Dissipation Behavior and Dietary Risk Assessment of Thiamethoxam, Pyraclostrobin, and Their Metabolites in Home-Style Pickled Cowpea

Abstract

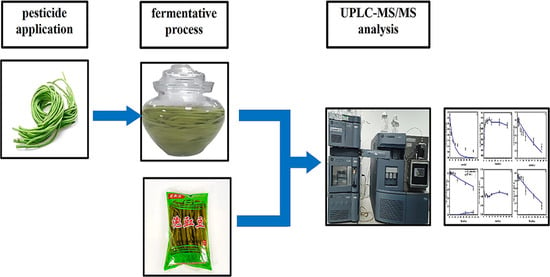

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Materials

2.3. Pickling Process

2.4. Sample Pretreatment

2.5. UPLC-MS/MS Analysis

2.6. Method Validation

2.7. Collection and Analysis of Real Samples

2.8. Statistical Analysis

3. Results and Discussion

3.1. Method Validation

3.2. Dissipation and Degradation Behavior of Pesticides in the Pickled Process of Cowpea

3.3. Real Sample Analyses

3.4. Dietary Exposure Risk Assessment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, Z.; Wang, Y.; Xiang, F.; Hou, Q.; Zhang, Z. Bacterial Diversity in Pickled Cowpea (Vigna unguiculata Linn. Walp) as Determined by Illumina MiSeq Sequencing and Culture-Dependent Methods. Curr. Microbiol. 2021, 78, 1286–1297. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Liu, H.; Yan, S.; Chen, D.; Mei, X. Changes in phenolic composition and bioactivity of raw and pickled cowpea (Vigna unguiculata L. Walp.) green pod after in vitro simulated gastrointestinal digestion. Food Sci. Technol. Res. 2021, 27, 769–778. [Google Scholar] [CrossRef]

- Dong, B.; Yang, Y.; Pang, N.; Hu, J. Residue dissipation and risk assessment of tebuconazole, thiophanatemethyl and its metabolite in table grape by liquid chromatography-tandem mass spectrometry. Food Chem. 2018, 260, 66–72. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, F.Z.; Li, X.Y.; Meng, W.; Yu, Z.; Jiao, Y.; Fei, H.Y.; Zhang, C. Effects of Different Processing Methods on Four Kinds of Pesticide Residue in Cowpea. Storage Process 2016, 16, 80–86. [Google Scholar]

- Jin, Y.; Qi, Y.; Fan, M.; Zhang, J.; Kong, B.; Shao, B. Biotransformation of carbendazim in cowpea pickling process. Food Chem. 2023, 415, 135766. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Farha, W.; Abd El-Aty, A.M.; Kabir, M.H.; Im, S.J.; Jung, D.-I.; Choi, J.-H.; Kim, S.-W.; Son, Y.W.; Shim, J.H.; et al. Dynamic behaviour and residual pattern of thiamethoxam and its metabolite clothianidin in Swiss chard using liquid chromatography-tandem mass spectrometry. Food Chem. 2015, 174, 248–255. [Google Scholar] [CrossRef]

- Fan, Y.; Shi, X. Characterization of of the metabolic transformation of thiamethoxam to clothianidin in Helicoverpa armigera larvae by SPE combined UPLC-MS/MS and its relationship with the toxicity of thiamethoxam to Helicoverpa armigera larvae. J. Chromatogr. B Anal. Technol. Biomed. Life Sci. 2017, 1061, 349–355. [Google Scholar] [CrossRef]

- Mercader, J.V.; Suarez-Pantaleon, C.; Agullo, C.; Abad-Somovilla, A.; Abad-Fuentes, A. Production and characterization of monoclonal antibodies specific to the strobilurin pesticide pyraclostrobin. J. Agric. Food Chem. 2008, 56, 7682–7690. [Google Scholar] [CrossRef]

- Mondal, S.N.; Bhatia, A.; Shilts, T.; Timmer, L.W. Baseline sensitivities of fungal pathogens of fruit and foliage of citrus to azoxystrobin, pyraclostrobin, and fenbuconazole. Plant Dis. 2005, 89, 1186–1194. [Google Scholar] [CrossRef]

- Wise, K.A.; Bradley, C.A.; Pasche, J.S.; Gudmestad, N.C.; Dugan, F.M.; Chen, W. Baseline sensitivity of Ascochyta rabiei to azoxystrobin, pyraclostrobin, and boscalid. Plant Dis. 2008, 92, 295–300. [Google Scholar] [CrossRef]

- JMPR—Joint FAO/WHO Meeting on Pesticide Residues. Pyraclostrobin (Evaluation). Available online: https://www.fao.org/fileadmin/user_upload/IPM_Pesticide/JMPR/Evaluations/2004/Pyraclostrobinaf.pdf (accessed on 30 August 2023).

- You, X.; Peng, W.; Liu, F.; Shi, K.; Li, Y. Simultaneous determination of five strobilurin fungicides and the metabolite BF-500-3 in cereals, fruits and vegetables. Int. J. Environ. Anal. Chem. 2015, 95, 989–1000. [Google Scholar] [CrossRef]

- Meng, B.; Yu, Y.; Zhang, Q.; Wang, S.; Hu, D.; Zhang, K. Simultaneous determination of residues of thiamethoxam and its metabolite clothianidin in tobacco leaf and soil using liquid chromatography-tandem mass spectrometry. Biomed. Chromatogr. 2018, 32, e4225. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Yang, S.; Li, T.; Li, X.; Huang, X.; Gao, Y.; Li, B.; Lin, J.; Mu, W. Determination of pyraclostrobin dynamic residual distribution in tilapia tissues by UPLC-MS/MS under acute toxicity conditions. Ecotoxicol. Environ. Saf. 2020, 206, 111182. [Google Scholar] [CrossRef] [PubMed]

- Hooser, E.A.; Belden, J.B.; Smith, L.M.; Mcmurry, S.T. Acute toxicity of three strobilurin fungicide formulations and their active ingredients to tadpoles. Ecotoxicology 2012, 21, 1458–1464. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Xu, Y.T.; Ying, Z.T.; Tang, T.; Hu, S.T. Integrated exposure assessment and potential risks of neonicotinoids in vegetables from three different sources in Zhejiang, China (2018–2020). Environ. Sci. Pollut. Res. 2023, 30, 22941–22949. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.M.; Fan, S.F.; Yang, L.Q.; He, L.N.; Zhai, H.W.; Ren, X.W.; Li, Q.; Zhang, Y. Rapid screening of 420 pesticide residues in fruits and vegetables using ultra high performance liquid chromatography combined with quadrupole-time of flight mass spectrometry. Food Sci. Hum. Wellness 2023, 12, 1064–1070. [Google Scholar] [CrossRef]

- Liao, L.; Wang, D.; Zhang, C. Degradation of avermectin and thimethoxam applied atdifferent growth periods of cowbean. Zhejiang Agric Sci. 2020, 61, 433–436. (In Chinese) [Google Scholar]

- Chen, L.; Li, F.; Jia, C.; Yu, P.; Zhao, E.; He, M.; Jing, J. Determination of thiamethoxam and its metabolite clothianidin residue and dissipation in cowpea by QuEChERS combining with ultrahigh-performance liquid chromatography-tandem mass spectrometry. Environ. Sci. Pollut. Res. 2021, 28, 8844–8852. [Google Scholar] [CrossRef]

- Han, S.; Bi, Y.; Han, L.; Song, S.; Ye, Z.; Qin, F.; Lv, X. Residue Behavior and Risk Assessment of Pyraclostrobin and Thifluzamide in Cowpea. Bull. Environ. Contam. Toxicol. 2022, 108, 786–790. [Google Scholar] [CrossRef]

- Guo, H.-M.; Zhao, Y.; Yang, M.-N.O.; Yang, Z.-H.; Li, J.-H. The enantioselective effects and potential risks of paclobutrazol residue during cucumber pickling process. J. Hazard. Mater. 2020, 386, 121882. [Google Scholar] [CrossRef]

- Anastassiades, M.; Lehotay, S.J.; Štajnbaher, D.; Schenck, F.J. Fast and Easy Multiresidue Method Employing Acetonitrile Extraction/Partitioning and “Dispersive Solid-Phase Extraction” for the Determination of Pesticide Residues in Produce. J. AOAC Int. 2019, 86, 412–431. [Google Scholar] [CrossRef]

- Sharma, K.; Mullangi, R. A concise review of HPLC, LC-MS and LC-MS/MS methods for determination of azithromycin in various biological matrices. Biomed. Chromatogr. 2013, 27, 1243–1258. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Guidance Document on Analytical Quality Control and Method Validation Procedures for Pesticide Residues Analysis in Food and Feed—SANTE/12682/2019; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Li, Y.; An, Q.; Zhang, C.; Pan, C.; Zhang, Z. Comparison of Sin-QuEChERS Nano and d-SPE Methods for Pesticide Multi-Residues in Lettuce and Chinese Chives. Molecules 2020, 25, 3391. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Guidance Document on Analytical Quality Control and Method Validation Procedures for Pesticide Residues and Analysis in Food and Feed—SANTE/11813/2017; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Chen, L.; Wu, C.; Xu, M.; Cang, T.; Wang, X.; Zhao, X.; Zhang, C. Assessment of Carbendazim Residues and Safety in Celery Under Different Cultivation Conditions. Bull. Environ. Contam. Toxicol. 2021, 107, 276–280. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.X.; Hu, J.Y. Residue levels and dietary risk assessment of fluopimomide, pyraclostrobin and its metabolite BF-500-3 in garlic ecosystems under field conditions. Environ. Sci. Pollut. Res. 2023, 30, 19803–19813. [Google Scholar] [CrossRef]

- Abbassy, M.A.; Salim, Y.M.M.; Shawir, M.S.; Nassar, A.M.K. Disappearance and hazard quotient of chlorpyrifos-methyl, fipronil, and imidacloprid insecticides from dates. J. Consum. Prot. Food Saf. 2017, 12, 223–230. [Google Scholar] [CrossRef]

- Kabir, M.H.; Abd El-Aty, A.M.; Rahman, M.M.; Kim, S.W.; Lee, H.S.; Chung, H.S.; Jeong, J.H.; Chang, B.J.; Chang, M.I.; Shim, J.H.; et al. Dissipation kinetics, pre-harvest residue limits, and hazard quotient assessments of pesticides flubendiamide and fluopicolide in Korean melon (Cucumis melo L. var. makuwa) grown under regulated conditions in plastic greenhouses. Environ. Sci. Pollut. Res. 2017, 24, 22241–22250. [Google Scholar] [CrossRef]

- Qian, Y.; Matsumoto, H.; Liu, X.; Li, S.; Liang, X.; Liu, Y.; Zhu, J.; Wang, M. Dissipation, occurrence and risk assessment of a phenyturea herbicide tebuthiuron in sugarcane and aquatic ecosystems in South China. Environ. Pollut. 2017, 227, 389–396. [Google Scholar] [CrossRef]

- JMPR. Pesticide Residues in Food. Evaluations, Part I Residues—Bifenazate; Joint FAO/WHO Meeting on Pesticide Residues: Rome, Italy, 2014. [Google Scholar]

- ICAMA (Institute Control of Agrochemicals, Ministry of Agriculture, P.R. China). Diet Risk Assessment Model. Available online: http://sitem.herts.ac.uk/aeru/iupac/search_alt.htm (accessed on 19 December 2020).

- WHO. Dietary Exposure Assessment of Chemicals in Food: Report of a Joint FAO/WHO Consultation; WHO: Geneva, Switzerland, 2016. [Google Scholar]

- Hiemstra, M.; De Kok, A. Comprehensive multi-residue method for the target analysis of pesticides in crops using liquid chromatography-tandem mass spectrometry. J. Chromatogr. A 2007, 1154, 3–25. [Google Scholar] [CrossRef]

- Xiao, J.; Xu, X.; Wang, F.; Ma, J.; Liao, M.; Shi, Y.; Fang, Q.; Cao, H. Analysis of exposure to pesticide residues from Traditional Chinese Medicine. J. Hazard. Mater. 2019, 365, 857–867. [Google Scholar] [CrossRef]

- Dong, X.; Zhu, B.; Zhao, X.; Wang, H.; Liu, S. Transfer rates on nine pesticides from dry tea to infusion by QuEChERS purification followed by LC-MS/MS analysis. Int. J. Environ. Anal. Chem. 2021, 103, 2931–2947. [Google Scholar] [CrossRef]

- Karmakar, R.; Singh, S.B.; Kulshrestha, G. Kinetics and mechanism of the hydrolysis of thiamethoxam. J. Environ. Sci. Health Part B Pestic. Food Contam. Agric. Wastes 2009, 44, 435–441. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.R.; Shi, L.H.; Meng, X.G.; Xu, J.; Jia, G.F.; Gui, T.; Zhang, Y.P.; Hu, D.Y. Evaluation of photolysis and hydrolysis of pyraclostrobin in aqueous solutions and its degradation products in paddy water. J. Environ. Sci. Health Part B Pestic. Food Contam. Agric. Wastes 2019, 54, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; He, L.; Wei, W.; Hao, L.; Ji, X.; Zhou, Y.; Wang, Q. Chlorpyrifos residue levels on field crops (rice, maize and soybean) in China and their dietary risks to consumers. Food Control 2015, 51, 212–217. [Google Scholar] [CrossRef]

- You, X.; Liu, C.; Liu, F.; Liu, Y.; Dong, J. Dissipation of pyraclostrobin and its metabolite BF-500-3 in maize under field conditions. Ecotoxicol. Environ. Saf. 2012, 80, 252–257. [Google Scholar] [CrossRef] [PubMed]

| Pesticides | Matrices | Linear Range (mg·L−1) | Standard Curve Equations | R2 | ME |

|---|---|---|---|---|---|

| THI | Solvent | 0.01–0.5 | y = 366887x − 2103 | 0.9988 | / |

| Cowpea | y = 34922x + 24 | 0.9987 | 0.10 | ||

| Brine | y = 55360x − 75 | 0.9965 | 0.15 | ||

| CLO | Solvent | 0.01–0.5 | y = 55729x + 656 | 0.9978 | / |

| Cowpea | y = 7934.6x + 66 | 0.9980 | 0.14 | ||

| Brine | y = 13295x + 58 | 0.9988 | 0.24 | ||

| PYR | Solvent | 0.005–0.5 | y = 746678x + 14518 | 0.9942 | / |

| Cowpea | y = 638872x + 5660 | 0.9960 | 0.86 | ||

| Brine | y = 653173x + 11039 | 0.9943 | 0.87 | ||

| BF 500-3 | Solvent | 0.005–0.5 | y = 2444053x − 14511 | 0.9987 | / |

| Cowpea | y = 1671010x − 2685 | 0.9997 | 0.68 | ||

| Brine | y = 1696270x − 6609 | 0.9978 | 0.69 |

| Matrices | Pesticides | Spiking Levels (mg·kg−1) | AR (%) | RSD (%) | LOQ (mg·kg−1) |

|---|---|---|---|---|---|

| Cowpea | THI | 0.01 | 111 | 4.6 | 0.01 |

| 0.1 | 106 | 9.1 | |||

| 1 | 105 | 2.7 | |||

| CLO | 0.01 | 95 | 6.0 | 0.01 | |

| 0.1 | 104 | 8.8 | |||

| 1 | 102 | 6.8 | |||

| PYR | 0.005 | 103 | 7.0 | 0.005 | |

| 0.1 | 103 | 1.3 | |||

| 1 | 100 | 5.8 | |||

| BF 500-3 | 0.005 | 89 | 5.1 | 0.005 | |

| 0.1 | 108 | 2.0 | |||

| 1 | 103 | 5.0 | |||

| Brine | THI | 0.01 | 102 | 6.9 | 0.01 |

| 0.05 | 104 | 1.7 | |||

| 0.5 | 93 | 2.8 | |||

| CLO | 0.01 | 107 | 7.4 | 0.01 | |

| 0.05 | 91 | 2.0 | |||

| 0.5 | 101 | 5.3 | |||

| PYR | 0.005 | 88 | 8.3 | 0.005 | |

| 0.05 | 97 | 2.4 | |||

| 0.5 | 98 | 3.8 | |||

| BF 500-3 | 0.005 | 104 | 5.5 | 0.005 | |

| 0.05 | 105 | 3.4 | |||

| 0.5 | 89 | 3.7 |

| Sample No. | THI | CLO | PYR | BF 500-3 | Total PYR |

|---|---|---|---|---|---|

| 1 | 0.021 | <0.01 | 0.010 | <0.005 | 0.015 |

| 2 | 0.015 | <0.01 | 0.192 | 0.024 | 0.218 |

| 3 | <0.01 | <0.01 | 0.185 | 0.052 | 0.241 |

| 4 | <0.01 | <0.01 | 0.006 | <0.005 | 0.011 |

| 5 | <0.01 | <0.01 | <0.005 | <0.005 | <0.01 |

| 6 | <0.01 | <0.01 | 0.016 | <0.005 | 0.021 |

| 7 | <0.01 | <0.01 | 0.066 | 0.009 | 0.076 |

| 8 | <0.01 | <0.01 | 0.028 | 0.009 | 0.038 |

| 9 | <0.01 | <0.01 | <0.005 | <0.005 | <0.01 |

| 10 | <0.01 | <0.01 | <0.005 | <0.005 | <0.01 |

| 11 | <0.01 | <0.01 | 0.047 | 0.01 | 0.058 |

| 12 | <0.01 | <0.01 | <0.005 | <0.005 | <0.01 |

| 13 | <0.01 | <0.01 | 0.014 | <0.005 | 0.019 |

| 14 | <0.01 | <0.01 | 0.034 | 0.008 | 0.043 |

| 15 | <0.01 | <0.01 | 0.045 | 0.005 | 0.050 |

| 16 | <0.01 | <0.01 | 0.203 | 0.049 | 0.256 |

| 17 | <0.01 | <0.01 | 0.014 | <0.005 | 0.019 |

| 18 | <0.01 | <0.01 | 0.073 | 0.012 | 0.086 |

| 19 | <0.01 | <0.01 | <0.005 | <0.005 | <0.01 |

| 20 | <0.01 | <0.01 | <0.005 | <0.005 | <0.01 |

| Pesticides | Maximum Residue (mg·Kg−1) | Dietary Risk Quotient | ||

|---|---|---|---|---|

| EDI | ADI | RQ | ||

| THI | 0.021 | 0.0002 | 0.08 | 4 × 10−5 |

| CLO | <0.01 | 0.0001 | 0.1 | 2 × 10−5 |

| Total PYR | 0.256 | 0.0026 | 0.03 | 1 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wu, H.; Yang, K.; Fang, N.; Wen, H.; Zhang, C.; Wang, X.; Pan, D. Dissipation Behavior and Dietary Risk Assessment of Thiamethoxam, Pyraclostrobin, and Their Metabolites in Home-Style Pickled Cowpea. Foods 2023, 12, 3337. https://doi.org/10.3390/foods12183337

Wang X, Wu H, Yang K, Fang N, Wen H, Zhang C, Wang X, Pan D. Dissipation Behavior and Dietary Risk Assessment of Thiamethoxam, Pyraclostrobin, and Their Metabolites in Home-Style Pickled Cowpea. Foods. 2023; 12(18):3337. https://doi.org/10.3390/foods12183337

Chicago/Turabian StyleWang, Xumi, Huanqi Wu, Kongtan Yang, Nan Fang, Hong Wen, Changpeng Zhang, Xiangyun Wang, and Daodong Pan. 2023. "Dissipation Behavior and Dietary Risk Assessment of Thiamethoxam, Pyraclostrobin, and Their Metabolites in Home-Style Pickled Cowpea" Foods 12, no. 18: 3337. https://doi.org/10.3390/foods12183337