Advance Time to Determine Injection and Flushing Times in Drip Fertigation

Abstract

:1. Introduction

2. Material and Methods

2.1. Study Area and Drip Irrigation System

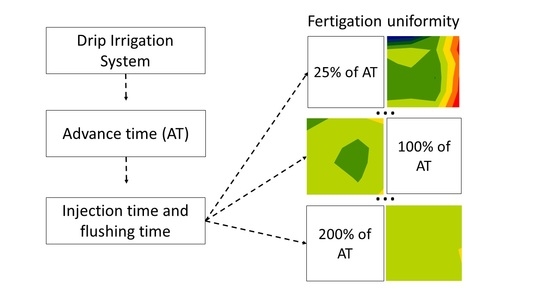

2.2. Fertilizer Injection and Advance Time

2.3. Treatments

2.4. Measurement of Fertigation Performance

2.5. Data Analysis

3. Results

3.1. Test 1—Uniformity of Spatial Distribution of KCL and Water as a Function of Injection Time

3.2. Test 2—KCl and Water Distribution Uniformity as a Function of Flushing Time

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bar-Yosef, B. Advances in Fertigation. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 1999; pp. 1–77. [Google Scholar] [CrossRef]

- Li, H.; Mei, X.; Wang, J.; Huang, F.; Hao, W.; Li, B. Drip fertigation significantly increased crop yield, water productivity and nitrogen use efficiency with respect to traditional irrigation and fertilization practices: A meta-analysis in China. Agric. Water Manag. 2021, 244, 106534. [Google Scholar] [CrossRef]

- Liang, X.; Gao, Y.; Zhang, X.; Tian, Y.; Zhang, Z.; Gao, L. Effect of Optimal Daily Fertigation on Migration of Water and Salt in Soil, Root Growth and Fruit Yield of Cucumber (Cucumis sativus L.) in Solar-Greenhouse. PLoS ONE 2014, 9, e86975. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Lv, H.; Qasim, W.; Wan, L.; Wang, Y.; Lian, X.; Liu, Y.; Hu, J.; Wang, Z.; Li, G.; et al. Drip fertigation with straw incorporation significantly reduces N2O emission and N leaching while maintaining high vegetable yields in solar greenhouse production. Environ. Pollut. 2021, 273, 116521. [Google Scholar] [CrossRef] [PubMed]

- USDA. National Engineering Handbook; Sprinkler Irrigation; The U.S. Department of Agriculture: Washington, DC, USA, 2016; p. 236. Available online: https://directives.sc.egov.usda.gov/OpenNonWebContent.aspx?content=39754.wba (accessed on 21 November 2021).

- Oliveira, M.V.A.M.D. Modelo Matemático Para Estimativa do Tempo de Fertirrigação. Tese de Doutorado. Universidade Estadual Paulista. “Júlio de Mesquita Filho”. Faculdade de Ciências Agronômicas. 2006. Available online: https://repositorio.unesp.br/handle/11449/103438 (accessed on 23 July 2021).

- Fan, J.; Wu, L.; Zhang, F.; Yan, S.; Xiang, Y. Evaluation of Drip Fertigation Uniformity Affected by Injector Type, Pressure Difference and Lateral Layout. Irrig. Drain. 2017, 66, 520–529. [Google Scholar] [CrossRef]

- Tang, P.; Li, H.; Issaka, Z.; Chen, C. Effect of manifold layout and fertilizer solution concentration on fertilization and flushing times and uniformity of drip irrigation systems. Agric. Water Manag. 2018, 200, 71–79. [Google Scholar] [CrossRef]

- Bracy, R.P.; Parish, R.L.; Rosendale, R.M. Fertigation Uniformity Affected by Injector Type. HortTechnology 2003, 13, 103–105. [Google Scholar] [CrossRef]

- Li, J.; Meng, Y.; Li, B. Field evaluation of fertigation uniformity as affected by injector type and manufacturing variability of emitters. Irrig. Sci. 2007, 25, 117–125. [Google Scholar] [CrossRef]

- Borssoi, A.L.; Vilas Boas, M.A.; Reisdörfer, M.; Hernández, R.H.; Follador, F.A.C. Water application uniformity and fertigation in a dripping irrigation set. Eng. Agrícola 2012, 32, 718–726. [Google Scholar] [CrossRef] [Green Version]

- do Bomfim, G.V.; Manzano, J.; de Azevedo, B.M.; Vasconcelos, D.V.; de, A. Viana, T.V. Potassium distribution in drip irrigation with fertigation for different injection distances in the main line. Eng. Agrícola 2014, 34, 1150–1161. [Google Scholar] [CrossRef]

- Kumar, M.; Rajput, T.B.S.; Patel, N. Water and Nitrogen Distribution Uniformity for Different Drip-lengths under Drip Irrigation System. J. Agric. Eng. 2014, 51, 37–43. [Google Scholar]

- de Oliveira, M.V.A.M.; Bôas, R.L.V.; Garcia, C.J.B.; Nascimento, F.R. Uniformidade de distribuição de potássio num sistema de irrigação por gotejamento quando aplicado por diferentes injetores. Irriga 2003, 8, 234–241. [Google Scholar] [CrossRef]

- de Sousa, V.F.; Folegatti, M.V.; Frizzone, J.A.; de L. Corrêa, R.A.; Alencar, C.M. Distribuição de fertilizantes em um sistema de fertigação por gotejamento. Rev. Bras. Eng. Agrícola E Ambient. 2003, 7, 186–189. [Google Scholar] [CrossRef] [Green Version]

- Jimenez-Bello, M.A.; Martínez, F.; Bou, V.; Bartolín, H. Analysis, assessment, and improvement of fertilizer distribution in pressure irrigation systems. Irrig. Sci. 2011, 29, 45–53. [Google Scholar] [CrossRef]

- Haman, D.Z.; Zazueta, F.S. Chemical Injection Methods for Irrigation; Department of Agricultural and Biological Engineering: Gainesville, FL, USA, 2021. [Google Scholar]

- Christiansen, J.E. Irrigation by Sprinkling; University of California: California, CA, USA, 1942. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021; Version 4.1.0. [Google Scholar]

- Merriam, J.L.; Keller, J. Farm Irrigation System Evaluation: A Guide for Management, 3rd ed.; State University: Logan, UT, USA, 1978. [Google Scholar]

- Kumar, M.; Kumar, R.; Rajput, T.B.S.; Patel, N. Efficient Design of Drip Irrigation System using Water and Fertilizer Application Uniformity at Different Operating Pressures in a Semi-Arid Region of India. Irrig. Drain. 2017, 66, 316–326. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z.; Li, J.; Li, Y. Field evaluation of fertigation performance for a drip irrigation system with different lateral layouts under low operation pressures. Irrig. Sci. 2021, 40, 191–201. [Google Scholar] [CrossRef]

- Tayel, M.Y.; Pibars, S.K.; Mansour, H.A.-G. Effect of drip irrigation method, nitrogen source, and flushing schedule on emitter clogging. Agric. Sci. 2013, 04, 131–137. [Google Scholar] [CrossRef]

- Magalhães, M.I. Uniformidade da Fertirrigação em um Sistema de Irrigação por Gotejamento. Dissertação de Mestrado. Universidade Federal do Ceará. 1996. Available online: http://www.repositorio.ufc.br/handle/riufc/44570 (accessed on 21 November 2021).

- Li, J.; Chen, P.; Sun, X.; Liu, P. Effects of fertigation strategies on water and nitrogen distribution under water storage pit irrigation for orchards. Int. J. Agric. Biol. Eng. 2018, 11, 165–171. [Google Scholar] [CrossRef]

- Satpute, S.T.; Singh, M. Potassium and sulfur dynamics under surface drip fertigated onion crop. J. Soil Salin. Water Qual. 2017, 9, 226–236. [Google Scholar]

| Tests | PIT | IT | FT | FD |

|---|---|---|---|---|

| min | % AT (min) | % AT (min) | min | |

| 1 | 4.0 | 200% (25.00) 1 | 200% (25.00) 1 | 54.0 |

| 4.0 | 150% (18.75) | 200% (25.00) | 47.8 | |

| 4.0 | 100% (12.50) | 200% (25.00) | 41.5 | |

| 4.0 | 75% (9.38) | 200% (25.00) | 38.4 | |

| 4.0 | 50% (6.25) | 200% (25.00) | 35.3 | |

| 4.0 | 25% (3.13) | 200% (25.00) | 32.1 | |

| 2 | 4.0 | 200% (25.00) | 100% (12.50) | 41.8 |

| 4.0 | 200% (25.00) | 200% (25.00) | 54.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, G.H.; da Cunha, F.F.; de Brito, L.F.A. Advance Time to Determine Injection and Flushing Times in Drip Fertigation. Horticulturae 2022, 8, 1103. https://doi.org/10.3390/horticulturae8121103

da Silva GH, da Cunha FF, de Brito LFA. Advance Time to Determine Injection and Flushing Times in Drip Fertigation. Horticulturae. 2022; 8(12):1103. https://doi.org/10.3390/horticulturae8121103

Chicago/Turabian Styleda Silva, Gustavo Henrique, Fernando França da Cunha, and Letícia Fonseca Anício de Brito. 2022. "Advance Time to Determine Injection and Flushing Times in Drip Fertigation" Horticulturae 8, no. 12: 1103. https://doi.org/10.3390/horticulturae8121103