1. Introduction

Paracentrotus lividus (Lamark 1816) is a widespread sea urchin species in the Mediterranean area, appreciated worldwide for the taste of its gonads [

1].

P. lividus is a sedentary echinoderm that mainly colonizes rocky bottoms rich in vegetation or lives on sandy bottom colonies within the

Poseidonia oceanica.

P. lividus feeds on plant forms and animal organisms such as small crustaceans and mollusks, sponges, and coelenterates [

2]. The edible part is represented by the reproductive system, the gonads, commonly called pulp or eggs.

Sea urchin gonads have high water and protein levels and low lipid and carbohydrate content and can be considered a low-calorie commodity [

3].

The fat fraction is characterized by significant polyunsaturated fatty acids (PUFAs). Eicosapentaenoic acid (EPA), docosahexaenoic acid (DHA), docosapentaenoic acid (DPA), docosatetraenoic acid, and docosadienoic acid are the most represented [

4].

The commercial value of the gonads is strictly associated with their organoleptic features, which consists of maintaining their granular surface without melting. Consumers demand a product that is easy and ready to use, easy to store, and economical, with a high degree of food safety, and a high nutritional and organoleptic value. Therefore, food preservation approaches should respect all quality parameters requested for sea urchins. Gonads can be commercialized fresh, frozen, and sterilized after packaging in tinplate boxes and glass jars. Fresh gonads recovered from the shell (consisting of calcite which incorporates various metals), stored at 5 °C, and with an expected shelf life of about 5 days are intended for immediate consumption and local market only [

5]. However, this preparation can present microbiological problems of contamination. The freezing process, conducted at −30/−40 °C, or more often at −18 °C, decreases the enzymatic and microbial activity allowing storage up to 3 months before flavor and texture lessening [

5].

High-temperature food preservation technologies (110 °C for 90 s) are known to denature proteins and lower fatty-acid content in food [

6], in addition to changing the rheologic properties and modifying sea urchin nutritional and organoleptic characteristics. For this reason, the decontamination systems based on heat do not apply to

P. lividus.

High-pressure processing (HPP) is classified as a nonthermal method of preservation; for this reason, it has been accepted and adopted for commercial processing on many foods worldwide. HPP can provide a thermal equivalent to pasteurization, ensuring microbial safety without changing the raw material’s color, flavor, and texture during storage [

7].

The antimicrobial mechanism of HPP consists of an alteration of macromolecules, intracellular proteins, hydrophobic bonds, and electrostatic interactions weakening cell membranes and inducing cell death. HPP deactivation is affected by microbial species, pressure level, and holding time applied to the food product’s physicochemical characteristics (aw and pH) [

8,

9,

10,

11,

12,

13,

14]. Low pH values showed a higher degree of microbial inactivation [

8]. However, HPP applications for viruses and bacteria should consider the individual characteristics of the pathogenic microorganisms; hepatitis (HAV) can be reduced between 300 and 450 MPa, whereas poliovirus needs 5 min at 600 MPa, and norovirus needs 5 min at 275 MPa [

15,

16].

Although lethal to microorganisms, pressure treatment does not break covalent bonds, showing a minimal effect on food nutritional and sensory properties. Moreover, this process’s low energy value supply does not promote the development of undesirable chemical compounds, such as free radicals, that could rise with other preservation methods. Thus, the final sanitized product shows organoleptic and nutritional characteristics comparable to the fresh product [

8].

Today, the use of HPP is extensively diffused in the food industry, and the commercialization of pressurized foods has increased around the world to produce jams, juices, sauces, smoothies, ready-to-eat meat products, guacamole, and oysters [

11,

17,

18].

Numerous studies have been performed on fish, especially cod, salmon, and mackerel. Studies have highlighted that different species behave differently depending on the species and HPP setting; moreover, the level of fats and protein can be influenced, leading to nutritional modifications [

19,

20]. In addition, fish eggs such as bottarga or caviar are processed by dry salting or wet salting [

21,

22], and no data were found in the literature regarding the use of HPP on fish eggs.

Sea urchins have an aw of 0.98, which is considered suitable for HPP treatments, associated with a pH value (6.00) highly favorable to microbial growth, thus representing a potential risk for human health. Therefore, to obtain longer shelf life, the application of suitable technologies for keeping the product in microbiological and chemical conditions ideal for consumption is required.

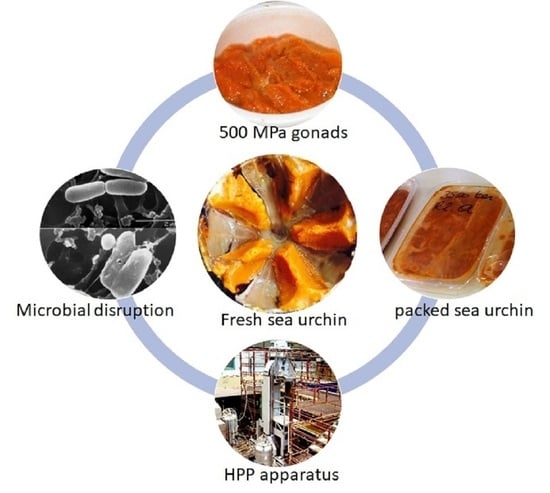

This study aimed to evaluate the effect of the HPP technology on the microbial inactivation and biochemical characteristics of P. lividus raw gonads. Moreover, we assessed the shelf life of the gonads together with the changes in the rheological and nutritional aspects.

2. Materials and Methods

2.1. Samples Collection and Processing

Samples of Paracentrotus lividus (Lamarck, 1816) were collected from a rocky substrate in wild-growing areas (between 5 and 10 m depth) located at Capo Pecora, Bugerru, Italy (39°27′15.58′′ N, 8°22′43.18′′ E) in February 2015. Random specimens (n = 150) were harvested and carried to the laboratory in a refrigerated box (5 °C). Sea urchins were manually opened with a stainless-steel cutter. Gonads were separated from the gut, immediately stored in a water/ice bath to avoid degradation, washed with purified water, and drained in a sieve to eliminate the excess of water. Fresh gonads for each HPP treatment were merged to obtain a homogeneous sample. Finally, gonads were put in a plastic box, hot-sealed with a plastic film, and stored at 2 °C until HPP treatments.

2.2. HPP Processing

A FOOD PRESS 35L-600 system (Avure Technologies, JBT Group, Middletown, OH, USA) was used for the HPP process, applying two different pressures (350 and 500 MPa). Temperature (20 °C) and time (10 min) were kept constant in all experiments.

A total of 30 plastic boxes containing 100 g each of fresh raw gonads were used for each repetition (three replicates for each HPP process). Control samples not subjected to HPP treatments were stored at 5 °C.

2.3. Chemicals and Reagents

Hexane, ethylic ether, petroleum ether, and methanol were ultra-residue solvents of analytical grade purchased from Merck (Darmstadt, Germany). NaCl, MgSO4 anhydrous and Na2SO4 anhydrous, KOH, and KCl were of analytical grade (Sigma Aldrich Chemie, Darmstadt, Germany). Methanolic potash was prepared at 2 N.

The marine oil FAME mix analytical standard was purchased from Restek (Bellefonte, PA, USA). Working standard solutions were prepared by diluting the stock solution with hexane with the appropriate volume. The amino-acid mix solution was purchased from Merck (Darmstadt, Germany). Double-deionized water, with a conductivity of less than 18.2 MW, was obtained with a Milli-Q system (Millipore, Bedford, MA, USA).

2.4. Physical, Chemical, and Organoleptic Characteristics

For moisture determination, 5 g of homogenized samples were weighed in a crucible and dried at 105 °C until a constant weight was achieved (~24 h). Water activity (aw) was assessed by using a Thermobalance (DiniArgeo, Modena, Italy), while pH was determined with an Orion Star™ A214 pH/ISE Benchtop Meter (Thermo Fisher Scientific, Milano, Italy). The sensory quality of the raw and processed gonads was assessed according to Prato et al. [

23]. Briefly, assessors (selected among regular consumers of sea urchins and trained to describe the organoleptic properties) were invited to classify the color, odor, texture, and firmness of gonads from freshly collected wild urchins and processed using a subjective scale. Score 1 was the ideal score, whereas, for texture (including firmness), the worst score was 4 (

Table 1).

2.5. Total Lipid

The analysis of the lipid content was performed according to the Folch method. First, 0.2 g of homogenized sample was accurately weighed in an extraction thimble plus 3 mL of a CHCl3/CH3OH mixture (2/1, v/v) and 0.5 mL of a 0.88% (w/v) KCl solution. The samples were vortexed for 2 min centrifuged at 3154× g for 10 min.

Once the phases had been separated, 1 mL of the organic phase was placed in a previously calibrated 8 mL Pyrex glass tube. The sample was dried at room temperature and placed in a desiccator for about 1 h.

The quantitative determination of the lipid content was determined with the following formula:

where P is the net weight of the sample in g, CH

3Cl A is the chloroform extract, taken and dried, in mL, and CH

3Cl B is the chloroform used for the extraction in mL.

2.6. Fatty Acid

Fatty acid analyses were carried out according to Angioni et al. [

4]. Briefly, 2 g of homogenized samples were accurately weighed in a screw-capped tube of 40 mL, plus 6 mL of hexane, 3 g of NaCl, and 2 g of MgSO

4. After mixing and centrifugation, fatty acids were subjected to transesterification, adding 200 µL of alcoholic potash (KOH 2 N in MeOH) to 500 µL of the organic phase, and analyzed in GC–MS. Analysis was carried out using a gas chromatograph TRACE GC ULTRA and a Single Quad DSQ mass detector (Thermo Finnigan, Milan, Italy), equipped with a COMBI PAL autosampler (CTC Analytics, Zwingen, Switzerland) and a split/splitless injector. The column was a Varian Factor Four VFWAX (60 m × 0.25 mm i.d. × 0.25 µm film thickness; Varian, Milan, Italy). The sample (1 µL) was injected in splitless mode (1 min). Helium was the carrier gas at 1 mL/min. The mass detector was operated in electron ionization (EI) positive mode, with a solvent delay of 5.5 min. The temperature of the injector, ion source, and transfer line was set at 50, 200, and 250 °C, respectively. The oven was programmed as follows: 90 °C (1 min), raised to 160 °C (3 °C/min), then 198 °C (1 °C/min), and further to 250 °C (5 °C/min), before being held for 15 min. Peak identification was carried out comparing full mass spectra (50–550

m/

z) and retention times (r.t.) from authentic standards, a homemade library, and the NIST MS spectra library.

2.7. Total Protein

Total protein content was analyzed according to the Kjeldahl method. An aliquot of a well-homogenized sample (0.5 g) was weighed in Speed-Digester flasks. Then, 20 mL of concentrated H

2SO

4 (96%), 0.5 g of sodium sulfate, and a tip of copper sulfate were added to the mineralization flask. After mineralization, the solution was left to cool, and 50 mL of H

2O MilliQ was added. The flask was inserted into the distillation unit when the solution reached a light blue color. A concentrated solution of NaOH was added directly to the distiller and subjected to distillation until obtaining a brownish-black color. Then, 100–150 mL of sample was collected, and a known quantity of H

2SO

4 0.5 N plus a few drops of methyl red were added. After distillation, quantitative analyses were conducted by titration using NaOH 0.5 N.

where a is the volume of 0.5 N H

2SO

4 added to the collection flask in mL, b is the volume of titrant used (NaOH 0.5 N) in mL, c is the conversion factor of mL of H

2SO

4 0.5 N in g of nitrogen (0.007), and K is the general nitrogen–protein conversion factor (6.25) [

24].

2.8. Amino-Acid Analysis

An aliquot (1 g) of the homogenized sample was weighed in a 15 mL falcon tube plus 3 mL of a MeOH/H2O solution (20:80). The falcon was agitated for 5 min in a vortex (Falc Instrument, Treviglio, Italy) and 15 min in a rotatory wheel (F205, Falc Instrument, Treviglio, Italy); after that, it was centrifuged for 10 min at 3154× g and 10 °C (Centrifuge 5810 R, Eppendorf AG 22331 Hamburg, Germany). The supernatant was collected, filtered at 0.45 mm, and injected into UHPLC/MSMS for analysis.

An Agilent 1290 Infinity II UHPLC LC coupled to an Agilent 6470 Triple Quad LC–MS/MS mass detector (Agilent Technologies Italia, Milano, Italy) with a MassHunter ChemStation, was used. The column was a ZORBAX Luna Hilic (200 Å, 4.6 × 150 mm, 5 μm) at a controlled temperature of 30 °C. A binary gradient, H

2O at 0.1% formic acid (A) and acetonitrile at 0.1% formic acid (B), was set as follows: T = 0 min, B 100%; T = 7 min, B 89%; T = 10 min, B 88%; T = 16 min, B 75%; T = 16.5 min, B 100%; post-run, 20 min. The flow was 0.6 mL/min, and the injection sample was 5 μL. The mass detector was operated in SCAN positive mode (capillary 4000 V) in the range 25–300

m/

z with the following parameters: gas and curtain gas, 300 °C; gas flow, 13 L/min; curtain gas flow, 12 L/min; nebulizer, 40 psi; nozzle voltage, +1000 V. Detection was carried out in Dynamic MRM (

Table 2).

2.9. Microbiological Analysis

Analysis was performed on fresh control raw samples and after HPP. All samples were stored in a thermostated cell at 3 °C ± 2 °C and collected after 20 and 50 days of storage. The following test methods were applied: mesophilic and psychrophilic total charge, Enterobacteriaceae, yeast and mold, sulfite-reducing anaerobic bacteria,

Pseudomonas spp.,

Salmonella spp., and

Listeria monocytogenes (

Table 3).

2.10. Statistical Analysis

Analysis of variance (ANOVA) was carried out with the software XLSTAT (Addinsolf L.T.D., Version 19.4); mean comparisons of the effects of treatments were calculated by the Fisher’s least significant difference test at p ≤ 0.05.

4. Discussion

HPP technology consists of vacuum packing a food product and subjecting it to isostatic compression with pressure values not exceeding 700 MPa in current industrial practice. HPP microbiological activity is mainly related to extensive modifications of cellular membranes, blocking cellular functions responsible for reproduction and resulting in the most important causes of bacterial death [

27]. Literature data have shown that different taxa of microorganisms and viruses work in different ways [

28,

29], and several studies associated with particular microorganisms have been reported [

30]. On the other hand, papers dealing with the relationship between fish products and HPP treatments are limited to Atlantic species such as salmon, cod, mackerel, and sea bass [

19,

31,

32,

33].

Our experiments used a semi-industrial system at two pressure levels, 350 and 500 MPa, and a standard temperature (20 °C). The samples were packed in rectangular polypropylene (PP) trays with a capacity of 100 mL, with a closing film in PET/adhesive/PP (12/2/40 mm) and a total thickness of 54 mm.

Trials on sea urchin were successfully carried out using a model system equipped with a press with a capacity of 2 L; the samples were packaged in plastic cups and reached a shelf life of 60 days [

34]. The trials assured complete microbial safety; however, no data were reported on the biochemical effect after HPP treatment and storage.

In our experiments, the microbial analysis of the working environment showed a total mesophilic count >800 CFU/m

3 overcoming the limits considered acceptable for contamination (500 CFU/m

3) and the presence of

Aspergillus brasiliensis. In addition, the analysis of the water used for cleaning the gonads and the ice showed significant contamination of mesophilic bacteria. Among the two HPP treatments carried out, only 500 MPa effectively reduced contamination. In contrast, at 350 MPa, the mesophil contamination remained unchanged, with values overlapping the starting matrix. The data obtained in this study agree with previous studies on HPP applications on foods [

18,

30,

34].

Studies on the effect of HPP on foods with a different water activity (aw) showed that lowering aw could lead to incomplete microbial inactivation [

35]; the data reported in this study showed high levels of aw in all samples before and after HPP treatments allowing a suitable sanification process.

HPP treatments on fish showed an increase in pH after HPP treatments and storage for 1 week, before decreasing for more extended storage periods [

20,

36]. The data reported in our experiments agree with this tendency with an increase after treatment and a decrease during storage, with overlapping values in the two treatments.

In addition, sea urchins showed only relatively small pH variations before and after the treatments [

20].

The fresh gonads’ physicochemical composition was in accordance with other authors on sea urchins [

5,

37,

38]. The HPP treatments influenced the protein content during the shelf life, leading to lower values than the control samples according to similar trials on fish and crustaceans [

39,

40]. However, the decrease in the protein fraction was more significant after treatment at 350 MPa than at 500 MPa. These data were confirmed by analyzing the free amino-acid fraction, agreeing with Skipnes et al. (2008) [

6]. At 350 MPa, the amino acids showed a higher rate of degradation associated with a characteristic fishy odor and texture modification of the gonads. As reported by Sukmanov on meat and meat products, texture modification can be related to protein denaturation [

41].

On the contrary, at 500 MPa, higher levels of free amino acids were revealed. In addition, the gonads maintained the organoleptic characteristic similar to the fresh product. This fact can be ascribed to enzyme inactivation by HPP treatment, which is less effective at 350 MPa [

42].

In contrast, total lipids increased after both treatments’ shelf life, following a slightly different trend.

Data on the lipid fraction of mackerel highlighted the efficiency of HPP treatments in reducing lipid damage, together with an increase in free fatty acid [

43]. However, the overall free fatty-acid composition of sea urchins under HPP treatments was not affected. Indeed, a decrease in SAFAs and PUFAs, as well as an increase in MUFAs, during the shelf life at 500 MPa was detected, even if the SAFA/PUFA ratio remained unchanged. These data were in discordance with data on ragworms which showed an increase in both SAFA and MUFA, whereas data on lamb meat confirmed this behavior [

39,

44].

5. Conclusions

Although sea urchin gonads were processed in an environment contaminated by Aspergillus brasiliensis, the products showed no presence of this microorganism. From a microbiological perspective, the fresh sea urchin gonads showed a starting contamination of no more than 10 CFU/g. The treatments carried out at pressures of 350 MPa and 500 MPa led to obtaining samples in which microbial contamination was maintained within levels below 10 CFU/g after 40 days of storage at 4 °C.

HPP at 350 MPa resulted in a visual alteration of the texture of the fresh product immediately after processing. In addition, the fresh product’s olfactory, color, and gustatory traits were lost after 20 days. The chemical composition of the gonads confirmed organoleptic observations with a higher decrease in protein and free amino acids.

On the other hand, gonad samples stored for 40 days after treatments at 500 MPa showed a good organoleptic performance.

This paper highlighted the advantages of HPP to enhance the shelf life of sea urchin gonads. In addition, HPP caused a low modification of color and taste, preserving the nutritional and organoleptic properties of the gonads. This process, providing minimal thermal energy, can represent an effective alternative system to remove the bacterial flora and inactivate enzymes.

Moreover, to exploit the antimicrobial properties of this technology, HPP parameters should be calibrated for each specific food. Indeed, treatments at 350 MPa at 20 °C were not suitable for maintaining the organoleptic and physicochemical characteristics of unaltered sea urchins, whereas, at 500 Mpa, samples remained edible for 40 days.

On the basis of these observations, HPP could be an exciting option for enhancing sea urchins’ gonad shelf life by preserving the original organoleptic traits; more in-depth studies should be developed to obtain the ideal commercial product.