Physiochemical Quality and Sensory Characteristics of koji Made with Soybean, Rice, and Wheat for Commercial doenjang Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Koji Sample Preparation

2.2. Physiochemical Quality Characteristic Analyses

2.3. Enzymatic Activity Analysis

2.4. Descriptive Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Comparison of the Physiochemical Quality Characteristics of koji

3.2. Enzymatic Activity Results

3.3. Descriptive Analysis Results

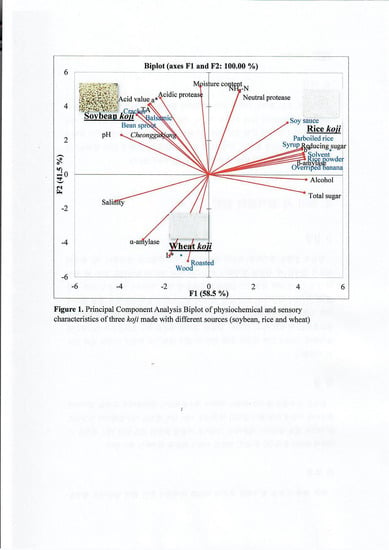

3.4. Correlating Physiochemical Quality Characteristics, Enzymatic Activities, and Descriptive Analyses Result

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jo, Y.J.; Cho, I.H.; Song, C.K.; Shin, H.W.; Kim, Y.S. Comparison of fermented soybean paste (Doenjang) prepared by different methods based on profiling of volatile compounds. J. Food Sci. 2011, 76, C368–C379. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.K.; Lee, K.G. Correlating consumer perception and consumer acceptability of traditional Doenjang in Korea. J. Food Sci. 2014, 79, S2330–S2336. [Google Scholar] [CrossRef] [PubMed]

- Park, K.Y.; Hwang, K.M.; Jung, K.O.; Lee, K.B. Studies on the standardization of Doenjang (Korean Soybean Paste) 1. Standardization of Manufacturing Method of Doenjang by Literature. J. Korean Soc. Food Sci. Nutr. 2002, 31, 343–350. [Google Scholar] [CrossRef]

- Ito, K.; Yoshida, K.; Ishikawa, T.; Kobayashi, S. Volatile compounds produced by the Fungus Aspergillus oryzae in Rice koji and their changes during cultivation. J. Ferm. Bioeng. 1990, 70, 169–172. [Google Scholar] [CrossRef]

- Chancharoonpong, C.; Hsieh, P.C.; Sheu, S.C. Enzyme production and growth of aspergillus oryzae S. on soybean koji fermentation. APCBEE Procedia 2012, 2, 57–61. [Google Scholar] [CrossRef] [Green Version]

- Jun, J.Y.; Lee, M.H.; Jeong, I.H.; Jung, M.J.; Kim, B.M. Effects of seaweeds on rice koji production and enzyme activity. Korean J. Fish. Aquat. Sci. 2018, 51, 369–375. [Google Scholar] [CrossRef]

- Bechman, A.; Phillips, R.D.; Chen, J. Changes in selected physical property and enzyme activity of rice and barley koji during fermentation and storage. J. Food Sci. 2012, 77, M318–M322. [Google Scholar] [CrossRef]

- Kim, B.M.; Park, J.H.; Kim, D.S.; Kim, Y.M.; Jun, J.Y.; Jeong, I.H.; Nam, S.Y.; Chi, Y.M. Effects of rice koji inoculated with Aspergillus Iuchuensis on the biochemical and sensory properties of a sailfin sandfish (Arctoscopus japonicus) fish sauce. Int. J. Food Sci. Technol. 2016, 51, 1888–1899. [Google Scholar] [CrossRef]

- Lee, D.E.; Lee, S.; Jang, E.S.; Shin, H.W.; Moon, B.S.; Lee, C.H. Metabolomic profiles of Aspergillus oryzae and Bacillus amyloliquefaciens during rice koji fermentation. Molecules 2016, 21, 773. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.Y.; Kwon, D.J. Quality characteristics of doenjang manufactured with soybean koji. Korean J. Food Preserv. 2014, 21, 434–441. [Google Scholar] [CrossRef] [Green Version]

- Yong, F.M.; Wood, B.J. B Biochemical changes in experimental soy sauce koji. Int. J. Food Sci. Technol. 1977, 12, 163–175. [Google Scholar] [CrossRef]

- Chiou, R.Y.Y.; Cheng, S.L. Isoflavone transformation during soybean koji preparation and subsequent miso fermentation supplemented with ethanol and NaCl. J. Agric. Food Chem. 2001, 49, 3656–3660. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.G.; Lyu, J.; Kim, M.K.; Lee, K.G. Effect of citrulline, urea, ethanol, and urease on the formation of ethyl carbamate in soybean paste model system. Food Chem. 2015, 189, 74–79. [Google Scholar] [CrossRef]

- Kim, M.K.; Chung, H.J.; Bang, W.S. Correlating physiochemical quality characteristics to consumer hedonic perception of traditional Doenjang (fermented soybean paste) in Korea. J. Sens. Stud. 2018, 33, e12462. [Google Scholar] [CrossRef]

- Xiao, Z.; Storms, R.; Tsang, A. A quantitative starch–iodine method for measuring alpha-amylase and glucoamylase activities. Anal. Biochem. 2006, 351, 146–148. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Kim, D.H. Changes in Physicochemical properties of low-salt Doenjang during fermentation. J. Korean Food Sci. Technol. 2012, 44, 592–599. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, J.H.; Chang, Y.E.; Kim, G.C.; Kim, K.M. The quality characteristics of rice mash by mixing ratios of rice and rice koji. J. Korean Soc. Food Sci. Nutr. 2013, 42, 2035–2041. [Google Scholar] [CrossRef]

- Chutmanop, J.; Chuichulcherm, S.; Chisti, Y.; Srinophakun, P. Protease production by Aspergillus oryzae in solid-state fermentation using agroindustrial substrates. J. Chem. Technol. Biotechnol. 2008, 83, 1012–1018. [Google Scholar] [CrossRef]

- Lee, G.R.; Ko, Y.J.; Kim, E.J.; Kim, I.H.; Shim, K.H.; Kim, Y.G.; Ryu, C.H. Quality characteristics of wheat Doenjang according to mixing ratio of Meju. Korean J. Food Preserv. 2013, 20, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Choi, I.D. Physicochemical properties of rice cultivars with different amylose contents. J. Korean Soc. Food Sci. Nutr. 2010, 39, 1313–1319. [Google Scholar] [CrossRef] [Green Version]

- Su, N.W.; Wang, M.L.; Kwok, K.F.; Lee, M.H. Effects of temperature and sodium chloride concentration on the activities of proteases and amylases in soy sauce koji. J. Agric. Food Chem. 2005, 53, 1521–1525. [Google Scholar] [CrossRef]

- Lee, S.J.; Ahn, B. Comparison of volatile components in fermented soybean pastes using simultaneous distillation and extraction (SDE) with sensory characterization. Food Chem. 2009, 114, 600–609. [Google Scholar] [CrossRef]

- Kim, H.G.; Hong, J.H.; Song, C.K.; Shin, H.W.; Kim, K.O. Sensory characteristics and consumer acceptability of fermented soybean paste (Doenjang). J. Food Sci. 2010, 75, S375–S383. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.K.; Kwak, H.S.; Kim, M.J.; Kim, S.S. Identification of sensory characteristics that drive consumer preferences of commercially mass-produced doenjang in Korea. J. Sens. Stud. 2018, 33, e12323. [Google Scholar] [CrossRef]

- Lee, J.H.; Jeong, D.W.; Kim, M.K. Influence of bacterial starter cultures on the sensory characteristics of Doenjang, a fermented soybean paste, and their impact on consumer hedonic perception. J. Sens. Stud. 2019, 34, e12508. [Google Scholar] [CrossRef]

| Soybean koji | Rice koji | Wheat koji | p-Value | ||

|---|---|---|---|---|---|

| Moisture content (%) | 61.8 ± 0.9 a | 51.1 ± 4.3 b | 26.9 ± 1.3 c | 0.00 | |

| Color measurement | L* | 8.8 ± 5.2 | 7.6 ± 2.7 | 13.4 ± 13.2 | 0.46 |

| a* | 3.4 ± 1.2 a | 0.6 ± 2.0 b | 0.0 ± 2.0 b | 0.01 | |

| b* | 4.4 ± 2.0 | 6.8 ± 1.6 | 4.6 ± 1.9 | 0.08 | |

| pH value | 6.2 ± 0.8 a | 5.5 ± 0.2 b | 5.7 ± 0.3 a, b | 0.08 | |

| Titratable acidity (mL) | 3.2 ± 1.7 a | 0.9 ± 0.1 b | 0.8 ± 0.4 b | 0.00 | |

| Acid value (KOH/g) | 21.4 ± 4.0 a | 6.7 ± 1.7 b | 3.1 ± 0.4 c | 0.00 | |

| Salinity (%) | 10.0 ± 0.4 | 8.2 ± 0.2 | 10.3 ± 0.3 | 0.54 | |

| NH2-N (mg/%) | 1.1 ± 1.4 | 1.2 ± 0.8 | 1.3 ± 0.4 | 0.22 | |

| Alcohol (g/%) | 3.8 ± 1.2 b | 5.2 ± 0.8 a | 4.3 ± 0.7 a, b | 0.06 | |

| Reducing sugar (mg/g) | 13.9 ± 1.8 b | 90.3 ± 43.1 a | 15.2 ± 5.1 b | 0.00 | |

| Total sugar (mg/g) | 16.8 ± 11.7 c | 107.5 ± 10.9 a | 61.1 ± 5.7 b | 0.00 | |

| Enzymatic Activities | Soybean koji | Rice koji | Wheat koji |

|---|---|---|---|

| α-amylase (unit/g) | 35.7 ± 0.6 a, b | 34.8 ± 0.5 b | 36.3 ± 0.4 a |

| β-amylase (unit/g) | 48.3 ± 4.4 b | 75.1 ± 2.4 a | 52.0 ± 8.0 b |

| Acidic protease (unit/g) | 24.0 ± 5.4 a | 8.5 ± 5.2 b | 1.5 ± 1.1 b |

| Neutral protease (unit/g) | 13.5 ± 1.8 a | 15.1 ± 2.4 a | 1.2 ± 2.2 b |

| Term | Definition | Soybean koji | Rice koji | Wheat koji |

|---|---|---|---|---|

| Bean sprout | The aromatics associated with bean sprout (Ref: steaming bean sprout in water for 20 min) | 0.07 a | 0.00 a | 0.00 a |

| Balsamic | The aromatics associated with balsamic vineager (Ref: balsamic vinegar, Ottugi, Anyang, Gyeonggi-do, Korea) | 0.20 a | 0.00 a | 0.00 a |

| Soy sauce | The aromatics associated with commercially-made soy sauce (Ref: 501 soy sauce, Sempio®, Icheon, Gyeonggi-do, Korea) | 0.86 b | 1.67 a | 0.47 b |

| Cheonggukjang | The aromactics associated with cheonggukjang (Ref: Cheonggukjang, Pulmuone, Iksan, Jellabuk-do, Korea) | 1.95 a | 0.00 b | 0.00 b |

| Cracker | The aromatics associated with unsalted cracker (Ref: Cham-cracker, Crown, Deajeon, Korea) | 0.40 a | 0.00 b | 0.00 b |

| Solvent | The aromatics associated with chemical refrigerator | 0.27 b | 1.73 a | 0.36 b |

| Rice powder | The aromatics associated with rice powder (Ref: Organic rice powder, Momsrice, Gwangju, Gyeonggi-do, Korea) | 0.00 a | 0.06 a | 0.01 a |

| Parboiled rice | The aromatics associated with parboiled rice (Ref: Instant rice without heating, CJ Cheil-jedang, Gangneung, Gangwon-do, Korea) | 0.00 a | 0.07 a | 0.00 a |

| Overriped banana | The aromatics associated with overly-ripped banana (Ref: overly-riped banana) | 0.00 b | 1.83 a | 0.00 b |

| Syrup | The aromatics associated with maple syrup (Ref: maple syrup, L.B. Maple Treat Corp, Quebec, Canada) | 0.00 b | 1.18 a | 0.00 b |

| Wood | The aromatics associated with wet wood (Ref: hot steaming wet sauna) | 0.00 b | 0.00 b | 0.47 a |

| Roasted | The aromatics associated with popcorn (Ref: Lohi popcorn, Sajo, Yeongcheon, Gyeongsangbuk-do, Korea) | 0.00 b | 0.00 b | 2.31 a |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, H.H.; Kim, M.K. Physiochemical Quality and Sensory Characteristics of koji Made with Soybean, Rice, and Wheat for Commercial doenjang Production. Foods 2020, 9, 975. https://doi.org/10.3390/foods9080975

Hong HH, Kim MK. Physiochemical Quality and Sensory Characteristics of koji Made with Soybean, Rice, and Wheat for Commercial doenjang Production. Foods. 2020; 9(8):975. https://doi.org/10.3390/foods9080975

Chicago/Turabian StyleHong, Hyun Hee, and Mina K. Kim. 2020. "Physiochemical Quality and Sensory Characteristics of koji Made with Soybean, Rice, and Wheat for Commercial doenjang Production" Foods 9, no. 8: 975. https://doi.org/10.3390/foods9080975