Combined Effect of Dipping in Oxalic or in Citric Acid and Low O2 Modified Atmosphere, to Preserve the Quality of Fresh-Cut Lettuce during Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material and Sample Preparation

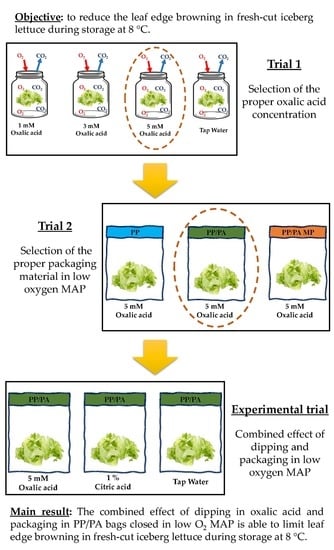

2.1.1. Preliminarily Trials

Selection of the Proper Oxalic Acid Concentration

Selection of the Proper Packaging Material

2.1.2. Combined Effect of Dipping in Oxalic or in Citric Acid and Low O2 MAP

2.2. Respiration Rate and Headspace Analysis

2.3. Sensory Evaluation, Colour, Texture and Weight Loss

2.4. Electrolyte Leakage and Ammonium Content

2.5. Total Phenol Content and O-Quinones Determination

2.6. Statistical Analysis

3. Results

3.1. Oxalic Acid Concentration and Packaging Selection

3.2. Combined Effect of Dipping and MAP to Extend the Marketability of Fresh-Cut Lettuce

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pace, B.; Capotorto, I.; Ventura, M.; Cefola, M. Evaluation of L-cysteine as anti-browning agent in fresh-cut lettuce processing. J. Food Process. Preserv. 2015, 39, 985–993. [Google Scholar] [CrossRef]

- Heimdal, H.; Kühn, B.F.; Poll, L.; Larsen, L.M. Biochemical changes and sensory quality of shredded and MA-packaged iceberg lettuce. J. Food Sci. 1995, 60, 1265–1268. [Google Scholar] [CrossRef]

- Amodio, M.L.; Cefola, M.; Pace, B.; Colelli, G. Fresh-Cut Fruits and Vegetables. In Postharvest Physiological Disorders in Fruits and Vegetables, 1st ed.; Tonetto de Freitas, S., Pareek, S., Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 761–784. ISBN 13:978-1138035508. [Google Scholar]

- Tudela, J.A.; Gil, M.I. Leafy vegetables: Fresh-cut lettuce. In Controlled and Modified Atmospheres for Fresh and Fresh-Cut Produce, 1st ed.; Gil, M.I., Beaudry, R., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 545–550. [Google Scholar] [CrossRef]

- Altunkaya, A.; Gökmen, V. Effect of various inhibitors on enzymatic browning, antioxidant activity and total phenol content of fresh lettuce (Lactuca sativa). Food Chem. 2008, 107, 1173–1179. [Google Scholar] [CrossRef]

- Altunkaya, A.; Gökmen, V. Effect of various anti-browning agents on phenolic compounds profile of fresh lettuce (L. sativa). Food Chem. 2009, 117, 122–126. [Google Scholar] [CrossRef]

- Soares, C.D.F.; Martin, J.G.P.; Berno, N.D.; Kluge, R.A. Antioxidant chemical treatment affects physiology and quality of minimally-processed escarole. Horticulturae 2019, 5, 75. [Google Scholar] [CrossRef] [Green Version]

- Saltveit, M.E. Physical and physiological changes in minimally processed fruits and vegetables. In Phytochemistry of Fruit and Vegetables; Tomás-Barberán, F.A., Ed.; Oxford University Press: New York, NY, USA, 1997; pp. 205–220. [Google Scholar]

- Gorny, J.R. A summary of CA and MA requirements and recommendations for fresh-cut (minimally processed) fruits and vegetables. Acta Hort. 2003, 600, 609–614. [Google Scholar] [CrossRef]

- Suttirak, W.; Manurakchinakorn, S. Potential application of ascorbic acid, citric acid and oxalic acid for browning inhibition in fresh-cut fruits and vegetables. Walailak J. Sci. Tech. 2010, 7, 5–14. [Google Scholar]

- Cefola, M.; Pace, B. Application of oxalic acid to preserve the overall quality of rocket and baby spinach leaves during storage. J. Food Process. Preserv. 2015, 39, 2523–2532. [Google Scholar] [CrossRef]

- Ahvenainen, R. New approaches in improving the shelf life of minimally processed fruit and vegetables. Trends Food Sci. Technol. 1996, 7, 179–187. [Google Scholar] [CrossRef]

- Barberis, A.; Cefola, M.; Pace, B.; Azara, E.; Spissu, Y.; Serra, P.R.; Logrieco, A.F.; D’hallewin, G.; Fadda, A. Postharvest application of oxalic acid to preserve overall appearance and nutritional quality of fresh-cut green and purple asparagus during cold storage: A combined electrochemical and mass-spectrometry analysis approach. Postharvest Biol. Technol. 2019, 148, 158–167. [Google Scholar] [CrossRef]

- Zheng, J.; Li, S.; Xu, Y.; Zheng, X. Effect of oxalic acid on edible quality of bamboo shoots (Phyllostachys prominens) without sheaths during cold storage. LWT 2019, 109, 194–200. [Google Scholar] [CrossRef]

- Ali, S.; Khan, A.S.; Anjum, M.A.; Nawaz, A.; Naz, S.; Ejaz, S.; Hussain, S. Effect of postharvest oxalic acid application on enzymatic browning and quality of lotus (Nelumbo nucifera Gaertn.) root slices. Food Chem. 2020, 312, 126051. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.L.; Brecht, J.K. Oxalic acid treatments. In Novel Postharvest Treatments of Fresh Produce, 1st ed.; Pareek, S., Ed.; CRC Press: Boca Raton, FL, USA, 2018; pp. 35–49. [Google Scholar] [CrossRef]

- Kader, A.A. Methods of gas mixing, sampling and analysis. In Postharvest Technology of Horticultural Crops, 3rd ed.; Kader, A.A., Ed.; ANR Publication: Oakland, CA, USA, 2020; pp. 145–148. [Google Scholar]

- Cefola, M.; Carbone, V.; Minasi, P.; Pace, B. Phenolic profiles and postharvest quality changes of fresh-cut radicchio (Cichorium intybus L.): Nutrient value in fresh vs. stored leaves. J. Food Comp. Anal. 2016, 51, 76–84. [Google Scholar] [CrossRef]

- Cefola, M.; D’Antuono, I.; Pace, B.; Calabrese, N.; Carito, A.; Linsalata, V.; Cardinali, A. Biochemical relationships and browning index for assessing the storage suitability of artichoke genotypes. Food Res. Int. 2012, 48, 397–403. [Google Scholar] [CrossRef]

- Kim, J.G.; Luo, Y.; Tao, Y.; Saftner, R.A.; Gross, K.C. Effect of initial oxygen concentration and film oxygen transmission rate on the quality of fresh-cut romaine lettuce. J. Sci. Food Agric. 2005, 85, 1622–1630. [Google Scholar] [CrossRef]

- Fadda, A.; Pace, B.; Angioni, A.; Barberis, A.; Cefola, M. Suitability for ready-to-eat processing and preservation of six green and red baby leaves cultivars and evaluation of their antioxidant value during storage and after the expiration date. J. Food Process. Pres. 2016, 40, 550–558. [Google Scholar] [CrossRef]

- Degl’Innocenti, E.; Pardossi, A.; Tognoni, F.; Guidi, L. Physiological basis of sensitivity to enzymatic browning in “lettuce”, “escarole” and “rocket salad” when stored as fresh-cut products. Food Chem. 2007, 104, 209–215. [Google Scholar] [CrossRef]

- Zhou, T.; Harrison, A.D.; McKellar, R.; Young, J.C.; Odumeru, J.; Piyasena, P.; Lu, X.; Mercer, D.G.; Karr, S. Determination of acceptability and shelf life of ready-to-use lettuce by digital image analysis. Food Res. Int. 2004, 37, 875–881. [Google Scholar] [CrossRef]

- Pace, B.; Cefola, M.; Da Pelo, P.; Renna, F.; Attolico, G. Nondestructive evaluation of quality and ammonia content in whole and fresh-cut lettuce by computer vision system. Food Res. Int. 2014, 64, 647–655. [Google Scholar] [CrossRef]

- Martínez-Sánchez, A.; Tudela, J.A.; Luna, C.; Allende, A.; Gil, M.I. Low oxygen levels and light exposure affect quality of fresh-cut Romaine lettuce. Postharvest Biol. Technol. 2011, 59, 34–42. [Google Scholar] [CrossRef]

- Cantwell, M.; Suslow, T. Lettuce: Crisphead or Iceberg. Recommendations for Maintaining Postharvest Quality. 2001. Available online: http://ucanr.edu/sites/Postharvest_Technology_Center_/Commodity_Resources/Fact_Sheets/Datastores/Vegetables_English/?uid=19&ds=799 (accessed on 21 May 2020).

- Lopez-Gàlvez, G.; Salveit, M.; Cantwell, M. The visual quality of minimally processed lettuces stored in air or controlled atmosphere with emphasis on romaine and iceberg types. Postharvest Biol. Technol. 1996, 8, 179–190. [Google Scholar] [CrossRef]

- Gorny, J.R. A summary of CA and MA requirements and recommendations for fresh-cut (minimally processed) fruits and vegetables. In Proceedings of the 7th International Controlled Atmosphere Conference, University of California, Davis, CA, USA, 13–18 July 1997; Volume 5, pp. 30–66. [Google Scholar]

- Hertog, M.L.A.T.; Peppelenbos, H.W.; Evelo, R.G.; Tijskens, L.M.M. A dynamic and generic model of gas exchange of respiring produce: The effects of oxygen, carbon dioxide and temperature. Postharvest Biol. Technol. 1998, 14, 335–349. [Google Scholar] [CrossRef]

- Ruíz-Jiménez, J.M.; Zapata, P.J.; Serrano, M.; Valero, D.; Martínez-Romero, D.; Castillo, S.; Guillén, F. Effect of oxalic acid on quality attributes of artichokes stored at ambient temperature. Postharvest Biol. Technol. 2014, 95, 60–63. [Google Scholar] [CrossRef]

- Ali, H.M.; El-Gizawy, A.M.; El-Bassiouny, R.E.; Saleh, M.A. The role of various amino acids in enzymatic browning process in potato tubers, and identifying the browning products. Food Chem. 2016, 192, 879–885. [Google Scholar] [CrossRef]

| Parameter | Combined Treatment (A) | Storage (B) | Combined Treatment × Storage (A × B) |

|---|---|---|---|

| Respiration rate (mL CO2 kg−1·h−1) | ns | * | *** |

| Hue angle (h°) | *** | *** | *** |

| Texture (N·g−1) | ns | ns | ns |

| Weight loss % | * | *** | ns |

| Visual Quality (VQ) | *** | ns | * |

| Off Odour | ns | ns | ns |

| Electrolyte leakage % | * | * | ns |

| Ammonium content (mmol·kg−1 NH4+) | ** | *** | ns |

| Total phenols (mg·kg−1 gallic acid) | ns | * | ns |

| o-quinones (OD 427 nm) | * | ns | ns |

| Main Factors | Weight Loss % | Electrolyte Leakage % | Ammonium Content (mmol·kg−1 NH4+) | Total Phenols (mg·kg−1 gallic acid) | O-Quinones (OD 427 nm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Combined Treatments | ||||||||||

| OA-MAP | 0.361 | b | 41.4 | b | 1.99 | b | 83.1 | ns | 0.10 | b |

| CIT-MAP | 0.445 | ab | 44.3 | a | 2.17 | a | 89.6 | ns | 0.12 | ab |

| CTRL-MAP | 0.512 | a | 44.1 | a | 1.96 | b | 83.9 | ns | 0.14 | a |

| Storage | ||||||||||

| 3 | 0.295 | b | 42.5 | b | 1.72 | b | 76.4 | b | 0.13 | ns |

| 6 | 0.484 | a | 45.2 | a | 2.15 | a | 88.6 | a | 0.11 | ns |

| 8 | 0.539 | a | 42.1 | b | 2.27 | a | 91.7 | a | 0.13 | ns |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pace, B.; Capotorto, I.; Palumbo, M.; Pelosi, S.; Cefola, M. Combined Effect of Dipping in Oxalic or in Citric Acid and Low O2 Modified Atmosphere, to Preserve the Quality of Fresh-Cut Lettuce during Storage. Foods 2020, 9, 988. https://doi.org/10.3390/foods9080988

Pace B, Capotorto I, Palumbo M, Pelosi S, Cefola M. Combined Effect of Dipping in Oxalic or in Citric Acid and Low O2 Modified Atmosphere, to Preserve the Quality of Fresh-Cut Lettuce during Storage. Foods. 2020; 9(8):988. https://doi.org/10.3390/foods9080988

Chicago/Turabian StylePace, Bernardo, Imperatrice Capotorto, Michela Palumbo, Sergio Pelosi, and Maria Cefola. 2020. "Combined Effect of Dipping in Oxalic or in Citric Acid and Low O2 Modified Atmosphere, to Preserve the Quality of Fresh-Cut Lettuce during Storage" Foods 9, no. 8: 988. https://doi.org/10.3390/foods9080988