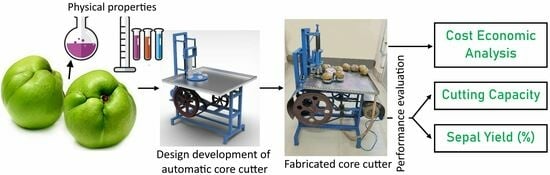

Development and Performance Analysis of an Automatic Core Cutter for Elephant Apple (Dillenia indica L.) Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Collection of Elephant Apple Fruit

2.2. Traditional Cutting Method

2.3. Foot-Operated Core Cutter

2.4. Separation of the Central Core

2.5. Analysis of Physical Properties of Elephant Apple Fruit and Central Core

2.5.1. Dimensions

2.5.2. Arithmetic Mean Diameter

2.5.3. Geometric Mean Diameter

2.5.4. Surface Area

2.5.5. Sphericity

2.5.6. Aspect Ratio

2.5.7. Weight

2.5.8. Density

2.5.9. Percentage Edible Matter

2.5.10. Percentage Non-Edible Matter

2.5.11. Sepal Thickness

2.5.12. Moisture Content

2.6. Design Development

2.7. Fabrication

2.8. Parts of the ACC

2.8.1. Core Cutter

2.8.2. Fruit Holder

2.9. Operating Principle

2.10. Performance Metrics

2.10.1. Cutter Capacity

- Q = ACC Capacity, kg/h,

- W = Total weight of processed fruit, kg,

- T = Time, min.

2.10.2. Sepal Yield

- Y = Sepal yield, %,

- W1 = Total weight of processed fruit, kg,

- W2 = Total weight of obtained sepals, kg.

2.11. Cost Analysis

2.12. Statistical Analysis

3. Results and Discussion

3.1. Physical Properties of Elephant Apple Fruit and Central Core

3.2. Performance Evaluation

3.3. Cost Analysis of the ACC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saikia, D.; Nayak, P.K.; Radhakrishnan, K.; Barbhuiya, J.A.; Mandal, S. Design, Development and Performance Evaluation of Foot Operated Elephant Apple Core Cutter. In Ergonomics for Design and Innovation; HWWE 2021. Lecture Notes in Networks and Systems; Chakrabarti, D., Karmakar, S., Salve, U.R., Eds.; Springer: Cham, Switzerland, 2022; Volume 391, pp. 605–617. [Google Scholar]

- Abdille, M.H.; Singh, R.P.; Jayaprakasha, G.K.; Jena, B.S. Antioxidant Activity of the Extracts from Dillenia indica Fruits. Food Chem. 2005, 90, 891–896. [Google Scholar] [CrossRef]

- Dutta, S.K.; Vanlalhmangaiha; Akoijam, R.S.; Lungmuana; Boopathi, T.; Saha, S. Bioactivity and Traditional Uses of 26 Underutilized Ethno-Medicinal Fruit Species of North-East Himalaya, India. J. Food Meas. Charact. 2018, 12, 2503–2514. [Google Scholar] [CrossRef]

- Jaiswal, S.; Mansa, N.; Pallavi Prasad, M.S.; Jena, B.S.; Negi, P.S. Antibacterial and Antimutagenic Activities of Dillenia indica Extracts. Food Biosci. 2014, 5, 47–53. [Google Scholar] [CrossRef]

- Kumar, D.; Mallick, S.; Vedasiromoni, J.R.; Pal, B.C. Anti-Leukemic Activity of Dillenia indica L. Fruit Extract and Quantification of Betulinic Acid by HPLC. Phytomedicine 2010, 17, 431–435. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.S.; Shams-ud-Doha, K.M.; Rahman, R. Antidiarrhoeal Activity of the Leaf and Fruit Extracts of Dillenia indica. Int. J. Biosci. 2011, 1, 39–46. [Google Scholar]

- Saikia, D.; Kesavan, R.; Inbaraj, B.S.; Dikkala, P.K.; Nayak, P.K.; Sridhar, K. Bioactive Compounds and Health-Promoting Properties of Elephant Apple (Dillenia indica L.): A Comprehensive Review. Foods 2023, 12, 2993. [Google Scholar] [CrossRef] [PubMed]

- Sarker, M.M.R.; Nimmi, I.; Kawsar, M.H. Preliminary Screening of Six Popular Fruits of Bangladesh for in Vitro IgM Production and Proliferation of Splenocytes. Bangladesh Pharm. J. 2012, 15, 31–37. [Google Scholar]

- Saikumar, A.; Nickhil, C.; Badwaik, L.S. Physicochemical Characterization of Elephant Apple (Dillenia indica L.) Fruit and Its Mass and Volume Modeling Using Computer Vision. Sci. Hortic. 2023, 314, 111947. [Google Scholar] [CrossRef]

- Bianchi, T.; Guerrero, L.; Gratacós-Cubarsí, M.; Claret, A.; Argyris, J.; Garcia-Mas, J.; Hortós, M. Textural Properties of Different Melon (Cucumis melo L.) Fruit Types: Sensory and Physical-Chemical Evaluation. Sci. Hortic. 2016, 201, 46–56. [Google Scholar] [CrossRef]

- Vashishth, R.; Semwal, A.D.; Murugan, M.P.; Sharma, G.K. Post Harvest Processing, Cooking and Textural Properties of Horse Gram (Mycrotyloma uniflorum) Varieties. J. Food Meas. Charact. 2018, 12, 257–268. [Google Scholar] [CrossRef]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials: Structure Physical Characteristics and Mechanical Properties, 2nd ed.; Gordon and Breach Science Publisher: New York, NY, USA, 1986; ISBN 9781003062325. [Google Scholar]

- Pradhan, R.C.; Naik, S.N.; Bhatnagar, N.; Vijay, V.K. Moisture-Dependent Physical Properties of Jatropha Fruit. Ind. Crops Prod. 2009, 29, 341–347. [Google Scholar] [CrossRef]

- Ranganna, S. Hand Book of Anlaysis and Quality Control for Fruit and Vegetable Products, 2nd ed.; TataMcgraw Hill: New Delhi, India, 2007. [Google Scholar]

- Singh, A. Fruit Physiology and Production, 5th ed.; Kalyani Publishers: Ludhiana, India, 2016. [Google Scholar]

- AOAC. Official Methods of Analysis, 21st ed.; AOAC International: Washington, DC, USA, 2019; Volume 1. [Google Scholar]

- Obayopo, S.O.; Taiwo, K.A.; Owolarafe, O.K.; Adio, S.A. Development of a Plantain Slicing Device. J. Food Sci. Technol. 2014, 51, 1310–1317. [Google Scholar] [CrossRef]

- Behera, G.; Rayaguru, K. Development and Performance Evaluation of Manually Operated Star Fruit Slicer. J. Agric. Eng. 2024, 53, 10–18. [Google Scholar] [CrossRef]

- Pandey, I.M. Financial Management, 11th ed.; Vikas Publishing House: New Delhi, India, 2015; ISBN 978-93259-8229-1. [Google Scholar]

- Singh, J.; Bargale, P.C. Development of a Small Capacity Double Stage Compression Screw Press for Oil Expression. J. Food Eng. 2000, 43, 75–82. [Google Scholar] [CrossRef]

| Details of Items | Quantity (kg) | Cost Unit (USD) | Total Cost (USD) |

|---|---|---|---|

| Stainless steel sheet 316 | 15 | 5.43 | 81.48 |

| Mild Steel Angle, Flat Bar, Sheet, Rod, Pipe, Plate, Channel, Square Pipe, etc. | 120 | 1.21 | 144.85 |

| Power Transmission: Bearings, Pulley, Pinion, V-Belt, Shaft, etc. | 117.69 | ||

| Fastening Components: Nuts, Bolts, Screws, Springs, Fly Nuts, Washers, etc. | 12.07 | ||

| Oil and Lubricants, Grease, etc. | 6.04 | ||

| Power Unit (Electric Motor, Electric Wire, Cable, Switches, etc.) | 181.06 | ||

| Metallic Paint | 24.14 | ||

| Fabrication Cost | 96.56 | ||

| Total Cost | 663.88 | ||

| Component of Cutter | Material Type | Dimensions |

|---|---|---|

| Frame (L × B × H) | Mild steel | 1067 × 610 × 1270 mm |

| Disc with fruit holder | Stainless steel 316 | 305 mm (Diameter) |

| Fruit holder | Stainless steel 316 | 80 mm (Diameter) × 5 |

| Lever | Mild steel | 550 mm |

| Collecting Tray (L × B) | Stainless steel 316 | 990 × 610 mm |

| Cutter die | Stainless steel pipe 316 | 50 mm (Diameter) |

| Connecting Shafts | Mild steel pipe | 300 and 200 mm |

| Connecting Rod | Mild steel pipe | 500 mm |

| V-belt Pulley | Mild steel | 305 mm (Diameter) |

| V-belt | Synthetic Rubber | 1372 mm |

| Pinion Gear | Case Carburized Steel | 381 mm (Diameter) |

| Motor Pulley | Mild steel | 76 mm (Diameter) |

| Bearing | Steel | 7 (Pcs) |

| Electric Motor | - | 745.7 W |

| Physical Properties | Group 1 | Group 2 | ||

|---|---|---|---|---|

| Whole Fruit | Central Core | Whole Fruit | Central Core | |

| Length (L), mm | 116.85 ± 5.45 | 68.43 ± 4.22 | 94.41 ± 3.69 | 54.26 ± 3.67 |

| Width (W), mm | 103.44 ± 6.72 | 59.64 ± 4.37 | 82.93 ± 5.37 | 45.19 ± 3.54 |

| Thickness (T), mm | 102.21 ± 5.24 | 57.81 ± 3.73 | 81.26 ± 4.24 | 44.36 ± 3.15 |

| Arithmetic mean diameter (Da), mm | 107.50 ± 5.80 | 61.96 ± 4.11 | 86.20 ± 4.43 | 47.94 ± 3.45 |

| Geometric mean diameter (Dg), mm | 107.30 ± 5.77 | 61.79 ± 4.09 | 86.01 ± 4.38 | 47.74 ± 3.45 |

| Surface area (S), mm2 | 36,151.73 ± 104.54 | 11,988.53 ± 52.53 | 23,228.84 ± 60.24 | 7156.40 ± 37.37 |

| Sphericity (∅) | 0.92 ± 0.05 | 0.90 ± 0.06 | 0.91 ± 0.05 | 0.88 ± 0.06 |

| Aspect ratio (Ra) | 0.89 ± 0.06 | 0.87 ± 0.06 | 0.88 ± 0.06 | 0.83 ± 0.07 |

| Weight, g | 475.84 ± 4.18 | 90.79 ± 5.16 | 432.36 ± 5.35 | 78.74 ± 6.71 |

| Density, g/cm3 | 0.99 ± 0.02 | - | 0.99 ± 0.02 | - |

| % edible matter | 79.45 ± 5.53 | - | 80.13 ± 6.12 | - |

| % non-edible matter | 19.40 ± 4.25 | - | 18.69 ± 5.52 | - |

| Sepal thickness, mm | 6.62 ± 1.34 | - | 4.84 ± 1.18 | - |

| Moisture content, % w.b. | 87.57 ± 1.59 | - | 85.93 ± 2.06 | - |

| Batch (10 Elephant Apples Each) | Traditional Cutting Method | Foot-Operated Core Cutter 1 | Automatic Core Cutter | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cutting Time (s) | Mass of Fruit (g) | Mass of Sepals (g) | Sepal Yield (%) | Mass of Pulp (g) | Cutting Time (s) | Mass of Fruit (g) | Mass of Sepals (g) | Sepal Yield (%) | Mass of Pulp (g) | Cutting Time (s) | Mass of Fruit (g) | Mass of Sepals (g) | Sepal Yield (%) | Mass of Pulp (g) | |

| 1 | 1036 | 4389 | 2832 | 64.53 | 1466 | 147 | 4371 | 3680 | 84.18 | 667 | 60 | 4518 | 3973 | 87.94 | 512 |

| 2 | 1164 | 4471 | 2938 | 65.71 | 1454 | 145 | 4748 | 4118 | 86.73 | 611 | 60 | 4597 | 3827 | 83.25 | 741 |

| 3 | 1187 | 4632 | 2980 | 64.33 | 1568 | 144 | 4692 | 3911 | 83.35 | 749 | 60 | 4641 | 4019 | 86.59 | 589 |

| 4 | 1148 | 4716 | 3151 | 66.82 | 1487 | 146 | 4763 | 4079 | 85.64 | 658 | 60 | 4483 | 3795 | 84.65 | 653 |

| 5 | 1132 | 4538 | 3058 | 67.39 | 1409 | 147 | 4574 | 4016 | 87.80 | 536 | 60 | 4821 | 4145 | 85.98 | 638 |

| Total | 5667 | 22,746 | 14,959 | - | 7384 | 729 | 23,148 | 19,804 | - | 3221 | 300 | 23,060 | 19,759 | - | 3133 |

| Mean | 1133.4 | 4549.2 | 2991.8 | 65.76 | 1476.8 | 145.8 | 4629.6 | 3960.8 | 85.55 | 644.2 | 60 | 4612 | 3951.8 | 85.68 | 626.6 |

| SD | 58.19 | 129.02 | 120.72 | 1.35 | 58.43 | 1.30 | 162.54 | 175.40 | 1.81 | 78.27 | 0 | 132.5 | 143.57 | 1.8 | 84.35 |

| Parameters | Values | |

|---|---|---|

| FOCC | ACC | |

| Machine Parameters | ||

| Cutter Cost, INR | 3000 | 55,000 |

| Effective capacity, kg of fruit processed/h | 115 | 270 |

| Life of cutter, year | 3 | 5 |

| Operating hrs/day | 7 | 7 |

| Operating days/year | 150 | 150 |

| Electricity consumption at 0.746 kWh, units per year | - | 784 |

| Fixed Cost | ||

| Annual processing capacity of the raw material (elephant apple fruit), kg | 120,750 | 283,500 |

| Depreciation of the machine (salvage value @ 10% of initial cost), INR | 300 | 5500 |

| Interest on cutter cost @ 10% p.a., INR | 300 | 5500 |

| Insurance @ 2% p.a. of cutter cost, INR | 60 | 1100 |

| Housing @ 2% of the initial cutter cost/year, INR | 60 | 1100 |

| Annual Fixed Cost, INR | 720 | 13,200 |

| Variable Cost | ||

| Maintenance cost annually @ 2% of cutter cost, INR | 60 | 1100 |

| Wages of two labor annually @ 350 INR per labor per day | 105,000 | 105,000 |

| Annual electricity charge @ 8.00 INR/kWh | - | 6272 |

| Cost of elephant apple fruit @ 3.50 INR/kg | 422,625 | 992,250 |

| Interest @ 10% p.a., INR on cost of procured elephant apple fruit | 42,263 | 99,225 |

| Cost of storage/losses of elephant apple fruit annually @ 5% of its cost, INR | 21,131 | 49,613 |

| Annual Present Value of Elephant Apple Fruit, INR | 486,019 | 1,141,088 |

| Annual Operating/Variable Cost, INR | 591,079 | 1,253,460 |

| Revenue | ||

| Average content of elephant apple sepals in fruit, % | 85 | 85 |

| Annual production of edible elephant apple sepals, kg | 102,638 | 240,975 |

| Annual production of unused central core per kg of elephant apple, kg | 18,112 | 42,525 |

| Total Annual Revenue for Sale of Elephant Apple Sepals @ 15.00 INR/kg, INR | 1,539,570 | 3,614,625 |

| Annual Net Profit (Total Annual Revenue—(Fixed Cost + Variable Cost)), INR | 947,771 | 2,347,965 |

| Benefit-Cost Ratio (BCR) | 1.60 | 1.85 |

| Return-On-Investment (ROI, %) | 178.24 | 197.34 |

| Pay Back-Period (PBP, Year) | 0.63 | 0.54 |

| Cost of processing 1 kg of elephant apple fruit, INR | 1.40 | 0.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saikia, D.; Kesavan, R.; Sharma, M.; Inbaraj, B.S.; Nayak, P.K.; Sridhar, K. Development and Performance Analysis of an Automatic Core Cutter for Elephant Apple (Dillenia indica L.) Processing. Foods 2024, 13, 848. https://doi.org/10.3390/foods13060848

Saikia D, Kesavan R, Sharma M, Inbaraj BS, Nayak PK, Sridhar K. Development and Performance Analysis of an Automatic Core Cutter for Elephant Apple (Dillenia indica L.) Processing. Foods. 2024; 13(6):848. https://doi.org/10.3390/foods13060848

Chicago/Turabian StyleSaikia, Deepanka, Radhakrishnan Kesavan, Minaxi Sharma, Baskaran Stephen Inbaraj, Prakash Kumar Nayak, and Kandi Sridhar. 2024. "Development and Performance Analysis of an Automatic Core Cutter for Elephant Apple (Dillenia indica L.) Processing" Foods 13, no. 6: 848. https://doi.org/10.3390/foods13060848