3.1. Selection of the Solvent for Extraction and the Single-Factor Experiments

The effect of extraction solvent and diverse factors such as extraction time, extraction temperature, alkaline concentration, liquid-to-material ratio, and extraction repetition were explored by the single-factor experiments.

Figure 2A shows that the protein content in 0.1 mol/L NaOH solution was significantly higher (

p < 0.05) than in other systems after 1 h of extraction reacted with the condition of the liquid-to-material ratio of 10:1 and extraction temperature of 50 °C for SER powder. Therefore, the NaOH solution was selected as the system for the extraction of SEP.

For the evaluation of the extraction time, the liquid-to-material ratio was 20:1, the alkaline concentration was 0.1 mol/L, the extraction temperature was 50 °C, and the extraction time was evaluated in a range between 1 and 5 h.

Figure 2B shows that the protein content in the solution was significantly increased from 1–3 h (

p < 0.05), and decreased from 3–5 h with increasing extraction time. This result may have been caused by the reduced protein content in the solution, as the protein was denatured during the long reaction time. Therefore, 3 h was selected as the best length of time for the extraction of SEP.

For the evaluation of the extraction temperature, the liquid-to-material ratio was 20:1, the alkaline concentration was 0.1 mol/L, the extraction temperature was 50 °C, and the extraction temperature was evaluated in a range between 30 and 70 °C.

Figure 2C shows that the protein content in the solution increased and then decreased as the extraction temperature increased. The protein content was up to 31.24 mg/g at the extraction temperature of 60 °C. When the extraction temperature was 70 °C, the protein content decreased significantly (

p < 0.05). This result could be attributed to the fact that the denaturation of the protein was induced by the high temperature, which in turn affected the protein solubilization [

20]. Therefore, 60 °C was selected as the optimal temperature for the extraction of SEP.

For the evaluation of the alkaline concentration, the liquid-to-material ratio was 20:1, the extraction time was 3 h, the extraction temperature was 60 °C, and the alkaline concentration was evaluated in a range between 0.1 and 0.3 mol/L.

Figure 2D shows that the protein content in the solution rapidly increased when the alkaline concentration was increased from 0.05 mol/L to 0.15 mol/L, and there was a significant difference (

p < 0.05) between the 0.05 and 0.15 mol/L levels. This result may be caused by the increased protein content in the solution, as the cell structure was destroyed by the alkaline solvent. The rising trend was slow and showed no significant change at 0.15–0.25 mol/L concentration level. With the alkaline concentration at 0.25–0.30 mol/L level, the protein content in the system was significantly decreased (

p < 0.05). Related studies have shown that amino acid structures such as Lys and Cys, etc., are disrupted at a high alkaline concentration, which in turn leads to a decreased in the selenium content of the SEP [

23]. Therefore, 0.25 mol/L was selected as the optimal alkaline concentration for the extraction of SEP.

For the evaluation of the liquid-to-material ratio, the alkaline concentration was 0.25 mol/L, the extraction time was 3 h, the extraction temperature was 60 °C, and the liquid-to-material ratio was evaluated in a range between 10:1 and 70:1 mL/g.

Figure 2E shows that there was a little protein in the system when the liquid-to-material ratio was low. The cellulose and other substances in the plant powder absorbed water and swelled, causing the system to be viscous, which resulted in the dissolution of protein molecules slowing down [

24]. With the increase in the liquid-to-material ratio, the protein content in the solution was rapidly increased, and when the liquid-to-material ratio reached 60:1 mL/g, the protein content reached a maximum of 53.02 mg/g. Therefore, 60:1 mL/g was selected as the optimal liquid-to-material ratio for the extraction of SEP.

For the evaluation of the extraction repetition, the alkaline concentration was 0.25 mol/L, the extraction time was 3 h, the extraction temperature was 60 °C, the liquid-to-material ratio was 60:1 mL/g, and the extraction repetition was evaluated in a range between 1 and 3 times.

Figure 2F shows that the protein content in the solution increased with the increase of extraction repetition, but there was no significant difference between the two and three times. Therefore, two times for the extraction were selected as the optimal extraction repetition for the extraction of the SEP.

3.2. RSM Modeling

The purpose of process optimization in this study was to improve the extraction of the SEP. Based on the principle of the Box–Behnken experiment and the results of the single-factor experiments, the extraction temperature (A), extraction time (B), alkaline concentration (C), and liquid-to-material ratio (D) were selected as independent variables to design a 4-factor, 3-level response surface methodology (RSM) model, and the results of RSM model are shown in

Table 1. (Since the factor level table of the Design-Expert 13.0 software only allowed setting specific values, the liquid-to-material ratio in the factor experiment table was simplified from X:1 mL/g to X mL/g).

The factors and results in

Table 1 were analyzed by multiple quadratic regression fitting using Design-Expert 13.0, and the model regression equation was obtained as Y = 55.58 + 3.56A − 0.9043B − 2.36C + 2.38D + 1.16AB + 0.5888AC − 1.34AD − 1.16BC − 2.07BD − 0.9455CD − 3.37A

2 − 2.48B

2 − 5.01C

2 − 5.16D

2. The results of the response surface quadratic regression model ANOVA for the SEP extraction process are shown in

Table 2.

The effect of the independent variable on the dependent variable was determined by the significance test in the ANOVA [

25].

Table 2 shows that the F-value of this model was 27.70, and its

p-value was less than 0.01, which the model judged to be extremely significant. The

p value of the out-of-fit was 0.1558 > 0.05, indicating that the model was not affected by the out-of-fit factor. The coefficient of determination R

2 was 0.9652, and the difference between Adjusted R² and Predicted R² was less than 0.2, indicating that the actual situation was adequately reflected by the model.

The

p values of factors A (extraction temperature), B (extraction time), C (alkaline concentration), and D (liquid-to-material ratio) in

Table 2 were all less than 0.05, indicating that Y (protein content in solution) was significantly influenced by factors A, B, C, and D. The

p values of factors A, C, and D were less than 0.01, indicating that factors A, C, and D showed extremely significant effects on Y.

The

p values of the cross terms such as BD, A

2, B

2, C

2, and D

2 were less than 0.01, indicating that these cross terms showed an extremely significant effect on Y. The rest of the cross terms showed a non-significant effect. Comparing the F-value of the factor, it could be seen that the effect of each factor on the protein content in descending order was A > D > C > B [

26]. The normal probabilities distribution of the residuals obtained by Design-Expert 13.0 software is shown in

Figure 3.

Figure 3 shows that the probability of residual points in the SEP extraction model was basically distributed on the same straight line. The normal distribution was obeyed by outer residuals, indicating that the actual protein content of the SEP extraction was less different than the predicted content of protein. The 3D surface map and contour analysis of the model are shown in

Figure 4.

The effect of the interaction of four factors (A, B, C, and D) on Y was intuitively reflected by observing the steepness, contour density, and contour presentation shape of the 3D surface map [

27].

Figure 4 shows that Y tended to increase and then decrease with increasing factor levels when A, B, C, and D interacted with any two factors. The optimal conditions of the RSM model obtained by analysis with the Design-Expert software were that the extraction temperature was 62.5 °C, the extraction time was 3.0 h, the alkaline concentration was 0.25 mol/L, and the liquid-to-material ratio was 62.2:1 mL/g.

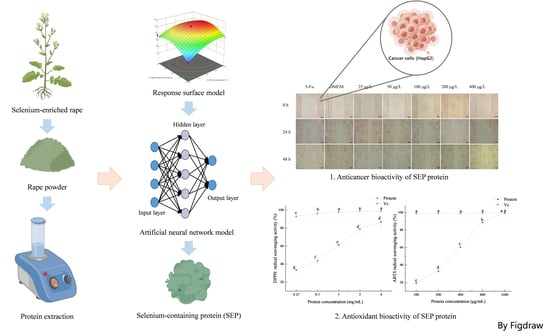

3.8. Antioxidant Activity

The antioxidant activity of the SEP is shown in

Figure 10, and the antioxidant activity of the SEP increased with increasing protein concentration. DPPH radicals were significantly scavenged by the SEP at concentrations ranging from 0.25 to 2 mg/mL (

p < 0.05). The DPPH radical scavenging rate reached 86.8% when the SEP concentration was 4 mg/mL. The scavenging rate of ABTS radicals was significant (

p < 0.05) for all the protein concentration levels. When the SEP concentration reached 1600 μg/mL, the scavenging rate of the ABTS radicals reached 99.65% with no significant difference in V

C.

The antioxidant activity of the SEPs was not only related to the hydrophobic amino acids in the protein but also related to the selenium content of the protein. Xiang et al. [

36] compared the selenium content and antioxidant activity of two selenium-containing proteins after purification and concluded that the higher the selenium content in the protein the better its free radical scavenging ability. Zhu et al. [

37] showed that selenium-enriched peptides had better antioxidant activity than non-selenium-containing peptides, and the selenium content in the peptides was positively correlated with the antioxidant capacity. In this study, it can be concluded that the antioxidant capacity of the SEP increased with the increase in the SEP concentration.

Another bioactivity of selenium is anticancer activity. In this study, the anticancer activity of SEP was preliminarily explored by using an in vitro cytological method.