Nutrient Composition and Flavor Profile of Crucian Carp Soup Utilizing Fish Residues through Comminution and Pressure-Conduction Treatment

Abstract

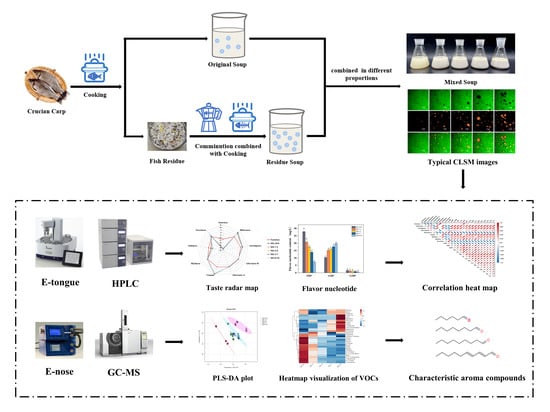

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Total Solids Analysis

2.4. Soluble Proteins Analysis

2.5. Proximate Analysis

2.6. Calcium Content Analysis

2.7. Microstructure Measurements

2.8. Sensory Analysis

2.9. Free Amino Acid Analysis

2.10. 5′-Nucleotides Analysis

2.11. Electronic Nose Detection

2.12. Electronic Tongue Detection

2.13. Volatile Compounds Analysis

2.14. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Residue Soup

3.2. Composition and Structure in MNCPs

3.3. Sensory Characteristics of Crucian Carp Soup

3.4. Content of Free Amino Acids in Crucian Carp Soup

3.5. Flavor Nucleotide of Crucian Carp Soup

3.6. E-Tongue Analyses of Crucian Carp Soup

3.7. E-Nose Analyses of Crucian Carp Soup

3.8. Volatile Flavor Component Analysis of Crucian Carp Soup

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, G.; Zheng, S.; Feng, Y.; Shen, G.; Xiong, S.; Du, H. Changes in nutrient profile and antioxidant activities of different fish soups, before and after simulated gastrointestinal digestion. Molecules 2018, 23, 1965. [Google Scholar] [CrossRef]

- Halim NR, A.; Yusof, H.M.; Sarbon, N.M. Functional and bioactive properties of fish protein hydolysates and peptides: A comprehensive review. Trends Food Sci. Technol. 2016, 51, 24–33. [Google Scholar] [CrossRef]

- Zou, J.; Xu, M.; Zou, Y.; Yang, B. Chemical compositions and sensory characteristics of pork rib and Silkie chicken soups prepared by various cooking techniques. Food Chem. 2021, 345, 128755. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, Y.; Song, H.; Pan, W.; Chen, W. The fishy off-odor removal and umami enhancing effect of enzymatic hydrolysis of fish by-products by proteases. J. Aquat. Food Prod. Technol. 2023, 32, 218–234. [Google Scholar] [CrossRef]

- Bruno, S.F.; Kudre, T.G.; Bhaskar, N. Impact of pretreatment-assisted enzymatic extraction on recovery, physicochemical and rheological properties of oil from Labeo rohita head. J. Food Process Eng. 2019, 42, e12990. [Google Scholar] [CrossRef]

- Shin, Y.R.; Roy, V.C.; Park, J.S.; Zhang, W.; Chun, B.S. Consecutive extraction of neutral and polar lipids from skipjack tuna (Katsuwonus pelamis) byproducts using supercritical carbon dioxide. J. Supercrit. Fluids 2024, 206, 106175. [Google Scholar] [CrossRef]

- Zheng, J.N.; Han, L.; Wang, Y.; Jiang, P.F.; Qin, L.; Dong, X.P. Effects of Thermal Processing Methods on Nutritional Components and Edible Quality of Fish Soup. J. Chin. Inst. Food Sci. Technol. 2023, 23, 222–231. [Google Scholar] [CrossRef]

- Ozogul, F.; Cagalj, M.; Šimat, V.; Ozogul, Y.; Tkaczewska, J.; Hassoun, A.; Kaddour, A.A.; Kuley, E.; Rathod, N.B.; Phadke, G.G. Recent developments in valorisation of bioactive ingredients in discard/seafood processing by-products. Trends Food Sci. Technol. 2021, 116, 559–582. [Google Scholar] [CrossRef]

- Fukuuchi, T.; Iyama, N.; Yamaoka, N.; Kaneko, K. Simultaneous quantification by HPLC of purines in umami soup stock and evaluation of their effects on extracellular and intracellular purine metabolism. Nucleosides Nucleotides Nucleic Acids 2018, 37, 273–279. [Google Scholar] [CrossRef]

- Dong, H.; Liu, J.; Zeng, X.; Bai, W.; Yu, L. Enzymatic hydrolysis pretreatment for enhancing the protein solubility and physicochemical quality of Cordyceps militaris chicken soup. Food Sci. Nutr. 2020, 8, 2436–2444. [Google Scholar] [CrossRef] [PubMed]

- Lowry, O.; Rosebrough, N.; Farr, A.L.; Randall, R. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of AOAC International, Official Method 988.05 and 963.15, 20th ed.; AOAC International: Gaithersburg, MA, USA, 2016. [Google Scholar]

- GB 5009.8; National food Safety Standard-Meat Products-Determination of total Sugars Content. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China: Beijing, China, 2016.

- Manuelian, C.; Currò, S.; Penasa, M.; Cassandro, M.; De Marchi, M. Characterization of major and trace minerals, fatty acid composition, and cholesterol content of Protected Designation of Origin cheeses. J. Dairy Sci. 2017, 100, 3384–3395. [Google Scholar] [CrossRef]

- Qian, X.; Fan, X.; Su, H.; Zhang, J.; Tao, N.; Zhong, J.; Wang, X.; Han, B. Migration of lipid and other components and formation of micro/nano-sized colloidal structure in Tuna (Thunnus obesus) head soup. LWT Food Sci. Technol. 2019, 111, 69–76. [Google Scholar] [CrossRef]

- Xie, D.; Hu, H.; Huang, Q.; Lu, X. Influence of oleogel/hydrogel ratios and emulsifiers on structural and digestion properties of food-grade 3D printed bigels as carriers for quercetin and catechin. Food Hydrocoll. 2023, 144, 108948. [Google Scholar] [CrossRef]

- PN EN ISO 8586; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. European Committee for Standardization: Brussels, Belgium, 2014; pp. 1–16.

- Tanimoto, S.; Kawakami, K.; Morimoto, S. Changes in the free amino acid content of the shucked oyster crassostrea gigas stored in salt water at 3 °C. Fish. Aquat. Sci. 2013, 16, 63–69. [Google Scholar] [CrossRef]

- Qiu, W.Q.; Chen, S.S.; Xie, J.; Qu, Y.H.; Song, X. Analysis of 10 nucleotides and related compounds in Litopenaeus vannamei during chilled storage by HPLC-DAD. LWT Food Sci. Technol. 2016, 67, 187–193. [Google Scholar] [CrossRef]

- Ke, Y. Analysis of flavor ingredients for Ruditapes philippinarum by headspace solid-phase microextraction and gas chromatograph-mass spectrometer-computer method. Adv. J. Food Sci. Technol. 2013, 5, 1149–1152. [Google Scholar] [CrossRef]

- Huang, X.H.; Zheng, X.; Chen, Z.H.; Zhang, Y.Y.; Du, M.; Dong, X.P.; Qin, L.; Zhu, B.W. Fresh and grilled eel volatile fingerprinting by e-Nose, GC-O, GC–MS and GC × GC-QTOF combined with purge and trap and solvent-assisted flavor evaporation. Food Res. Int. 2019, 115, 32–43. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.P.; Li, D.Y.; Huang, Y.; Wu, Q.; Liu, W.T.; Qin, L.; Zhou, D.Y.; Prakash, S.; Yu, C.X. Nutritional value and flavor of turbot (Scophthalmus maximus) muscle as affected by cooking methods. Int. J. Food Prop. 2018, 21, 1972–1985. [Google Scholar] [CrossRef]

- Zhao, Z.; Chao, H.; Ji, A.G. Determination and nutritional assessment on the content of mineral matters in the bone soup. Food Res. Dev. 2008, 29, 126–128. [Google Scholar]

- Yao, H.; Liu, W.; Lin, L.; Lu, Y.; Gan, J.H.; Liu, Y.; Tao, N.P.; Wang, X.C.; Hong, M.S.; Xu, C.H. Micro-nano particle formation and transformation mechanisms of broth in meat braised processing. Food Chem. 2021, 342, 128383. [Google Scholar] [CrossRef]

- Fan, X.; Li, X.; Tao, N.; Zhang, J.; Wang, M.; Qian, X.; Su, H.; Zhong, J. Effect of salt addition time on the nutritional profile of Thunnus obesus head soup and the formation of micro/nano-sized particle structure. Molecules 2019, 24, 4447. [Google Scholar] [CrossRef]

- Sandria, F.; Pratama, R.I.; Liviawaty, E. Composition of flavour non volatile compound steamed snakehead fish (Channa striata). Asian J. Fish. Aquat. Res. 2022, 19, 30–39. [Google Scholar] [CrossRef]

- Hidalgo, F.J.; León, M.M.; Zamora, R. Amino acid decarboxylations produced by lipid-derived reactive carbonyls in amino acid mixtures. Food Chem. 2016, 209, 256–261. [Google Scholar] [CrossRef]

- Zhang, R.; Qiu, W.; Zhang, M.; Row, K.H.; Cheng, Y.; Jin, Y. Effects of different heating methods on the contents of nucleotides and related compounds in minced Pacific white shrimp and Antarctic krill. LWT Food Sci. Technol. 2018, 87, 142–150. [Google Scholar] [CrossRef]

- Dermiki, M.; Phanphensophon, N.; Mottram, D.S.; Methven, L. Contributions of non-volatile and volatile compounds to the umami taste and overall flavour of shiitake mushroom extracts and their application as flavour enhancers in cooked minced meat. Food Chem. 2013, 141, 77–83. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Ismail, I.; Joo, S.T. Identification of umami taste in sous-vide beef by chemical analyses, equivalent umami concentration, and electronic tongue system. Foods 2020, 9, 251. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Chen, M.; Xing, S. Characterization of the key odorants of crucian carp soup and flavour improvement by modulated temperature mode in electrical stewpot. Flavour Fragr. J. 2021, 36, 637–651. [Google Scholar] [CrossRef]

- ALjahdali, N.; Carbonero, F. Impact of Maillard reaction products on nutrition and health: Current knowledge and need to understand their fate in the human digestive system. Crit. Rev. Food Sci. Nutr. 2019, 59, 474–487. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Domínguez, R. Cooking losses, lipid oxidation and formation of volatile compounds in foal meat as affected by cooking procedure. Flavour Fragr. J. 2014, 29, 240–248. [Google Scholar] [CrossRef]

- Wall, K.R.; Kerth, C.R.; Miller, R.K.; Alvarado, C. Grilling temperature effects on tenderness, juiciness, flavor and volatile aroma compounds of aged ribeye, strip loin, and top sirloin steaks. Meat Sci. 2019, 150, 141–148. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Chen, L.; Liu, Y.; Olajide, T.M.; Jiang, Y.; Cao, W. Identification of key aroma-active compounds in beef tallow varieties using flash GC electronic nose and GC × GC-TOF/MS. Eur. Food Res. Technol. 2022, 248, 1733–1747. [Google Scholar] [CrossRef]

| Chemical Compositions | OS | RS |

|---|---|---|

| Total Solids (%) | 2.10 ± 0.06 b | 12.18 ± 0.22 a |

| Soluble Proteins (mg/100 mL) | 13.20 ± 0.09 b | 82.36 ± 0.32 a |

| Total Lipids (g/100 mL) | 0.34 ± 0.03 b | 1.50 ± 0.01 a |

| Total Proteins (g/100 mL) | 1.30 ± 0.02 b | 4.39 ± 0.06 a |

| Total Sugars (mg/100 mL) | 13.75 ± 0.25 b | 36.04 ± 0.81 a |

| Calcium Content (mg/L) | 115.26 ± 0.71 b | 532.98 ± 0.68 a |

| Compounds | Threshold (µg/kg) | Odor Characteristics | ROAV | ||||

|---|---|---|---|---|---|---|---|

| MS-10:0 | MS-7:3 | MS-5:5 | MS-3:7 | MS-0:10 | |||

| Pentanal | 12 | Almond, Bitter, Malt, Oil, Pungent | 0.03 | <0.01 | / | / | / |

| Hexanal | 4.5 | Apple, Fat, Fresh, Green, Oil | 100 | 100 | 100 | 100 | 0.18 |

| (E)-2-Pentenal | 1500 | / | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Acetal | 1000 | Creamy, Fruit, Pleasant | / | / | <0.01 | <0.01 | <0.01 |

| Heptanal | 3 | Citrus, Fat, Green, Nut | 0.27 | 0.27 | 0.45 | 0.39 | 0.11 |

| Octanal | 0.7 | Citrus, Fat, Green, Oil, Pungent | 1.12 | 1.09 | 0.85 | 0.96 | 0.27 |

| Nonanal | 1 | Fat, Floral, Green, Lemon | 2.90 | 2.45 | 4.03 | 4.21 | 100 |

| (E)-2-Octenal | 3 | Dandelion, Fat, Fruit, Grass, Green | 0.13 | 0.08 | 0.04 | 0.03 | 0.01 |

| (E, E)-2,4-Heptadienal | 10 | Fatty, Grassy | 0.02 | 0.01 | <0.01 | <0.01 | / |

| 5-Methylfuranal | 0.5 | Fatty, Nutty | 0.14 | 0.07 | <0.01 | / | / |

| 2,4-Decadienal | 0.3 | Coriander, Deep Fried, Fat, Oil | 0.72 | 0.44 | 0.28 | 0.10 | / |

| (E, E)-2,4-Decadienal | 0.07 | Coriander, Deep Fried, Fat, Oil | 25.95 | 16.58 | 25.35 | 10.08 | 1.40 |

| Decanal | 2.6 | Sweet, Floral, Waxy, Fried | 0.29 | 0.27 | 0.49 | 0.47 | 0.14 |

| 2,3-Butanediol | 100,000 | Sweet | / | / | <0.01 | <0.01 | <0.01 |

| 1-Octen-3-ol | 1 | Mushroom, Oily, Earthy | 0.22 | 0.31 | 0.63 | 0.65 | 0.42 |

| 2-Heptanone | 140 | Citrus, Fried, Mushroom, Oil | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| 3-Hydroxy-2-butanone | 800 | Butter, Creamy, Green Pepper | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| 2-Octanone | 50 | Fat, Fragrant, Mold | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| p-Xylene | 450.23 | / | <0.01 | <0.01 | <0.01 | <0.01 | / |

| o-Xylene | 68.6 | / | <0.01 | <0.01 | <0.01 | <0.01 | / |

| Ethylbenzene | 2205.25 | Fruity, Floral | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| Naphthalene | 60 | Camphor | / | / | / | / | <0.01 |

| Tetradecane | 1000 | / | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

| 2-Pentylfuran | 5.8 | Butter, Floral, Fruit, Green Bean | 0.04 | 0.13 | 0.28 | 0.54 | 0.17 |

| 2,4-Di-tert-butylphenol | 200 | Phenolic Flavor | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Wang, Z.; Yang, X.; Fan, X.; Pan, J.; Dong, X. Nutrient Composition and Flavor Profile of Crucian Carp Soup Utilizing Fish Residues through Comminution and Pressure-Conduction Treatment. Foods 2024, 13, 800. https://doi.org/10.3390/foods13050800

Wang Q, Wang Z, Yang X, Fan X, Pan J, Dong X. Nutrient Composition and Flavor Profile of Crucian Carp Soup Utilizing Fish Residues through Comminution and Pressure-Conduction Treatment. Foods. 2024; 13(5):800. https://doi.org/10.3390/foods13050800

Chicago/Turabian StyleWang, Qi, Zheming Wang, Xiaoqing Yang, Xinru Fan, Jinfeng Pan, and Xiuping Dong. 2024. "Nutrient Composition and Flavor Profile of Crucian Carp Soup Utilizing Fish Residues through Comminution and Pressure-Conduction Treatment" Foods 13, no. 5: 800. https://doi.org/10.3390/foods13050800