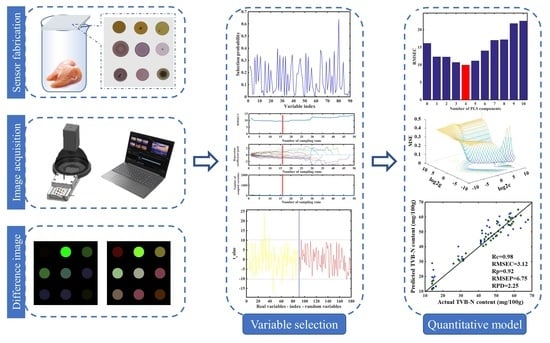

A Novel Colorimetric Sensor Array Coupled Multivariate Calibration Analysis for Predicting Freshness in Chicken Meat: A Comparison of Linear and Nonlinear Regression Algorithms

Abstract

:1. Introduction

2. Experimental Sections

2.1. Collection and Preparation of Chicken Samples

2.2. Reference Measurement of TVB-N Content

2.3. Fabrication of the Colorimetric Sensor Array (CSA)

2.4. Collection of CSA Data

2.5. Multivariable Calibration Analysis

2.5.1. Theory of Partial Least Squares (PLS) Model

2.5.2. Theory of Support Vector Machine (SVM) Model

2.5.3. Theory of Random Frog (RF) Model

2.5.4. Theory of Uninformative Variable Elimination (UVE) Model

2.5.5. Theory of Competitive Adaptive Reweighted Sampling (CARS) Model

2.6. Statistical Data Analysis

3. Results and Discussion

3.1. Reference Measurement Results

3.2. Colorimetric Sensor Array Characteristics Variables (CSA)

3.3. Sample Classification and Evaluation of the Model Performance

3.4. Different Variable Selection Algorithms Based on Linear and Nonlinear Regression Models

3.4.1. Results Variable Selection Algorithms Based on PLS Linear Regression Model

3.4.2. Results Variable Selection Algorithms Based on SVM Nonlinear Regression Model

3.5. Discussion and Comparison of the Built Models

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alexandrakis, D.; Downey, G.; Scannell, A.G.M. Rapid Non-destructive Detection of Spoilage of Intact Chicken Breast Muscle Using Near-infrared and Fourier Transform Mid-infrared Spectroscopy and Multivariate Statistics. Food Bioprocess Technol. 2012, 5, 338–347. [Google Scholar] [CrossRef]

- Khulal, U.; Zhao, J.; Hu, W.; Chen, Q. Intelligent evaluation of total volatile basic nitrogen (TVB-N) content in chicken meat by an improved multiple level data fusion model. Sens. Actuators B Chem. 2016, 238, 337–345. [Google Scholar] [CrossRef]

- Wei, W.; Li, H.; Haruna, S.A.; Wu, J.; Chen, Q. Monitoring the freshness of pork during storage via near-infrared spectroscopy based on colorimetric sensor array coupled with efficient multivariable calibration. J. Food Compos. Anal. 2022, 113, 104726. [Google Scholar] [CrossRef]

- Cai, J.; Chen, Q.; Wan, X.; Zhao, J. Determination of total volatile basic nitrogen (TVB-N) content and Warner–Bratzler shear force (WBSF) in pork using Fourier transform near infrared (FT-NIR) spectroscopy. Food Chem. 2011, 126, 1354–1360. [Google Scholar] [CrossRef]

- Vasconcelos, H.; Saraiva, C.; De Almeida, J.M.M.M. Evaluation of the Spoilage of Raw Chicken Breast Fillets Using Fourier Transform Infrared Spectroscopy in Tandem with Chemometrics. Food Bioprocess Technol. 2014, 7, 2330–2341. [Google Scholar] [CrossRef]

- Rukchon, C.; Nopwinyuwong, A.; Trevanich, S.; Jinkarn, T.; Suppakul, P. Development of a food spoilage indicator for monitoring freshness of skinless chicken breast. Talanta 2014, 130, 547–554. [Google Scholar] [CrossRef]

- Khulal, U.; Zhao, J.; Hu, W.; Chen, Q. Nondestructive quantifying total volatile basic nitrogen (TVB-N) content in chicken using hyperspectral imaging (HSI) technique combined with different data dimension reduction algorithms. Food Chem. 2016, 197, 1191–1199. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zhu, L.; Jiang, Q.; Ge, X.; Fang, Y.; Peng, J.; Liu, Y. Real-time and rapid prediction of TVB-N of livestock and poultry meat at three depths for freshness evaluation using a portable fluorescent film sensor. Food Chem. 2023, 400, 134041. [Google Scholar] [CrossRef] [PubMed]

- Kuswandi, B.; Jayus; Oktaviana, R.; Abdullah, A.; Heng, L.Y. A Novel On-Package Sticker Sensor Based on Methyl Red for Real-Time Monitoring of Broiler Chicken Cut Freshness. Packag. Technol. Sci. 2013, 27, 69–81. [Google Scholar] [CrossRef]

- Li, H.; Haruna, S.A.; Geng, W.; Wei, W.; Zhang, M.; Ouyang, Q.; Chen, Q. Fabricating a novel colorimetric-bionic sensor coupled multivariate calibration for simultaneous determination of myoglobin proportions in pork. Sensors Actuators B Chem. 2021, 343, 130181. [Google Scholar] [CrossRef]

- Wijaya, D.R.; Sarno, R.; Zulaika, E. DWTLSTM for electronic nose signal processing in beef quality monitoring. Sens. Actuators B Chem. 2021, 326, 128931. [Google Scholar] [CrossRef]

- Zheng, W.; Shi, Y.; Ying, Y.; Men, H. Olfactory-taste synesthesia model: An integrated method for flavor responses of electronic nose and electronic tongue. Sens. Actuators A Phys. 2023, 350, 114134. [Google Scholar] [CrossRef]

- Korotcenkov, G.; Cho, B. Metal oxide composites in conductometric gas sensors: Achievements and challenges. Sensors Actuators B Chem. 2017, 244, 182–210. [Google Scholar] [CrossRef]

- Li, H.; Geng, W.; Hassan, M.; Zuo, M.; Wei, W.; Wu, X.; Ouyang, Q.; Chen, Q. Rapid detection of chloramphenicol in food using SERS flexible sensor coupled artificial intelligent tools. Food Control. 2021, 128, 108186. [Google Scholar] [CrossRef]

- Li, H.; Geng, W.; Zhang, M.; He, Z.; Haruna, S.A.; Ouyang, Q.; Chen, Q. Qualitative and quantitative analysis of volatile metabolites of foodborne pathogens using colorimetric-bionic sensor coupled robust models. Microchem. J. 2022, 177, 107282. [Google Scholar] [CrossRef]

- Lin, H.; Jiang, H.; He, P.; Haruna, S.A.; Chen, Q.; Xue, Z.; Chan, C.; Ali, S. Non-destructive detection of heavy metals in vegetable oil based on nano-chemoselective response dye combined with near-infrared spectroscopy. Sens. Actuators B Chem. 2021, 335, 129716. [Google Scholar] [CrossRef]

- Ajay Piriya, V.S.; Printo, J.; KirubaDaniel, S.G.G.; Susithra, L.; Takatoshi, K.; Sivakumar, M. Colorimetric sensors for rapid detection of various analytes. Mater. Sci. Eng. C 2017, 78, 1231–1245. [Google Scholar] [CrossRef]

- Abedalwafa, M.A.; Li, Y.; Ni, C.; Wang, L. Colorimetric sensor arrays for the detection and identification of antibiotics. Anal. Methods 2019, 11, 2836–2854. [Google Scholar] [CrossRef]

- Li, H.; Luo, X.; Haruna, S.A.; Zhou, W.; Chen, Q. Rapid detection of thiabendazole in food using SERS coupled with flower-like AgNPs and PSL-based variable selection algorithms. J. Food Compos. Anal. 2023, 115, 105016. [Google Scholar] [CrossRef]

- Haruna, S.A.; Li, H.; Wei, W.; Geng, W.; Luo, X.; Zareef, M.; Adade, S.Y.-S.S.; Ivane, N.M.A.; Isa, A.; Chen, Q. Simultaneous quantification of total flavonoids and phenolic content in raw peanut seeds via NIR spectroscopy coupled with integrated algorithms. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2023, 285, 121854. [Google Scholar] [CrossRef]

- Haruna, S.A.; Li, H.; Wei, W.; Geng, W.; Adade, S.Y.-S.S.; Zareef, M.; Ivane, N.M.A.; Chen, Q. Intelligent evaluation of free amino acid and crude protein content in raw peanut seed kernels using NIR spectroscopy paired with multivariable calibration. Anal. Methods 2022, 14, 2989–2999. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Hassan, M.; Wang, J.; Wei, W.; Zou, M.; Ouyang, Q.; Chen, Q. Investigation of nonlinear relationship of surface enhanced Raman scattering signal for robust prediction of thiabendazole in apple. Food Chem. 2020, 339, 127843. [Google Scholar] [CrossRef]

- Adade, S.Y.-S.S.; Lin, H.; Haruna, S.A.; Barimah, A.O.; Jiang, H.; Agyekum, A.A.; Johnson, N.A.N.; Zhu, A.; Ekumah, J.-N.; Li, H.; et al. SERS-based sensor coupled with multivariate models for rapid detection of palm oil adulteration with Sudan II and IV dyes. J. Food Compos. Anal. 2022, 114, 104834. [Google Scholar] [CrossRef]

- Gammermann, A. Support vector machine learning algorithm and transduction. Comput. Stat. 2000, 15, 31–39. [Google Scholar] [CrossRef]

- Zhu, C.; Jiang, H.; Chen, Q. Rapid detection of yeast growth status based on molecular spectroscopy fusion (MSF) technique. Infrared Phys. Technol. 2022, 127, 104438. [Google Scholar] [CrossRef]

- Centner, V.; Massart, D.-L.; de Noord, O.E.; de Jong, S.; Vandeginste, B.M.; Sterna, C. Elimination of Uninformative Variables for Multivariate Calibration. Anal. Chem. 1996, 68, 3851–3858. [Google Scholar] [CrossRef]

- Galvão, R.K.H.; Araujo, M.C.U.; José, G.E.; Pontes, M.; Silva, E.C.; Saldanha, T.C.B. A method for calibration and validation subset partitioning. Talanta 2005, 67, 736–740. [Google Scholar] [CrossRef] [PubMed]

| Constituents | Subsets | No. of Samples | Unit | Range | Mean | Standard Deviation |

|---|---|---|---|---|---|---|

| TVB-N | Calibration set | 48 | mg/100 g | 13.98–67.85 | 42.33 | 16.25 |

| Prediction set | 32 | 13.99–66.44 | 41.78 | 16.26 |

| Quantitative Algorithms | Variable Selection | Number of Variables | Calibration Set | Prediction Set | RPDe | ||

|---|---|---|---|---|---|---|---|

| Rc a | RMSECb | Rp c | RMSEPd | ||||

| PLS | - | 90 | 0.79 | 9.94 | 0.63 | 13.37 | 1.15 |

| RF | 30 | 0.86 | 8.53 | 0.81 | 9.65 | 1.61 | |

| UVE | 18 | 0.81 | 9.55 | 0.77 | 10.52 | 1.35 | |

| CARS | 13 | 0.85 | 8.58 | 0.81 | 9.71 | 1.58 | |

| SVM | - | 90 | 0.97 | 3.84 | 0.83 | 9.26 | 1.52 |

| RF | 30 | 0.99 | 2.30 | 0.86 | 9.17 | 1.57 | |

| UVE | 18 | 0.98 | 3.05 | 0.89 | 7.90 | 1.83 | |

| CARS | 13 | 0.98 | 3.12 | 0.92 | 6.75 | 2.25 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, W.; Haruna, S.A.; Li, H.; Kademi, H.I.; Chen, Q. A Novel Colorimetric Sensor Array Coupled Multivariate Calibration Analysis for Predicting Freshness in Chicken Meat: A Comparison of Linear and Nonlinear Regression Algorithms. Foods 2023, 12, 720. https://doi.org/10.3390/foods12040720

Geng W, Haruna SA, Li H, Kademi HI, Chen Q. A Novel Colorimetric Sensor Array Coupled Multivariate Calibration Analysis for Predicting Freshness in Chicken Meat: A Comparison of Linear and Nonlinear Regression Algorithms. Foods. 2023; 12(4):720. https://doi.org/10.3390/foods12040720

Chicago/Turabian StyleGeng, Wenhui, Suleiman A. Haruna, Huanhuan Li, Hafizu Ibrahim Kademi, and Quansheng Chen. 2023. "A Novel Colorimetric Sensor Array Coupled Multivariate Calibration Analysis for Predicting Freshness in Chicken Meat: A Comparison of Linear and Nonlinear Regression Algorithms" Foods 12, no. 4: 720. https://doi.org/10.3390/foods12040720