechol-rich polymers: A promising route for the simple construction of redox-active thin films. Mater. Adv. 2021, 2, 1248–1252. [Google Scholar] [CrossRef]

- Espinosa-Marzal, R.M.; Bielecki, R.M.; Spencer, N.D. Understanding the role of viscous solvent confinement in the tribological behavior of polymer brushes: A bioinspired approach. Soft Matter 2013, 9, 10572–10585. [Google Scholar] [CrossRef]

- Eduok, U.; Szpunar, J. Bioinspired and hydrophobic alkyl-silanized protective polymer coating for Mg alloy. Progress. Nat. Sci. Mater. Int. 2018, 28, 354–362. [Google Scholar] [CrossRef]

- Dobryden, I.; Steponaviciu Te, M.; Klimkevicius, V.; Makuska, R.; Dedinaite, A.; Liu, X.; Corkery, R.W.; Claesson, P.M. Bioinspired Adhesion Polymers: Wear Resistance of Adsorption Layers. Langmuir 2019, 35, 15515–15525. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Q.; Liang, L.; Ding, H.; Liang, X.; Sun, G. High-content graphene-reinforced polymer with bioinspired multilayer structure. J. Mater. Sci. 2020, 55, 16836–16845. [Google Scholar] [CrossRef]

- Zhang, H.; He, Q.; Yu, H.; Qin, M.; Feng, Y.; Feng, W. A Bioinspired Polymer-Based Composite Displaying Both Strong Adhesion and Anisotropic Thermal Conductivity. Adv. Funct. Mater. 2023, 33, 9. [Google Scholar] [CrossRef]

- Li, X.C.; Hao, D.Z.; Hao, W.J.; Guo, X.L.; Jiang, L. Bioinspired Hydrogel-Polymer Hybrids with a Tough and Antifatigue Interface via One-Step Polymerization. ACS Appl. Mater. Interfaces 2020, 12, 51036–51043. [Google Scholar] [CrossRef] [PubMed]

- Mizutani, T.; Okuda, N. Bioinspired Mechanical Materials—Development of High-Toughness Ceramics through Complexation of Calcium Phosphate and Organic Polymers. Ceramics 2023, 6, 2117–2133. [Google Scholar] [CrossRef]

- Seo, S.; Lee, D.W.; Ahn, J.S.; Cunha, K.; Filippidi, E.; Ju, S.W.; Shin, E.; Kim, B.S.; Levine, Z.A.; Lins, R.D.; et al. Significant Performance Enhancement of Polymer Resins by Bioinspired Dynamic Bonding. Adv. Mater. 2017, 29, 9. [Google Scholar] [CrossRef] [PubMed]

- Askarinejad, S.; Rahbar, N. Mechanics of bioinspired lamellar structured ceramic/polymer composites: Experiments and models. Int. J. Plast. 2018, 107, 122–149. [Google Scholar] [CrossRef]

- Picker, A.; Nuss, H.; Guenoun, P.; Chevallard, C. Polymer vesicles as microreactors for bioinspired calcium carbonate precipitation. Langmuir 2011, 27, 3213–3218. [Google Scholar] [CrossRef]

- Rout, A.; Gumaste, A.; Pandey, P.; Oliveira, E.F.; Demiss, S.; Mahesh, V.P.; Bhatt, C.; Raphael, K.; Ayyagari, R.S.; Autreto, P.A.S.; et al. Bioinspired Aluminum Composite Reinforced with Soft Polymers with Enhanced Strength and Plasticity. Adv. Eng. Mater. 2020, 22, 10. [Google Scholar] [CrossRef]

- Song, F.; Zhang, L.; Chen, R.; Liu, Q.; Liu, J.; Yu, J.; Liu, P.; Duan, J.; Wang, J. Bioinspired Durable Antibacterial and Antifouling Coatings Based on Borneol Fluorinated Polymers: Demonstrating Direct Evidence of Antiadhesion. ACS Appl. Mater. Interfaces 2021, 13, 33417–33426. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Su, J.; Li, T.; Ma, P.; Bai, H.; Xie, Y.; Chen, M.; Dong, W. A Novel UV-Shielding and Transparent Polymer Film: When Bioinspired Dopamine-Melanin Hollow Nanoparticles Join Polymers. ACS Appl. Mater. Interfaces 2017, 9, 36281–36289. [Google Scholar] [CrossRef]

- Wei, Y.-Z.; Wang, G.-S.; Wu, Y.; Yue, Y.-H.; Wu, J.-T.; Lu, C.; Guo, L. Bioinspired design and assembly of platelet reinforced polymer films with enhanced absorption properties. J. Mater. Chem. A 2014, 2, 5516–5524. [Google Scholar] [CrossRef]

- Song, S.; Zhai, Y.; Zhang, Y. Bioinspired Graphene Oxide/Polymer Nanocomposite Paper with High Strength, Toughness, and Dielectric Constant. ACS Appl. Mater. Interfaces 2016, 8, 31264–31272. [Google Scholar] [CrossRef]

- Wetzel, A.E.; Del Castillo Iniesta, N.; Engay, E.; Mandsberg, N.K.; Schou Dinesen, C.; Hanif, B.R.; Berg-Sorensen, K.; Bunea, A.I.; Taboryski, R. Bioinspired Microstructured Polymer Surfaces with Antireflective Properties. Nanomaterials 2021, 11, 2298. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, X.; Chen, Y.; Yang, X.; Ma, J.; Wang, J.; Wang, L.; Feng, W. Bioinspired Color-Changing Photonic Polymer Coatings Based on Three-Dimensional Blue Phase Liquid Crystal Networks. ACS Appl. Mater. Interfaces 2021, 13, 41102–41111. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wang, H.; Qian, B.; Li, H.; Ren, F. Copper-polydopamine composite derived from bioinspired polymer coating. J. Alloys Compd. 2018, 742, 191–198. [Google Scholar] [CrossRef]

- Chiloeches, A.; Echeverría, C.; Fernández-García, M.; Muñoz-Bonilla, A. Influence of Polymer Composition and Substrate on the Performance of Bioinspired Coatings with Antibacterial Activity. Coatings 2019, 9, 10. [Google Scholar] [CrossRef]

- Kühnle, R.I.; Gebauer, D.; Börner, H.G. Calcium ions as bioinspired triggers to reversibly control the coil-to-helix transition in peptide-polymer conjugates. Soft Matter 2011, 7, 9616–9619. [Google Scholar] [CrossRef]

- Lin, S.; Zhao, X.; Jiang, X.; Wu, A.; Ding, H.; Zhong, Y.; Li, J.; Pan, J.; Liu, B.; Zhu, H. Highly Stretchable, Adaptable, and Durable Strain Sensing Based on a Bioinspired Dynamically Cross-Linked Graphene/Polymer Composite. Small 2019, 15, e1900848. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Zuckermann, R.N. Peptoid polymers: A highly designable bioinspired material. ACS Nano 2013, 7, 4715–4732. [Google Scholar] [CrossRef] [PubMed]

- Tan, G.; Yu, Q.; Liu, Z.; Wang, X.; Zhang, M.; Liu, Y.; Zhang, Z.; Ritchie, R.O. Compression fatigue properties and damage mechanisms of a bioinspired nacre-like ceramic-polymer composite. Scr. Mater. 2021, 203, 5. [Google Scholar] [CrossRef]

- Zhu, W.K.; Cong, H.P.; Yao, H.B.; Mao, L.B.; Asiri, A.M.; Alamry, K.A.; Marwani, H.M.; Yu, S.H. Bioinspired, Ultrastrong, Highly Biocompatible, and Bioactive Natural Polymer/Graphene Oxide Nanocomposite Films. Small 2015, 11, 4298–4302. [Google Scholar] [CrossRef]

- Balme, S.; Janot, J.M.; Berardo, L.; Henn, F.; Bonhenry, D.; Kraszewski, S.; Picaud, F.; Ramseyer, C. New bioinspired membrane made of a biological ion channel confined into the cylindrical nanopore of a solid-state polymer. Nano Lett. 2011, 11, 712–716. [Google Scholar] [CrossRef]

- Chen, X.; Pan, S.; Feng, P.J.; Bian, H.; Han, X.; Liu, J.H.; Guo, X.; Chen, D.; Ge, H.; Shen, Q.D. Bioinspired Ferroelectric Polymer Arrays as Photodetectors with Signal Transmissible to Neuron Cells. Adv. Mater. 2016, 28, 10684–10691. [Google Scholar] [CrossRef]

- Deng, H.; Dong, Y.; Su, J.W.; Zhang, C.; Xie, Y.; Zhang, C.; Maschmann, M.R.; Lin, Y.; Lin, J. Bioinspired Programmable Polymer Gel Controlled by Swellable Guest Medium. ACS Appl. Mater. Interfaces 2017, 9, 30900–30908. [Google Scholar] [CrossRef] [PubMed]

- He, G.; Yang, Z.; Pan, L.; Zhang, J.; Liu, S.; Yan, Q.-L. Bioinspired interfacial reinforcement of polymer-based energetic composites with a high loading of solid explosive crystals. J. Mater. Chem. A 2017, 5, 13499–13510. [Google Scholar] [CrossRef]

- He, G.; Li, X.; Jiang, Y.; Dai, Y.; Xu, R.; Zeng, C.; Tu, X.; Yang, Z. Bioinspired hierarchical interface design for improved mechanical and safety properties in energetic polymer composites. J. Mater. Sci. 2020, 55, 15726–15740. [Google Scholar] [CrossRef]

- Jiang, J.; Zhu, L.; Zhu, L.; Zhang, H.; Zhu, B.; Xu, Y. Antifouling and antimicrobial polymer membranes based on bioinspired polydopamine and strong hydrogen-bonded poly(N-vinyl pyrrolidone). ACS Appl. Mater. Interfaces 2013, 5, 12895–12904. [Google Scholar] [CrossRef]

- Tamang, A.; Ghosh, S.K.; Garain, S.; Alam, M.M.; Haeberle, J.; Henkel, K.; Schmeisser, D.; Mandal, D. DNA-Assisted beta-phase Nucleation and Alignment of Molecular Dipoles in PVDF Film: A Realization of Self-Poled Bioinspired Flexible Polymer Nanogenerator for Portable Electronic Devices. ACS Appl. Mater. Interfaces 2015, 7, 16143–16147. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Cho, E.J.; Bekker, L.; Talin, A.A.; Lee, E.; Pascall, A.J.; Worsley, M.A.; Zhou, J.; Cook, C.C.; Kuntz, J.D.; et al. A Bioinspired Artificial Injury Response System Based on a Robust Polymer Memristor to Mimic a Sense of Pain, Sign of Injury, and Healing. Adv. Sci. 2022, 9, e2200629. [Google Scholar] [CrossRef]

- Zou, X.; Jiang, Q.; Wang, X.; He, Y.; Chai, Y.; Ma, H.; Ma, X.; Wang, Y.; Xue, M. Bioinspired Gas-Confined Hollow Microfiber with 2D Conducting Polymer/Graphene Skeleton for Ultrasensitive Liquid Environment Sensor. Adv. Mater. Interfaces 2021, 8, 9. [Google Scholar] [CrossRef]

| Bioinspired Species | Synthetic Polymer | Achievement and Applications | Ref. |

|---|---|---|---|

| General Bioinspiration | 4-arm poly(ethylene glycol) hydrogels | Dynamic mechanical loading, viscoelastic properties, metal–ligand crosslinks | [1] |

| General Bioinspiration | Polymer–inorganic hybrid materials | Crystal growth, structured polymer templates, inorganic hybrid | [2] |

| Spider Silk | Polymer nanocomposites for high temperatures | Energy density, nanoconfinement effect, high-temperature performance | [3] |

| Bone | Calcium phosphate oligomers in PVA/Alg networks | Ultra-tough laminate, bending strain and toughness, water content | [4] |

| Nacre (Mollusk Shell) | MXene-based polymer composites | Finite elements analysis, Young’s modulus, strength, damage resistance | [5] |

| Various Biological Structures | Various FRP composites | Toughening mechanisms, manufacturing processes, damage mitigation | [6] |

| Graphene | Graphene-based polymer nanocomposites | Strength, toughness, hierarchical structure, mechanical properties | [7] |

| General Bioinspiration | Ceramic platelet-reinforced piezoelectric polymer | Tensile toughness, thermal annealing, piezoelectric properties | [8] |

| General Bioinspiration | Cholesteric nanocomposites with cellulose nanocrystals | Hierarchical self-assembly, photonic response, mechanical properties | [9] |

| Nacre | Alginate–alumina composite films | Strong, stiff, tough, hydrogel-film casting, microstructure | [10] |

| General Bioinspiration | Clay/polymer aerogels | Mineralization, mechanical properties’ improvement, freeze-drying technique | [11] |

| Beetles (Wing Locking Device) | High-aspect-ratio polymer fibers interlocker | Reversible interlocking, van der Waals force, shear force | [12] |

| General Bioinspiration | Nucleobase-containing polymers | Tough bioplastics, adhesives, hydrogen-bonding interactions | [13] |

| Biomineralization Principles | Coating polymers with prismatic films | Crystallization technique, graphene oxide, tribological performance | [14] |

| General Bioinspiration | Cd-based coordination polymer | Luminescence-based sensing, Schottky diode, hydrothermal synthesis | [15] |

| General Bioinspiration | Liquid crystal nanoparticle actuator | Adjustable light, color change, photo-humidity response | [16] |

| General Bioinspiration | Graphene–polymer heterogeneous sensing junction | Humidity sensor, fast response, water metabolism monitoring | [17] |

| General Bioinspiration | Paper/polymer bilayer actuator | Electrically driven, anisotropic deformation, bioinspired applications | [18] |

| General Bioinspiration | Conjugated polymers/liquid crystal elastomers | NIR light-induced actuation, soft robotics, tunable deformation | [19] |

| General Bioinspiration | Graphene oxide–polymer hybrid hydrogels | Smart actuator, strong mechanical properties, thermo-responsive | [20] |

| Marine Mussels | Metal–polymer hybrid nanostructures in nanofibers | Electrospinning, catechol-grafted polymer, metal nanostructures | [21] |

| General Bioinspiration | Catecholamine polymers for organ-on-chip | Microfluidic coating, cell culture stability, flow-based technique | [22] |

| General Bioinspiration | Theranostic coordination polymer nanoparticles | Parkinson’s Disease, dopamine replacement, nanoencapsulation, intranasal delivery | [23] |

| General Bioinspiration | Biomimetic silicified gelatin scaffolds | Angiogenesis, bone regeneration, bioactive hybrid scaffold | [24] |

| Ice-Binding Proteins (IBPs) | Threonine-based polymers for IRI | Ice recrystallization inhibition, phosphate-buffered saline, low molecular weights | [25] |

| Hair or Skin | Polymers on chemically structured substrates | Adsorption/desorption, hydrophilic homopolymers, molecular dynamics simulations | [26] |

| Leaves | Nano-porous polytetrafluoroethene surface | Superhydrophobic properties, hierarchical wrinkling, water repellence | [27] |

| Carbonic Anhydrase | Porous organic polymer-functionalized membranes | CO2 capture, mixed matrix membranes, biomimetic material | [28] |

| Brown Algae | Polysaccharide-based 3D crosslinked network binder | Li-ion battery, Si anodes, volume expansion prevention | [29] |

| General Bioinspiration | Carboxylate–water coordination polymers | Electrochemical water splitting, hydrogen bond clusters, bimetallic CPs | [30] |

| General Bioinspiration | Redox-active catechol-bearing polymers | Organic cathodes, lithium storage, catechol polymers | [31] |

| Sandcastle Worm | Polymer carbon dot membranes | Proton exchange, electrostatic complexation, fuel cells | [32] |

| General Bioinspiration | Catechol-grafting PEDOT cathode | Aqueous proton battery, high voltage, rate capacity | [33] |

| General Bioinspiration | Electrically conductive bioinspired adhesive polymer | Metal-free, water-dispersible, high electrical conductivity, adhesive strength | [34] |

| General Bioinspiration | Chitosan-based resistive-switching memory | Natural solid polymer electrolyte, nonvolatile memory, transparency | [36] |

| General Bioinspiration | Saccharide-responsive smart copolymer | Enrichment of sialylated glycopeptides, saccharide interaction, glycosylation | [37] |

| General Bioinspiration | Plant cell wall polymer assemblies | Carbohydrate-binding modules, lignocellulose-acting enzymes, biorefinery | [38] |

| General Bioinspiration | Uracil-functionalized poly(3-thiophene) | Organic light-emitting diodes, hole-conducting polymers, thermal stability | [39] |

| General Bioinspiration | Core-shell Au nanorod@TiO2 with l-DOPA polymer | Photovoltaic, enzymatic sensing, bioinspired heterostructure | [40] |

| General Bioinspiration | Antifouling polymers | Biointerface control, nonspecific interaction reduction, biomedical applications | [41] |

| General Bioinspiration | Phospholipid polymer biomaterials | Artificial organs, blood compatibility, polymer biomaterials | [42] |

| General Bioinspiration | Glycopolypeptides | Biomedical applications, stimuli-responsive behavior, self-assembling structures | [43] |

| Creeper Suckers | Dendritic-crystal-reinforced polymer gel | Reversible adhesion, phase-transition, finite element analysis | [44] |

| General Bioinspiration | Catechol-rich polymers | Redox-active, plasma deposition, lithium-ion battery cathode | [45] |

| Synovial Joints (Lubrication) | Poly(dodecyl methacrylate) brushes | Tribological behavior, solvent confinement, viscoelastic behavior, load shielding | [46] |

| Lotus Plant | Alkyl-silanized coating for Mg alloy | Hydrophobicity, corrosion resistance, silica surface modification | [47] |

| Mussel Adhesive Polymers | Copolymers with poly(ethylene oxide) side chains | Wear resistance, adsorption layers, electrostatic and catechol anchoring | [48] |

| Nacre (Mollusk Shell) | Graphene-reinforced polymer with multilayer structure | Tensile strength, electrical conductivity, graphene content | [49] |

| Snail and Mussel | Poly(dopamine methacrylate-co-hydroxyethyl methacrylate) | Strong adhesion, thermal conductivity, carbon nanotubes, phonon transport | [50] |

| Barnacles | Hydrogel–polymer hybrids | Adhesive strength, hydrophobic interface, antifatigue, one-step polymerization | [51] |

| Bone | Calcium phosphate and organic polymer composites | High-toughness ceramics, carbonated apatite, organic-inorganic interface | [52] |

| Marine Mussels | Catecholic priming layer for polymers | Enhanced adhesion, crosslinked polymethacrylate, molecular dynamics | [53] |

| Nacre | Alumina/polymer composites | Lamellar structure, freeze casting, mechanical performance, fracture mechanics | [54] |

| General Bioinspiration | Calcium carbonate precipitation in polymer vesicles | Microreactors, polymersomes, mineralization, calcium carbonate | [55] |

| General Bioinspiration | Aluminum–polyethylene terephthalate composite | Enhanced strength and plasticity, friction stir processing | [56] |

| General Bioinspiration | Borneol fluorinated polymers | Antibacterial, antifouling, fluorine components, natural antifouling agent | [57] |

| General Bioinspiration | Dopamine-melanin nanoparticles in polymers | UV-Shielding, hollow nanoparticles, dopamine polymerization | [58] |

| General Bioinspiration | CuS/PVDF nanocomposite films | Platelet-reinforced, enhanced absorption, brick-and-mortar structure | [59] |

| General Bioinspiration | Shape-memory polymer with light-coded crystallinity | 4D transformation, photothermal effect, spatial heterogeneity | [35] |

| General Bioinspiration | Graphene oxide/polymer nanocomposite paper | High strength, toughness, dielectric constant, graphene oxide | [60] |

| Peacock Spider | Micro-structured polymer surfaces | Antireflective, scanning electron microscope, optical properties | [61] |

| General Bioinspiration | Photonic polymer coatings | Color-changing, humidity-responsive, liquid crystal networks | [62] |

| General Bioinspiration | Copper–polydopamine composite | Metal matrix composites, electrical conductivity, thermal conductivity | [63] |

| General Bioinspiration | Methacrylic copolymers with thiazolium and catechol | Antibacterial coatings, thermogravimetric analysis, differential scanning calorimetry | [64] |

| General Bioinspiration | Peptide–polymer conjugates | Coil-to-helix transition, calcium ion control, bioconjugate | [65] |

| General Bioinspiration | Graphene/polymer composite strain sensor | Stretchable, adaptable, self-healing, biomineralization-inspired | [66] |

| General Bioinspiration | Peptoid Polymers | Bioinspired, sequence-specific, biomedicine, nanoscience | [67] |

| Nacre (Seashells) | Ceramic–polymer composite | Compression fatigue, dental applications, brick-and-mortar structure | [68] |

| General Bioinspiration | Konjac glucomannan/graphene oxide nanocomposite | Biocompatibility, bioactivity, tissue engineering, food packaging | [69] |

| Gramicidin-A (Ion Channel) | Solid-state polymer with biological ion channel | Nano-porous membrane, ionic permeability, molecular simulations | [70] |

| General Bioinspiration | Ferroelectric polymer arrays | Photodetector, neuron signal transduction, photoisomerization | [71] |

| Ice Plant Seed Capsules | Programmable polymer gel | Responsive materials, 3D origami structures, direct laser writing | [72] |

| Mussels | Polymer-based energetic composites | Explosive crystals, polydopamine coating, enhanced mechanical properties | [73] |

| General Bioinspiration | Energetic polymer composites | Mechanical properties, safety, hierarchical interface design | [74] |

| Mussel | Antifouling and antimicrobial polymer membranes | Polydopamine, poly(N-vinyl pyrrolidone), strong hydrogen bonding | [75] |

| General Bioinspiration | Bioinspired polymer for Li-ion battery | Flexible nanogenerator, piezoelectricity, energy harvesting | [76] |

| General Bioinspiration | Robust polymer memristor | Artificial injury response, sense of pain, flexible electronic skin | [77] |

| Fish Swim Bladder | Hollow microfiber with conducting polymer/graphene | Liquid environment sensor, hollow-structured, triple-phase interface | [78] |

| Polymer/Composition | Preparation | Ref |

|---|---|---|

| Materials Science and Composite Development | ||

| 4-arm poly(ethylene glycol) hydrogels crosslinked with dynamic metal–ligand coordinate complexes | Engineered for decoupled spatial structure and mechanical performance, with control over mechanical hierarchy and viscoelastic properties through the concentration of metal–ligand crosslinks. | [1] |

| Polymer–inorganic hybrid materials | Utilization of structured polymer templates as substrates to support crystal growth, leading to the formation of polymer–inorganic hybrid materials through the translation of the polymer-film pattern into the crystal nucleation face. | [2] |

| Polymer nanocomposites with poly(aryl ether sulfone) and wide-bandgap artificial nanosheets | Inspired by spider silk, anchoring poly(aryl ether sulfone) to the surface of nanosheets to prepare nanocomposites that exhibit enhanced mechanical and electrical performances at high temperatures. | [3] |

| Ultra-tough composite with poly(vinyl alcohol) (PVA), sodium alginate (Alg), and ultrasmall calcium phosphate oligomers (CPO) | Integration of CPO within PVA and Alg networks through a simple three-step strategy, inspired by bone structure, to achieve strong multiple molecular interactions and high bending toughness. | [4] |

| Polymer vesicles as microreactors for calcium carbonate precipitation, using polymersomes loaded with carbonate ions | Encapsulation of salts and selective permeability to calcium ions triggered by calcimycin, demonstrating mineralization of calcium carbonate within polymersomes. | [55] |

| Mechanical Performance and Composite Materials’ Enhancement | ||

| MXene/polymer nanocomposites with nacre-mimetic brick-and-mortar structure | Modeled and analyzed for deformation behavior, showing enhanced Young’s modulus and strength via the interlocking mechanism between MXene fillers in the polymer matrix. | [5] |

| Bioinspired toughening of fiber-reinforced polymer composites | Review of biomimetic approaches and engineering composite developments for designing and manufacturing high mechanical performance and multifunctional composite structures. | [6] |

| Graphene-based nanocomposites | Advances in bioinspired approaches to improve mechanical properties, involving the structure and mechanical properties of GO papers, novel graphene–polymer interphases, and synergistic mechanical improvements. | [7] |

| Piezoelectric polymer composite reinforced with sapphire platelets: poly(vinylidene fluoride-trifluoroethylene) (P(VDF-TrFE)) | Layer-by-layer fabrication of sheets reinforced by aligned sub-micron-thick sapphire platelets, with thermal annealing to improve crystallinity and mechanical properties. | [8] |

| Hierarchically self-assembled, cholesteric nanocomposite with cellulose nanocrystals (CNC) and polymers featuring ureidopyrimidinone (UPy) motifs | Synthesis of hydrophilic, nonionic polymers with UPy motifs via reversible addition-fragmentation transfer polymerization, co-assembled with CNC to form ordered cholesteric phases with controlled helical pitch. | [9] |

| Polymer composite films with alginate (Alg) matrix and alumina (Alu) micro-platelets, crosslinked by calcium ions (Ca2⁺) and improved by polyvinylpyrrolidone (PVP) coating on platelets | Hydrogel-film-casting method for layered organic/inorganic microstructure, aiming for simultaneously strong, stiff, and tough composites. | [10] |

| Mineralized clay/polymer aerogels | A bioinspired approach using a layer-by-layer method to produce alternate layers of polymer and silica on the surface, improving mechanical properties. | [11] |

| Aluminum composite reinforced with soft polymers (polyethylene terephthalate) | Processed using the friction stir processing technique, showing enhancement in strength and toughness. | [56] |

| Platelet-reinforced polymer films with CuS hexagonal nanoplatelets and polyvinylidene fluoride (PVDF) | Self-assembly of CuS hexagonal platelets into brick-and-mortar structure CuS/PVDF nanocomposite films for enhanced absorption properties. | [59] |

| Copolymer comprised of polydimethylsiloxane (PDMS) and poly(glycidyl methacrylate) (PGMA) | Atom transfer radical polymerization method. PDMS provides flexibility, and PGMA offers reactive groups and adhesiveness, used as an adhesive between GO nanosheets for the fabrication of GO/PDMS-PGMA papers, enhancing tensile strength, toughness, and dielectric constant. | [60] |

| Copper-PDA (Cu-PDA) composite derived from polydopamine coating on copper powder particles | Coating Cu powder with PDA films and sintering to enhance electrical and thermal conductivity, inspired by metal matrix composites with nanocarbon phases. | [63] |

| Organic–inorganic composite materials of calcium phosphate and organic polymers | Bottom-up coprecipitation of polymer and inorganic crystals to mimic bone formation, using eco-friendly materials, such as cellulose and starch, for high-toughness ceramics. | [52] |

| High-content graphene-reinforced polymer with bioinspired multilayer structure (HEC, HPMC, and PVA)/graphene | Simple solution evaporation and reduction method to prepare polymers/graphene-layered composites with high-content graphene (45 to 75%), optimizing the mechanical and electrical properties. | [49] |

| Bioinspired lamellar structured ceramic/polymer composites (Alumina/polydimethylsiloxane (Al2O3/PDMS) and alumina/polyurethane (Al2O3/PU)) | Freeze-casting technique to create lamellar structures that mimic the mechanical performance of nacre, including detailed mechanical performance analysis and modeling. | [54] |

| Adhesion and Surface Engineering | ||

| High-aspect-ratio polymer fibers | Development of a reversible interlocker inspired by beetle wing locking, using van der Waals force-assisted binding between high-aspect-ratio polymer fibers for flexible, strong shear locking force and easy lift-off. | [12] |

| Nucleobase-containing polymers | Efficient thiol-ene polymerization to produce nucleobase-functionalized homopolymers and statistical copolymers, harnessing complementary hydrogen-bonding interactions for toughness and adhesive properties. | [13] |

| Dendritic-crystal-reinforced polymer gel | Introduction of a room-temperature crystallizable solvent into the polymer network, forming a gel adhesive through hydrogen-bonding interaction between crystal fibers and polymer network for reversible adhesion. | [44] |

| Crosslinked polymethacrylate resin enhanced by a catecholic priming layer | Bioinspired dynamic bonding via a thin catecholic layer to significantly enhance the adhesion strength and toughness of polymer resins on mineral surfaces. | [53] |

| Polymer-based composite with poly(dopamine methacrylate-co-hydroxyethyl methacrylate) (P(DMA-HEMA)) and vertically aligned carbon nanotubes (VACNTs) | Inspired by snail and mussel adhesion, synthesizing a copolymer that forms strong bonding with VACNTs through pi–pi interactions, achieving high thermal conductivity and strong adhesion. | [50] |

| Hydrogel–polymer hybrids with a hydrophobic interface | Inspired by barnacle adhesion, combining hydrogels and polymers through introducing an adhesive layer via one-step polymerization, achieving a tough and antifatigue interface. | [51] |

| Tribological Performance | ||

| Polymers coated with self-organized prismatic films of calcite nano-coatings | GO-mediated compartmentalization and templating prismatic growth of calcite via control of ionic diffusivity into microcompartments for tribological performance enhancement. | [14] |

| Poly(dodecyl methacrylate) (P12MA) | Brush structures sliding in oil, evaluated under high-viscosity conditions for low wear rates, mimicking the lubricating mechanism in synovial joints. | [46] |

| Statistical copolymers with medium-length poly(ethylene oxide) side chains | Anchored to surfaces via electrostatic forces, catechol groups, or both, and evaluated for wear resistance under water. | [48] |

| Sensing and Actuation | ||

| Cd-based coordination polymer with N-nicotinoylglycinate: [Cd-(C8N2O3H7)2(H2O)2]n | Hydrothermal method using N-nicotinoylglycinate for turn-on luminescence-based sensing and Schottky diode behavior in device fabrication. | [15] |

| Liquid crystal nanoparticle actuator (LCNA) with 2-(3′,3′-dimethylSP) | Supramolecular self-assembly via a surfactant-assisted method from functional liquid crystal molecules for bioinspired smart interfaces with adjustable light and changeable color. | [16] |

| Graphene–polymer heterogeneous sensing junction for humidity fluctuation sensors | Bioinspired atomic-precise tunable sensing junction by confining sensing material into graphene nanochannels for high-performance wearable devices. | [17] |

| Anisotropic paper/polymer bilayer actuators | Combining hygro-expansion and thermal expansion, fabricated by a simple printing method to exhibit large and anisotropic deformation with a reversible color-change function. | [18] |

| Conjugated polymers/liquid crystal elastomers actuators | Synthesis of organic photothermal dopant via palladium-catalyzed Stille cross-coupling polymerization, integrated into liquid crystal elastomers for NIR light-induced, ultrafast soft actuators with tunable deformation. | [19] |

| Polymer–clay hydrogel hybrid | Series combination of tough polymer–clay hydrogels, successively irradiated by near-infrared (NIR) for comprehensive “extension–grasp–retraction” actuation, leveraging GO’s rapid NIR energy absorption for thermo-energy transformation. | [20] |

| Graphene/polymer composite with dynamic crosslinking for stretchable strain sensing | Biomineralization-inspired creation of a composite from graphene, poly(acrylic acid), and amorphous calcium carbonate, yielding highly adaptable and durable strain sensors. | [66] |

| Ferroelectric polymer arrays with embedded dye molecules for photodetection transmissible to neuron cells | Utilizing photoisomerization of dye molecules in ferroelectric polymer membrane for electric polarization change under light. | [71] |

| Hollow-structured microfiber with 2D polypyrrole (2DPPy) and reduced GO skeleton for liquid environment sensing | Inspired by fish swim bladder, creating a microfiber with a hollow structure and 2D conducting polymer/graphene skeleton for ultrasensitive sensing in liquid environments. | [78] |

| Hybrid nano-porous membrane with Gramicidin-A confined in solid-state polymeric thin film | Confined selective ion channel inside nanopores of a solid-state polymer, enhancing ionic permeability. | [70] |

| Programmable polymer gel controlled by swellable guest medium | Implanting swellable guest medium inside non-swellable host polymers to enhance swelling inhomogeneity for responsive 3D shape transformation. | [72] |

| Poly(vinylidene fluoride) (PVDF) film with deoxyribonucleic acid (DNA) for beta-phase nucleation | Using DNA to align molecular dipoles in PVDF, resulting in piezoelectricity without electrical poling for energy harvesting. | [76] |

| Biomedical Applications and Drug Delivery | ||

| Metal–polymer hybrid nanostructures within 3D electrospun nanofibers, using catechol-grafted poly(vinyl alcohol) | Electrospinning of redox-active polymer for immobilizing and reducing noble metal ions to solid metal nanostructures at ambient temperature. | [21] |

| Catecholamine polymer-coated microfluidic chips | Flow-based coating technique using bioinspired polymers PDA and polynorepinephrine (PNE) for shelf-stable coating in microfluidic organ-on-a-chip applications. | [22] |

| Bioinspired theranostic coordination polymer nanoparticles for dopamine replacement in Parkinson’s Disease | Encapsulation of dopamine within nanoparticles through reversible coordination complexation, offering a new therapeutic approach for symptomatic therapy. | [23] |

| Silicified gelatin scaffolds via bioinspired polymer-induced liquid precursor (PILP) for bone regeneration and angiogenesis | Fabrication of hybrid nanocomposite scaffolds through impregnation of Si-containing PILP into porous gelatin scaffolds, followed by in situ polymerization, mimicking natural bone mineralization. | [24] |

| Phospholipid polymer biomaterials with 2-methacrylooyloxyethyl phosphorylcholine (MPC) polymers | Synthesis inspired by biomembrane surface structure for high-performance artificial organs with excellent blood compatibility. | [42] |

| Glycopolypeptides synthesized via N-Carboxyanhydride (NCA) polymerization | Production of smart biofunctional materials for biomedical applications, including targeted drug delivery, and potential structural materials for bioinspired hierarchical structures. | [43] |

| Methacrylic copolymers bearing thiazolium cationic groups and catechol moieties | Coating various substrates with copolymers for antibacterial activity, with adhesion and performance influenced by polymer composition and substrate. | [64] |

| Peptide–polymer conjugates sensitive to calcium ions (Ca2+) for reversible coil-to-helix transition | Utilizing calcium ions to regulate the secondary structure transition in peptide–polymer conjugates, with reversible control achieved via competitive Ca2+-ion binders. | [65] |

| Peptoid polymers with tunable structures for biomedicine and nanoscience | Synthesizing N-substituted glycine backbone polymers offering designable structures bridging proteins and traditional polymers. | [67] |

| Konjac glucomannan/GO nanocomposite films for biocompatible and bioactive surfaces | Solution-casting method to fabricate ultra-strong, biocompatible nanocomposite films with enhanced mechanical properties. | [69] |

| Antifouling and antimicrobial polymer membranes with PDA and poly(N-vinyl pyrrolidone) | Coating polypropylene membranes with PDA and further modification by PVP via hydrogen-bonding interactions for enhanced antifouling and antimicrobial activities. | [75] |

| Nacre-like ceramic–polymer composite for compression fatigue properties | Mimicking brick-and-mortar structure for high fatigue resistance, showing potential in dental applications. | [68] |

| Biomedical and Environmental Applications | ||

| Poly(2-hydroxypropyl methacrylamide) (pHPMA) | Synthesized using pThr as a model and tested for IRI activity in neutral PBS. Exhibited potent IRI activity at both low (2.3 kDa) and high molecular weights (32.8 kDa). | [25] |

| Hydrophilic flexible homopolymers on chemically patterned substrates | Coarse-grained molecular dynamics simulations to study polymer adsorption and desorption on bioinspired, chemically structured substrates for ecofriendly product development. | [26] |

| Hierarchically wrinkled nano-porous polytetrafluoroethylene (PTFE) surfaces on thermoretractable polystyrene (PS) sheet | PTFE dispersion coated on PS sheet, followed by thermal treatment to induce surface wrinkling through dynamic thermal contraction, resulting in superhydrophobic properties. | [27] |

| Antifouling polymers | Development of surfaces resistant to fouling by proteins, cells, and bacteria, leveraging specific interactions between designed surfaces, biomolecules, and cells for biomedical applications. | [41] |

| Hydrophobic alkyl-silanized protective polymer coating for magnesium alloy, modified by trimethylsilylation with hexamethyldisilazane | Reinforcement with nano-silica powder and chemical modification to enhance hydrophobicity and corrosion resistance, inspired by lotus plant leaf structures. | [47] |

| Electrical and Electronic Materials | ||

| Electrically conductive bioinspired adhesive polymers: poly(N-methacryloyl-3,4-dihydroxyl-L-phenylalanine-co-3-sulfopropyl methacrylate):poly(3,4-ethylenedioxythiophene) (PMS:PEDOT) | Synthesis involving radical polymerization and oxidative polymerization to create a water-dispersible, lightweight, highly flexible, biocompatible adhesive with high electrical conductivity. | [34] |

| Chitosan (a natural solid polymer electrolyte) | Solution-processed to form a resistive-switching memory device with a Pt/Ag-doped chitosan/Ag structure, demonstrating reproducible and reliable bipolar resistive switching characteristics. | [36] |

| Polylactide (a re-processable thermoplastic shape-memory polymer) | Utilizes a digital photothermal effect for spatio-selective programming of crystallinity by physical phase transformation (crystallization), enabling repeated erasing and reprogramming for 4D shape transformation. | [35] |

| Environmental and Antifouling Solutions | ||

| Borneol fluorinated polymers: poly(methyl methacrylate-co-ethyl acrylate-co-hexafluorobutyl methacrylate-co-isobornyl methacrylate) copolymer | Free radical polymerization method incorporating fluorine components and borneol for antibacterial and antifouling activities. | [57] |

| UV-shielding and transparent polymer film with bioinspired dopamine–melanin hollow nanoparticles | Synthesis of dopamine–melanin nanoparticles integrated into poly(vinyl alcohol) to enhance UV-shielding performance. | [58] |

| Humidity-driven color-changing photonic polymer coatings based on hydrogen-bonded, three-dimensional blue-phase liquid crystal networks | Fabrication of coatings exhibiting vivid structural colors and reversible color changes upon humidity variation, for applications such as information encryption and bioinspired camouflage. | [62] |

| Polyacrylate resin | Super-resolution 3D printing using two-photon polymerization to fabricate antireflective microarrays inspired by the peacock spider’s super black structures. The micro-lens arrays exhibit excellent antireflective properties, achieved through tightly packed arrays of slightly pyramidal lenses. | [61] |

| Energy Storage and Conversion | ||

| Three-dimensional crosslinked polysaccharide network binder for silicon (Si) anodes in lithium-ion batteries, crosslinked with citric acid (CA) | Formation of a 3D crosslinked network around Si particles using sodium alginate (SA) and CA, improving volume expansion handling and electrode robustness. | [29] |

| Carboxylate–water coordination polymers with hydrogen-bond clusters | Assembly of coordination polymers with transition-metal sites for electrochemical water splitting, inspired by photosystem II’s hydrogen bond cluster. | [30] |

| Redox-active catechol-bearing polymers as organic cathodes for lithium storage | Design of copolymers bearing catechol- and Li-ion-conducting anionic pendants for use in lithium-ion batteries. | [31] |

| Ultra-robust, highly proton-conductive polymer carbon dot membranes | Fabrication via electrostatic complexation between acidic-group-functionalized polymer carbon dots and sulfonated polyether ether ketone for fuel cell applications. | [32] |

| Poly(3,4-ethylenedioxythiophene) (PEDOT) with bioinspired catechol pendants for an aqueous proton battery cathode | Grafting PEDOT with catechol pendants to design a high-voltage and high-rate-capacity cathode for aqueous proton batteries. | [33] |

| Catechol-rich polymers deposited via atmospheric plasma for redox-active thin films | One-step plasma-based synthesis and deposition of catechol-rich polymers, demonstrating potential as organic cathode materials. | [45] |

| Environmental and Materials Science | ||

| Porous organic polymer-functionalized membranes for CO2 capture | Incorporating biomimetic material Co-BBP on POPs surface in Pebax matrix, enhancing CO2 separation performance. | [28] |

| Energetic polymer composites with hierarchical interface design | Bioinspired “grafting from” polymerization of hyperbranched polyurethane on PDA surface to improve mechanical and safety properties. | [74] |

| Polymer-based energetic composites with solid explosive crystals reinforced by PDA coating | Coating 1,3,5-triamino-2,4,6-trinitrobenzene (TATB) crystals with PDA to enhance interfacial interactions in polymer-bonded explosives. | [73] |

| Bioprocessing and Biomolecular Engineering | ||

| Saccharide-responsive smart copolymer (SRSC) with allose units for specific enrichment of sialylated glycopeptides | Integration of allose units into a polyacrylamide chain, enhancing selectivity and binding tunability toward sialic acids through pH and solution polarity. | [37] |

| Lignocellulose-acting enzymes with carbohydrate-binding modules (CBMs) for bioinspired model assemblies | Designing bioinspired assemblies to study CBM mobility and binding affinity, revealing oligomerization and ferulic acid motifs’ role in affinity. | [38] |

| Uracil-functionalized poly(3-thiophene) for hole-conducting in organic light-emitting diodes | Forms physical cross-linkages for high thermal stability and enhanced hole injection/transport capabilities. | [39] |

| Core-shell Au nanorod@TiO2 heterostructure coupled with l-DOPA polymer | Designing a composite to enhance photovoltaic and enzymatic sensing performance, where l-DOPA polymer enhances light harvesting and electron transfer. | [40] |

| Copolymer of chlorotrifluoroethylene and vinylidene fluoride (FK-800) for a flexible and robust diffusive memristor | Fabricating a memristor to mimic human-like self-protection modalities with a sense of pain, sign of injury, and healing. | [77] |

| Category | Description | Ref. # |

|---|---|---|

| Bioinspired Structural Design for Mechanical Enhancement | Bioinspired designs improving mechanical properties (strength, toughness, and Young’s modulus) via brick-and-mortar, hierarchical structures. | [4,5,9,59] |

| Advanced Material Composition for Broad Property Enhancement | Polymer–inorganic hybrids and graphene-based nanocomposites enhancing energy density and electrical/thermal conductivity. | [2,3,7,49,55,60,63] |

| Innovative Adhesion, Surface Engineering, and Tribological Performance | Molecular/surface interactions leading to ultra-strong adhesives and surfaces with controllable adhesion-detachment, inspired by natural mechanisms. | [12,13,44,50,51,53] |

| Improved wear resistance, lower friction coefficients under various conditions, and mimicking natural lubrication systems. | [14,46,48] | |

| Sensing, Actuation, and Biomedical Applications | Responsive materials for smart textiles, soft robotics, bioelectronics through luminescence, color change, and humidity sensing. | [15,16,17,18,19,20,71,72] |

| Advancements in tissue engineering, drug delivery systems, antibacterial coatings for improved health outcomes, and medical devices. | [21,23,24,38,42,43,64] | |

| Energy Storage, Conversion, and Environmental Sustainability | Improved mechanical strength, cycle retention in Si anodes, redox-active thin films, electrocatalytic performance, and proton-conductive membranes. | [29,30,31,32,33,45] |

| CO2 separation performance and mechanical properties of energetic composites for environmental sustainability and safety. | [28,73,74] | |

| Bioprocessing and Biomolecular Engineering | Breakthroughs in sialylated glycopeptide enrichment, optimization of bioprocesses, organic electronics, and enzymatic sensing. | [37,38,39,40,77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omidian, H.; Babanejad, N. Bioinspired Polymers: Bridging Nature’s Ingenuity with Synthetic Innovation. Macromol 2024, 4, 190-212. https://doi.org/10.3390/macromol4020010

Omidian H, Babanejad N. Bioinspired Polymers: Bridging Nature’s Ingenuity with Synthetic Innovation. Macromol. 2024; 4(2):190-212. https://doi.org/10.3390/macromol4020010

Chicago/Turabian StyleOmidian, Hossein, and Niloofar Babanejad. 2024. "Bioinspired Polymers: Bridging Nature’s Ingenuity with Synthetic Innovation" Macromol 4, no. 2: 190-212. https://doi.org/10.3390/macromol4020010