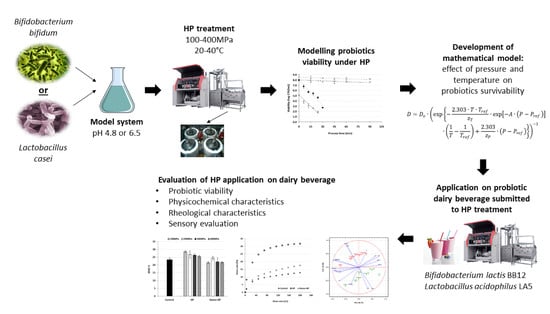

Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the Inocula for Kinetics Study

2.2. Yoghurt Preparation

2.3. High-Pressure Processing

2.4. Microbiological Analysis

2.5. Physicochemical Analysis

2.6. Rheological Properties

2.7. Sensory Evaluation

2.8. Data Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Probiotics Viability Loss as a Function of Pressure and Temperature

3.2. Modeling Probiotics Viability Loss as a Function of Temperature and Pressure

3.3. Selection of Optimal HP Conditions-Application in Yoghurt Production

3.3.1. Viability of Starter Culture and Probiotic Bacteria in Yoghurt Samples

3.3.2. Physicochemical/Rheological Characteristics After HP Treatment and During Storage

3.3.3. Sensory Profile of the HP Yoghurts

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations/World Health Organization (FAO/WHO). Report of a Joint FAO/WHO Working Group on Drafting Guidelines for the Evaluation of Probiotics in Food; Food and Agriculture Organization of the United Nations/World Health Organization: London, ON, Canada, 2002. [Google Scholar]

- Hill, C.; Guarner, F.; Reid, G.; Gibson, G.R.; Merenstein, D.J.; Pot, B.; Morelli, L.; Canani, R.B.; Flint, H.J.; Salminen, S.; et al. The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat. Rev. Gastroenterol. Hepatol. 2014, 11, 506–514. [Google Scholar] [CrossRef] [Green Version]

- Şanlier, N.; Gökcen, B.B.; Sezgin, A.C. Health benefits of fermented foods. Crit. Rev. Food Sci. Nutr. 2017, 59, 506–527. [Google Scholar] [CrossRef]

- Collado, M.C.; Isolauri, E.; Salminen, S.; Sanz, Y. The impact of probiotic on gut health. Curr. Drug. Metab. 2008, 10, 68–78. [Google Scholar] [CrossRef] [PubMed]

- Tripathy, M.K.; Giri, S.K. Probiotic functional foods: Survival of probiotics during processing and storage. J. Funct. Foods 2014, 9, 225–241. [Google Scholar] [CrossRef]

- Lucey, J.A. Formation and physical properties of milk protein gels. J. Dairy Sci. 2002, 85, 281–294. [Google Scholar] [CrossRef]

- Leroy, F.; De Vuyst, L. Lactic acid bacteria as functional starter cultures for the food fermentation industry. Trends Food Sci. Technol. 2004, 15, 67–78. [Google Scholar] [CrossRef]

- Trujillo, A.J.; Capellas, M.; Saldo, J.; Gervilla, R.; Guamis, B. Application of high-hydrostatic pressure on milk and dairy products: A review. Innov. Food Sci. Emerg. 2002, 3, 295–307. [Google Scholar] [CrossRef]

- Anema, S.G.; Lauber, S.; Lee, S.K.; Henle, T.; Klostermeyer, H. Rheological properties of acid gels prepared from pressure- and transglutaminase-treated skim milk. Food Hydrocoll. 2006, 19, 879–887. [Google Scholar] [CrossRef]

- Penna, A.L.B.; Subbarao-Gurram, G.V.; Barbosa-Cánovas, G.V. High hydrostatic pressure processing on microstructure of probiotic low-fat yogurt. Food Res. Int. 2007, 40, 510–519. [Google Scholar] [CrossRef]

- Masson, L.M.P.; Rosenthal, A.; Calado, V.M.A.; Dliza, R.; Tashima, L. Effect of ultra-high pressure homogenization on viscosity and shear stress of fermented dairy beverage. LWT-Food Sci. Technol. 2011, 44, 495–501. [Google Scholar] [CrossRef]

- Tsevdou, M.S.; Eleftheriou, E.G.; Taoukis, P.S. Transglutaminase treatment of thermally and high pressure processed milk: Effects on the properties and storage stability of set yoghurt. Innov. Food Sci. Emerg. 2013, 17, 144–152. [Google Scholar] [CrossRef]

- Loveday, S.M.; Sarkar, A.; Singh, H. Innovative yoghurts: Novel processing technologies for improving acid milk gel texture. Trends Food Sci. Technol. 2013, 33, 5–20. [Google Scholar] [CrossRef]

- Tanaka, T.; Hatanaka, K. Application of hydrostatic pressure to yoghurt to prevent its after-acidification. J. Jpn. Soc. Food Sci. 1992, 39, 173–177. [Google Scholar] [CrossRef]

- Krompkamp, J.; Moreira, R.M.; Langeveld, L.P.M.; Van Mil, P.J.J.M. Microorganisms in milk and yoghurt: Selective inactivation by high hydrostatic pressure. In Proceedings of the IDF Symposium Heat Treatments and Alternative Methods, Vienna, Austria, 6–8 September 1995. [Google Scholar]

- de Ancos, B.; Cano, M.P.; Gómez, R. Characteristics of stirred low-fat yoghurt as affected by high pressure. Int. Dairy J. 2000, 10, 105–111. [Google Scholar] [CrossRef] [Green Version]

- Tarmaraj, N.; Shah, N.P. Selective Enumeration of Lactobacillus delbrueckii ssp. bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacteria, Lactobacillus casei, Lactobacillus rhamnosus and Propionibacteria. J. Dairy Sci. 2003, 86, 2288–2296. [Google Scholar] [CrossRef]

- International Dairy Federation (IDF). Yogurt: Determination of Titratable Acidity. International IDF Standard, ISO 1991; International Dairy Federation: Vienna, Austria, 1991. [Google Scholar]

- Harte, F.; Luedecke, L.; Swanson, B.; Barbosa-Cánovas, G.V. Low-fat set yogurt made from milk subjected to combinations of high hydrostatic pressure and thermal processing. J. Dairy Sci. 2003, 86, 1074–1082. [Google Scholar] [CrossRef] [Green Version]

- Akhtar, M.; Murray, B.S.; Dickinson, E. Perception of creaminess of model oil-in-water dairy emulsions: Influence of the shear-thinning nature of a viscosity-controlling hydrocolloid. Food Hydrocoll. 2006, 20, 839–847. [Google Scholar] [CrossRef]

- ISO 13300-1. Sensory Analysis—General Guidance for the Staff of a Sensory Evaluation Laboratory—Part 1: Staff Responsibilities; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 13300-2. Sensory Analysis—General Guidance for the Staff of a Sensory EVALUATION Laboratory—Part 2: Recruitment and Training of Panel Leaders; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 8589. Sensory Analysis—General Guidance for the Design of Test Rooms; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Katsaros, G.I.; Tsevdou, M.; Panagiotou, T.; Taoukis, P.S. Kinetic study of high pressure microbial and enzyme inactivation and selection of pasteurization conditions for Valencia Orange Juice. Int. J. Food Sci. Technol. 2010, 45, 1119–1129. [Google Scholar] [CrossRef]

- Kanta, A.; Soukoulis, C.; Tzia, C. Eliciting the Sensory Modalities of Fat Reformulated Yoghurt Ice Cream Using Oligosaccharides. Food Bioprocess Technol. 2018, 11, 885–900. [Google Scholar] [CrossRef]

- Dave, R.I.; Shah, N.P. Effect of Cysteine on the Viability of Yoghurt and Probiotic Bacteria in Yoghurts Made with Commercial Starter Cultures. Int. Dairy J. 1997, 7, 537–545. [Google Scholar] [CrossRef]

- Gomez, A.; Malcata, F. Bifidobacterium spp. and Lactobacillus acidophilus: Biological, biochemical, technological and therapeutical properties relevant for use as a probiotic. Trends Food Sci. Technol. 1999, 10, 139–157. [Google Scholar] [CrossRef]

- Reyns, K.M.F.A.; Sootjens, C.C.F.; Cornelis, K.; Weemars, C.A.; Hendrickx, M.E.; Michiels, C.W. Kinetics analysis and modeling of combined high–pressure–temperature inactivation of the yeast Zygosaccharomyces bailii. Int. J. Food Microbiol. 2000, 56, 199–210. [Google Scholar] [CrossRef]

- Godwart, G.; Kailasapathy, K. Viability and survival of free, encapsulated probiotic bacteria in yoghurt. Milchwissenschaft 2003, 58, 396–399. [Google Scholar]

- Yilmaztekin, M.; Özer, B.H.; Atasoy, F. Survival of Lactobacillus acidophilus LA-5 and Bifidobacterium bifidum BB-02 in white-brined cheese. Int. J. Food Sci. Nutr. 2004, 55, 53–60. [Google Scholar] [CrossRef]

- Özer, B.; Kirmaci, H.A.; Şenel, E.; Atamer, M.; Hayaloğlu, A. Improving the viability of Bifidobacterium bifidum BB-12 and Lactobacillus acidophilus LA-5 in white-brined cheese by microencapsulation. Int. Dairy J. 2009, 19, 22–29. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations/World Health Organization (FAO/WHO). Standard for Fermented Milks, Revised Standard. Codex Alimentarius. STAN 243-2003; Food and Agriculture Organization of the United Nations/World Health Organization: Rome, Italy, 2011. [Google Scholar]

- Senaka Ranadheera, C.; Evans, C.A.; Adams, M.C.; Baines, S.K. Probiotic viability and physico-chemical and sensory properties of plain and stirred fruit yogurts made from goat’s milk. Food Chem. 2012, 135, 1411–1418. [Google Scholar] [CrossRef]

- Jankowska, A.; Grześkiewicz, A.; Wiśniewska, K.; Reps, A. Application of probiotic bacteria in production of yoghurt preserved under high pressure. High Press. Res 2005, 25, 57–62. [Google Scholar] [CrossRef]

- Jankowska, A.; Grześkiewicz, A.; Wiśniewska, K.; Reps, A. Examining the possibilities of applying high pressure to preserve yoghurt supplemented with probiotic bacteria. High Press. Res. 2012, 32, 339–346. [Google Scholar] [CrossRef]

- Oey, I.; Lille, M.; Van Loey, A.; Hendrickx, M. Effect of high pressure processing on colour, texture and flavour of fruit and vegetable-based food products: A review. Trends Food Sci. Technol. 2008, 19, 320–328. [Google Scholar] [CrossRef]

- Barba, F.J.; Esteve, M.J.; Frigola, A. Physicochemical and nutritional characteristics of blueberry juice after high pressure processing. Food Res. Int. 2008, 50, 545–549. [Google Scholar] [CrossRef]

- Liu, X.; Powers, J.R.; Swanson, B.G.; Hill, H.H.; Clark, S. Modification of whey protein concentrate hydrophobicity by high hydrostatic pressure. Innov. Food Sci. Emerg. 2005, 6, 310–317. [Google Scholar] [CrossRef]

- Lee, W.; Clark, S.; Swanson, B.G. Functional properties of high hydrostatic pressure-treated whey protein. J. Food Process. Preserv. 2006, 30, 488–501. [Google Scholar] [CrossRef]

- Soukoulis, C.; Lyroni, E.; Tzia, C. Sensory profiling and hedonic judgement of probiotic ice cream as a function of hydrocolloids, yogurt and milk fat content. LWT-Food Sci. Technol. 2010, 43, 1351–1358. [Google Scholar] [CrossRef]

- Lesme, H.; Rannou, C.; Famelart, M.-H.; Bouhallab, S.; Prost, C. Yogurts enriched with milk proteins: Texture properties, aroma release and sensory perception. Trends Food Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Tsevdou, M.; Soukoulis, C.; Cappellin, L.; Gasperi, F.; Taoukis, P.S.; Biasioli, F. Monitoring and Modeling of Endogenous Flavour Compounds Evolution during Fermentation of Thermally, High Hydrostatic Pressure or Transglutaminase Treated Milk using PTR-TOF-MS. Food Chem. 2013, 138, 2159–2167. [Google Scholar] [CrossRef]

- Soukoulis, C.; Cappellin, L.; Aprea, E.; Costa, F.; Viola, R.; Märk, T.D.; Gasperi, F.; Biasioli, F. PTR-ToF-MS, A Novel, Rapid, High Sensitivity and Non-Invasive Tool to Monitor Volatile Compound Release During Fruit Post-Harvest Storage: The Case Study of Apple Ripening. Food Bioprocess. Technol. 2013, 6, 2831–2843. [Google Scholar] [CrossRef]

| Decimal Reduction Times (D, min) of B. bifidum in pH 4.80 | |||||

| 20 °C | 25 °C | 30 °C | 35 °C | zT (°C) | |

| 100 MPa | 435 (±23) | 400 (± 19) | 263 (± 5.2) | 250 (± 7.3) | 62.2 (± 16) |

| 200 MPa | 313 (±9.0) | 40.3 (± 1.4) | 18.6 (± 2.0) | 16.2 (± 0.7) | 11.9 (± 3.2) |

| 300 MPa | 4.08 (±0.01) | 2.53 (± 0.04) | 1.43 (± 0.1) | 0.71 (± 0.06) | 19.8 (± 1.7) |

| 400 MPa | 0.25 (±0.03) | 0.27 (± 0.01) | 0.24 (± 0.01) | 0.11 (± 0.00) | 37.5 (± 3.4) |

| zP (MPa) | 90.9 (± 5.1) | ||||

| Decimal Reduction Times (D, min) of B. bifidum in pH 6.50 | |||||

| 25 °C | 30 °C | 35 °C | 40 °C | zT (°C) | |

| 100 MPa | - | 526 (± 15) | 333 (± 2.1) | 185 (± 9.0) | 22.1 (± 2.3) |

| 200 MPa | 303 (± 3.0) | 128 (± 10) | 108 (± 9.3) | 95.2 (± 7.0) | 78.4 (± 9.4) |

| 300 MPa | 38.6 (± 2.1) | 36.5 (± 1.9) | 35.2 (± 0.6) | 15.8 (± 2.0) | 39.7 (± 1.6) |

| 400 MPa | 6.47 (± 1.1) | 6.20 (± 0.9) | 2.22 (± 0.3) | 2.09 (± 0.4) | 28.9 (± 1.2) |

| zP (MPa) | 151 (± 8.0) | ||||

| Parameter | Estimated Value pH 4.80 | Estimated Value pH 6.50 |

|---|---|---|

| Pref (MPa) | 200 | 200 |

| Tref (°C) | 25 | 25 |

| Do (min) | 44.5 ± 6.39 | 281 ± 19.7 |

| zT (°C) | 5.91 ± 0.44 | 22.9 ± 3.50 |

| zP (MPa) | 90 (constant) | 140 (constant) |

| A (MPa−1) | 0.016 ± 0.002 | 0.002 ± 0.000 |

| R2 | 0.99 | 0.95 |

| Plain Yoghurt | ||||

|---|---|---|---|---|

| Control * | - | |||

| D + 1 | 8.9 ± 0.2 i | - | - | |

| D + 15 | 8.8 ± 0.1 hi | |||

| D + 28 | 8.7 ± 0.0 gh | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.7 ± 0.1 fgh | 8.7 ± 0.1 fgh | 8.4 ± 0.2 bcd | N.D. |

| D + 15 | 8.5 ± 0.1 defg | 8.2 ± 0.3 abc | 8.5 ± 0.1 def | N.D. |

| D + 28 | 8.5 ± 0.1 def | 8.2 ± 0.1 ab | 8.5 ± 0.1 def | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.7 ± 0.2 gh | 8.6 ± 0.1 efgh | 8.6 ± 0.0 defgh | N.D. |

| D + 15 | 8.5 ± 0.0 defgh | 8.1 ± 0.1 a | 8.6 ± 0.0 defgh | N.D. |

| D + 28 | 8.4 ± 0.0 cde | 8.1 ± 0.1 a | 8.5 ± 0.1 defg | N.D. |

| Cherry-Flavored Yoghurt | - | - | - | |

| Control * | - | - | - | - |

| D + 1 | 8.8 ± 0.0 ij | - | - | - |

| D + 15 | 8.4 ± 0.0 bcd | |||

| D + 28 | 8.3 ± 0.1 bc | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.9 ± 0.0 j | 8.6 ± 0.0 fgh | 8.5 ± 0.1 cde | N.D. |

| D + 15 | 8.8 ± 0.1 ij | 8.2 ± 0.1 a | 8.3 ± 0.1 b | N.D. |

| D + 28 | 8.5 ± 0.0 def | 8.3 ± 0.1 bc | 8.5 ± 0.1 cde | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.7 ± 0.1 hi | 8.7 ± 0.1 hi | 8.6 ± 0.1 fg | N.D. |

| D + 15 | 8.6 ± 0.0 gh | 8.5 ± 0.0 cde | 8.4 ± 0.0 bc | N.D. |

| D + 28 | 8.5 ± 0.1 efg | 8.3 ± 0.0 b | 8.2 ± 0.0 a | N.D. |

| Plain Yoghurt | ||||

| Control * | - | |||

| D + 1 | 8.2 ± 0.1 jk | - | - | |

| D + 15 | 8.3 ± 0.2 jk | |||

| D + 28 | 8.3 ± 0.1 k | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.1 ± 0.1 hijk | 7.9 ± 0.0 fghi | 6.8 ± 0.3 c | N.D. |

| D + 15 | 8.1 ± 0.1 ghijk | 7.8 ± 0.1 fg | 6.3 ± 0.1 ab | N.D. |

| D + 28 | 8.1 ± 0.1 ghijk | 7.8 ± 0.1 fgh | 6.1 ± 0.1 a | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.1 ± 0.1 fghij | 8.0 ± 0.1 fghij | 7.1 ± 0.2 d | N.D. |

| D + 15 | 8.1 ± 0.0 ijk | 7.8 ± 0.3 f | 6.7 ± 0.1 c | N.D. |

| D + 28 | 8.1 ± 0.1 hijk | 7.4 ± 0.1 e | 6.5 ± 0.1 bc | N.D. |

| Cherry-Flavored Yoghurt | - | - | - | |

| Control * | - | - | - | - |

| D + 1 | 8.4 ± 0.0 e | - | - | - |

| D + 15 | 8.2 ± 0.0 d | |||

| D + 28 | 8.1 ± 0.1 d | |||

| HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.2 ± 0.0 d | 7.9 ± 0.0 c | 6.5 ± 0.1 a | N.D. |

| D + 15 | 8.1 ± 0.0 d | 7.7 ± 0.0 bc | 6.5 ± 0.1 a | N.D. |

| D + 28 | 8.1 ± 0.1 d | 7.7 ± 0.1 bc | 6.5 ± 0.2 a | N.D. |

| Homo-HP | 100 MPa | 200 MPa | 300 MPa | 400 MPa |

| D + 1 | 8.2 ± 0.1 d | 7.8 ± 0.0 c | 6.6 ± 0.2 a | N.D. |

| D + 15 | 8.2 ± 0.0 d | 7.8 ± 0.0 c | 6.4 ± 0.2 a | N.D. |

| D + 28 | 8.1 ± 0.1 d | 7.6 ± 0.1 b | 6.4 ± 0.1 a | N.D. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsevdou, M.; Ouli-Rousi, M.; Soukoulis, C.; Taoukis, P. Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt. Foods 2020, 9, 360. https://doi.org/10.3390/foods9030360

Tsevdou M, Ouli-Rousi M, Soukoulis C, Taoukis P. Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt. Foods. 2020; 9(3):360. https://doi.org/10.3390/foods9030360

Chicago/Turabian StyleTsevdou, Maria, Maria Ouli-Rousi, Christos Soukoulis, and Petros Taoukis. 2020. "Impact of High-Pressure Process on Probiotics: Viability Kinetics and Evaluation of the Quality Characteristics of Probiotic Yoghurt" Foods 9, no. 3: 360. https://doi.org/10.3390/foods9030360