Physical and Microstructure Properties of Oyster Mushroom-Soy Protein Meat Analog via Single-Screw Extrusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing of Gray Oyster Mushroom

2.3. Preparation of Feed Mixtures

2.4. Extrusion Cooking

2.5. Factorial Experiment Design

2.6. Characterization of Oyster Mushroom-Soy Protein Extrudate Physical Properties

2.6.1. Expansion Ratio

2.6.2. Apparent Density

2.6.3. Water Absorption Index

2.6.4. Moisture Content

2.6.5. Texturization Index

2.6.6. Scanning Electron Microscopy Analysis.

2.6.7. Data Analysis

3. Results and Discussions

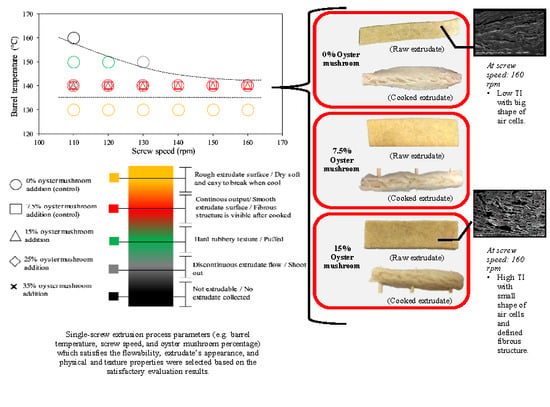

3.1. Evaluation of Extrusion Ability and Physical Characteristics of Oyster Mushroom-Soy Protein Extrudate

3.2. Oyster Mushroom-Soy Protein Extrudate’s Physical Properties under Selected Extrusion Process Conditions

3.2.1. Expansion Ratio and Apparent Density

3.2.2. Moisture Content

3.2.3. Water Absorption Index

3.2.4. Texturization Index

3.2.5. Microstructural Properties of Oyster Mushroom-Soy Protein Extrudate

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Askew, K. Meat Analogues: A “Big Opportunity” for Improved Quality. Available online: https://www.foodnavigator.com/Article/2019/06/19/Meat-analogues-A-big-opportunity-for-improved-quality (accessed on 19 June 2019).

- Asgar, M.A.; Fazilah, A.; Huda, N.; Bhat, R.; Karim, A.A. Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Food Saf. 2010, 9, 513–529. [Google Scholar] [CrossRef]

- Maida, J. Global Meat Substitutes Market 2017–2021. Available online: https://www.technavio.com/report/global-meat-substitutes-market (accessed on 20 June 2017).

- Rehrah, D.; Ahmedna, M.; Goktepe, I.; Yu, J. Extrusion parameters and consumer acceptability of a peanut-based meat analogue. Int. J. Food Sci. Technol. 2009, 44, 2075–2084. [Google Scholar] [CrossRef]

- Thadavathi, Y.L.N.; Wassén, S.; Kádár, R. In-line rheological and microstroctural characterization of high moisture content protein vegetable mixtures in single screw extrusion. J. Food Eng. 2019, 245, 112–123. [Google Scholar] [CrossRef]

- Caporgno, M.P.; Böcker, L.; Müssner, C.; Stirnemann, E.; Haberkorn, I.; Adelmann, H.; Handschin, S.; Windhab, E.J.; Mathys, A. Extruded meat analogues based on yellow, heterotrophically cultivated Auxenochlorella protothecoides microalgae. Innov. Food Sci. Emerg. Technol. 2020, 59, 102275. [Google Scholar] [CrossRef]

- Krintiras, G.A.; Gadea Diaz, J.G.; van der Goot, A.J.; Stankiewicz, A.I.; Stefanidis, G.D. On the use of the Couette Cell technology for large scale production of textured soy-based meat replacers. J. Food Eng. 2016, 169, 205–213. [Google Scholar] [CrossRef] [Green Version]

- Nieuwland, M.; Geerdink, P.; Brier, P.; van den Eijnden, P.; Henket, J.T.M.M.; Langelaan, M.L.P.; Stroeks, N.; van Deventer, H.C.; Martin, A.H. Reprint of “Food-grade electrospinning of proteins”. Innov. Food Sci. Emerg. Technol. 2014, 24, 138–144. [Google Scholar] [CrossRef]

- Milani, T.M.G.; Menis, M.E.C.; Jordano, A.; Boscolo, M.; Conti-Silva, A.C. Pre-extrusion aromatization of a soy protein isolate using volatile compounds and flavor enhancers: Effects on physical characteristics, volatile retention and sensory characteristics of extrudates. Food Res. Int. 2014, 62, 375–381. [Google Scholar] [CrossRef]

- Ma, X.; Ryu, G. Effects of green tea contents on the quality and antioxidant properties of textured vegetable protein by extrusion-cooking. Food Sci. Biotechnol. 2019, 28, 67–74. [Google Scholar] [CrossRef]

- Croan, S.C. Conversion of conifer wastes into edible and medicinal mushrooms. For. Prod. J. 2004, 54, 68–76. [Google Scholar]

- Synytsya, A.; Míčková, K.; Jablonský, I.; Sluková, M.; Čopíková, J. Mushrooms of genus Pleurotus as a source of dietary fibres and glucans for food supplements. Czech J. Food Sci. 2009, 26, 441–446. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, M.; Abdullah, N.; Nuruddin, N.N. Yield and nutritional composition of oyster mushrooms: An alternative nutritional source for rural people. Sains Malays. 2016, 45, 1609–1615. [Google Scholar]

- Wan Rosli, W.I.; Aishah, M.A.; Nik Fakurudin, N.A.; Mohsin, S.S.J. Colour, textural properties, cooking characteristics and fibre content of chicken patty added with oyster mushroom (Pleurotus sajor-caju). Int. Food Res. J. 2011, 18, 621–627. [Google Scholar]

- Myrdal Miller, A.; Mills, K.; Wong, T.; Drescher, G.; Lee, S.M.; Guinard, J.X. Flavor-enhancing properties of mushrooms in meat-based dishes in which sodium has been reduced and meat has been partially substituted with mushrooms. J. Food Sci. 2014, 79, 1795–1804. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Banerjee, D.K.; Das, A.K.; Banerjee, R.; Pateiro, M.; Nanda, P.K.; Gadekar, Y.P.; Biswas, S.; McClements, D.J.; Lorenzo, J.M. Application of enoki mushroom (Flammulina velutipes) stem wastes as functional ingredients in goat meat nuggets. Foods 2020, 9, 432. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahirwar, R.; Jayathilakan, K.; Reddy, K.J.; Pandey, M.C.; Batra, H.V. Development of mushroom and wheat gluten based meat analogue by using response surface methodology. Int. J. Adv. Res. 2015, 3, 923–930. [Google Scholar]

- (FAMA) Federal Agricultural Marketing Authority. Kualiti Cendawan Tiram Kelabu Berpandukan, Malaysian Standard (MS 2515:2012). Available online: http://www.fama.gov.my/documents/20143/0/cendawan+red.pdf/63676187-392a-48ce-4405-6d4090cb5568 (accessed on 30 September 2017).

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Anderson, R.A. Water absorption and solubility and amylograph characteristics of roll-cooked small grain products. Cereal Chem. 1982, 59, 265–269. [Google Scholar]

- Omohimi, C.I.; Sobukola, O.P.; Sarafadeen, K.O.; Sanni, L.O. Effect of thermo-extrusion process parameters on selected quality attributes of meat analogue from mucuna bean seed flour. Niger. Food J. 2014, 32, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.; Sun, Y.; Bi, C.; Ji, F.; Li, B.; Xing, J. Effects of extrusion conditions on the physicochemical properties of soy protein/gluten composite. Int. J. Agric. Biol. Eng. 2018, 11, 205–210. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B.; Ojokoh, A.O. System parameters and product properties response of soybean protein extruded at wide moisture range. J. Food Eng. 2010, 96, 208–213. [Google Scholar] [CrossRef]

- Samard, S.; Gu, B.Y.; Ryu, G.H. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef]

- Bhattacharya, S. Twin-screw extrusion of rice-green gram blend: Extrusion and extrudate characteristics. J. Food Eng. 1997, 32, 83–99. [Google Scholar] [CrossRef]

- Arhaliass, A.; Bouvier, J.M.; Legrand, J. Melt growth and shrinkage at the exit of the die in the extrusion-cooking process. J. Food Eng. 2003, 60, 185–192. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Extrusion process parameters, sensory characteristics, and structural properties of a high moisture soy protein meat analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- Samard, S.; Ryu, G.H. A comparison of physicochemical characteristics, texture, and structure of meat analogue and meats. J. Sci. Food Agric. 2019, 99, 2708–2715. [Google Scholar] [CrossRef]

- Ning, L.; Villota, R. Influence of 7s and 11s globulins on the extrusion performance of soy protein concentrates. J. Food Process. Preserv. 1994, 18, 421–436. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Struct. 2019, 19, 100102. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, B.; Wei, Y. Effects of the specific mechanical energy on the physicochemical properties of texturized soy protein during high-moisture extrusion cooking. J. Food Eng. 2014, 121, 32–38. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.; Zhang, B.; Drago, S.R.; Zhang, J. Relationships between the gelatinization of starches and the textural properties of extruded texturized soybean protein-starch systems. J. Food Eng. 2016, 174, 29–36. [Google Scholar] [CrossRef]

- Takei, R.; Hayashi, M.; Umene, S.; Kobayashi, Y.; Masunaga, H. Texture and microstructure of enzyme-treated chicken breast meat for people with difficulties in mastication. J. Texture Stud. 2016, 47, 231–238. [Google Scholar] [CrossRef]

- Huang, F.F.; Rha, C. Protein structures and protein fibers: A review. Polym. Eng. Sci. 1974, 14, 81–91. [Google Scholar] [CrossRef]

- Stanley, D.W.; deMan, J.M. Structural and mechanical properties of textured proteins. J. Texture Stud. 1978, 9, 59–76. [Google Scholar] [CrossRef]

- Arêas, J.A.G. Extrusion of food proteins. Crit. Rev. Food Sci. Nutr. 1992, 32, 365–392. [Google Scholar] [CrossRef] [PubMed]

| Ingredients | Formulations (wb%) | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Base mixture | Soy protein concentrate (SP) | 50 | 50 | 50 | 50 | 50 |

| Isolated soy protein (ISP) | 50 | 50 | 50 | 50 | 50 | |

| Additional ingredients (% by total weight of the base mixture) | Wheat flour | 2 | 2 | 2 | 2 | 2 |

| Soy lecithin | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Sodium metabisulfite | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | |

| Salt | 3 | 3 | 3 | 3 | 3 | |

| Cooking palm oil | 10 | 10 | 10 | 10 | 10 | |

| Distilled water | 70 | 70 | 70 | 70 | 70 | |

| Oyster mushroom | 0 | 7.5 | 15 | 25 | 35 | |

| Run | Oyster Mushroom (%) | Extrusion Process Variables | Categorization | Summary | |||

|---|---|---|---|---|---|---|---|

| Barrel Temperature (°C) | Screw Speed (rpm) | Extrudability | Extrudate Characteristic | Illustration | |||

| 1 | 0 | 130 | 110 | Extrudable | 1. Intermittent extrudate flow. 2. Soft and easy to break when cool. |  | Dissatisfied |

| 2 | 120 | ||||||

| 3 | 130 | ||||||

| 4 | 140 | ||||||

| 5 | 150 | ||||||

| 6 | 160 | ||||||

| 7 | 140 | 110 | Extrudable | 1. Continuous extrudate flow 2. Smooth extrudate surface 3. The fibrous structure is visible |  | Satisfied | |

| 8 | 120 | ||||||

| 9 | 130 | ||||||

| 10 | 140 | ||||||

| 11 | 150 | ||||||

| 12 | 160 | ||||||

| 13 | 150 | 110 | Extrudable | 1. Continuous extrudate flow 2. Extrudate puffed at die |  | Dissatisfied | |

| 14 | 120 | ||||||

| 15 | 130 | 3. Intermittent extrudate flow and extrudate shoot out form die |  | Dissatisfied | |||

| 16 | 160 | 110 | Not extrudable | 1. Extrudate hardened at die 2. No extrudate collected | Not available | Dissatisfied | |

| 17 | 7.5 | 140 | 110 | Extrudable | 1. Continuous extrudate flow 2. Smooth extrudate surface 3. The fibrous structure is visible |  | Satisfied |

| 18 | 120 | ||||||

| 19 | 130 | ||||||

| 20 | 140 | ||||||

| 21 | 150 | ||||||

| 22 | 160 | ||||||

| 23 | 15 | 140 | 110 | Extrudable | 1. Continuous extrudate flow 2. Smooth extrudate surface 3. The fibrous structure is visible |  | Satisfied |

| 24 | 120 | ||||||

| 25 | 130 | ||||||

| 26 | 140 | ||||||

| 27 | 150 | ||||||

| 28 | 160 | ||||||

| 29 | 25 | 140 | 110 | Extrudable | 1. Intermittent extrudate flow 2. Extrudate shoot out from die |  | Dissatisfied |

| 30 | 120 | ||||||

| 31 | 130 | ||||||

| 32 | 35 | 140 | 110 | Extrudable | 1. Intermittent extrudate flow 2. Extrudate shoot out from die |  | Dissatisfied |

| Run | Barrel Temperature (°C) | Oyster Mushroom Addition (%) | Screw Speed (rpm) | Physical and Textural Properties of the Extrudates | ||||

|---|---|---|---|---|---|---|---|---|

| ER | Moisture Content (%) | WAI (g/g) | TI | |||||

| 1 | 140 | 0 | 110 | 1.17 ± 0.01 | 1380.96 ± 10.12 | 31.40 ± 1.03 | 2.91 ± 0.10 | 0.77 ± 0.01 |

| 2 | 120 | 1.17 ± 0.01 | 1381.55 ± 19.29 | 32.33 ± 0.28 | 3.17 ± 0.08 | 0.83 ± 0.08 | ||

| 3 | 130 | 1.09 ± 0.01 | 1393.70 ± 6.30 | 29.49 ± 0.13 | 3.22 ± 0.07 | 0.85 ± 0.02 | ||

| 4 | 140 | 1.15 ± 0.02 | 1284.80 ± 8.41 | 28.79 ± 0.37 | 3.48 ± 0.01 | 1.01 ± 0.01 | ||

| 5 | 150 | 1.16 ± 0.05 | 1261.27 ± 13.41 | 26.99 ± 0.49 | 3.41 ± 0.06 | 0.87 ± 0.07 | ||

| 6 | 160 | 1.26 ± 0.01 | 1182.72 ± 6.12 | 29.56 ± 0.33 | 3.54 ± 0.03 | 0.83 ± 0.12 | ||

| 7 | 140 | 7.5 | 110 | 1.01 ± 0.02 | 1339.92 ± 6.55 | 35.64 ± 0.23 | 3.61 ± 0.08 | 1.09 ± 0.01 |

| 8 | 120 | 1.02 ± 0.01 | 1331.66 ± 2.97 | 35.71 ± 0.18 | 3.48 ± 0.12 | 1.01 ± 0.01 | ||

| 9 | 130 | 1.09 ± 0.01 | 1370.92 ± 17.29 | 35.49 ± 0.08 | 3.72 ± 0.08 | 1.02 ± 0.02 | ||

| 10 | 140 | 1.12 ± 0.01 | 1354.46 ± 2.20 | 35.29 ± 0.37 | 3.64 ± 0.04 | 0.99 ± 0.00 | ||

| 11 | 150 | 1.02 ± 0.02 | 1351.17 ± 10.27 | 35.08 ± 0.04 | 3.96 ± 0.02 | 1.05 ± 0.02 | ||

| 12 | 160 | 1.08 ± 0.01 | 1322.25 ± 5.71 | 34.77 ± 0.08 | 3.83 ± 0.02 | 1.12 ± 0.02 | ||

| 13 | 140 | 15 | 110 | 0.99 ± 0.01 | 1327.08 ± 3.20 | 37.32 ± 0.13 | 3.76 ± 0.18 | 1.09 ± 0.02 |

| 14 | 120 | 0.99 ± 0.01 | 1302.90 ± 8.74 | 37.72 ± 0.05 | 3.77 ± 0.09 | 1.09 ± 0.12 | ||

| 15 | 130 | 0.98 ± 0.01 | 1315.44 ± 3.51 | 37.74 ± 0.22 | 3.86 ± 0.04 | 1.07 ± 0.03 | ||

| 16 | 140 | 1.00 ± 0.01 | 1285.62 ± 8.97 | 37.50 ± 0.05 | 4.04 ± 0.07 | 0.97 ± 0.02 | ||

| 17 | 150 | 1.01 ± 0.02 | 1298.37 ± 9.09 | 37.93 ± 0.05 | 3.97 ± 0.07 | 0.95 ± 0.01 | ||

| 18 | 160 | 1.00 ± 0.01 | 1272.73 ± 2.94 | 36.17 ± 0.01 | 3.92 ± 0.18 | 1.19 ± 0.04 | ||

| ER | Moisture Content | WAI | TI | |||

|---|---|---|---|---|---|---|

| p-value | OM | 0.0001 **** | 0.017 * | 0.0001 **** | 0.0001 **** | 0.0001 **** |

| SS | 0.015 * | 0.0001 **** | 0.015 * | 0.0001 **** | 0.059 | |

| R2 | 0.85 | 0.58 | 0.88 | 0.94 | 0.71 | |

| ER | Moisture Content | WAI | TI | ||

|---|---|---|---|---|---|

| ER | 1 | ||||

| −0.175 | 1 | ||||

| Moisture Content | −0.820 **** | 0.140 | 1 | ||

| WAI | −0.642 **** | −0.349 ** | 0.678 **** | 1 | |

| TI | −0.688 **** | −0.080 | 0.620 **** | 0.657 **** | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamad Mazlan, M.; Talib, R.A.; Chin, N.L.; Shukri, R.; Taip, F.S.; Mohd Nor, M.Z.; Abdullah, N. Physical and Microstructure Properties of Oyster Mushroom-Soy Protein Meat Analog via Single-Screw Extrusion. Foods 2020, 9, 1023. https://doi.org/10.3390/foods9081023

Mohamad Mazlan M, Talib RA, Chin NL, Shukri R, Taip FS, Mohd Nor MZ, Abdullah N. Physical and Microstructure Properties of Oyster Mushroom-Soy Protein Meat Analog via Single-Screw Extrusion. Foods. 2020; 9(8):1023. https://doi.org/10.3390/foods9081023

Chicago/Turabian StyleMohamad Mazlan, Mazween, Rosnita A. Talib, Nyuk Ling Chin, Radhiah Shukri, Farah Saleena Taip, Mohd Zuhair Mohd Nor, and Norazlin Abdullah. 2020. "Physical and Microstructure Properties of Oyster Mushroom-Soy Protein Meat Analog via Single-Screw Extrusion" Foods 9, no. 8: 1023. https://doi.org/10.3390/foods9081023