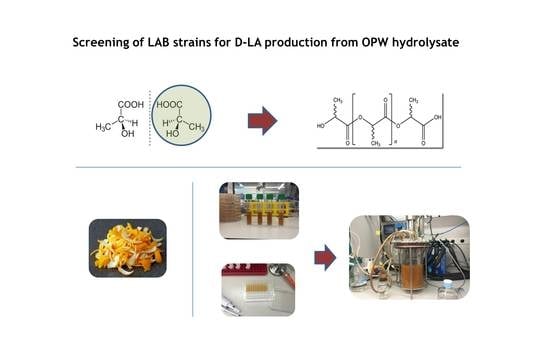

Production of D-Lactic Acid by the Fermentation of Orange Peel Waste Hydrolysate by Lactic Acid Bacteria

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bacterial Strains, Media and Growth Conditions

2.2. OPW Hyrolysate Tolerance Assays

2.3. Fermentation Assays

2.4. OPW Pretreatments

2.5. Analytical Procedures

3. Results and Discussion

3.1. Screening of LAB Strains for D-LA Production

3.2. Use of OPW Hydrolysate for D-LA Production by Selected Strains

3.3. D-LA Production by L. delbrueckii ssp. delbrueckii CECT 286 vs. L. delbrueckii ssp. bulgaricus CECT 5037

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Esteban, J.; Ladero, M. Food waste as a source of value-added chemicals and materials: A biorefinery perspective. Int. J. Food. Sci. Technol. 2018, 53, 1095–1108. [Google Scholar] [CrossRef]

- John, R.P.; Anisha, G.; Nampoothiri, K.M.; Pandey, A. Direct lactic acid fermentation: Focus on simultaneous saccharification and lactic acid production. Biotechnol. Adv. 2009, 27, 145–152. [Google Scholar] [CrossRef]

- Abdel-Rahman, M.A.; Tashiro, Y.; Sonomoto, K. Lactic acid production from lignocellulose-derived sugars using lactic acid bacteria: Overview and limits. J. Biotechnol. 2011, 156, 286–301. [Google Scholar] [CrossRef]

- Klotz, S.; Kaufmann, N.; Kuenz, A.; Prüße, U. Biotechnological production of enantiomerically pure D-lactic acid. Appl. Microbiol. Biotechnol. 2016, 100, 9423–9437. [Google Scholar] [CrossRef]

- Wang, Y.; Tashiro, Y.; Sonomoto, K. Fermentative production of lactic acid from renewable materials: Recent achievements, prospects, and limits. J. Biosci. Bioeng. 2015, 119, 10–18. [Google Scholar] [CrossRef]

- Singhvi, M.; Zendo, T.; Sonomoto, K. Free lactic acid production under acidic conditions by lactic acid bacteria strains: Challenges and future prospects. Appl. Microbiol. Biotechnol. 2018, 102, 1–14. [Google Scholar] [CrossRef]

- John, R.P.; Nampoothiri, K.M.; Pandey, A. Fermentative production of lactic acid from biomass: An overview on process developments and future perspectives. Appl. Microbiol. Biotechnol. 2007, 74, 524–534. [Google Scholar] [CrossRef]

- Tashiro, Y.; Kaneko, W.; Sun, Y.; Shibata, K.; Inokuma, K.; Zendo, T.; Sonomoto, K. Continuous D-lactic acid production by a novel thermo tolerant Lactobacillus delbrueckii subsp. lactis QU 41. Appl. Microbiol. Biotechnol. 2011, 89, 1741–1750. [Google Scholar] [CrossRef]

- Zhang, Y.; Vadlani, P.V. D-Lactic acid biosynthesis from biomass derived sugars via Lactobacillus delbrueckii fermentation. Bioprocess Biosyst. Eng. 2013, 36, 1897–1904. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, T.; Hoshina, M.; Tanabe, S.; Sakai, K.; Ohtsubo, S.; Taniguchi, M. Production of D-lactid acid from defatted rice bran by simultaneous saccarification and fermentation. Bioresour. Technol. 2006, 97, 211–217. [Google Scholar] [CrossRef]

- Abdel-Rahman, M.A.; Tashiro, Y.; Sonomoto, K. Recent advances in lactic acid production by microbial fermentation processes. Biotechnol. Adv. 2013, 31, 877–902. [Google Scholar] [CrossRef]

- Zhang, Y.; Vadlani, P.V.; Kumar, A.; Hardwidge, P.R.; Govind, R.; Tanaka, T.; Kondo, A. Enhanced D-lactic acid production from renewable resources using engineered Lactobacillus plantarum. Appl. Microbiol. Biotechnol. 2016, 100, 279–288. [Google Scholar] [CrossRef]

- Idris, A.; Suzana, W. Effect of sodium alginate concentration, bead diameter, initial pH and temperature on lactic acid production from pineapple waste using immobilized Lactobacillus delbrueckii. Process. Biochem. 2006, 41, 1117–1123. [Google Scholar] [CrossRef]

- Choi, M.; Al-Zahrani, S.M.; Lee, S.Y. Kinetic model-based feed-forward controlled fed-batch fermentation of Lactobacillus rhamnosus for the production of lactic acid from Arabic date juice. Bioprocess Biosyst. Eng. 2014, 37, 1007–1015. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, Z.; Lin, Y.; Zhao, S.; Mei, Y.; Liang, Y.; Peng, N. High-titer lactic acid production from NaOH-pretreated corn stover by Bacillus coagulans LA204 using fed-batch simultaneous saccharification and fermentation under non-sterile condition. Bioresour. Technol. 2015, 182, 251–257. [Google Scholar] [CrossRef]

- Hama, S.; Mizuno, S.; Kihara, M.; Tanaka, T.; Ogino, C.; Noda, H.; Kondo, A. Production of D-lactic acid from hard wood pulp by mechanical milling followed by simultaneous saccharification and fermentation using metabolically engineered Lactobacillus plantarum. Bioresour. Technol. 2015, 187, 167–172. [Google Scholar] [CrossRef]

- Okano, K.; Hama, S.; Kihara, M.; Noda, H.; Tanaka, T.; Kondo, A. Production of optically pure D-lactic acid from brown rice using metabolically engineered Lactobacillus plantarum. Appl Microbiol. Biotechnol. 2017, 101, 1869–1875. [Google Scholar]

- Van Dyk, J.S.; Gama, R.; Morrison, D.; Swart, S.; Pletschke, B.I. Food processing waste: Problems, current management and prospects for utilisation of the lignocellulose component through enzyme synergistic degradation. Renew. Sust. Energ. Rev. 2013, 26, 521–531. [Google Scholar] [CrossRef]

- Girotto, F.; Alibardi, L.; Cossu, R. Food waste generation and industrial uses: A review. Waste. Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef]

- Rezzadori, K.; Benedetti, S.; Amante, E.R. Proposals for the residues recovery: Orange waste as raw material for new products. Food Bioprod. Process. 2012, 90, 606–614. [Google Scholar] [CrossRef]

- Negro, V.; Mancini, G.; Ruggeri, B.; Fino, D. Citrus waste as feedstock for bio-based products recovery: Review on limonene case study and energy valorization. Bioresour. Technol. 2016, 214, 806–815. [Google Scholar] [CrossRef]

- De la Torre, I.; Ravelo, M.; Segarra, S.; Tortajada, M.; Santos, V.E.; Ladero, M. Study on the effects of several operational variables on the enzymatic batch saccharification of orange solid waste. Bioresour. Technol. 2017, 245, 906–915. [Google Scholar] [CrossRef]

- Choi, I.S.; Lee, Y.G.; Khanal, S.K.; Park, B.J.; Bae, H.-J. A low-energy, cost-effective approach to fruit and citrus peel waste processing for bioethanol production. Appl. Energy 2015, 140, 65–74. [Google Scholar] [CrossRef]

- Rafiq, S.; Kaul, R.; Sofi, S.A.; Bashir, N.; Nazir, F.; Ahmad Nayik, G. Citrus peel as a source of functional ingredient: A review. J. Saudi Soc. Agric. Sci. 2016, 17, 351–358. [Google Scholar] [CrossRef] [Green Version]

- Martín, M.A.; Siles, J.A.; Chica, A.F.; Martín, A. Biomethanization of orange peel waste. Bioresour. Technol. 2010, 101, 8993–8999. [Google Scholar] [CrossRef]

- Pourbafrani, M.; Forgács, G.; Horváth, I.S.; Niklasson, C.; Taherzadeh, M.J. Production of biofuels, limonene and pectin from citrus wastes. Bioresour. Technol. 2010, 101, 4246–4250. [Google Scholar] [CrossRef]

- Oberoi, H.S.; Vadlani, P.V.; Madl, R.L.; Saida, L.; Abeykoon, J.P. Ethanol production from orange peels: Two-stage hydrolysis and fermentation studies using optimized parameters through experimental design. J. Agric. Food Chem. 2010, 58, 3422–3429. [Google Scholar] [CrossRef]

- Lugo-Lugo, V.; Barrera-Díaz, C.; Ureña-Núñez, F.; Bilyeu, B.; Linares-Hernández, I. Biosorption of Cr(III) and Fe(III) in single and binary systems onto pretreated orange peel. J. Environ. Manag. 2012, 112, 120–127. [Google Scholar] [CrossRef]

- Mazzoli, R.; Bosco, F.; Mizrahi, I.; Bayer, E.A.; Pessione, E. Towards lactic acid bacteria-based biorefineries. Biotechnol. Adv. 2014, 32, 1216–1236. [Google Scholar] [CrossRef]

- Eiteman, M.A.; Ramalingam, S. Microbial production of lactic acid. Biotechnol. Lett. 2015, 37, 955–972. [Google Scholar] [CrossRef]

- Calabia, B.P.; Tokiwa, Y. Production of D-lactic acid from sugar cane molasses, sugarcane juice and sugar beet juice by Lactobacillus delbrueckii. Biotechnol. Lett. 2007, 29, 1329–1332. [Google Scholar] [CrossRef]

- De la Torre, I.; Ladero, M.; Santos, V.E. Production of D-lactic acid by Lactobacillus delbrueckii ssp. delbrueckii from orange peel waste: Techno-economical assesment of nitrogen sources. Appl. Microbiol. Biotechnol. 2018, 102, 10511–10521. [Google Scholar]

- Benthin, S.; Villadsen, J. Production of optically pure D-lactate by Lactobacillus bulgaricus and purification by crystallisation and liquid/liquid extraction. Appl. Microbiol. Biotechnol. 1995, 42, 826–829. [Google Scholar] [CrossRef]

- Benthin, S.; Villadsen, J. Different inhibition of Lactobacillus delbrueckii subsp. bulgaricus by D- and L-lactic acid: Effects on lag phase, growth rate and cell yield. J. Appl. Biotecnol. 1995, 78, 647–654. [Google Scholar]

- Adamberg, K.; Kaska, S.; Lahta, T.M.; Paalmea, T. The effect of temperature and pH on the growth of lactic acid bacteria: A pH-auxostat study. Int. J. Food. Microbiol. 2003, 85, 171–183. [Google Scholar] [CrossRef]

- Aghababaie, M.; Beheshti, M.; Khanahmadi, M. Effect of temperature and pH on formulating the kinetic growth parameters and lactic acid production of Lactobacillus bulgaricus. Nutr. Food. Sci. Res. 2014, 1, 49–56. [Google Scholar]

- Bernard, N.; Ferain, T.; Garmyn, D.; Hols, P.; Delcour, J. Cloning of the D-lactate dehydrogenase gene from Lactobacillus delbrueckii subsp. bulgaricus by complementation in Escherichia coli. FEBS Lett. 1991, 290, 61–64. [Google Scholar] [CrossRef] [Green Version]

- Hofvendahl, K.; Hahn–Hägerdal, B. Factors affecting the fermentative lactic acid production from renewable resources. Enzyme Microb. Technol. 2000, 26, 87–107. [Google Scholar] [CrossRef]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass; Laboratory Analytical Procedure (LAP); Sluiter, A., Ed.; National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Sugars, Byproducts, and Degradation Products in Liquid Fraction Process Samples; Laboratory Analytical Procedure (LAP); Sluiter, A., Ed.; National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Laboratory Analytical Procedure (LAP); Sluiter, A., Ed.; National Renewable Energy Laboratory: Golden, CO, USA, 2012.

- Archibald, F.S.; Fridovich, I. Manganese and defenses against oxygen toxicity in Lactobacillus plantarum. J. Bacteriol. 1981, 145, 442–451. [Google Scholar]

- Bevilacqua, A.; Corbo, M.R.; Sinigaglia, M. In vitro evaluationof the antimicrobial activity of eugenol, limonene, and citrus extract against bacteriaand yeasts, representativeofthe spoilingmicroflora of fruit juices. J. Food Prot. 2010, 73, 888–894. [Google Scholar] [CrossRef]

- Grobben, G.J.; Chin-Joe, I.; Kitzen, V.A.; Boels, I.C.; Boer, F.; Sikkema, J.; Smith, M.R.; De Bont, J.A.M. Enhancement of exopolysaccharide production by Lactobacillus delbrueckii subsp. bulgaricus NCFB 2772 with a simplified defined medium. Appl. Environ. Microbiol. 1998, 64, 1333–1337. [Google Scholar]

- Chervaux, C.; Ehrlich, S.D.; Maguin, E. Physiological Study of Lactobacillus delbrueckii subsp. bulgaricus Strains in a Novel Chemically Defined Medium. Appl. Environ. Microbiol. 2000, 66, 5306–5311. [Google Scholar]

- Zhang, Y.; Yoshida, M.; Vadlani, P.V. Biosynthesis of D-lactic acid from lignocellulosic biomass. Biotechnol. Lett. 2018, 40, 1167–1179. [Google Scholar] [CrossRef]

- Kwon, S.; Lee, P.C.; Lee, E.G.; Chang, Y.K.; Chang, N. Production of lactic acid by Lactobacillus rhamnosus with vitamin-supplemented soybean hydrolysate. Enzym. Microb. Technol. 2000, 26, 209–215. [Google Scholar] [CrossRef]

- De la Torre, I.; Acedos, M.G.; Ladero, M.; Santos, V.E. On the use of resting L. delbrueckii spp. delbrueckii cells for D-lactic acid production from orange peel wastes hydrolysates. Biochem. Eng. J. 2019, 145, 162–169. [Google Scholar]

- Fukushima, K.; Sogo, K.; Miura, S.; Kimura, Y. Production of D-lactic acid by bacterial fermentation of rice starch. Macromol. Biosci. 2004, 4, 1021–1027. [Google Scholar] [CrossRef]

- Nguyen, C.M.; Kim, J.S.; Song, J.K.; Choi, G.J.; Choi, Y.H.; Jang, K.S.; Kim, J.C. D-lactic acid production from dry biomass of Hydrodictyon reticulatum by simultaneous saccharification and co-fermentation using Lactobacillus coryniformis subsp torquens. Biotechnol. Lett. 2012, 34, 2235–2240. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, C.M.; Kim, J.S.; Nguyen, T.N.; Kim, S.K.; Choi, G.J.; Choi, Y.H.; Jang, K.S.; Kim, J.C. Production of L- and D-lactic acid from waste Curcuma longa biomass through simultaneous saccharification and cofermentation. Bioresour. Technol. 2013, 146, 35–43. [Google Scholar] [CrossRef]

- Prasad, S.; Srikanth, K.; Limaye, A.M.; Sivaprakasam, S. Homo-fermentative production of d-lactic acid by Lactobacillus sp. employing casein whey permeate as a raw feed-stock. Biotechnol. Lett. 2014, 36, 1303–1307. [Google Scholar] [CrossRef]

- De Oliveira Moraes, A.; Ramirez, N.I.B.; Pereira, N. Evaluation of the fermentation potential of pulp mill residue to produce D (−)-lactic acid by separate hydrolysis and fermentation using Lactobacillus coryniformis subsp. torquens. Appl. Biochem. Biotechnol. 2016, 180, 1574–1585. [Google Scholar] [CrossRef]

| Microorganism | Strain Code |

|---|---|

| L. delbrueckii ssp. bulgaricus | CECT 4005 |

| L. delbrueckii ssp. bulgaricus | CECT 4006 |

| L. delbrueckii ssp. bulgaricus | CECT 5035 |

| L. delbrueckii ssp. bulgaricus | CECT 5036 |

| L. delbrueckii ssp. bulgaricus | CECT 5037 |

| L. delbrueckii ssp. bulgaricus | CECT 5038 |

| Component | % Dry Weight (w/w) |

|---|---|

| Total solids | 19.2 ± 0.5 |

| Ash | 3.9 ± 0.2 |

| Fats | n.d. |

| Water extractives | 37.5 ± 0.4 |

| Free sugars | 36.4 ± 0.6 |

| Glucan | 19.1 ± 0.1 |

| Hemicellulose | 14.8 ± 0.2 |

| Lignin | 6.2± 0.5 |

| Pectin | 17.9 ± 1.5 |

| Feedstock | Microorganism | Process | Yield (g g−1) | Productivity (g L−1 h−1) | D-LA (%) | Reference |

|---|---|---|---|---|---|---|

| Rice starch | L. delbrueckii LD 0028 | SHF | 0.70 | 1.55 | 97.5 | [49] |

| Defatted rice bran | L. delbrueckii IFO 3202 | SSF | 0.78 | 1.25 | > 95 | [10] |

| Sugarcane molasses | L. delbrueckii JCM 1148 | -- | 0.90 | 1.48 | 97.2 | [31] |

| Sugarcane juice | L. delbrueckii JCM 1148 | -- | 0.95 | 1.66 | 98.3 | [31] |

| Sugar beet juice | L. delbrueckii JCM 1148 | -- | 0.88 | 1.16 | 97.6 | [31] |

| Microalga | L. coryniformis ssp. torquens ATCC 25600 | SSF | 0.46 | 1.02 | 95.8 | [50] |

| Curcuma longa waste | L. coryniformis ssp. torquens ATCC 25600 | SSF | 0.65 | 2.08 | > 95 | [51] |

| Pulp | L. delbrueckii ATCC 9649 | SHF | 0.83 | 1.01 | 99 | [9] |

| Casein whey permeate | L. delbrueckii ssp. lactis ATCC 4797 | -- | 0.49 | 0.61 | > 98 | [52] |

| Pulp mill residues | L. coryniformes ssp. torquens ATCC 25600 | SHF | 0.97 | 2.80 | 99 | [53] |

| Orange peel waste | L. delbrueckii ssp. delbrueckii CECT 286 | SHF | 0.88 | 2.35 | > 95 | [32] |

| Orange peel waste | L. delbrueckii ssp. delbrueckii CECT 286 | SHF | 0.86 | 0.63 | 99.5 | This study |

| Orange peel waste | L. delbrueckii ssp. bulgaricus CECT 5037 | SHF | 0.84 | 0.55 | 99.3 | This study * |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bustamante, D.; Tortajada, M.; Ramón, D.; Rojas, A. Production of D-Lactic Acid by the Fermentation of Orange Peel Waste Hydrolysate by Lactic Acid Bacteria. Fermentation 2020, 6, 1. https://doi.org/10.3390/fermentation6010001

Bustamante D, Tortajada M, Ramón D, Rojas A. Production of D-Lactic Acid by the Fermentation of Orange Peel Waste Hydrolysate by Lactic Acid Bacteria. Fermentation. 2020; 6(1):1. https://doi.org/10.3390/fermentation6010001

Chicago/Turabian StyleBustamante, Daniel, Marta Tortajada, Daniel Ramón, and Antonia Rojas. 2020. "Production of D-Lactic Acid by the Fermentation of Orange Peel Waste Hydrolysate by Lactic Acid Bacteria" Fermentation 6, no. 1: 1. https://doi.org/10.3390/fermentation6010001