1. Introduction

In recent years, the amount of Municipal Solid Waste (MSW) generated by municipalities and industries has dramatically increased [

1]. Different strategies have been developed in order to reduce the amount of potentially recoverable MSW. Generally, source separation at individual households and subsequent separate collection systems are the most used approach [

2]. In this way, it is possible to extract from waste flows a great amount of recyclable materials to reprocess them in the manufacturing of goods production [

3]. Unfortunately, even if a perfect separation of waste is performed, an amount of residual waste is nevertheless produced. Not so many years ago, the ordinary management of residual waste was the disposal in landfill [

4]. Recently, the European Waste Framework Directive [

5] has emphasized the priority of recycling over waste disposal. According to this regulatory context, several strategies have been developed, such as incineration or waste pre-treatments before landfilling, with the objective of reducing the need of landfill space [

6]. Nevertheless, mostly because of its more positive public acceptance, Mechanical–Biological Treatment (MBT) is considered as the main system for residual MSW management [

7], and its importance is evident especially in contexts where the percentage of separate collection is not high [

8,

9]. Generally, MBT of residual MSW includes: (i) mechanical pre-processing stages to sort out recyclable and/or dry materials, such as paper, metals, and plastics; and (ii) biological stages to reduce and stabilize the biodegradable organic matter under controlled anaerobic and/or aerobic conditions [

10]. The stabilized stream, named Stabilized Organic Fraction (SOF), is generally disposed, whereas the dry one can be mechanically refined for the production of Refuse-Derived Fuel (RDF), delivered to dedicated Waste-to-Energy (WTE) plants [

11]. Within this general classification, multiple varieties and configurations of MBT plants can be found all over the world [

12]. The MBT term has come to embrace several types of processes and elements that are combined in a wide variety of ways to meet a range of objects [

13,

14,

15]. For example, MBT can also be considered as a pretreatment to improve the beginning of biogas production in the anaerobic digestion process [

16]. MBT may be designed for the production of marketable outputs or RDF, energy generation through biogas combustion produced in anaerobic biostabilization, as well as biologically stabilized waste to be used for land/soil applications [

17].

Currently, there is still a missing clarification about the performance of each type of MBT plant in the waste management system. From an environmental point of view, if MBT plant worked in an anaerobic environment for biogas production, they achieved more benefits than other WTE treatments (e.g., incineration) [

18]. On the other hand, aerobic MBT facilities resulted in high impact, due to their energy-intensive process, relative low yields, and the disposal in landfill of the majority of the output flow [

19]. Regarding the sorting process, in some cases, a light mechanical pre-treatment could generate less impact than the production of high-heating value RDF, followed by its combustion into a dedicated plant [

20]. However, there is an evident lack in scientific literature on specific assessments and comparisons of different MBT schemes. Montejo et al. [

12] analyzed, from an environmental point of view, eight MBT operating in Spain with different recovery efficiencies, but the analysis involved only two main types of biological treatment. The state of art of environmental assessments of MBT plants reveals how the studies refer to few technologies adopted by the plants. What is generally missing is an assessment that takes into account a wider number of plant configurations and specific efficiencies (i.e., materials and energy recovery).

Hence, the objective of this work is to thoroughly evaluate the impacts that the current operation of different MBT plants operating in the waste treatment has on the environment. In this context, combining Life Cycle Assessment (LCA) and Material Flow Analysis (MFA) approaches could be a suitable technical support for decision-making processes. LCA is a holistic approach widely adopted in MSW management that quantifies all the environmental impacts throughout the life cycle of products or processes [

21]. MFA quantifies the mass flow and loss in a system throughout the entire pipeline of waste management, and also facilitates data reconciliation in a well-defined space and time [

22]. MFA and LCA are a suitable tool for the comparison of different scenarios, especially in the waste management field [

23].

Therefore, the aims of this work are to assess and compare the current environmental performance of seven selected MBT plants with different operational systems in order to illustrate the processes contributing to significant environmental burdens or benefits. For the scope, WRATE (Waste and Resource Assessment Tool for Environment) software has been used. A quantification of the mass balance for each MBT assessed and the environmental impact of the corresponding process have been carried out. At the end, a thorough discussion about the comparison of the different MBT schemes has been provided. In this context, this paper helps to determine the most sustainable options for the management of residual waste through MBT according to the necessity of the context.

3. Results

3.1. Material Flow Analysis

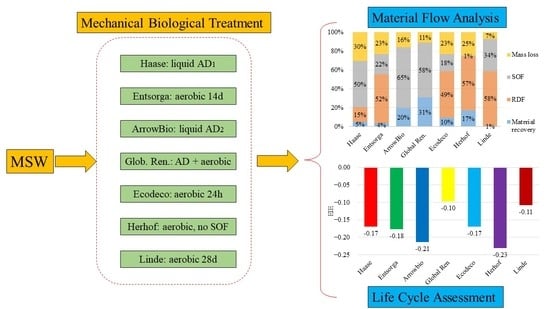

As shown in

Figure 1, the Sankey diagram summarizes the mass flow of the residual waste treatment of each MBT assessed (mass losses are not reported in the figures). High quality figures are provided in

Supplementary Materials (Figures S8–S14).

The main output streams in each MBT were RDF (if provided) and SOF. It is important to note that for ArrowBio and Global Renewables plants, a further transportation of rejected materials to the landfill was necessary, and material recovery seemed to be much lower than the previous ones. Generally, ferrous and non-ferrous (except for Linde) metals were recovered in every plant. A more articulated selection of other waste was performed in ArrowBio and Global Renewables plants. Herhof and Global Renewables MBT were the only plants that recovered inert waste and paper waste, respectively.

The mass balance of every MBT plant is reported in

Figure 2, showing the corresponding percentage amount of recovered materials, RDF, SOF, and mass loss streams.

In

Figure 2, it is shown again that ArrowBio and Global Renewables MBT plants were not provided for the RDF production. On the other hand, Herhof plant achieved a negligible amount of SOF because its scheme could dispense with landfill of it. The highest and lowest (not considering Herhof plant) SOF streams were achieved by ArrowBio (65%) and Ecodeco (18%). RDF streams appeared to be more consistent, ranging from 58% to 49%. The minimum value of 15% was obtained by Haase plant. Generally, material recovery did not exceed the value of 30%. Linde MBT did not perform any recovery, and high amounts were obtained by ArrowBio and Global Renewables plants. Focusing on the mass loss, values ranged from 7% (Linde MBT) to 30% (Haase MBT). On average, Entsorga, Ecodeco, and Herhof plants achieved a mass loss of about 25%.

Focusing on the RDF and SOF streams,

Figure 3 shows their composition in terms of waste fraction. SOF was characterized by a significant presence of putrescible (as organic and fine waste) and non-combustible materials (especially glass and inert waste). Indeed, Entsorga SOF flow achieved a half composition of inert waste, but dry waste (such as plastic, combustibles, and textiles) was almost null. Other relevant results were the high values of paper, metals, and wood in Haase, Entsorga, and Ecodeco SOF streams, respectively. Concerning RDF, it is clear that the putrescible fraction decreased when compared to SOF flows. On the other hand, plastic, paper, and combustibles waste had a considerable presence. In most RDF streams, combustibles waste was about 80% of the whole flow. Haase MBT achieved an RDF flow with an absence of waste that did not contribute to the WTE process, such as inert, metals, and putrescible waste. The higher presence of metals in Linde MBT compared to the other ones was remarkable. The RDF stream of Herhof MBT was characterized by a significant presence of putrescible fraction, in line with the aim of the plant that also involved organic waste in such a stream.

3.2. Life Cycle Impact Assessment

In this section, a comparison of the environmental performance among all the seven MBT plants in terms of six different categories is provided.

Table S2 of

Supplementary Materials presents the characterization results of the seven MBT in each one of the six impact categories considered in this study. Normalized results of the seven MBT for each impact category are shown in

Figure 4. A negative value means an environmental benefit/credit, whereas a positive value indicates an environmental burden.

Concerning Global Warming, all the MBT achieved environmental benefits. This was mainly due to the avoided landfilling of the residual waste. Moreover, the increase in the percentage of RDF utilized in the WTE process decreases the environmental benefit (as expressed in Linde MBT). ArrowBio was the best option in this impact category.

For Acid Rain, environmental credits were reached by all the MBT. The release of ammonia, NOx, and SO2 during aerobic biodegradation or WTE treatment affected this impact category. On the other end, the production of energy from waste avoided the use of a fossil source for energy generation. In addition, the material recovery helped to obtain an environmental benefit. Again, ArrowBio was the best option in this impact category.

Regarding Eutroph’n, six MBT presented an environmental burden, with the exception of the Herhof one. The release of leachate and the production of phosphoric compound during the process were the causes of these values. The values were lower than the environmental credits of the other impact categories.

Considering Aqua Ecotox, all the MBT were characterized by environmental benefits. The influence of recycling strongly affected the results, since the release of heavy metals that characterize the MBT process [

31] was not so high for this category. It is important to note that the recirculation of leachate performed by Ecodeco MBT did not have an evident effect on this category. The best result was achieved by Linde MBT.

Referring to Health, environmental credits were achieved by all the MBT, except for Linde plant. The small amount of recovered materials affected the benefit. Again, the impact due to heavy metals emission was exceeded by the environmental benefits related to recycling. Global Renewables MBT (characterized by the highest recovered materials amount) was the best option for this impact category.

Resources was the impact category in which results achieved the highest absolute values. All the MBT exceeded −0.08 EIE; ArrowBio presented the best value among the other MBT. The environmental burden for Global Renewables was caused by the high need of energy from the plant. Indeed, the numerous pre-treatments, the percolation stage, the three-stage anaerobic digestion, and the final composting process required an amount of energy that exceeded the energy produced through RDF usage.

Figure 5 shows the contribution of landfill, MBT, recycling, and the incinerator stage on the LCA cumulated results.

From the analysis of

Figure 5, it is evident that the main contribution to the environmental impact was given by materials and energy recovery. The sum of these two processes ranged from 93% to 57% of the total impact. Moreover, the MBT affected less LCA results: the MBT contribution was, on average, 14% of the total impact, with maximum and minimum values of 32% in Global Renewables and 4% in Entsorga, respectively. The contribution of landfill did not exceed 15%. From this kind of evaluation, it was not possible to directly evaluate the type of contribution (environmental benefit or burden) in the LCA results, which is possible through the analysis of characterization results in

Table S2.

4. Discussion

The environmental performance of seven different MBT plants have been evaluated through a combined LCA and MFA analysis.

The layout of the plant is fundamental to understand its role and the reason it was designed. Most of the MBT plants were designed for RDF production, but there are other plants (such as the ArrowBio and Global Renewables ones) that do not provide this stage. Landfilling was a common allocation for plant outputs, especially for SOF streams. Herhof MBT aimed to recover even SOF streams, eliminating the need of landfill. Ferrous and non-ferrous materials recovery was an operation generally provided in every MBT plant. On the other hand, other materials, such as glass and plastics, but also paper and inert materials, could be recovered from waste during the MBT process. From

Figure 1 and

Figure 2, it can be seen that the two highest amounts and types of recovered materials were achieved in the MBT plants where the RDF production was not provided (Global Renewables and ArrowBio). In addition, the amount of recovered materials for each MBT plant assessed and the corresponding efficiency of separation are shown in

Table 3. Ferrous and non-ferrous metals recovery show a high efficiency of separation: in most cases, all the input metals were removed through magnetic separation, and, in two plants, the recovery efficiency exceeded 99%. This condition could be associated with the fact that the recovered materials were not composed of metals only. The contamination of foreign fractions, such as plastic, organic, and paper, could affect the quality of recovered materials, increasing the corresponding amounts [

32]. Due to its difficulty in selection and recovery, plastic film is the is the principal fraction involved in contamination [

33]. The efficiency of 19% reached by Linde MBT could be associated with the process itself. Differently from the other MBT, the metals recovery was performed at the beginning of the process, before the biostabilization, causing a decrease in the recovery efficiency. The low metals recovery of Linde MBT was confirmed by the high presence of metals in its RDF stream (

Figure 3). The great amount of ferrous and non-ferrous metals recovered by Global Renewables MBT was the result of a double recovery stage. Regarding the selection of plastic, results showed that ArrowBio MBT, characterized by a liquid-based technology, achieved better efficiency then the other [

34]. The glass selection gave mixed results for the scarce information about the selection process. A large amount of paper could be recovered too, despite the quality being quite low.

MFA results can be discussed in terms of mass loss. Ecodeco MBT showed that even a 24 h-long process could achieve a significant biostabilization (23%). The adoption of a bio-tunnel did not seem to be a great choice because, in Linde MBT, the mass loss hardly exceeds 10%. Indeed, to avoid troubles in the reuse of the organic fractions (e.g., landspreading) or in the landfill disposal (e.g., biogas generation without recovery system), a further biostabilization was necessary [

35]. Anaerobic digestions reached important values if also considering the energy production during the biological process. Haase MBT reached a higher mass loss than the ArrowBio one, due to its wet process and its further dewatering stage at the end of the digestion. Overall, the mass loss during anaerobic biostabilization of residual waste was similar to the one obtained from source-separated organic waste [

36]. Aerobic biostabilization showed a mass loss of about 25%: this value was achieved by both Entsorga and Herhof MBT, despite the first performing the process in twice as long a time.

The discussion of MFA output could be strengthened with the normalized LCA results. As it has been stated above, the environmental benefits that characterized most of the impact category results were due to the materials and energy recovery process of the scenario. Indeed, as confirmed in previous works [

12], recycling and the operational product output stage of the system affected the LCA results, giving an environmentally-friendly direction (

Figure S15 in

Supplementary Materials).

Figure 5 shows that, despite the low contribution of landfill on the environmental impacts, the amount of produced SOF was directly proportional to the effect of such treatment in the results. In addition, the energy output, such as incineration, WTE process, or the gas recovery in the anaerobic digestion stage (if provided in the MBT), was the main part of the environmental benefit (from 40% to 73%). On the other hand, the energy required for the operational MBT process appeared to be negligible compared to the other contribution (<5%). Global Renewables was excluded by this trend because the energy request for the MBT process was very high. For this plant, the energy input affected for 33% the LCA results in a burden way, and the MBT treatment gave the maximum contribution among the other MBT. In addition, energy output could not balance the energy needs of the plant. As a consequence, the LCA results (especially for the Resources category) were very distant from the ones reached by the other plants. Another remarkable aspect is that, despite Haase MBT having an RDF flow entirely composed of combustibles waste and anaerobic digestion producing energy from the biogas recovered, the full recovery of waste in Herhof MBT showed the highest energy production. Indeed, the amount of RDF produced by Haase was very low compared to the Herhof one. Despite anaerobic digestion having great energy production efficiency, the nature of MSW (which, in this study, was almost poor in putrescible fractions) did not allow a high methane yield [

37]. On the other hand, the amount of energy produced during the anaerobic digestion process of Haase plant was enough to fulfil the energy needs of liquid digestate dewatering. In particular, the digestate dewatering through reverse osmosis in Haase did not reveal a significant difference in energy needs (

Figure S15), since the impact contribution of that plant was comparable with the one of ArrowBio (which performed a liquid anaerobic digestion with other dewatering systems). Therefore, from an environmental point of view, the maximum energy production of a MBT plant was not always achieved by reaching a high-quality or quantity RDF stream, but through a balanced combination of them. In addition, by combining the results shown in

Figure 4 and

Figure 5, it can be seen that with the rising of the putrescible fraction in SOF, the contribution of landfill on the LCA results increased.

To sum up,

Figure 6 shows the aggregation of the LCIA normalized results. Aggregation was performed by the simple summation of the normalized results of all impact categories, without a weighting step. As indicated in Den Boer et al. [

38], it should be noted that one EIE in an impact category does not have an identical physical meaning to one EIE for another category. As such, this condensed result does not present a physical sense, but it enables a comparison among several scenarios, allowing the classification of them in terms of global environmental effect [

31]. As expected, the combination of anaerobic and aerobic processes with the further implementation of pre-treatments (Global Renewables) presented the worst results, due to the highest energy consumption. Linde MBT reached a near value for its low amount of recovered materials. Haase, Entsorga, and Ecodeco reached a similar value, revealing how neither the anaerobic or aerobic process affected the results, as well as the residence time of the plant (10–14 days, 24 h, and 1 month for Entsorga, Ecodeco, and Linde, respectively). The higher amount of recovered materials helped ArrowBio and, in particular, Herhof MBT to achieve better results (regardless of anaerobic or aerobic environment, respectively). Material recovery was not the only recycling process, as the WTE process also had an influence in the scheme.

It is important to underline how these results refer to an environmental point of view only. Economic and technical analysis would need to be carried out in order to have a comprehensive overview on the sustainability of the different MBT configurations assessed, since those aspects have significant relevance on MBT facilities [

18].

5. Conclusions

The aims of this work were to assess and then compare the current environmental performance of seven selected MBT plants with different operational systems in order to illustrate the processes contributing to significant environmental burdens or benefits. Concerning the plant layout examination, the metals recovery was a common practice in MBT, which achieved a sorting efficiency of over 80%. Further recovery of different types of waste were also performed; plastic recovery seemed to be most effective through a liquid-based technology. The RDF production was not a constant operation in the MBT process. Regarding the mass balance, the adoption of bio-tunnels in the biostabilization stage achieved an insufficient value in terms of mass loss. LCA results showed that every MBT plant achieved environmental benefit, ranging from −0.11 to −0.23 EIE. From, an environmental point of view, results revealed that, among the seven MBT plants, the best performance was achieved when the highest amount of waste was recovered (not only with material recycling). LCA results were strongly affected by the recycling processes and the energy production, with a small contribution from the energy requirement. For the latter, the case of Global Renewables (characterized with several pre-treatments, a percolation stage, a three-stage anaerobic digestion, and a final composting process) showed a significant energy consumption that created an environmental burden in the Resources impact category. The re-circulation of leachate produced during the biostabilization stage did not have a significant environmental benefit. The impacts achieved by the MBT process were, on average, 14% of the total one; they ranged from a maximum value of 32% to a minimum one of 4%. The RDF quality (in terms of putrescible content) was not the only condition to achieve the highest energy production. Indeed, despite no trace of putrescible matter found in the RDF flow, the energy output could be lower than other MBT with worse RDF quality. Thus, the main condition for a well-performing result is not a perfect material recovery or a high-quality RDF, but a combination of materials recovery for the production of new raw materials, avoiding disposal in landfill, and RDF production for the WTE process. Focusing on the role of landfill in LCA results, it can be seen that the rise of putrescible fractions in SOF increased the contribution of the disposal on the total impact achieved. This work is one of the first environmental assessments that takes into account plant-specific efficiencies (i.e., materials and energy recovery) and the type of marginal energy source replaced. From these results, future investigations can be carried out, focusing on the role of MSW composition and energy-mix. The impact estimation of different MBT plant configurations can be of help to operators and planners when they are asked to define the most suitable treatment schemes for an MBT plant. Thus, this work could be a suitable benchmark for researchers and practitioners working in the municipal solid waste sector.