Best Combination of Vegetable By-Products for the Shelf-Life Extension of Fresh Pasta

Abstract

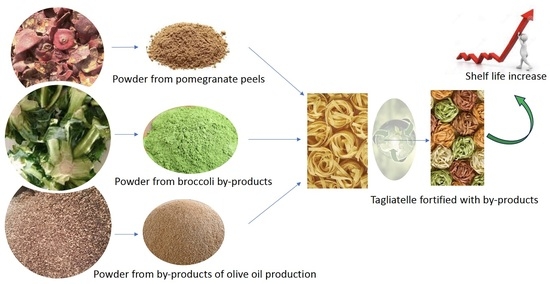

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Tagliatelle Preparation

2.3. Microbiological Quality of Fresh Tagliatelle

2.3.1. Microbiological Analyses

2.3.2. Microbiological Data Modeling

2.4. Sensory Quality of Fresh Tagliatelle

2.4.1. Sensory Analyses

2.4.2. Sensory Data Modeling

2.5. Chemical Quality of Fresh Tagliatelle

2.5.1. Reagents

2.5.2. Extraction from Fresh Tagliatelle

2.5.3. Total Phenolic Content

2.5.4. Total Flavonoid Content

2.5.5. Antioxidant Activity

2.6. Moisture Content

2.7. pH Measurement

2.8. Pasta Shelf Life

2.9. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content, pH and Chemical Quality

3.2. Microbiological Quality of Handmade Fresh Tagliatelle

3.3. Sensory Analysis

3.4. Pasta Shelf Life

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Helkar, P.B.; Sahoo, A.K.; Patil, N.J. Review: Food Industry By-Products used as a Functional Food Ingredients. Int. J. Waste Res. 2016, 6, 248. [Google Scholar]

- Cadiz-Gurrea, M.; Villegas-Aguilar, M.; Leyva-Jimenez, F.J.; Pimentel-Moral, S.; Fernandez-Ochoa, A.; Alanona, M.E.; Segura-Carretero, A. Revalorization of bioactive compounds from tropical fruit by-products and industrial applications by means of sustainable approaches. Food Res. Int. 2020, 138, 109786. [Google Scholar] [CrossRef] [PubMed]

- Nocente, F.; Taddei, F.; Galassi, E.; Gazza, L. Upcycling of brewers’ spent grain by production of dry pasta with higher nutritional potential. LWT-Food Sci. Technol. 2019, 114, 108421. [Google Scholar] [CrossRef]

- Gòmez, M.; Martines, M.M. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2119–2135. [Google Scholar] [CrossRef] [PubMed]

- Nakov, G.; Brandolini, A.; Hidalgo, A.; Ivanova, N.; Stamatovska, V.; Dimov, I. Effect of grape pomace powder addition on chemical, nutritional and technological properties of cakes. LWT-Food Sci. Technol. 2020, 134, 109950. [Google Scholar] [CrossRef]

- Shih, Y.T.; Wang, W.; Hasenbeck, A.; Stone, D.; Zhao, Y. Investigation of physicochemical, nutritional, and sensory qualities of muffins incorporated with dried brewer’s spent grain flours as a source of dietary fiber and protein. J. Food Sci. 2020, 85, 3943–3953. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Ahmed, S.; Mehmood, A.; Bilal, M.; Patil, P.J.; Akram, K.; Farooq, U. Effect of apple pomace on nutrition, rheology of dough and cookies quality. J. Food Sci. Technol. 2020, 57, 3244–3251. [Google Scholar] [CrossRef]

- Li, Y.; Bahadur, R.; Ahuja, J.; Pehrsson, P.; Harnly, J. Macro-and micronutrients in raw plant foods: The similarities of foods and implication for dietary diversification. J. Food Compos. Anal. 2021, 102, 103993. [Google Scholar] [CrossRef]

- Krupa-Kozak, U.; Drabinska, N.; Baczek, N.; Šimková, K.; Starowicz, M.; Jelinski, T. Application of Broccoli Leaf Powder in Gluten-Free Bread: An Innovative Approach to Improve Its Bioactive Potential and Technological Quality. Foods 2021, 10, 819. [Google Scholar] [CrossRef]

- Angiolillo, L.; Spinelli, S.; Marinelli, V.; Conte, A.; Del Nobile, M.A. Extract from Broccoli by-products to extend the Shelf Life of Fish Burgers. J. Food Res. 2019, 8, 56. [Google Scholar] [CrossRef]

- Drabińska, N.; Nogueira, M.; Ciska, E.; Jeleń, H. Effect of Drying and Broccoli Leaves Incorporation on the Nutritional Quality of Durum Wheat Pasta. Pol. J. Food Nutr. Sci. 2022, 72, 273–285. [Google Scholar] [CrossRef]

- Hanani, Z.A.N.; Yee, F.C.; Nor-Khaizura, M.A.R. Effect of pomegranate (Punica granatum L.) peel powder on the antioxidant and antimicrobial properties of fish gelatin films as active packaging. Food Hydrocoll. 2019, 89, 253–259. [Google Scholar] [CrossRef]

- Bourekoua, H.; Rózyło, R.; Gawlik-Dziki, U.; Benatallah, L.; Zidoune, M.N.; Dziki, D. Pomegranate seed powder as a functional component of gluten-free bread (Physical, sensorial and antioxidant evaluation). Food Sci. Technol. 2018, 53, 1906–1913. [Google Scholar] [CrossRef]

- Lacivita, V.; Marziliano, M.; Conte, A.; Del Nobile, M.A. Artisanal fresh filled pasta with pomegranate peels as natural preservative. LWT-Food Sci. Technol. 2022, 127, 114209. [Google Scholar] [CrossRef]

- Deng, Y.; Li, Y.; Yang, F.; Zeng, A.; Yang, S.; Luo, Y.; Zhang, Y.; Xie, Y.; Ye, T.; Xia, Y.; et al. The extract from Punica granatum (pomegranate) peel induces apoptosis and impairs metastasis in prostate cancer cells. Biomed. Pharmacother. 2017, 93, 976–984. [Google Scholar] [CrossRef] [PubMed]

- Gunjan, J.; Rahul, N.; Divya, S.; Praveen, K.S.; Diwaker, K.A. Antioxidant activity of various parts of Punica granatum: A review. J. Drug Deliv. Ther. 2012, 2, 138–141. [Google Scholar]

- Difonzo, G.; Troilo, M.; Squeo, G.; Pasqualone, A.; Caponio, F. Functional compounds from olive pomace to obtain high-added value foods—A review. J. Sci. Food Agric. 2021, 101, 15–26. [Google Scholar] [CrossRef]

- Nunes, M.A.; Pimentel, F.B.; Costa, A.S.; Alves, R.C.; Oliveira, M.B.P. Olive by-products for functional and food applications: Challenging opportunities to face environmental constraints. Inn. Food Sci. Emerg. Technol. 2016, 35, 139–148. [Google Scholar] [CrossRef]

- Tufariello, M.; Durante, M.; Veneziani, G.; Taticchi, A.; Servili, M.; Bleve, G.; Mita, G. Patè Olive Cake: Possible Exploitation of a By-product for Food Applications. Front. Nutr. 2019, 6, 3. [Google Scholar] [CrossRef]

- Balli, D.; Cecchi, L.; Innocenti, M.; Bellumori, M.; Mulinacci, N. Food by-products valorisation: Grape pomace and olive pomace (pâté) as sources of phenolic compounds and fiber for enrichment of tagliatelle pasta. Food Chem. 2021, 355, 129642. [Google Scholar] [CrossRef]

- Cecchi, L.; Schuster, N.; Flynn, D.; Mulinacci, N.; Guinard, J.-X. Sensory Profiling and Consumer Acceptance of Pasta, Bread, and Granola Bar Fortified with Dried Olive Pomace (Pâté): A Byproduct from Virgin Olive Oil Production. J. Food Sci. 2019, 84, 2995–3008. [Google Scholar] [CrossRef] [PubMed]

- Simonato, B.; Trevisan, S.; Tolve, R.; Favati, F.; Pasini, G. Pasta fortification with olive pomace: Effects on the technological characteristics and nutritional properties. LWT-Food Sci. Technol. 2019, 114, 108368. [Google Scholar] [CrossRef]

- Altamore, L.; Bacarella, S.; Columba, P.; Chironi, S.; Ingrassia, M. The Italian Consumers’ Preferences for Pasta: Does Environment Matter? Chem. Eng. Trans. 2017, 58, 859–864. [Google Scholar]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, nutritional and sensory properties of pasta fortified with agroindustrial by-products: A review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Carpentieri, S.; Larrea-Wachtendorff, D.; Donsì, F.; Ferrari, G. Functionalization of pasta through the incorporation of bioactive compounds from agri-food by-products: Fundamentals, opportunities, and drawbacks. Trends Food Sci. Technol. 2022, 122, 49–65. [Google Scholar] [CrossRef]

- Ainsa, A.; Roldan, S.; Marquina, P.L.; Roncalés, P.; Beltrán, J.A.; Calanche Morales, J.B. Quality parameters and technological properties of pasta enriched with a fish by-product: A healthy novel food. J. Food Process. Preserv. 2022, 46, e16261. [Google Scholar] [CrossRef]

- Amoriello, T.; Mellara, F.; Ruggeri, S.; Ciorba, R.; Ceccarelli, D.; Ciccoritti, R. Artichoke by-products valorization for phenols-enriched fresh egg pasta: A sustainable food design project. Sustainability 2022, 14, 14778. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- la Gatta, B.; Rutigliano, M.; Dilucia, F.; Liberatore, M.T.; Viscecchia, R.; Bimbo, F.; Di Luccia, A. Protein network assessment and sensory characteristics of durum wheat fresh pasta fortified with artichoke bracts and tomato powders. Food Biosci. 2023, 54, 102858. [Google Scholar] [CrossRef]

- la Gatta, B.; Rutigliano, M.; Liberatore, M.T.; Dilucia, F.; Palmitessa, M.; Di Luccia, A.; Lamacchia, C. Effect of the addition of freeze-dried grape pomace on fresh tagliatelle gluten network and relationship to sensory and chemical quality. Foods 2023, 12, 2699. [Google Scholar] [CrossRef]

- la Gatta, B.; Rutigliano, M.; Liberatore, M.T.; Dilucia, F.; Spadaccino, G.; Quinto, M.; Di Luccia, A. Preservation of bioactive compounds occurring in fresh pasta fortified with artichoke bracts and tomato powders obtained with a novel pre-treatment. LWT-Food Sci. Technol. 2023, 187, 115298. [Google Scholar] [CrossRef]

- Crizel, T.; Rios, A.; Thys, R.; Flores, S. Effects of orange by-product fiber incorporation on the functional and technological properties of pasta. Food Sci. Technol. 2015, 35, 546–551. [Google Scholar] [CrossRef]

- Lomuscio, E.; Bianchi, F.; Cervini, M.; Giuberti, G.; Simonato, B.; Rizzi, C. Durum Wheat Fresh Pasta Fortification with Trub, a Beer Industry By-Product. Foods 2022, 11, 2496. [Google Scholar] [CrossRef] [PubMed]

- Lončarić, A.; kosović, I.; Marko, J.; Žaneta, U.; Pilizota, V. Effect of apple by-product as a supplement on antioxidant activity and quality parameters of pasta. J. Food Sci. Technol. 2014, 6, 97–103. [Google Scholar] [CrossRef]

- Tolve, R.; Pasini, G.; Vignale, F.; Favati, F.; Simonato, B. Effect of grape pomace addition on the technological, sensory, and nutritional properties of durum wheat pasta. Foods 2020, 9, 354. [Google Scholar] [CrossRef] [PubMed]

- Panza, O.; Conte, A.; Del Nobile, M.A. Recycling of fig peels to enhance the quality of handmade pasta. LWT-Food Sci. Technol. 2022, 168, 113872. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jougerburger, I.; Rombouts, F.M.; van’T Riet, K. Modeling of the bacterial growth curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef] [PubMed]

- Flores, S.; Conte, A.; Campos, C.; Gerschenson, L.; Del Nobile, M.A. Mass transport properties of tapioca-based active edible films. J. Food Eng. 2007, 81, 580–586. [Google Scholar] [CrossRef]

- Panza, O.; Lacivita, V.; Tarantino, F.; Manzi, A.; Conte, A.; Del Nobile, M.A. Fruit and vegetable by-products as source of bioactive compounds to preserve handmade fresh pasta. LWT-Food Sci. Technol. 2023, 190, 115584. [Google Scholar] [CrossRef]

- El Barnossi, A.; Moussaid, F.; Housseini, A.I. Tangerine, banana and pomegranate peels valorisation for sustainable environment: A review. Biotechnol. Rep. 2021, 29, e00574. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Antimicrobial potential of pomegranate peel: A review. Int. J. Food Sci. Technol. 2019, 54, 959–965. [Google Scholar] [CrossRef]

| Samples | Broccoli (%) | Olive Oil by-Products (%) | Pomegranate (%) | Water for Powder Hydration (g) |

|---|---|---|---|---|

| Ctrl #1 | 0 | 0 | 0 | - |

| 0%BOP-0%PMG | 10 | 0 | 0 | 92.81 |

| 3%BOP-0%PMG | 10 | 3 | 0 | 118.3 |

| 6%BOP-0%PMG | 10 | 6 | 0 | 142.82 |

| 0%BOP-3%PMG | 10 | 0 | 3 | 118.3 |

| 3%BOP-3%PMG | 10 | 3 | 3 | 142.82 |

| Ctrl #2 | 0 | 0 | 0 | - |

| 6%BOP-3%PMG | 10 | 6 | 3 | 166.41 |

| 0%BOP-6%PMG | 10 | 0 | 6 | 142.82 |

| 3%BOP-6%PMG | 10 | 3 | 6 | 166.41 |

| 6%BOP-6%PMG | 10 | 6 | 6 | 189.13 |

| Samples | Moisture Content [ti] | Moisture Content [tf] |

|---|---|---|

| Ctrl #1 | 32.59 ± 0.01 G,a | 30.66 ± 0.52 E,b |

| 0%BOP-0%PMG | 35.15 ± 0.06 F,a | 34.74 ± 1.05 C,a |

| 3%BOP-0%PMG | 35.50 ± 0.43 F,a | 35.29 ± 0.06 C,a |

| 6%BOP-0%PMG | 36.58 ± 0.04 C,b | 38.18 ± 0.28 A,a |

| 0%BOP-3%PMG | 35.68 ± 0.18 E,a | 35.06 ± 0.02 C,b |

| 3%BOP-3%PMG | 37.96 ± 0.08 A,a | 37.80 ± 0.23 A,a |

| Ctrl #2 | 31.61 ± 0.10 H,a | 31.58 ± 0.08 D,b |

| 6%BOP-3%PMG | 37.12 ± 0.13 B,a | 37.07 ± 0.03 B,b |

| 0%BOP-6%PMG | 36.28 ± 0.08 D,a | 36.44 ± 0.42 B,a |

| 3%BOP-6%PMG | 37.03 ± 0.03 B,a | 36.48 ± 0.09 B,b |

| 6%BOP-6%PMG | 38.06 ± 0.06 A,b | 38.23 ± 0.12 A,a |

| Samples | pH [ti] | pH [tf] |

|---|---|---|

| Ctrl #1 | 6.67 ± 0.00 A,a | 5.82 ± 0.02 A,b |

| 0%BOP-0%PMG | 6.20 ± 0.01 C,a | 5.05 ± 0.01 E,b |

| 3%BOP-0%PMG | 5.66 ± 0.00 E,a | 4.93 ± 0.01 G,b |

| 6%BOP-0%PMG | 5.19 ± 0.01 I,a | 4.84 ± 0.02 H,b |

| 0%BOP-3%PMG | 6.11 ± 0.01 D,a | 5.24 ± 0.04 C,b |

| 3%BOP-3%PMG | 5.56 ± 0.01 G,a | 5.21 ± 0.01 C,D,b |

| Ctrl #2 | 6.44 ± 0.01 B,a | 5.83 ± 0.00 A,b |

| 6%BOP-3%PMG | 5.24 ± 0.01 H,a | 4.98 ± 0.01 E,b |

| 0%BOP-6%PMG | 5.67 ± 0.01 E,a | 5.59 ± 0.01 B,b |

| 3%BOP-6%PMG | 5.59 ± 0.01 F,a | 5.19 ± 0.03 D,b |

| 6%BOP-6%PMG | 5.19 ± 0.01 I,a | 4.94 ± 0.04 F,b |

| Samples | TPC | TFC | ABTS |

|---|---|---|---|

| Ctrl #1 | 0.49 ± 0.15 f,g | 0.18 ± 0.06 e | 0.89 ± 0.13 e |

| 0%BOP-0%PMG | 0.58 ± 0.07 e,f | 0.75 ± 0.25 a,b,c | 1.45 ± 0.15 d |

| 3%BOP-0%PMG | 0.97 ± 0.11 a,b | 0.91 ± 0.15 a,b | 3.62 ± 0.43 b |

| 6%BOP-0%PMG | 1.12 ± 0.03 a | 0.94 ± 0.25 a | 4.54 ± 0.07 a |

| 0%BOP-3%PMG | 0.75 ± 0.09 c,d | 0.61 ± 0.07 b,c,d | 2.19 ± 0.20 c |

| 3%BOP-3%PMG | 0.87 ± 0.12 b,c | 0.54 ± 0.13 c,d | 3.23 ± 0.42 b |

| Ctrl #2 | 0.37 ± 0.03 g | 0.14 ± 0.05 e | 0.74 ± 0.51 e |

| 6%BOP-3%PMG | 0.88 ± 0.08 b,c | 0.57 ± 0.13 c,d | 3.70 ± 0.10 b |

| 0%BOP-6%PMG | 0.59 ± 0.07 e,f | 0.36 ± 0.08 d,e | 2.47 ± 0.07 c |

| 3%BOP-6%PMG | 0.71 ± 0.07 d,e | 0.66 ± 0.05 a,b,c,d, | 3.67 ± 0.16 b |

| 6%BOP-6%PMG | 1.07 ± 0.03 a | 0.80 ± 0.29 a,b,c | 4.56 ± 0.08 a |

| Sample | MAL MES. | MAL PSI. | MAL YEAST | MAL MOLD | MAL COLIF. | VM | SAL_Uncooked | SAL_Cooked | SL |

|---|---|---|---|---|---|---|---|---|---|

| [day] | [day] | [day] | [day] | ||||||

| Ctrl #1 | 3.92 | 5.79 | 4.33 | 11.97 | 3.27 | >27 | 12.69 | 11.33 | 3.27 |

| 0%BOP-0%PMG | 9.57 | 11.77 | 11.68 | >27 | 13.89 | 20 | 15.5 | 15.07 | 9.57 |

| 3%BOP-0%PMG | 9.64 | 10.55 | 11.5 | >27 | 24.65 | 20 | 20.76 | 18.79 | 9.64 |

| 6%BOP-0%PMG | 11.83 | 13.61 | 14.58 | 18.72 | >27 | 15 | 19.93 | 15.91 | 11.83 |

| 0%BOP-3%PMG | 11.70 | 13.71 | 16.97 | 20.75 | 6.65 | 15 | 18.18 | 14.87 | 6.65 |

| 3%BOP-3%PMG | 29.22 | 35.88 | 18.12 | 18.53 | >27 | 15 | 19.18 | 15.09 | 15 |

| Ctrl #2 | 4.21 | 4.35 | 2.62 | 8.31 | 3.80 | >27 | 7.64 | 7.86 | 2.62 |

| 6%BOP-3%PMG | >27 | 32.21 | 10.14 | 18.99 | >27 | 20 | >17 | 16.11 | 10.14 |

| 0%BOP-6%PMG | 26.24 | 26.76 | 11.45 | 24.28 | >27 | 20 | >17 | 17.60 | 11.45 |

| 3%BOP-6%PMG | 33.18 | >27 | 11.64 | 17.06 | >27 | 13 | 14.05 | 12.55 | 11.64 |

| 6%BOP-6%PMG | >27 | >27 | 13.30 | 17.34 | >27 | 15 | >17 | 14.72 | 13.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lordi, A.; Panza, O.; Conte, A.; Del Nobile, M.A. Best Combination of Vegetable By-Products for the Shelf-Life Extension of Fresh Pasta. Foods 2024, 13, 44. https://doi.org/10.3390/foods13010044

Lordi A, Panza O, Conte A, Del Nobile MA. Best Combination of Vegetable By-Products for the Shelf-Life Extension of Fresh Pasta. Foods. 2024; 13(1):44. https://doi.org/10.3390/foods13010044

Chicago/Turabian StyleLordi, Adriana, Olimpia Panza, Amalia Conte, and Matteo Alessandro Del Nobile. 2024. "Best Combination of Vegetable By-Products for the Shelf-Life Extension of Fresh Pasta" Foods 13, no. 1: 44. https://doi.org/10.3390/foods13010044