Incorporation of Tapioca Starch and Wheat Flour on Physicochemical Properties and Sensory Attributes of Meat-Based Snacks from Beef Scraps

Abstract

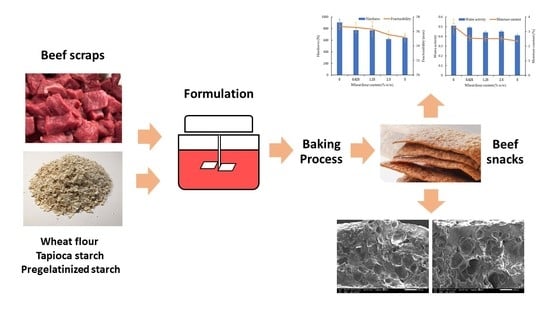

:1. Introduction

2. Materials and Methods

2.1. Preparation of Beef Snack Chip

2.2. Analysis Methods

2.2.1. Measurement of Water Activity (aw)

2.2.2. Measurement of Moisture Content

2.2.3. Measurement of Color

2.2.4. Measurement of Texture Profile

2.3. Sensory Evaluation

2.4. Microstructure Evaluation

2.5. Statistical Analysis

3. Results

3.1. Effect of Starch or Flour Type on the Physicochemical Properties and Sensory Evaluation of Beef Snacks

3.2. Effect of Wheat Flour Content on the Physicochemical Properties and Sensory Evaluation of Beef Snacks

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Serra, A.; Gallart-Palau, X.; Koh, W.Y.; Chua, Z.J.Y.; Guo, X.; Chow, C.J.J.C.; Chen, W.M.; Park, J.E.; Li, T.; Tam, J.P.; et al. Prooxidant modifications in the crptome of beef jerky, the deleterious post-digestion composition of processed meat snacks. Food Res. Int. 2019, 125, 108569. [Google Scholar] [CrossRef] [PubMed]

- Alarcón-García, M.A.; Perez-Alvarez, J.A.; López-Vargas, J.H.; Pagán-Moreno, M.J. Meat snacks consumption: Aspects that the consumer looks for to consider them a healthy food. Proceedings 2021, 70, 82. [Google Scholar]

- Zdanowska-Sasiadex, Z.; Marchewka, J.; Horbanczuk, J.O.; Wierzbicka, A.; Lipinska, P.; Jozwik, A.; Atanasov, A.G.; Huminiecki, L.; Sieron, A.; Sieron, K.; et al. Nutrients composition in fit snacks made from ostrich, beef and chicken dried meat. Molecules 2018, 23, 1267. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, C. The role of beef in human nutrition and health. In Ensuring Safety and Quality in the Production of Beef; Dikeman, M.E., Ed.; Burleigh Dodds Science Publishing Limited: London, UK, 2017; Volume 2, pp. 329–338. [Google Scholar]

- Kumar, M.; Tomar, M.; Potkule, J.; Reetu; Punia, S.; Dhakane-Lad, J.; Singh, S.; Dhumal, S.; Pradhan, P.C.; Bhushan, B.; et al. Functional characterization of plant-based protein to determine its quality for food applications. Food Hydrocoll. 2022, 123, 106986. [Google Scholar] [CrossRef]

- Marmonier, C.; Chapelot, D.; Louis-Sylvestre, J. Effects of macronutrient content and energy density of snacks consumed in a satiety state on the onset of the next meal. Appetite 1999, 34, 161–168. [Google Scholar] [CrossRef]

- Muthia, D.; Nurul, H.; Noryati, I. The effects of tapioca, wheat, sago and potato flours on the physicochemical and sensory properties of duck sausage. Int. Food Res. J. 2010, 17, 877–884. [Google Scholar]

- Wang, W.; Hostettler, C.E.; Damberger, F.F.; Kossmann, J.; Lloyd, J.R.; Zeeman, S.C. Modification of cassava root starch phosphorylation enhances starch functional properties. Front. Plant Sci. 2018, 9, 1562. [Google Scholar] [CrossRef]

- Vanier, N.L.; Pozzada dos Santos, J.; Pinheiro, B.G.; Zavareze, E.R. Starches in foods and beverages. In Handbook of Eating and Drinking; Meiselman, H., Ed.; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Kumar, P.; Verma, A.K.; Kumar, D.; Umaraw, P.; Mehta, N.; Malav, O.P. Meat snacks: A novel technological perspective. In Innovations in Traditional Foods; Galanakis, C.M., Ed.; Woodhead Publishing: London, UK, 2019; pp. 293–321. [Google Scholar]

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef] [Green Version]

- Alao, B.O.; Falowo, A.B.; Chulayo, A.; Muchenje, V. The Potential of Animal By-Products in Food Systems: Production, Prospects and Challenges. Sustainability 2017, 9, 1089. [Google Scholar] [CrossRef] [Green Version]

- Shah Mohammadi, H.R.; Bakar, J.; Russly, A.R.; Noranizan, M.A.; Mirhosseini, H. Puffed Corn-Fish Snack Development by Extrusion Technology. Iran. J. Fish. Sci. 2014, 13, 748–760. [Google Scholar]

- Nawaz, A.; Xiong, Z.; Xiong, H.; Chen, L. The effects of fish meat and fish bone addition on nutritional value, texture and microstructure of optimised fried snacks. Int. J. Food Sci. Technol. 2019, 54, 1045–1053. [Google Scholar] [CrossRef]

- Nawaz, A.; Xiong, Z.; Li, Q.; Xiong, H.; Irshad, S.; Chen, L.; Wang, P.; Zhang, M.; Hina, S.; Regenstein, J.M. Evaluation of physicochemical, textural and sensory quality characteristics of red fish meat-based fried snacks. J. Sci. Food Agric. 2019, 99, 5771–5777. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, A.; Li, E.; Khalifa, I.; Walayat, N.; Liu, J.; Irshad, S.; Zahra, A.; Ahmed, S.; Simirgiotis, M.J.; Pateiro, M.; et al. Effect of Different Processing Methods on Quality, Structure, Oxidative Properties and Water Distribution Properties of Fish Meat-Based Snacks. Foods 2021, 10, 2467. [Google Scholar] [CrossRef] [PubMed]

- Lund, M.N.; Ray, C.A. Control of maillard reactions in foods: Strategies and chemical mechanisms. J. Agric. Food Chem. 2017, 65, 4537–4552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zulaikha, Y.; Yao, S.H.; Chang, Y.W. Physicochemical and functional properties of snack bars enriched with Tilapia (Oreochromis niloticus) by-product powders. Foods 2021, 10, 1908. [Google Scholar] [CrossRef]

- Bainy, E.M.; Bertan, L.C.; Corazza, M.L.; Lenzi, M.K. Effect of grilling and baking on physicochemical and textural properties of tilapia (Oreochromis niloticus) fish burger. J. Food Sci. Technol. 2015, 52, 5111–5119. [Google Scholar] [CrossRef] [Green Version]

- Landillon, V.; Cassan, D.; Morel, M.H.; Cuq, B. Flowability, cohesive, and granulation properties of wheat powders. J. Food Eng. 2008, 86, 178–193. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; Fallah, E.; Hamer, R.J.; Van Der Goot, A.J. Aeration of bread dough influenced by different way of processing. J. Cereal Sci. 2010, 51, 89–95. [Google Scholar] [CrossRef]

- Shewry, P.R.; Popineau, Y.; Lafiandra, D.; Belton, P. Wheat glutenin subunits and dough elasticity: Findings of the EUROWHEAT project. Trends Food Sci. Technol. 2001, 11, 433–441. [Google Scholar] [CrossRef] [Green Version]

- Shewry, P.R.; Halford, N.G.; Belton, P.S.; Tatham, A.S. The structure and properties of gluten: An elastic protein from wheat grain. Philos. Trans. R. Soc. 2002, 357, 133–142. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Ma, H.; Liu, M.; Liang, Y.; Zheng, X.; Sun, L.; Dang, W.; Li, J.; Li, L.; Liu, C. Research progress on properties of pre-gelatinized starch and its application in wheat flour products. Grain Oil Sci. Technol. 2022, in press. [CrossRef]

- Zhang, B.; Qiao, D.; Zhao, S.; Lin, Q.; Wang, J.; Xie, F. Starch-based food matrices containing protein: Recent understanding of morphology, structure, and properties. Trends Food Sci. Technol. 2021, 114, 212–231. [Google Scholar] [CrossRef]

- Erkmen, O.; Bozoglu, T.F. Food Microbiology: Principles into Practice; Wiley-Blackwell: Hoboken, NJ, USA, 2016. [Google Scholar]

- Pereira, J.; Hu, H.; Xing, L.; Zhang, W.; Zhou, G. Influence of rice flour, glutinous rice flour, and tapioca starch on the functional properties and quality of an emulsion-type cooked sausage. Foods 2020, 9, 9. [Google Scholar] [CrossRef] [Green Version]

- Karoyo, A.H.; Wilson, L.D. A review on the design and hydration properties of natural polymer-based hydrogels. Materials 2021, 14, 1095. [Google Scholar] [CrossRef]

- Aprianita, A.; Vasiljevic, T.; Bannikova, A.; Kasapis, S. Physicochemical properties of flours and starches derived from traditional Indonesian tubers and roots. J. Food Sci. Technol. 2014, 51, 3669–3679. [Google Scholar] [CrossRef] [Green Version]

- Oladunmoye, O.O.; Aworh, O.C.; Maziya-Dixon, B.; Erukainure, O.L.; Elemo, G.N. Chemical and functional properties of cassava starch, durum wheat semolina flour, and their blends. Food. Sci. Nutr. 2014, 2, 132–138. [Google Scholar] [CrossRef]

| Ingredients | Concentration (%, w/w) |

|---|---|

| Beef scraps | 77.00–79.50 |

| Sugar | 9.50 |

| Soy sauce | 7.50 |

| Coriander powder, cumin powder, ground black pepper | 1.50 |

| Table salt | 1.00 |

| Sodium bicarbonate | 1.00 |

| Starch/flour 1 | 0.00–2.50 |

| Physical Properties | Control | Tapioca Starch | Modified Starch | Wheat Flour | Tapioca Starch + Wheat Flour |

|---|---|---|---|---|---|

| Lightness (L*) | 19.16 ± 1.98 b | 19.34 ± 1.70 b | 22.22 ± 2.37 ab | 23.80 ± 2.82 a | 25.04 ± 1.52 a |

| Redness (a*) | 7.37 ± 0.72 b | 9.43 ± 1.48 a | 10.30 ± 0.78 a | 10.67 ± 0.76 a | 9.17 ± 0.65 a |

| Yellowness (b*) | 14.67 ± 0.16 c | 16.06 ± 0.79 c | 19.86 ± 1.38 b | 21.63 ± 0.67 a | 20.23 ± 0.11 ab |

| Moisture content (%) | 3.36 ± 0.75 | 2.40 ± 0.05 | 2.98 ± 0.07 | 2.84 ± 0.13 | 2.72 ± 0.10 |

| Water activity | 0.51 ± 0.02 | 0.44 ± 0.01 | 0.48 ± 0.01 | 0.45 ± 0.01 | 0.46 ± 0.01 |

| Hardness (N) | 903.87 ± 80.57 b | 734.46 ± 55.53 c | 1030.57 ± 0.39 a | 570.89 ± 75.60 d | 558.36 ± 40.15 d |

| Fracturability (mm) | 76.67 ± 0.41 | 76.07 ± 0.20 | 75.50 ± 0.31 | 75.75 ± 0.89 | 75.98 ± 0.15 |

| Formulations | Color | Flavor | Crispness | Overall Acceptability |

|---|---|---|---|---|

| Control | 3.50 ± 1.50 c | 4.20 ± 1.60 c | 3.33 ± 2.07 c | 3.87 ± 1.57 c |

| Tapioca starch | 4.23 ± 1.35 b | 5.00 ± 1.29 b | 4.90 ± 1.24 b | 5.10 ± 1.21 b |

| Modified starch | 5.33 ± 1.45 a | 5.30 ± 1.09 ab | 5.80 ± 1.00 a | 5.80 ± 1.13 a |

| Wheat flour | 5.50 ± 1.25 a | 5.73 ± 0.98 a | 6.13 ± 1.07 a | 5.83 ± 1.02 a |

| Tapioca starch + Wheat flour | 5.57 ± 1.28 a | 5.23 ± 1.55 ab | 5.60 ± 1.50 ab | 5.63 ± 1.45 ab |

| Wheat Flour (%w/w) | Lightness (L*) | Redness (a*) | Yellowness (b*) |

|---|---|---|---|

| 0 | 19.16 ± 1.98 b | 7.37 ± 0.72 b | 14.67 ± 0.16 b |

| 0.625 | 26.30 ± 0.95 a | 9.50 ± 1.15 a | 17.94 ± 0.38 a |

| 1.25 | 27.97 ± 0.86 a | 9.88 ± 1.33 a | 19.15 ± 0.57 a |

| 2.50 | 28.75 ± 2.44 a | 10.62 ± 0.60 a | 19.62 ± 0.72 a |

| 5.00 | 28.43 ± 0.14 a | 11.12 ± 0.31 a | 19.88 ± 1.31 a |

| Wheat Flour (%w/w) | Color | Flavor | Crispness | Overall Acceptability |

|---|---|---|---|---|

| 0 | 3.50 ± 1.50 c | 4.20 ± 1.60 b | 3.33 ± 2.07 b | 3.87 ± 1.57 c |

| 0.625 | 5.27 ± 1.36 a | 5.53 ± 1.20 a | 5.47 ± 1.20 a | 5.63 ± 1.32 a |

| 1.25 | 5.27 ± 1.39 a | 5.27 ± 1.55 a | 5.27 ± 1.34 a | 5.13 ± 1.80 ab |

| 2.50 | 5.10 ± 1.45 ab | 5.33 ± 1.45 a | 5.00 ± 1.51 a | 5.00 ± 1.60 ab |

| 5.00 | 5.67 ± 1.67 b | 5.07 ± 1.62 a | 4.93 ± 1.64 a | 4.77 ± 1.65 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nimitkeatkai, H.; Pasada, K.; Jarerat, A. Incorporation of Tapioca Starch and Wheat Flour on Physicochemical Properties and Sensory Attributes of Meat-Based Snacks from Beef Scraps. Foods 2022, 11, 1034. https://doi.org/10.3390/foods11071034

Nimitkeatkai H, Pasada K, Jarerat A. Incorporation of Tapioca Starch and Wheat Flour on Physicochemical Properties and Sensory Attributes of Meat-Based Snacks from Beef Scraps. Foods. 2022; 11(7):1034. https://doi.org/10.3390/foods11071034

Chicago/Turabian StyleNimitkeatkai, Hataitip, Kannika Pasada, and Amnat Jarerat. 2022. "Incorporation of Tapioca Starch and Wheat Flour on Physicochemical Properties and Sensory Attributes of Meat-Based Snacks from Beef Scraps" Foods 11, no. 7: 1034. https://doi.org/10.3390/foods11071034