4.2. Meat Quality

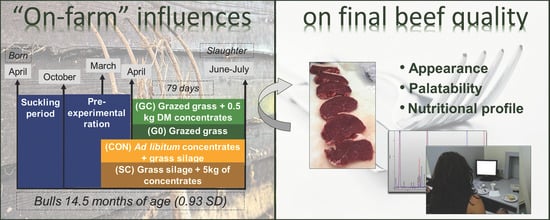

Mean carcass weights differed in this study and we acknowledge that carcass weight can influence meat characteristics [

27]. In the current study, muscle from the grazing systems had lower IMF and lower protein in line with previous studies [

10,

28]. Banović et al. [

29] reported that consumers pay more attention and choose more often meat products with lower fat content while Grunert [

30,

31] reported that visual fat has generally a negative effect on purchase decision. Therefore, while the leanness of beef cuts from grazing cattle may be appreciated by the consumer as a reduced fat product, low fat accretion in the animal will lead to a negative carcass classification based on EUROP scheme [

32]. Thus, unlike the carcass grading system used in Australia [

32], the lack of a relationship between carcass grading and eating quality in Europe is to the detriment of the primary producer and consumer.

The ultimate pH in the current investigation was within the normal range (5.4–5.8) described by Viljoen et al. [

33] and agrees with previous studies [

10,

34]. Some authors have linked a higher pH in muscle from pasture animals with lower glycogen stores in muscle and/or increased stress during transport and slaughter management, since outdoor animals are not accustomed to human handling [

27]. The latter is especially important in bulls, as male animals are more prone to suffer stress when forced into close social contact with their cohorts during transportation and lairage [

35,

36]. With correct management, normal ultimate pH can be achieved in under 16 months bulls independently of the dietary treatment.

The darker meat in the grazing groups is in line with previous studies [

37,

38]. Why SC was also darker than CON is not clear, since ultimate pH was similar, and the animals were managed similarly indoors. Darker colour may also be related to a higher myoglobin concentration in grass-fed animals. However, the redness (a) value indicates less red meat from grazed animals, which suggests that a higher pigment concentration is unlikely. However, myoglobin concentration measurement is needed to confirm this point.

In the present study, the steaks were aged for exactly 14 days as this is common industry practice. The lack of differences in the instrumental texture variables (WBSF, Modulus and Energy) agrees with those authors [

39] who indicate that after 12 day of ageing differences in instrumental texture between factors such as gender or breed disappear [

38,

39].

Despite the lack of difference between treatments in instrumental texture, meat from SC was rated more highly by the sensory panel than meat from GC. Inconsistency between sensory and instrumental measurement results is common and is reflected in the modest correlation between both methods as reported by others [

40,

41]. Similar to the present study, Hedrick et al. [

42] found that meat from cattle finished on silage was as tender or more tender than grain-finished cattle. The detrimental effect of concentrate supplementation outdoors compared to indoors (GC v SC) on tenderness was observed previously in 19-month-old bulls [

34], albeit overall acceptability did not differ in that study.

The relationship of the rate and extent of post-mortem proteolysis with temperature and pH decline have been previously described [

43]. Therefore, at the same chilling temperature, carcass fat cover impacts temperature and pH decline and sensory evaluation as previously highlighted [

38,

44,

45].

The flavour of meat is dependent on the volatile profile [

46] which in turn is greatly influenced by fat level and fatty acid composition [

47,

48]. Grass-produced beef can have a slightly less intense flavour than grain-produced beef [

48], since higher levels of fat are associated with higher intensity of flavour. However, in the present experiment, flavour intensity was not assessed. In general, the effect of ration composition on flavour likeness results are inconsistent [

38,

49]. The higher rating in flavour for SC may be related to its higher fat content compared to outdoors animal and its lower SFA proportion compared to CON. This may give SC the best combination of IMF and fatty acid composition to meet consumer expectations. Overall, the lack of difference in sensory characteristics between CON and G0 is particularly noteworthy as G0 carcasses would be severely discounted relative to CON carcasses under the current EUROP grading system.

4.3. Fatty Acid Profile

Consumers are increasingly aware of the relationships between diet, health and well-being and this has resulted in a growing preference for foods which are healthier and more nutritious [

50,

51]. Some consumers prefer to purchase beef from grass fed cattle as meat and meat products from grass fed animals are often perceived as having higher amounts of nutritionally important compounds when compared with beef from non-grass-based production systems. In addition, ‘grass fed’ has been used to promote perception of animal health and well-being, and environmental sustainability [

52]. Accordingly, the fatty acid composition was measured in beef from the contrasting production systems in this study. The higher concentration of fatty acids in the CON group per se reflects the higher energy consumption and associated fat deposition and is a consequence of this production system. The higher fatty acid concentration is the sum of higher concentrations of individual classes of fatty acids. When comparing studies in the literature with respect to the fatty acid profile of beef, it is important to be aware of differences in carcass weight or fatness between treatments. The higher concentration of SFA in CON animals compared to grass-fed animals in this study agrees with Aldai et al. [

53] while other authors found no differences in SFA between grass and grain-fed meat [

54].

An increase in IMF concentration on a common diet can alter the proportions of fatty acids, generally increasing MUFA and decreasing PUFA proportions [

55,

56]. Therefore, in this study the individual fatty acid data are presented as a proportion of total fatty acids to gain a better insight into any changes in the pattern or profile of fatty acids due to the different production systems examined.

The change in the individual SFA profile is generally in agreement with that reported by Alfaia et al. [

54] and Aldai et al. [

53]. The change in the SFA profile also reflects the fatty acid composition of the feedstuffs consumed, particularly the concentrate rations used. The lack of differences in total SFA concentration and in the SFA profile between both grazed grass-based diets (GC and G0) is in line with French et al. [

28].

Three DMA derived from plasmalogen lipids were detected (16:0, 18:0 and 18:1). These DMA are generated from the vinyl chain linked at sn-1 position of plasmalogens, which are a particular class of glycerophospholipids present in cell membranes [

57]. The lower proportions of DMA in muscle from indoor cattle (

Table 4) agree with Aldai et al. [

53]. Few studies have examined the nutritional importance of DMA in beef but DMA deficiency in humans has been associated with some diseases [

57].

The higher concentration of MUFA in CON is consistent with previous investigations [

53,

54]. The alteration in the isomer profile of trans C18:1 observed in the present study has been previously reported [

53,

58]. A decrease in the trans-11 trans-10 18:1 ratio has been related with increased atherogenicity in animal models, while a higher ratio is related with increased rumenic acid (conjugated linoleic acid, see below) which has putative human health properties [

59]. Changes in the proportions of these isomers has been suggested to reflect changes in rumen microbiota characteristics due to alteration in the rate of fermentation of the diet and associated changes in ruminal pH. C18:1-t11 rather than C18:1-t10 production in the rumen is associated with

Butyrivibrio fibrisolvens which predominates in the rumen forage-finished animals [

60]. While generally, a higher concentration of PUFA is observed in grass-fed beef compared to concentrate-fed beef [

28,

54,

61], the lack of difference in the current study is likely related to the higher IMF concentration in CON. Also, many studies report fatty acid on a proportional basis. The proportions of PUFA (10.8, 15.3, 23.7 and 21.3 g/100 g fatty acids for CON, SC, GC and G0, respectively) in the present study support the literature but are high which likely reflects the very low total fatty acid concentration and very low neutral lipid proportion particularly in the grass-based production systems. In this regard, Nian et al. [

62] reported a PUFA proportion of 23.5 g/100 g fatty acids for muscle from dairy origin bulls that had an IMF concentration of 0.5%, consistent with our data.

Linolenic acid (C18:3, omega 3) and linoleic acid (18:2n-6, omega 6) were the major PUFA of the omega series identified in this study. The omega series fatty acids cannot be synthesised by humans and are considered essential nutrients for humans [

63]. The ratio is also considered important for human health since an excess of one family of omega 3 or omega 6 can interfere with the metabolism of the other [

63]. It has been suggested that a healthy diet should have an n-6:n3 PUFA ratio higher than 4 [

64], this ratio was only observed for outdoors animals suggesting that grass-fed beef has a higher nutritional value. For omega-3 fatty acids, EU (2010) states that a claim that a food is a source of omega-3 fatty acids may only be made where the product contains at least 300 mg α-linolenic acid per 100 g). The concentrations of linolenic acid in the present study were 9, 13, 17 and 18 mg/100 g muscle for CON, SC, GC and G0, respectively. None of the beef in this study meets this claim.

Higher linoleic acid in GC and G0 compared with CO animals is unusual based on the literature, but may reflect the extremely low IMF concentration in these groups. The higher proportion of linolenic acid its elongation products mainly C22-5n-3 and C20:5n-3 in GC and G0 is consistent with the literature [

28].

Two CLA isomers were detected in the present study, the major isomer rumenic acid (C18:2-c9,t11) and the minor isomer, C18:2 t10c12. The higher rumenic acid proportion in GC and G0 is also consistent with the literature [

28,

53]. Animal studies demonstrated that CLA can reduce carcinogenesis, atherosclerosis and diabetes [

65,

66,

67]. However, due to the higher IMF concentration in CON and SC compared to GC and G0 (

Table 6), an individual consuming 100 g beef would consume a similar amount of rumenic acid from beef from all the production systems examined.

Since humans are able to transform trans vaccenic acid (C18:1-t11) into rumenic acid (9c11t-C18:2) at a rate between 5 to 12% [

68], the higher concentration of trans vaccenic acid (6.3, 5.3, 7.0 and 7.5 mg/100 g muscle for CON, SC, GC and G0, respectively) would also contribute to a nutritional enhancement of beef from the grass-based production systems. We acknowledge that the proportion of CLA found in the present study was low compared with other studies, however the levels are similar to those reported by Aldai et al. [

53], who explained the lower CLA concentration on the basis of the late-maturing breeds used.

The HUFA meat content is also an important nutritional factor, since the human efficiency of transforming α-linolenic acid to EPA (eicosapentaenoic acid C20:5n-3), DPA (docosapentaenoic acid C22:5n-3) and DHA (docosahexaenoic acid C22:6 n-3) is very low. On the other hand, HUFA (especially DHA and EPA) have been related with the prevention of atherosclerosis, heart attack, depression and cancer [

69]. The higher concentration of HUFA and proportions of EPA and DPA in GC and G0 is similar to Alfaia et al. [

54]. For longer carbon chain omega-3 fatty acids, EU (2010) states that a claim that a food is a source of omega-3 fatty acids may only be made where the product contains at least 40 mg of the sum of EPA and DHA per 100 g.). In the present study, EPA + DHA concentrations were 9.5, 14.4, 14.0 and 14.5 mg/100 g muscle for CON, SC, GC and G0, respectively. None of the beef in this study meets this claim.

In line with previous results, the nutritional indices, AI and TI, were better for grass-fed beef compared to CON indicating a general improvement of the nutritional quality. Similarly, the PUFA:SFA ratio is suggested to be above 0.4 [

70] and only the grass-based production systems achieved this target.