Influence of Combined Effect of Ultra-Sonication and High-Voltage Cold Plasma Treatment on Quality Parameters of Carrot Juice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Procurement of Different Chemicals

2.2. Purchasing of Raw Material Blanching

2.3. High Voltage Cold Plasma and Ultra-Sonication Treatments

2.4. Determination of Total Carotenoids Content

2.5. Determination of Lycopene

2.6. Determination of Lutein

2.7. Determination of Chlorogenic Acid

2.8. Determination of Sugar Content in Carrot Juice

2.9. Determination of Mineral Contents

2.10. Physicochemical Analysis

2.10.1. Determination of °Brix

2.10.2. Determination of pH in Carrot Juice

2.10.3. Determination of Color Changes in Carrot Juice

2.11. Total Plate Count (TPC)

2.12. Yeast and Mold Counts

2.13. Statistical Analysis

3. Results and Discussion

3.1. Estimation of Chlorogenic Acid

3.2. Estimation of Coloring Compounds

3.2.1. Determination of Total Carotenoids

3.2.2. Effect of HVCP and US on Lycopene and Lutein Contents

3.3. Determination of Sugars Contents in Processed Carrot Juice

3.4. Impact of HVCP and US on the Mineral Profile of Carrot Juice

3.5. Combined Treatment Effect of HVCP and US on Physico-Chemical Properties

3.6. Antimicrobial Activity Assay

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAOSTAT. Food and Agriculture Organization of the United Nations. 2017. Available online: https://www.onlinegkguide.com/name-of-largest-producing-countries-of-agricultural-commodities-in-the-world (accessed on 9 June 2019).

- Qin, L.; Xu, S.Y.; Zhang, W.B. Effect of enzymatic hydrolysis on the yield of cloudy carrot juice and the effects of hydrocolloids on color and cloud stability during ambient storage. J. Sci. Food Agric. 2005, 85, 505–512. [Google Scholar] [CrossRef]

- Talcott, S.T.; Howard, L.R. Phenolic autoxidation is responsible for color degradation in processed carrot puree. J. Agric. Food Chem. 1999, 47, 2109–2115. [Google Scholar] [CrossRef]

- Nikfardjam, M.P.; Maier, D. Development of a headspace trap HRGC/MS method for the assessment of the relevance of certain aroma compounds on the sensorial characteristics of commercial apple juice. Food Chem. 2011, 126, 1926–1933. [Google Scholar] [CrossRef]

- Choi, E.J.; Park, H.W.; Kim, S.B.; Ryu, S.; Lim, J.; Hong, E.J.; Byeon, Y.S.; Chun, H.H. Sequential application of plasma-activated water and mild heating improves microbiological quality of ready-to-use shredded salted Chinese cabbage (Brassica pekinensis L.). Food Control. 2019, 98, 501–509. [Google Scholar] [CrossRef]

- Elisa, B.; Daniela, F.; Seixas, C.; Ana, A.O.; Xavier, A.Z.; Mercadante, N.M.A.; Hassimotto, F.M.L. Effect of Pasteurization on Flavonoids and Carotenoids in Citrus sinensis (L.) Osbeck cv. ‘Cara Cara’ and ‘Bahia’ Juices. J. Agri. Food Chem. 2017, 65, 1371–1377. [Google Scholar]

- Oliu, G.O.; Serrano, I.O.; Fortuny, R.S.; Belloso, O.M. Effects of high intensity pulsed electric field processing conditions on lycopene, vitamin C and antioxidant capacity of watermelon juice. Food Chem. 2009, 115, 1312–1319. [Google Scholar] [CrossRef]

- Aadil, R.M.; Zeng, X.N.; Sun, D.W.; Wang, M.S.; Liu, Z.W.; Zhang, Z.H. Combined effects of sonication and pulsed electric field on selected quality parameters of grapefruit juice. LWT Food Sci. Technol. 2015, 62, 890–893. [Google Scholar] [CrossRef]

- Abid, M.; Jabbar, S.; Wu, T.; Hashim, M.M.; Hu, B.; Lei, S.; Zhang, X.; Zeng, X. Effect of ultrasound on different quality parameters of apple juice. Ultrason. Sonochem. 2013, 20, 1182–1187. [Google Scholar] [CrossRef]

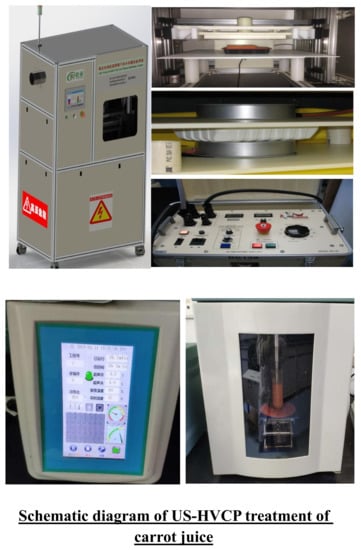

- Umair, M.; Saqib, J.; Mustapha, M.N.; Tayyaba, S.; Ahmed, M.S.; Faisal, N.A.; Zhuang, H.; Zhang, J.H. Exploring the potential of high-voltage electric field cold plasma (HVCP) using DBD as plasma source on the quality parameters of carrot juice. Antibiotics 2019. accepted. [Google Scholar]

- Urvi, S.; Pietro, R.; Yuyuan, Z.; Caroline, L.S.; Vandana, M.; Gregory, F.; Jasreen, K.S. Effects of cold plasma treatments on spot-inoculated Escherichia coli O157:H7 and quality of baby kale (Brassica oleracea) leaves. Innov. Food Sci. Emerg. Technol. 2019, 57, 102104. [Google Scholar]

- Dermesonlouoglou, E.; Chalkia, A.; Dimopoulos, G.; Taoukis, P. Combined effect of pulsed electric field and osmotic dehydration pre-treatments on mass transfer and quality of air dried goji berry. Innov. Food Sci. Emerg. Technol. 2018, 49, 106–115. [Google Scholar] [CrossRef]

- Traffano-Schiffo, M.V.; Tylewicz, U.; Castro-Giraldez, M.; Fito, P.J.; Ragni, L.; Dalla Rosa, M. Effect of pulsed electric fields pre-treatment on mass transport during the osmotic dehydration of organic kiwifruit. Innov. Food Sci. Emerg. Technol. 2016, 38, 243–251. [Google Scholar] [CrossRef]

- Kim, S.S.; Lee, S.Y.; Park, K.J.; Park, S.M.; An, H.J.; Hyun, J.M.; Choi, Y.H. Gluconacetobacter sp. gel_SEA623-2, bacterial cellulose producing bacterium isolated from citrus fruit juice. Saudi J. Biol. Sci. 2017, 24, 314–319. [Google Scholar] [CrossRef]

- Ekezie, F.-G.C.; Cheng, J.-H.; Sun, D.-W. A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends Food Sci. Tech. 2017, 69, 46–58. [Google Scholar] [CrossRef]

- Xiang, Q.; Liu, X.; Li, J.; Liu, S.; Zhang, H.; Bai, Y. Effects of dielectric barrier discharge plasma on the inactivation of Zygosaccharo mycesrouxii and quality of apple juice. Food Chem. 2018, 254, 201–207. [Google Scholar] [CrossRef]

- Bursać Kovačević, D.; Putnik, P.; Dragović-Uzelac, V.; Pedisić, S.; Režek Jambrak, A.; Herceg, Z. Effects of cold atmospheric gas phase plasma on anthocyanins and color in pomegranate juice. Food Chem. 2016, 190, 317–323. [Google Scholar] [CrossRef]

- Martínez-Hernández, G.B.; Amodio, M.L.; Colelli, G. Carvacrol-loaded chitosan nanoparticles maintain quality of fresh-cut carrots. Innov. Food Sci. Emerg. Technol. 2017, 41, 56–63. [Google Scholar] [CrossRef]

- Smet, C.; Baka, M.; Steen, L.; Fraeye, I.; Walsh, J.L.; Valdramidis, V.P.; Van Impe, J.F. Combined effect of cold atmospheric plasma, intrinsic and extrinsic factors on the microbial behavior in/on (food) model systems during storage. Innov. Food Sci. Emerg. Technol. 2019, 53, 3–17. [Google Scholar] [CrossRef]

- Cserhalmi, Z.S.; Sass-Kiss, Á.; Tóth-Markus, M.; Lechner, N. Study of pulsed electric field treated citrus juices. Innov. Food Sci. Emerg. Technol. 2006, 7, 49–54. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Yu, Q.; Zeng, X.A.; Han, Z.; Sun, D.W.; Aadil, R.M. Effects of pulsed electric field on selected properties of L-tryptophan. Int. J. Food Sci. Technol. 2015, 50, 1130–1136. [Google Scholar] [CrossRef]

- Liu, Z.W.; Zeng, X.A.; Sun, D.W.; Han, Z.; Aadil, R.M. Synergistic effect of thermal and pulsed electric field (PEF) treatment on the permeability of soya PC and DPPC vesicles. J. Food Eng. 2015, 153, 124–131. [Google Scholar] [CrossRef]

- Klockow, P.A.; Keener, K.M. Safety and quality assessment of packaged spinach treated with a novel ozone-generation system. LWT Food Sci. Technol. 2009, 42, 1047–1053. [Google Scholar] [CrossRef]

- Wang, J.M.; Zhuang, H.; Hiton, A., Jr.; Zhang, J.H. Influence of in-package cold plasma treatment on microbiological shelf life and appearance of fresh chicken breast fillets. Food Microbiol. 2016, 60, 142–146. [Google Scholar] [CrossRef] [PubMed]

- Saqib, J.; Muhammad, A.; Bing, H.; Tao, W.; Malik, M.H.; Shicheng, L.; Xiuling, Z.; Xiaoxiong, Z. Quality of carrot juice as influenced by blanching and sonication treatments. LWT Food Sci. Technol. 2014, 55, 16–21. [Google Scholar]

- Lieu, L.N.; Le, V.V.M. Application of ultrasound in grape mash treatment in juice processing. Ultrason. Sonochem. 2010, 17, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Saqib, J.; Abid, M.; Hu, B.; Muhammad, H.M.; Saeeduddin, M.; Lei, S.; Wu, T.; Zeng, X. Influence of sonication and high hydrostatic pressure on the quality of carrot juice. Int. J. Food Sci. Technol. 2014, 49, 2449–2457. [Google Scholar]

- Rawson, A.; Tiwari, B.K.; Patras, A.; Brunton, N.; Brennan, C.; Cullen, P.J. Effect of thermosonication on bioactive compounds in watermelon juice. Food Res. Int. 2011, 44, 1168–1173. [Google Scholar] [CrossRef]

- Kim, H.; Gerber, L. Influence of processing on quality of carrot juice. Korean J. Food Sci. Technol. 1988, 20, 683–690. [Google Scholar]

- Kahle, K.; Kraus, M.; Richling, E. Polyphenol profiles of apple juices. Mol. Nutr. Food Res. 2005, 49, 797–806. [Google Scholar] [CrossRef]

- Hurst, W.J.; Martin, R.A.; Zoumas, B.L. Application of HPLC to characterization of individual carbohydrates in foods. J. Food Sci. 1979, 44, 892–895. [Google Scholar] [CrossRef]

- American Public Health Association; Water Environment Federation. Standard Method for the Examination of Water and Wastewater; American Public Health Association (APHA): Washington, DC, USA, 1988. [Google Scholar]

- Saqib, J.; Abid, M.; Hu, B.; Hashim, M.M.; Lei, S.; Wu, T.; Zeng, X. Exploring the potential of thermosonication in carrot juice processing. J. Food Sci. Technol. 2015, 52, 7002–7013. [Google Scholar]

- Abid, M.; Jabbar, S.; Wu, T.; Hashim, M.M.; Hu, B.; Lei, S.; Zhang, X.; Zeng, X. Sonication enhances polyphenolic compounds, sugars, carotenoids and mineral elements of apple juice. Ultrason. Sonochem. 2014, 21, 93–97. [Google Scholar] [CrossRef] [PubMed]

- FDA Center for Food Safety and Applied Nutrition. Food and Drug Administration in Bacteriological Analytical Manual; FDA Center for Food Safety and Applied Nutrition: Silver Spring, MD, USA, 2001. [Google Scholar]

- Abid, M.; Jabbar, S.; Hu, B.; Hashim, M.M.; Wu, T.; Wu, Z.; Khan, M.A.; Zeng, X. Synergistic impact of sonication and high hydrostatic pressure on microbial and enzymatic inactivation of apple juice. LWT Food Sci. Technol. 2014, 59, 70–76. [Google Scholar] [CrossRef]

- Krinsky, N.I.; Yeum, K.J. Carotenoid-radical interactions. Biochem. Biophys. Res. Commun. 2003, 305, 754–760. [Google Scholar] [CrossRef]

- Shi, J.; Maguer, M.L. Lycopene in tomatoes: Chemical and physical properties affected by food processing. Crit. Rev. Food Sci. Nutr. 2000, 40, 1–42. [Google Scholar] [CrossRef] [PubMed]

- Garcia, A.R.; Dale, N.M. Feeding of un-ground pearl millet to laying hens. J. Appl. Poult. Res. 2006, 15, 574–578. [Google Scholar] [CrossRef]

- Rodrıguez-Sevilla, M.D.; Villanueva-Suárez, M.J.; Redondo-Cuenca, A. Effects of processing conditions on soluble sugars content of carrot, beetroot and turnip. Food Chem. 1999, 66, 81–85. [Google Scholar] [CrossRef]

- Fonteles, T.V.; Costa, M.G.M.; de Jesus, A.L.T.; de Miranda, M.R.A.; Fernandes, F.A.N.; Rodrigues, S. Power ultrasound processing of cantaloupe melon juice: Effects on quality parameters. Food Res. Int. 2012, 48, 41–48. [Google Scholar] [CrossRef]

- Sert, D.; Aygun, A.; Demir, M.K. Effects of ultrasonic treatment and storage temperature on egg quality. Poult. Sci. 2011, 90, 869–875. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Y.; Hu, X.; Wu, J.; Liao, X. Effect of high pressure carbon dioxide on the quality of carrot juice. Innov. Food Sci. Emerg. Technol. 2009, 10, 321–327. [Google Scholar] [CrossRef]

- Huang, W.; Bi, X.; Zhang, X.; Liao, X.; Hu, X.; Wu, J. Comparative study of enzymes, phenolics, carotenoids and color of apricot nectars treated by high hydrostatic pressure and high temperature short time. Innov. Food Sci. Emerg. Technol. 2013, 18, 74–82. [Google Scholar] [CrossRef]

- Santhirasegaram, V.; Razali, Z.; Somasundram, C. Effects of thermal treatment and sonication on quality attributes of Chokanan mango (Mangifera indica L.) juice. Ultrason. Sonochem. 2013, 20, 1276–1282. [Google Scholar] [CrossRef] [PubMed]

- Ying, W.; Zirong, W.; Yahong, Y.; Zhenpeng, G.; Kangquan, G.; Tianli, Y. Application of gas phase surface discharge plasma with a spray reactor for Zygosaccharomyces rouxii LB inactivation in apple juice. Innov. Food Sci. Emerg. Technol. 2019, 52, 450–456. [Google Scholar]

| S. No | Working Conditions | Flow Rate/Units |

|---|---|---|

| 1 | Elements (Na, P, K and Mg) | 589.5, 213.6, 766.5 and 285.2 |

| 2 | Nebulized gas discharge | 0.85 L/Min |

| 3 | Plasma gas discharge | 16.5 L/Min |

| 4 | Auxiliary gas discharge | 0.21 L/Min |

| 5 | Plasma gas discharge | 15 L/Min |

| 6 | Sample flow rate | 1.8 mL/Min |

| 7 | Operating power | 1450 W |

| 8 | View Axial | Interface shear gas |

| 9 | Sample uptake rate | 1.25 mL/min |

| 10 | Spray chamber | cyclonic |

| 11 | Nebulizer type | Meinhard |

| 12 | Nebulizer set up | Instant |

| 13 | Replicates | 3 times |

| S. No | Treatment | Chlorogenic Acid µg/mL | Total Carotenoids µg/mL | Lycopene Contents µg/mL | Lutein Contents µg/mL |

|---|---|---|---|---|---|

| 1 | Control | 22.30 ± 0.09 c | 8.22 ± 0.02 d | 0.52 ± 0.01 d | 1.22 ± 0.06 d |

| 2 | HVCP | 25.67 ± 0.08 b | 10.81 ± 0.03 b | 1.71 ± 0.09 b | 1.65 ± 0.05 b |

| 3 | US | 23.16 ± 0.02 b,c | 10.03 ± 0.08 b | 1.83 ± 0.05 c | 1.56 ± 0.09 c |

| 4 | US-HVCP | 27.31 ± 0.06 a | 11.03 ± 0.05 a | 1.93 ± 0.04 a | 2.03 ± 0.02 a |

| S. No | Treatment | Sucrose g/L | Fructose g/L | Glucose g/L |

|---|---|---|---|---|

| 1 | Control | 41.04 ± 0.01 c | 18.65 ± 0.01 b | 20.52 ± 0.06 c |

| 2 | HVCP | 42.13 ± 0.03 b | 19.11 ± 0.02 a | 21.91 ± 0.02 a |

| 3 | US | 41.88 ± 0.06 b | 15.03 ± 0.03 b,c | 19.83 ± 0.04 c |

| 4 | US-HVCP | 42.36 ± 0.06 a | 16.03 ± 0.04 c | 21.23 ± 0.06 b |

| Treatment | pH | °Brix | Coloring-Index | Hue (h°) | C* | BI | ΔE | ||

|---|---|---|---|---|---|---|---|---|---|

| L* | A* | B* | |||||||

| Control | 7.77 ± 0.20 a | 6.08 ± 0.01 a | 35.31 ± 0.24 a | 19.53 ± 0.22 a | 29.66 ± 0.10 a | 13.02 ± 0.03 | 21.05 ± 0.01 | 6.01 ± 0.62 | 0.24 ± 0.01 |

| HVCP | 7.77 ± 0.20 a | 6.08 ± 0.02 a | 36.83 ± 0.22 a | 18.58 ± 0.23 a | 31.59 ± 0.11 a | 13.22 ± 0.01 | 21.44 ± 0.03 | 7.89 ± 0.33 | 0.32 ± 0.01 |

| US | 7.77 ± 0.21 a | 6.08 ± 0.01 a | 38.72 ± 0.34 a | 20.83 ± 0.21 a | 32.95 ± 0.88 a | 13.25 ± 0.02 | 21.76 ± 0.06 | 8.11 ± 0.79 | 0.49 ± 0.02 |

| US-HVCP | 7.77 ± 0.21 a | 6.08 ± 0.01 a | 36.05 ± 0.12 a | 18.23 ± 0.20 a | 30.01 ± 0.21 a | 13.11 ± 0.01 | 21.14 ± 0.02 | 6.56 ± 0.02 | 0.27 ± 0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umair, M.; Jabbar, S.; Senan, A.M.; Sultana, T.; Nasiru, M.M.; Shah, A.A.; Zhuang, H.; Jianhao, Z. Influence of Combined Effect of Ultra-Sonication and High-Voltage Cold Plasma Treatment on Quality Parameters of Carrot Juice. Foods 2019, 8, 593. https://doi.org/10.3390/foods8110593

Umair M, Jabbar S, Senan AM, Sultana T, Nasiru MM, Shah AA, Zhuang H, Jianhao Z. Influence of Combined Effect of Ultra-Sonication and High-Voltage Cold Plasma Treatment on Quality Parameters of Carrot Juice. Foods. 2019; 8(11):593. https://doi.org/10.3390/foods8110593

Chicago/Turabian StyleUmair, Muhammad, Saqib Jabbar, Ahmed M. Senan, Tayyaba Sultana, Mustapha M. Nasiru, Assar A Shah, Hong Zhuang, and Zhang Jianhao. 2019. "Influence of Combined Effect of Ultra-Sonication and High-Voltage Cold Plasma Treatment on Quality Parameters of Carrot Juice" Foods 8, no. 11: 593. https://doi.org/10.3390/foods8110593