Overcoming Variability in Printed RF: A Statistical Method to Designing for Unpredictable Dimensionality

Abstract

:1. Introduction

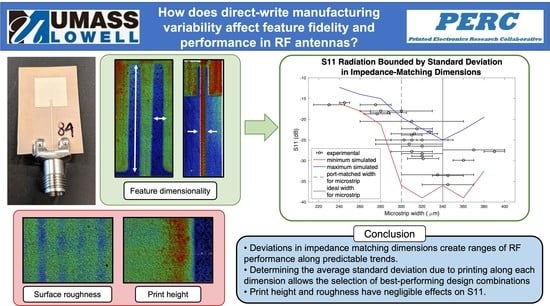

2. Materials and Methods

2.1. Antenna Design

2.2. Direct-Write Fabrication

3. Results

3.1. Printed Material Thickness and Surface Roughness

3.2. Variability in Printed RF Features

4. Discussion: Determining Design Metrics

4.1. Microstrip Width Metrics

4.2. Impedance Matching Inlet Width and Inlet Length

4.3. Combined Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Syafrindo, R.A.; Sumantyo, J.T.S.; Santosa, C.E.; Munir, A. 3D print X-band horn antenna for ground-based SAR application. In Proceedings of the 2017 Progress in Electromagnetics Research Symposium-Spring (PIERS), St Petersburg, Russia, 22–25 May 2017; pp. 1250–1253. [Google Scholar]

- Guo, C.; Shang, X.; Lancaster, M.J.; Xu, J. A 3-D printed lightweight X-band waveguide filter based on spherical resonators. IEEE Microw. Wirel. Compon. Lett. 2015, 25, 442–444. [Google Scholar] [CrossRef] [Green Version]

- Cai, F.; Khan, W.T.; Papapolymerou, J. A low loss X-band filter using 3-D polyjet technology. In Proceedings of the 2015 IEEE MTT-S International Microwave Symposium, Phoenix, AZ, USA, 17–22 May 2015; pp. 1–4. [Google Scholar]

- Zhao, Y.; Luo, J.; Lian, H.; Qi, L. 3D Printing of Micro Electrolyte Film by Using Micro-pen-writing. In Proceedings of the 2018 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Hangzhou, China, 13–17 August 2018; pp. 249–252. [Google Scholar]

- Luo, J.; Zhao, Z.; Qi, L.; Lian, H.; Zhao, Y. Direct Fabrication of Micron-Thickness PVA-CNT Patterned Films by Integrating Micro-Pen Writing of PVA Films and Drop-on-Demand Printing of CNT Micropatterns. Nanomaterials 2021, 11, 2335. [Google Scholar] [CrossRef] [PubMed]

- Paulsen, J.A.; Renn, M.; Christenson, K.; Plourde, R. Printing conformal electronics on 3D structures with Aerosol Jet technology. In Proceedings of the 2012 Future of Instrumentation International Workshop (FIIW) Proceedings, Gatlinburg, TN, USA, 8–9 October 2012; pp. 1–4. [Google Scholar]

- Jordan, C.D.; Thorne, B.R.; Wadhwa, A.; Losey, A.D.; Ozhinsky, E.; Kondapavulur, S.; Hetts, S.W. Wireless resonant circuits printed using aerosol jet deposition for MRI catheter tracking. IEEE Trans. Biomed. Eng. 2019, 67, 876–882. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Tajima, J.; Sydänheimo, L.; Nishikawa, H.; Ukkonen, L.; Virkki, J. Inkjet-printed antenna-electronics interconnections in passive UHF RFID tags. In Proceedings of the 2017 IEEE MTT-S International Microwave Symposium (IMS), Honololu, HI, USA, 4–9 June 2017; pp. 598–601. [Google Scholar]

- Tayyab, M.; Sharawi, M.S.; Shamim, A.; Al-Sarkhi, A. A low complexity RF based sensor array for lung disease detection using inkjet printing. Int. J. RF Microw. Comput.-Aided Eng. 2019, 29, e21586. [Google Scholar] [CrossRef]

- Shaker, G.; Safavi-Naeini, S.; Sangary, N.; Tentzeris, M.M. Inkjet printing of ultrawideband (UWB) antennas on paper-based substrates. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 111–114. [Google Scholar] [CrossRef] [Green Version]

- Vaillancourt, J.; Zhang, H.; Vasinajindakaw, P.; Xia, H.; Lu, X.; Han, X.; Renn, M. All ink-jet-printed carbon nanotube thin-film transistor on a polyimide substrate with an ultrahigh operating frequency of over 5 GHz. Appl. Phys. Lett. 2008, 93, 444. [Google Scholar] [CrossRef] [Green Version]

- Trotter, M.; Juric, D.; Bagherian, Z.; Borst, N.; Gläser, K.; Meissner, T.; Zimmermann, A. Inkjet-printing of nanoparticle gold and silver ink on cyclic olefin copolymer for DNA-sensing applications. Sensors 2020, 20, 1333. [Google Scholar] [CrossRef] [Green Version]

- Njogu, P.M.; Sanz-Izquierdo, B.; Jun, S.Y.; Kalman, G.; Gao, S.; Malas, A.; Gibbons, G.J. Evaluation of planar inkjet-printed antennas on a low-cost origami flapping robot. IEEE Access 2020, 8, 164103–164113. [Google Scholar] [CrossRef]

- Lopes, A.J.; MacDonald, E.; Wicker, R.B. Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp. J. 2012, 18, 129–143. [Google Scholar] [CrossRef]

- Zips, S.; Wenzel, O.J.; Rinklin, P.; Grob, L.; Terkan, K.; Adly, N.Y.; Wolfrum, B. Direct stereolithographic 3D printing of microfluidic structures on polymer substrates for printed electronics. Adv. Mater. Technol. 2019, 4, 1800455. [Google Scholar] [CrossRef]

- Santoliquido, O.; Camerota, F.; Rosa, A.; Ortona, A. A novel device to simply 3D print bulk green ceramic components by stereolithography employing viscous slurries. Open Ceram. 2021, 5, 100089. [Google Scholar] [CrossRef]

- Shemelya, C.; Cedillos, F.; Aguilera, E.; Maestas, E.; Ramos, J.; Espalin, D.; MacDonald, E. 3D printed capacitive sensors. In Proceedings of the SENSORS, 2013 IEEE, Baltimore, MD, USA, 3–6 November 2013; pp. 1–4. [Google Scholar]

- Shemelya, C.M.; Zemba, M.; Liang, M.; Espalin, D.; Kief, C.; Xin, H.; MacDonald, E.W. 3D printing multi-functionality: Embedded RF antennas and components. In Proceedings of the 2015 9th European Conference on Antennas and Propagation (EuCAP), Lisbon, Portugal, 13–17 April 2015; pp. 1–5. [Google Scholar]

- Yu, X.; Liang, M.; Shemelya, C.; Roberson, D.A.; Wicker, R.; MacDonald, E.; Xin, H. 3-D printed parts for a multilayer phased array antenna system. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2150–2154. [Google Scholar] [CrossRef]

- Liang, M.; Shemelya, C.; MacDonald, E.; Wicker, R.; Xin, H. Fabrication of microwave patch antenna using additive manufacturing technique. In Proceedings of the 2014 USNC-URSI Radio Science Meeting (Joint with AP-S Symposium), Memphis, TN, USA, 6–11 July 2014; p. 269. [Google Scholar]

- Liang, M.; Yu, X.; Shemelya, C.; MacDonald, E.; Xin, H. 3D printed multilayer microstrip line structure with vertical transition toward integrated systems. In Proceedings of the 2015 IEEE MTT-S International Microwave Symposium, Phoenix, AZ, USA, 17–22 May 2015; pp. 1–4. [Google Scholar]

- Shemelya, C.; Cedillos, F.; Aguilera, E.; Espalin, D.; Muse, D.; Wicker, R.; MacDonald, E. Encapsulated copper wire and copper mesh capacitive sensing for 3-D printing applications. IEEE Sens. J. 2014, 15, 1280–1286. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Wang, Y.; Kwok, H.Y.; Pan, W.; Zhang, Y.; Zhang, H.; Lu, X.; Leung, D.Y. Printing Al-air batteries on paper for powering disposable printed electronics. J. Power Sources 2020, 450, 227685. [Google Scholar] [CrossRef]

- Willert, A.; Baumann, R.R. Customized printed batteries driving sensor applications. In Proceedings of the 2013 International Semiconductor Conference Dresden-Grenoble (ISCDG), Dresden, Germany, 26–27 September 2013; pp. 1–4. [Google Scholar]

- Chason, M.; Brazis, P.W.; Zhang, J.; Kalyanasundaram, K.; Gamota, D.R. Printed organic semiconducting devices. Proc. IEEE 2005, 93, 1348–1356. [Google Scholar] [CrossRef]

- Unander, T.; Nilsson, H.E. Characterization of printed moisture sensors in packaging surveillance applications. IEEE Sens. J. 2009, 9, 922–928. [Google Scholar] [CrossRef]

- Nilsson, H.E.; Andersson, H.A.; Manuilskiy, A.; Unander, T.; Hammarling, K.; Siden, J.; Gulliksson, M. Printed write once and read many sensor memories in smart packaging applications. IEEE Sens. J. 2010, 11, 1759–1767. [Google Scholar] [CrossRef]

- Wu, T.; Gray, E.; Chen, B. A self-healing, adaptive and conductive polymer composite ink for 3D printing of gas sensors. J. Mater. Chem. C 2018, 6, 6200–6207. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Wu, D.; Zhao, Y.; Chen, Q.; Xie, Y.; Wang, M.; Sun, D. Direct write of a flexible high-sensitivity pressure sensor with fast response for electronic skins. Org. Electron. 2019, 67, 10–18. [Google Scholar] [CrossRef]

- Munasinghe, M.I.N.P.; Miles, L.; Paul, G. Direct-write fabrication of wear profiling IoT sensor for 3D printed industrial equipment. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction, ISARC 2019, Banff, AB, Canada, 21–24 May 2019. [Google Scholar]

- Zheng, L.R.; Nejad, M.B.; Rodriguez, S.; Zhang, L.; Chen, C.; Tenhunen, H. System-on-flexible-substrates: Electronics for future smart-intelligent world. In Proceedings of the Conference on High Density Microsystem Design and Packaging and Component Failure Analysis, 2006. HDP’06. Shanghai, China, 27–28 June 2006; pp. 29–36. [Google Scholar]

- Hoey, J.M.; Reich, M.T.; Halvorsen, A.; Vaselaar, D.; Braaten, K.; Maassel, M.; Schulz, D.L. Rapid prototyping RFID antennas using direct-write. IEEE Trans. Adv. Packag. 2009, 32, 809–815. [Google Scholar] [CrossRef]

- Anagnostou, D.E.; Gheethan, A.A.; Amert, A.K.; Whites, K.W. A direct-write printed antenna on paper-based organic substrate for flexible displays and WLAN applications. J. Disp. Technol. 2010, 6, 558–564. [Google Scholar] [CrossRef]

- Lee, H.; Tentzeris, M.M.; Markondeya, P.; Raj, M.K.; Kawahara, Y. Inkjet-printed ferromagnetic nanoparticles for miniaturization of flexible printed RF inductors. In Proceedings of the 2013 IEEE Antennas and Propagation Society International Symposium (APSURSI), Orlando, FL, USA, 7–13 July 2013; pp. 994–995. [Google Scholar]

- McKerricher, G.; Perez, J.G.; Shamim, A. Fully inkjet printed RF inductors and capacitors using polymer dielectric and silver conductive ink with through vias. IEEE Trans. Electron Devices 2015, 62, 1002–1009. [Google Scholar] [CrossRef]

- George, J.; Abdelghani, A.; Bahoumina, P.; Tantot, O.; Baillargeat, D.; Frigui, K.; Dejous, C. CNT-based inkjet-printed RF gas sensor: Modification of substrate properties during the fabrication process. Sensors 2019, 19, 1768. [Google Scholar] [CrossRef] [Green Version]

- Lis, M.; Plaut, M.; Zai, A.; Cipolle, D.; Russo, J.; Lewis, J.; Fedynyshyn, T. Polymer Dielectrics for 3D-Printed RF Devices in the Ka Band. Adv. Mater. Technol. 2016, 1, 1600027. [Google Scholar] [CrossRef]

- Bito, J.; Palazzi, V.; Hester, J.; Bahr, R.; Alimenti, F.; Mezzanotte, P.; Tentzeris, M.M. Millimeter-wave ink-jet printed RF energy harvester for next generation flexible electronics. In Proceedings of the 2017 IEEE Wireless Power Transfer Conference (WPTC), Taipei, Taiwan, 10–12 May 2017; pp. 1–4. [Google Scholar]

- Pham, D.T.; Subbaraman, H.; Chen, M.Y.; Xu, X.; Chen, R.T. Light Weight and Conformal 2-Bit, 1x4 Phased-Array Antenna With CNT-TFT-Based Phase Shifter on a Flexible Substrate. IEEE Trans. Antennas Propag. 2011, 59, 4553–4558. [Google Scholar] [CrossRef]

- Kimionis, J.; Georgiadis, A.; Isakov, M.; Qi, H.J.; Tentzeris, M.M. 3D/inkjet-printed origami antennas for multi-direction RF harvesting. In Proceedings of the 2015 IEEE MTT-S International Microwave Symposium, Phoenix, AZ, USA, 17–22 May 2015; pp. 1–4. [Google Scholar]

- Sarsen, A.; Valagiannopoulos, C. Robust polarization twist by pairs of multilayers with tilted optical axes. Phys. Rev. B 2019, 99, 115304. [Google Scholar] [CrossRef]

- Lu, Y.; Subramani, K.S.; Huang, H.; Kupp, N.; Huang, K.; Makris, Y. A comparative study of one-shot statistical calibration methods for analog/RF ICs. In Proceedings of the 2015 IEEE International Test Conference (ITC), Anaheim, CA, USA, 6–8 October 2015; pp. 1–10. [Google Scholar]

- Zhumabek, T.; Valagiannopoulos, C. Light trapping by arbitrarily thin cavities. Phys. Rev. Res. 2020, 2, 043349. [Google Scholar] [CrossRef]

- Fu, Z.; Angeline, V.; Sun, W. Evaluation of Printing Parameters on 3D Extrusion Printing of Pluronic Hydrogels and Machine Learning Guided Parameter Recommendation. Int. J. Bioprinting 2021, 7, 434. [Google Scholar] [CrossRef]

- Shi, J.; Song, J.; Song, B.; Lu, W.F. Multi-objective optimization design through machine learning for drop-on-demand bioprinting. Engineering 2019, 5, 586–593. [Google Scholar] [CrossRef]

- Shirsavar, M.A.; Taghavimehr, M.; Ouedraogo, L.J.; Javaheripi, M.; Hashemi, N.N.; Koushanfar, F.; Montazami, R. Machine Learning-Assisted E-jet Printing of Organic Flexible Biosensors. arXiv 2021, arXiv:2111.03985. [Google Scholar]

- Huang, H.J.; Zhou, M.B.; Yin, C.; Chen, Q.W.; Zhang, X.P. Preparation of a low temperature sintering silver nanoparticle ink and fabrication of conductive patterns on PET substrate. In Proceedings of the 2018 19th International Conference on Electronic Packaging Technology (ICEPT), Shanghai, China, 8–11 August 2018; pp. 482–485. [Google Scholar]

- Sharma, V.; Upadhayay, M.D.; Singh, A.V.; Prajapati, J. Hammer-Shaped Element-Based Compact MIMO Antenna for WLAN Application. Prog. Electromagn. Res. Lett. 2021, 97, 121–130. [Google Scholar] [CrossRef]

- Khraisat, Y.S.; Olaimat, M.M. Comparison between rectangular and triangular patch antennas array. In Proceedings of the 2012 19th International Conference on Telecommunications (ICT), Jounieh, Lebanon, 23–25 April 2012; pp. 1–5. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berry, K.; Brown, E.M.; Pothier, B.; Fedorka, S.; Akyurtlu, A.; Armiento, C.; Walsh, G.F.; Shemelya, C. Overcoming Variability in Printed RF: A Statistical Method to Designing for Unpredictable Dimensionality. Designs 2022, 6, 13. https://doi.org/10.3390/designs6010013

Berry K, Brown EM, Pothier B, Fedorka S, Akyurtlu A, Armiento C, Walsh GF, Shemelya C. Overcoming Variability in Printed RF: A Statistical Method to Designing for Unpredictable Dimensionality. Designs. 2022; 6(1):13. https://doi.org/10.3390/designs6010013

Chicago/Turabian StyleBerry, Katherine, Eric M. Brown, Bradley Pothier, Samuel Fedorka, Alkim Akyurtlu, Craig Armiento, Gary F. Walsh, and Corey Shemelya. 2022. "Overcoming Variability in Printed RF: A Statistical Method to Designing for Unpredictable Dimensionality" Designs 6, no. 1: 13. https://doi.org/10.3390/designs6010013