Blending Controlled-Release and Urease-Inhibitor Technologies as Innovative Solutions to Reduce Ammonia Emissions in Coffee Environments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterization of the Controlled-Release Fertilizers—CRFs

2.2. Experimental Conditions

2.3. Details of Field Experiments

2.4. Testing of N Release from the Fertilizers under Field Conditions and Laboratory Conditions

2.5. Ammonia (N-NH3) Volatilization

2.6. Coffee Bean Yield

2.7. Statistical Analyses

3. Results

3.1. CRF Coating Thickness and Uniformity

3.2. Climate Monitoring in the Field Study

3.3. N Release from the Fertilizers

Linear Regression between Tests of N Release in the Laboratory and in the Field

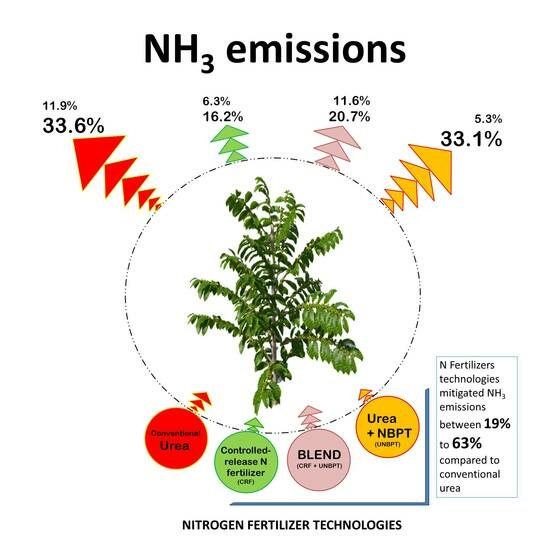

3.4. Ammonia (N-NH3) Volatilization

3.5. Coffee Bean Yield

4. Discussion

4.1. N Release

4.2. Ammonia (N-NH3) Volatilization

4.3. Coffee Bean Yield

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bruno, I.P.; Unkovich, M.J.; Bortolotto, R.P.; Bacchi, O.O.S.; Dourado-Neto, D.; Reichardt, K. Fertilizer Nitrogen in Fertigated Coffee Crop: Absorption Changes in Plant Compartments over Time. Field Crop. Res. 2011, 124, 369–377. [Google Scholar] [CrossRef]

- Salamanca-Jimenez, A.; Doane, T.A.; Horwath, W.R. Nitrogen Use Efficiency of Coffee at the Vegetative Stage as Influenced by Fertilizer Application Method. Front. Plant Sci. 2017, 8, 223. [Google Scholar] [CrossRef] [PubMed]

- Otto, R.; Cantarella, H.; Guelfi, D.; Carvalho, M.C.S. Nitrogênio Na Sustentabilidade de Sistemas Agrícolas. Informações Agronômicas NPCT 2021, 9, 30–50. [Google Scholar]

- IFA. Public Summary Short-Term Fertilizer Outlook; IFA: Berlin, Germany, 2021; pp. 13–14. [Google Scholar]

- Cantarella, H.; Otto, R.; Soares, J.R.; Silva, A.G. de B. Agronomic Efficiency of NBPT as a Urease Inhibitor: A Review. J. Adv. Res. 2018, 13, 19–27. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Xu, W.; Liu, X.; Li, Y.; Wei, J.; Gao, M.; Bi, J.; Lu, X.; Wang, Z.; et al. Challenges for Global Sustainable Nitrogen Management in Agricultural Systems. J. Agric. Food Chem. 2020, 68, 3354–3361. [Google Scholar] [CrossRef]

- Dominghetti, A.W.; Guelfi, D.R.; Guimarães, R.J.; Caputo, A.L.C.; Spehar, C.R.; Faquin, V. Nitrogen Loss by Volatilization of Nitrogen Fertilizers Applied to Coffee Orchard. Ciência Agrotecnologia 2016, 40, 173–183. [Google Scholar] [CrossRef]

- Chagas, W.F.T.; Silva, D.R.G.; Lacerda, J.R.; Pinto, L.C.; Andrade, A.B.; Faquin, V. Nitrogen Fertilizers Technologies for Coffee Plant. Coffee Sci. 2019, 14, 55–66. [Google Scholar] [CrossRef]

- Guimarães, P.; Reis, T.H.P.; Guelfi, D.; Mattiello, E.M.; Montanari, M. Correção e Adubação de Solo Em Cafeeiros Em Produção—Cultivo de Sequeiro. In Cafeicultura do Cerrado; Carvalho, G.R., Ferreira, A.D., Andrade, V.T., Botelho, C.E., C.J., Eds.; Epamig: Belo Horizonte, Brazil, 2021; pp. 141–172. (In Portuguese) [Google Scholar]

- Chagas, W.F.T.; Guelfi, D.R.; Caputo, A.L.C.; de Souza, T.L.; Andrade, A.B.; Faquin, V. Ammonia Volatilization from Blends with Stabilized and Controlled-Released Urea in the Coffee System. Ciência e Agrotecnologia. 2016, 40, 497–509. [Google Scholar] [CrossRef]

- USDA. Coffee: World Markets and Trade; USDA: Washington, DC, USA, 2020; p. 9. [Google Scholar]

- FAO. World Fertilizer Trends and Outlook to 2022; FAO: Rome, Italy, 2019; ISBN 9789251318942. [Google Scholar]

- Directive 2016/2284 of the European Parliament and of the Council, D. Directive 2016/2284 of the European Parliament and of the Council of 14 December 2016 on the Reduction of National Emissions of Certain Atmospheric Pollutants, Amending Directive 2003/35/EC and Repealing Directive 2001/81/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2016.344.01.0001.01.E (accessed on 28 September 2023).

- Hu, Y.; Schmidhalter, U. Urease Inhibitors: Opportunities for Meeting EU National Obligations to Reduce Ammonia Emission Ceilings by 2030 in EU Countries. Environ. Res. Lett. 2021, 16, 084047. [Google Scholar] [CrossRef]

- Draft Guidance Document for Preventing and Abating Ammonia Emissions from Agricultural Sources. In Working Group of Strategies and Review, 48th Session, 11-15 April 2011, Geneva Informal document No. 7; UN Economic and Social Council: Geneva, Switzerland, 2011.

- Snyder, C.S. Enhanced Nitrogen Fertiliser Technologies Support the “4R” Concept to Optimise Crop Production and Minimise Environmental Losses. Soil Res. 2017, 55, 463–472. [Google Scholar] [CrossRef]

- Guelfi, D. Fertilizantes Nitrogenados Estabilizados, de Liberação Lenta Ou Controlada. Informações Agronômicas 2017, 157, 1–14. [Google Scholar]

- Santos, C.F.; Nunes, A.P.P.; da Silva Aragão, O.O.; Guelfi, D.; de Souza, A.A.; de Abreu, L.B.; Lima, A.D.C. Dual Functional Coatings for Urea to Reduce Ammonia Volatilization and Improve Nutrients Use Efficiency in a Brazilian Corn Crop System. J. Soil Sci. Plant Nutr. 2021, 21, 1591–1609. [Google Scholar] [CrossRef]

- Klimczyk, M.; Siczek, A.; Schimmelpfennig, L. Improving the Efficiency of Urea-Based Fertilization Leading to Reduction in Ammonia Emission. Sci. Total Environ. 2021, 771, 145483. [Google Scholar] [CrossRef] [PubMed]

- Byrne, M.P.; Tobin, J.T.; Forrestal, P.J.; Danaher, M.; Nkwonta, C.G.; Richards, K.; Cummins, E.; Hogan, S.A.; O’Callaghan, T.F. Urease and Nitrification Inhibitors-As Mitigation Tools for Greenhouse Gas Emissions in Sustainable Dairy Systems: A Review. Sustainability 2020, 12, 6018. [Google Scholar] [CrossRef]

- Freitas, T.; Bartelega, L.; Santos, C.; Dutra, M.P.; Sarkis, L.F.; Guimarães, R.J.; Dominghetti, A.W.; Zito, P.C.; Fernandes, T.J.; Guelfi, D. Technologies for Fertilizers and Management Strategies of N-Fertilization in Coffee Cropping Systems to Reduce Ammonia Losses by Volatilization. Plants 2022, 2022, 11. [Google Scholar] [CrossRef]

- Souza, T.L.; de Oliveira, D.P.; Santos, C.F.; Reis, T.H.P.; Cabral, J.P.C.; da Silva Resende, ÉR.; Fernandes, T.J.; de Souza, T.R.; Builes, V.R.; Guelfi, D. Nitrogen fertilizer technologies: Opportunities to improve nutrient use efficiency towards sustainable coffee production systems. Agric. Ecosyst. Environ. 2023, 345, 108317. [Google Scholar] [CrossRef]

- Santos, C.F.; da Silva Aragão, O.O.; Silva, D.R.G.; Jesus, E. da C. ; Chagas, W.F.T.; Correia, P.S.; Souza Moreira, F.M. de Environmentally Friendly Urea Produced from the Association of N-(n-Butyl) Thiophosphoric Triamide with Biodegradable Polymer Coating Obtained from a Soybean Processing Byproduct. J. Clean. Prod. 2020, 276, 123014. [Google Scholar] [CrossRef]

- Sha, Z.; Lv, T.; Staal, M.; Ma, X.; Wen, Z.; Li, Q.; Pasda, G. Effect of combining urea fertilizer with P and K fertilizers on the efficacy of urease inhibitors under different storage conditions. Sci. Total. Environ. 2019, 655, 1387–1396. [Google Scholar] [CrossRef] [PubMed]

- Trenkel, M.E. Slow-and Controlled-Release and Stabilized Fertilizers: An Option for Enhancing Nutrient Use Efficiency in Agriculture; International Fertilizer Industry Association: Paris, France, 2010; ISBN 9782952313971. [Google Scholar]

- Timilsena, Y.P.; Adhikari, R.; Casey, P.; Muster, T.; Gill, H.; Adhikari, B. Enhanced Efficiency Fertilisers: A Review of Formulation and Nutrient Release Patterns. J. Sci. Food Agric. 2014, 95, 1131–1142. [Google Scholar] [CrossRef] [PubMed]

- Lawrencia, D.; Wong, S.K.; Yi, D.; Low, S.; Goh, H.; Goh, J.K.; Ruktanonchai, U.R.; Soottitantawat, A.; Lee, H.; Tang, S.Y.; et al. Controlled Release Fertilizers: A Review on Coating Materials and Mechanism of Release. Plants 2021, 10, 238. [Google Scholar] [CrossRef]

- Andrade, A.B.; Guelfi, D.R.; Chagas, W.F.T.; Cancellier, E.L.; de Souza, T.L.; Oliveira, L.S.S.; Faquin, V.; Du, C. Fertilizing Maize Croppings with Blends of Slow/Controlled-Release and Conventional Nitrogen Fertilizers. J. Plant Nutr. Soil Sci. 2021, 184, 227–237. [Google Scholar] [CrossRef]

- Incrocci, L.; Maggini, R.; Cei, T.; Carmassi, G.; Botrini, L.; Filippi, F.; Clemens, R.; Terrones, C.; Pardossi, A. Innovative Controlled-Release Polyurethane-Coated Urea Could Reduce n Leaching in Tomato Crop in Comparison to Conventional and Stabilized Fertilizers. Agronomy 2020, 10, 1827. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Y.; Gao, B.; Li, Y.C.; Xie, J. Bio-Based Elastic Polyurethane for Controlled-Release Urea Fertilizer: Fabrication, Properties, Swelling and Nitrogen Release Characteristics. J. Clean. Prod. 2019, 209, 528–537. [Google Scholar] [CrossRef]

- Rajan, M.; Shahena, S.; Chandran, V.; Mathew, L. Controlled Release of Fertilizers—Concept, Reality, and Mechanism. Control. Release Fertil. Sustain. Agric. 2021, 41–56. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Yang, X. The Diffusion Model of Nutrient Release from Membrane Pore of Controlled Release Fertilizer. Environ. Technol. Innov. 2022, 25, 102256. [Google Scholar] [CrossRef]

- ISO 21263:2017; Slow-Release Fertilizers—Determination of the Release of the Nutrients—Method for Coated Fertilizers. IOS: Geneva, Switzerland, 2017.

- Vejan, P.; Khadiran, T.; Abdullah, R.; Ahmad, N. Controlled Release Fertilizer: A Review on Developments, Applications and Potential in Agriculture. J. Control. Release 2021, 339, 321–334. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, Z.; He, X.; Wang, X.; Shi, X.; Zou, C.; Chen, X. The Effects of Controlled Release Urea on Maize Productivity and Reactive Nitrogen Losses: A Meta-Analysis. Environ. Pollut. 2019, 246, 559–565. [Google Scholar] [CrossRef]

- Ma, M.; Li, H.; Yan, D.; Zhang, Y.; Song, M.; Wang, Y.; Wang, H.; Shao, R.; Guo, J.; Yang, Q. Application of Blended Controlled-Release and Normal Urea with Suitable Maize Varieties to Achieve Integrated Agronomic and Environmental Impact in a High-Yielding Summer Maize System. Agriculture 2022, 12, 1247. [Google Scholar] [CrossRef]

- Zhang, X.; Guo, D.; Blennow, A.; Zörb, C. Mineral Nutrients and Crop Starch Quality. Trends Food Sci. Technol. 2021, 114, 148–157. [Google Scholar] [CrossRef]

- Dammann, L.G.; Shirley, A.R.; Us, A.L.; Van Pol, W.L.C.; Nl, M. Methods and Systems for Coating Granular Substrates. U.S. Patent 11,142,488 B2, 12 October 2021. [Google Scholar]

- Santos, H.G.; Jacomine, P.K.T.; Anjos, L.H.C.; Oliveira, V.A.; Lumbreras, J.F.; Coelho, M.R.; Almeida, J.A.; Cunha, T.J.F.; Oliveira, J.B. Brazilian System of Soil Classification, 3rd ed; Embrapa: Brasília, Brazil, 2013. [Google Scholar]

- Soil Survey Staff. Keys to Soil Taxonomy, 12th ed.; USDA-Natural Resources Conservation Service: Washington, DC, USA, 2014. [Google Scholar]

- Ribeiro, A.C.; Guimaraes, P.T.G.; Alvarez, V.V.H. Recomendação para o Uso de Corretivos e Fertilizantes em Minas Gerais: 5a Aproximação; Ribeiro, A.C., Guimarães, P.T.G., Alvares, V.H., Eds.; Comissão de Fertilidade do Solo do Estado de Minas Gerais: Viçosa, Brazil, 1999; Volume 46, pp. 289–302. [Google Scholar]

- Ministério da Agricultura, Pecuária e Abastecimento. Manual De Métodos Analíticos Oficiais Para Fertilizantes e Corretivos; Ministério da Agricultura, Pecuária e Abastecimento: Brasilia, Brazil, 2017; ISBN 9788579911095. [Google Scholar]

- Kjeldahl, J. Neue Methode Zur Bestimmung Des Stickstoffs in Organischen Körpern. Z. Anal. Chem. 1883, 22, 366–382. [Google Scholar] [CrossRef]

- Lara Cabezas, A.R.; Trivelin, P.C.O.; Bendassolli, J.A.; De Santana, D.G.; Gascho, G.J. Calibration of a Semi-Open Static Collector for Determination of Ammonia Volatilization from Nitrogen Fertilizers. Commun. Soil Sci. Plant Anal. 1999, 30, 389–406. [Google Scholar] [CrossRef]

- Ferreira, D.F. SISVAR: A Computer Analysis System to Fixed Effects Split Plot Type Designs. Rev. Bras. Biometria 2019, 37, 529–535. [Google Scholar] [CrossRef]

- Development Core Team R (Version 4.1.3). In R: A Language and Environment for Statistical Computing; R Found Stat Comput: Vienna, Austria, 2018.

- DaMatta, F.M.; Ronchi, C.P.; Maestri, M.; Barros, R.S. Ecophysiology of Coffee Growth and Production. Brazilian J. Plant Physiol. 2007, 19, 485–510. [Google Scholar] [CrossRef]

- Azeem, B.; Kushaari, K.; Man, Z.B.; Basit, A.; Thanh, T.H. Review on Materials & Methods to Produce Controlled Release Coated Urea Fertilizer. J. Control. Release 2014, 181, 11–21. [Google Scholar] [CrossRef] [PubMed]

- Irfan, S.A.; Razali, R.; KuShaari, K.Z.; Mansor, N.; Azeem, B.; Ford Versypt, A.N. A Review of Mathematical Modeling and Simulation of Controlled-Release Fertilizers. J. Control. Release 2018, 271, 45–54. [Google Scholar] [CrossRef]

- Laviola, B.G.; Martinez, H.E.P.; de Souza, R.B.; Salomão, L.C.C.; Cruz, C.D. Macronutrient Accumulation in Coffee Fruits at Brazilian Zona Da Mata Conditions. J. Plant Nutr. 2009, 32, 980–995. [Google Scholar] [CrossRef]

- ISO 18644:2016; Fertilizers and Soil Conditioners—Controlled-Release Fertilizer—General Requirements. International Organization for Standardization: Geneva, Switzerland, 2016.

- Lopes Cancellier, E.; Degryse, F.; Ramos, D.; Silva, G.; Coqui Da Silva, R.; McLaughlin, M.J. Rapid and Low-Cost Method for Evaluation of Nutrient Release from Controlled-Release Fertilizers Using Electrical Conductivity. J. Polym. Environ. 2018, 26, 4388–4395. [Google Scholar] [CrossRef]

- Keshavarz Afshar, R.; Lin, R.; Mohammed, Y.A.; Chen, C. Agronomic Effects of Urease and Nitrification Inhibitors on Ammonia Volatilization and Nitrogen Utilization in a Dryland Farming System: Field and Laboratory Investigation. J. Clean. Prod. 2018, 172, 4130–4139. [Google Scholar] [CrossRef]

- Wang, H.; Köbke, S.; Dittert, K. Use of Urease and Nitrification Inhibitors to Reduce Gaseous Nitrogen Emissions from Fertilizers Containing Ammonium Nitrate and Urea. Glob. Ecol. Conserv. 2020, 22, e00933. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, L.; Bai, Z.; Xu, W.; Zhang, F.; Zhang, X.; Liu, X.; Xie, Y. Comprehensive Quantification of Global Cropland Ammonia Emissions and Potential Abatement. Sci. Total Environ. 2021, 812, 151450. [Google Scholar] [CrossRef]

- Matiello, J.B. Cultura de Café No Brasil Manual de Recomendações; Futurama Editora: São Paulo, Brazil, 2015. [Google Scholar]

- Favarin, J.L.; Tezotto, T.; Neto, A.P. Balanço Nutricional Em Café: Estudo de Caso. Visão Agrícola 2013, 12, 79–81. [Google Scholar]

- Dobermann, A. Nutrient Use Efficiency—Measurement and Management. In Fertilizer Best Management Practices: General Principles, Strategy for Their Adoption and Voluntary Initiatives Versus Regulations, Proceedings of IFA International Workshop on Fertilizer Best Management Practices Brussels, Belgium, 7–9 March 2007; International Fertilizer Industry Association: Paris, France, 2007; pp. 1–28. [Google Scholar]

- Garcia, P.L.; Sermarini, R.A.; Trivelin, P.C.O. Nitrogen Fertilization Management with Blends of Controlled-Release and Conventional Urea Affects Common Bean Growth and Yield during Mild Winters in Brazil. Agronomy 2020, 10, 1935. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Y.; Blaylock, A.D.; Chen, X. Mixture of Controlled Release and Normal Urea to Optimize Nitrogen Management for High-Yielding (>15 Mg Ha−1) Maize. Field Crop. Res. 2017, 204, 23–30. [Google Scholar] [CrossRef]

| PARAMETERS OF THE REGRESSION ADJUSTED TO N RELEASE | ||||||||||

| 1* Fertilizer | 2 Parameter | 3 MDR | ||||||||

| α | Γ75% | β | k | R2 | ||||||

| (%) | (Day) | - | - | (% day−1 of N) | ||||||

| FIELD | ||||||||||

| ----------------------------------------------------------------------- 2017–2018 Crop year ----------------------------------------------------------------------- | ||||||||||

| EMax41 | 69.33 | PNA | 67.83 | 0.04 | 0.98 | 0.76 | ||||

| EMax43 | 91.87 | 70.10 | 42.64 | 0.05 | 0.99 | 1.25 | ||||

| Blend41 | 88.54 | 121.66 | 17.52 | 0.02 | 0.99 | 0.36 | ||||

| Blend43 | 97.07 | 52.09 | 13.11 | 0.03 | 0.99 | 0.76 | ||||

| ----------------------------------------------------------------------- 2018–2019 Crop year ----------------------------------------------------------------------- | ||||||||||

| EMax41 | 77.51 | 173.13 | 75.86 | 0.03 | 0.97 | 0.68 | ||||

| EMax43 | 78.29 | 125.18 | 49.80 | 0.04 | 0.98 | 0.81 | ||||

| Blend41 | 87.12 | 109.91 | 14.62 | 0.02 | 0.99 | 0.42 | ||||

| Blend43 | 90.80 | 80.62 | 6.32 | 0.02 | 0.99 | 0.46 | ||||

| LABORATORY | ||||||||||

| EMax41 | 86.87 | 94.13 | 45.21 | 0.04 | 0.98 | 0.82 | ||||

| EMax43 | 90.64 | 75.74 | 36.71 | 0.04 | 0.98 | 0.91 | ||||

| Blend41 | 96.19 | 59.76 | 1.60 | 0.02 | 1.00 | 0.53 | ||||

| Blend43 | 97.68 | 45.17 | −2.27 | 0.03 | 0.99 | 0.62 | ||||

| PARAMETERS OF THE REGRESSION ADJUSTED TO THE CUMULATIVE LOSSES OF N-NH3 BY VOLATILIZATION | ||||||||||

| 1 Fertilizer | 4 Parceled application | Parameter | 3 MDL | 5 Reduction in losses of N-NH3 in relation to UCon | Delay in MDL in relation to the mean b of UCon | |||||

| α | β | k | R2 | |||||||

| (kg N-NH3 ha−1) | (% of N-NH3) | (Day) | - | - | (kg N-NH3 ha−1 day−1 ) | (% day−1 of N-NH3) | % | (Day) | ||

| --------------------------------------------- 2017–2018 Crop year -------------------------------------------------- | ||||||||||

| UCon | 1 | 29.56 | 29.56 | 3.84 | 0.63 | 0.98 | 4.67 | 4.67 | - | - |

| 2 | 11.93 | 11.93 | 3.21 | 0.84 | 0.97 | 2.51 | 2.51 | - | - | |

| 3 | 14.64 | 14.64 | 1.02 | 0.74 | 0.89 | 2.69 | 2.69 | - | - | |

| § 3 AP | 56.13 | 18.71 | 2.69 | - | - | 3.29 | 1.10 | - | - | |

| UNBPT | 1 | 8.09 | 8.09 | 9.90 | 0.47 | 0.98 | 0.95 | 0.95 | 72.63 | 6.06 |

| 2 | 9.21 | 9.21 | 5.24 | 0.54 | 0.96 | 1.25 | 1.25 | 22.80 | 2.03 | |

| 3 | 5.26 | 5.26 | 2.93 | 0.24 | 0.94 | 0.32 | 0.32 | 64.07 | 1.91 | |

| § 3 AP | 22.56 | 7.52 | 6.02 | - | - | 0.84 | 0.28 | 59.81 | 3.43 | |

| EMax41 | Single | 18.89 | 6.29 | 54.14 | 0.05 | 0.99 | 0.23 | 0.08 | 66.35 | 51.45 |

| EMax43 | Single | 50.97 | 16.20 | 30.20 | 0.07 | 0.99 | 0.87 | 0.29 | 9.19 | 27.51 |

| Blend41 | Single | 34.75 | 11.58 | 23.55 | 0.07 | 0.96 | 0.63 | 0.21 | 38.09 | 20.86 |

| Blend43 | Single | 57.52 | 19.18 | 25.05 | 0.09 | 0.99 | 1.26 | 0.42 | −2.48 | 22.36 |

| Fertilizer | Parceled application | ----------------------------------------------- 2018–2019 Crop year ------------------------------------------------ | ||||||||

| UCon | 1 | 33.66 | 33.66 | 2.52 | 0.90 | 0.99 | 7.54 | 7.54 | - | - |

| 2 | 32.82 | 32.82 | 2.55 | 0.92 | 0.98 | 7.52 | 7.52 | - | - | |

| 3 | 24.44 | 24.44 | 1.72 | 0.64 | 0.99 | 3.93 | 3.93 | - | - | |

| § 3 AP | 90.92 | 30.31 | 2.26 | - | - | 6.33 | 2.11 | - | - | |

| UNBPT | 1 | 33.05 | 33.05 | 5.27 | 0.59 | 1.00 | 4.86 | 4.86 | 1.81 | 2.75 |

| 2 | 25.06 | 25.06 | 4.73 | 0.60 | 1.00 | 3.74 | 3.74 | 23.64 | 2.18 | |

| 3 | 25.50 | 25.50 | 2.86 | 0.51 | 1.00 | 3.29 | 3.29 | −4.34 | 1.14 | |

| § 3 AP | 83.61 | 27.87 | 4.29 | - | - | 3.96 | 1.32 | 8.04 | 2.03 | |

| EMax41 | Single | 35.87 | 11.96 | 35.36 | 0.05 | 0.99 | 0.42 | 0.14 | 60.55 | 33.10 |

| EMax43 | Single | 48.84 | 16.28 | 24.30 | 0.06 | 0.98 | 0.79 | 0.26 | 46.28 | 22.04 |

| Blend41 | Single | 49.57 | 16.52 | 12.39 | 0.08 | 0.93 | 1.05 | 0.35 | 45.48 | 10.13 |

| Blend43 | Single | 62.02 | 20.68 | 12.72 | 0.09 | 0.94 | 1.38 | 0.46 | 31.79 | 10.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freitas, T.; Oliveira, D.P.; Dutra, M.P.; Zito, P.C.; Reis, E.A.C.; Fernandes, T.J.; Nunes, A.P.P.; Guimarães, R.J.; Rabêlo, F.H.S.; Guelfi, D. Blending Controlled-Release and Urease-Inhibitor Technologies as Innovative Solutions to Reduce Ammonia Emissions in Coffee Environments. Soil Syst. 2023, 7, 83. https://doi.org/10.3390/soilsystems7040083

Freitas T, Oliveira DP, Dutra MP, Zito PC, Reis EAC, Fernandes TJ, Nunes APP, Guimarães RJ, Rabêlo FHS, Guelfi D. Blending Controlled-Release and Urease-Inhibitor Technologies as Innovative Solutions to Reduce Ammonia Emissions in Coffee Environments. Soil Systems. 2023; 7(4):83. https://doi.org/10.3390/soilsystems7040083

Chicago/Turabian StyleFreitas, Tainah, Damiany Pádua Oliveira, Mateus Portes Dutra, Pauliana Cristina Zito, Estevam Antônio Chagas Reis, Tales Jesus Fernandes, Ana Paula Pereira Nunes, Rubens José Guimarães, Flávio Henrique Silveira Rabêlo, and Douglas Guelfi. 2023. "Blending Controlled-Release and Urease-Inhibitor Technologies as Innovative Solutions to Reduce Ammonia Emissions in Coffee Environments" Soil Systems 7, no. 4: 83. https://doi.org/10.3390/soilsystems7040083